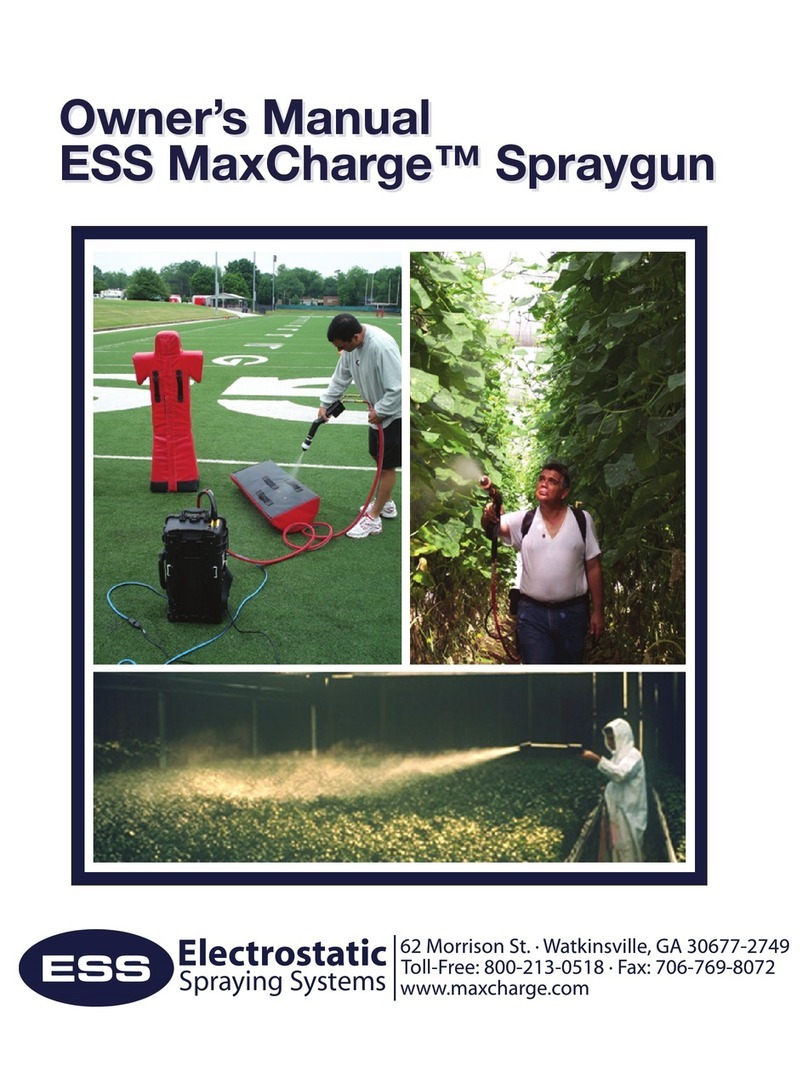

ESS SC-ET OWNER’S MANUAL

Air-assisted electrostac sprayers produce electrically charged spray drops that are

carried to the target in a low pressure, gentle, air stream. The heart of the SC-ET

sprayer is the patented MaxCharge™ nozzle.

Air and liquid enter separately at the rear of the nozzle. Just before leaving the

nozzle, the air hits the liquid stream to make many thousands of ny spray drop-

lets are blown out of the nozzle and move onto the target where they are aracted

to surfaces by electrostac forces. The electrostac charge induced by the

MaxCharge™ nozzle is strong enough to allow the droplets to move in any direc-

on to cover surfaces, even defying gravity to coat the underside of leaves and the

back side of the target objects. The result is uniform spray coverage on hidden

surfaces that other sprayers miss. Air-assisted electrostac sprayers give more

than twice the deposion eciency of hydraulic sprayers and non-

electrostac types of air-assisted sprayers. The grower benets in terms of signi-

cant reducons in applicaon costs and opmized insect and disease control,

sanizaon of beef or other coverage.

The MaxCharge™ nozzle is easy to clean and corrosion-proof. The interior ceramic

outlet resists the wear three mes beer than stainless steel outlets. These

features combine to give the best spray coverage on the market. This quality

product is virtually maintenance free, and assures you of savings in the

applicaon of chemical.

The comparison of air-assisted electrostac spraying versus convenonal spray-

ing is dramac.

Overview of the ESS Model SC-ET Air Assisted

Electrostac Sprayer

Where does the spray go?

The University of California completed a series of tests to

invesgate what happens to spray liquid aer it leaves the

nozzle.

Conclusion: ESS technology places over 4 mes the amount of

spray onto the plant surface using 1/2 the amount of chemicals.

Furthermore, they also reported that ESS sprayers send 2/3 less

chemicals to the ground and into the air. Less chemical used

overall, less waste, and less dri than convenonal equipment.

Imagine the environmental benet!

A Picture Worth A Thousand Words…

In this test, uorescent dye has been sprayed

on two round knobs. The le knob was

sprayed with the electrostac system ON;

the right knob was sprayed with the same

sprayer, but with the electrostac system

OFF. Note how even the coverage is on the

electrostac knob.

Electrostacally charged droplets

are strongly aracted to the

underside of surfaces.

1

The Maxcharge™ spray nozzle is

what makes ESS the industry leader

in the producon of electrostac

spraying equipment.

On Targeted Area

O Area On Targeted Area

O Area

Undetermined Undetermined