Graco 980S Operation manual

Other Graco Paint Sprayer manuals

Graco

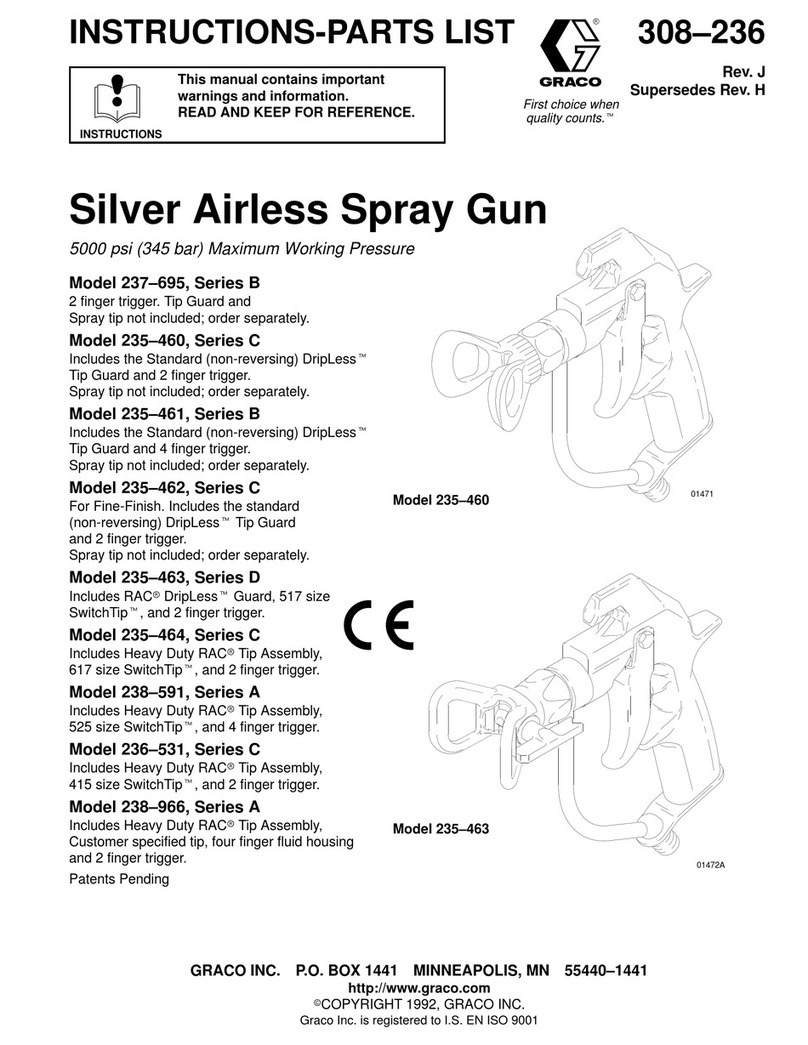

Graco 235-463 Operation manual

Graco

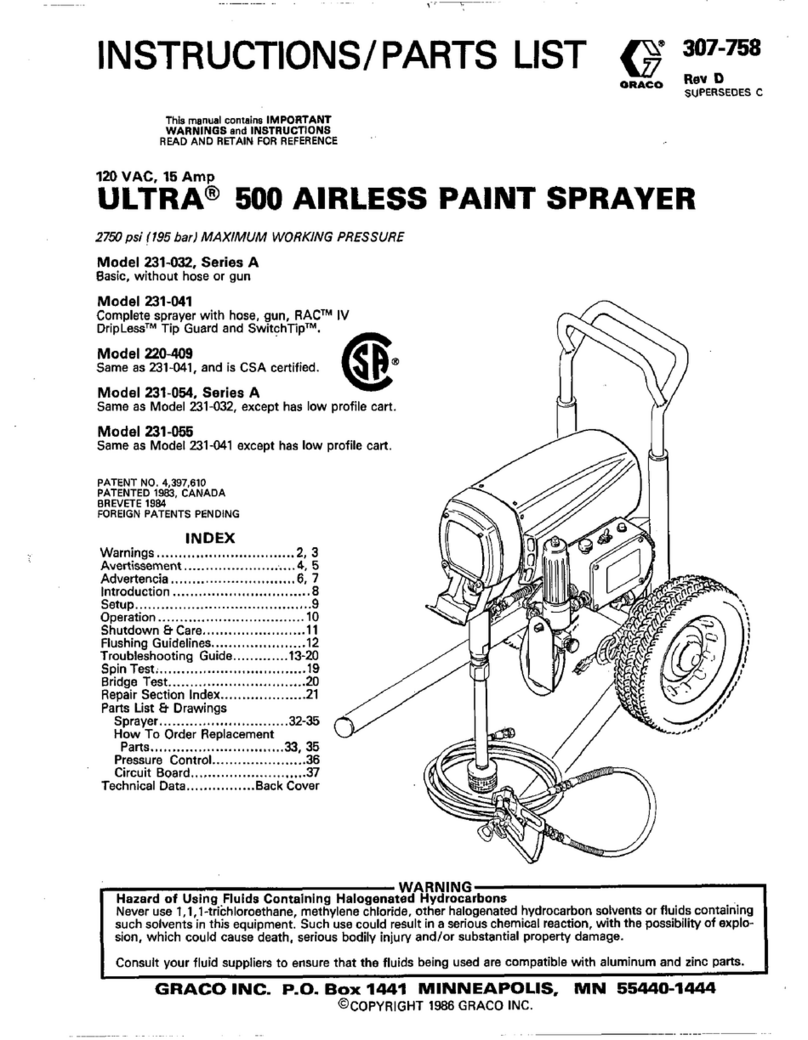

Graco ULTRA 500 Operation manual

Graco

Graco GX-7A User manual

Graco

Graco HYDRA-CLEAN C Series Operation manual

Graco

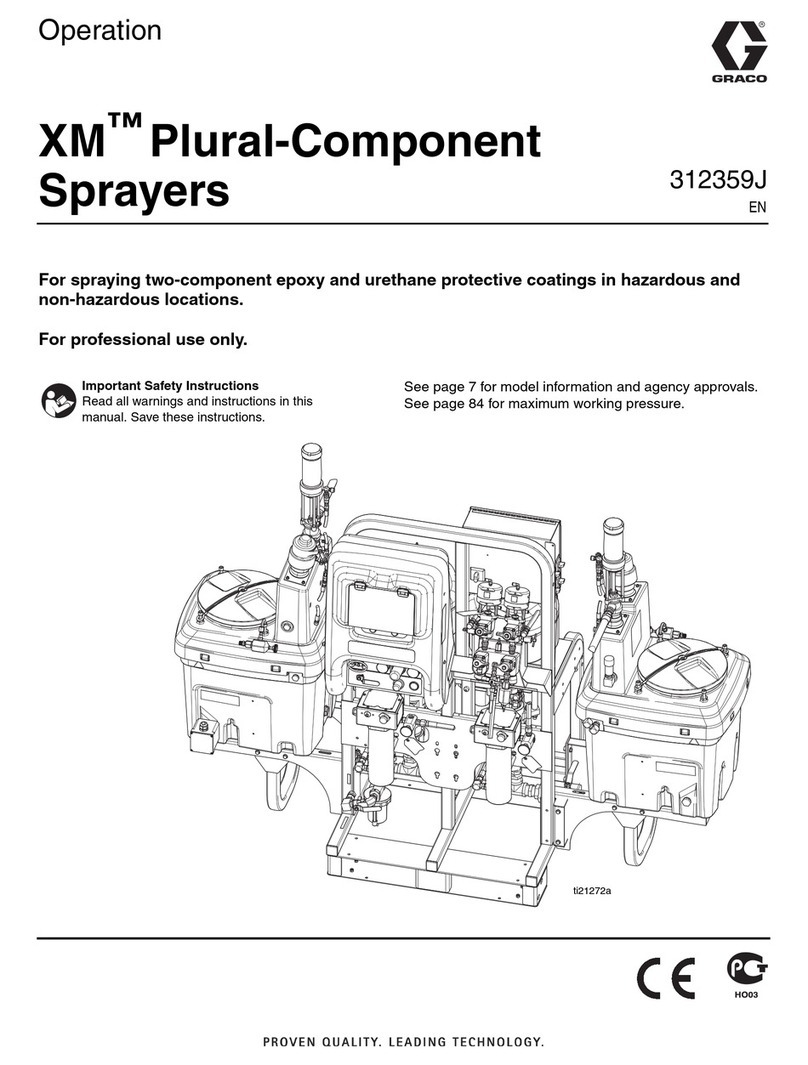

Graco XM Series User manual

Graco

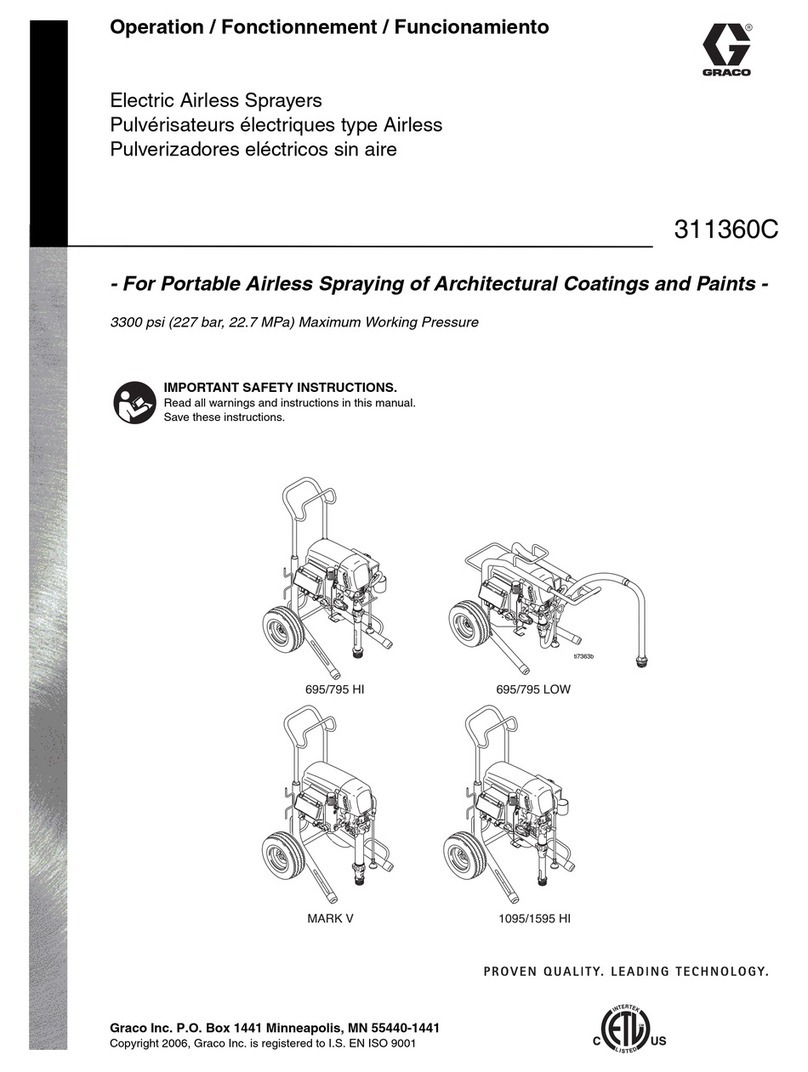

Graco 311360C Operation User manual

Graco

Graco Ultimate Mx II 695 User manual

Graco

Graco ULTRA MAX 795 Instruction Manual

Graco

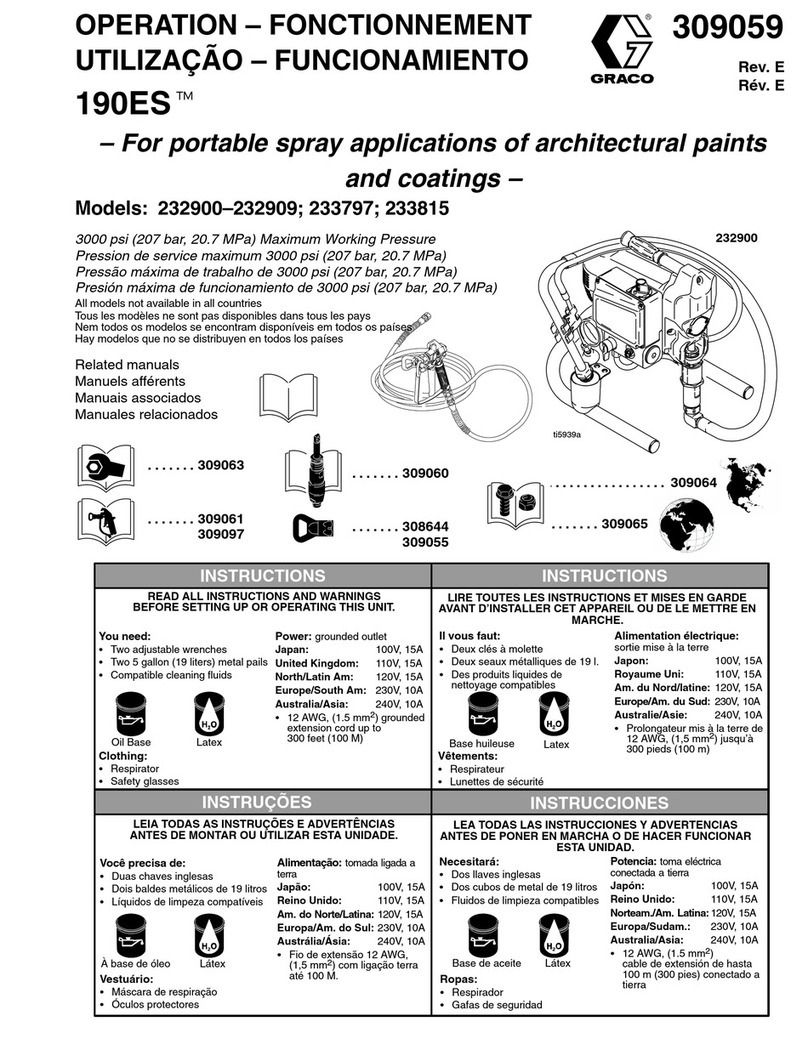

Graco 190ES 232909 Instruction Manual

Graco

Graco Fusion AP User manual

Graco

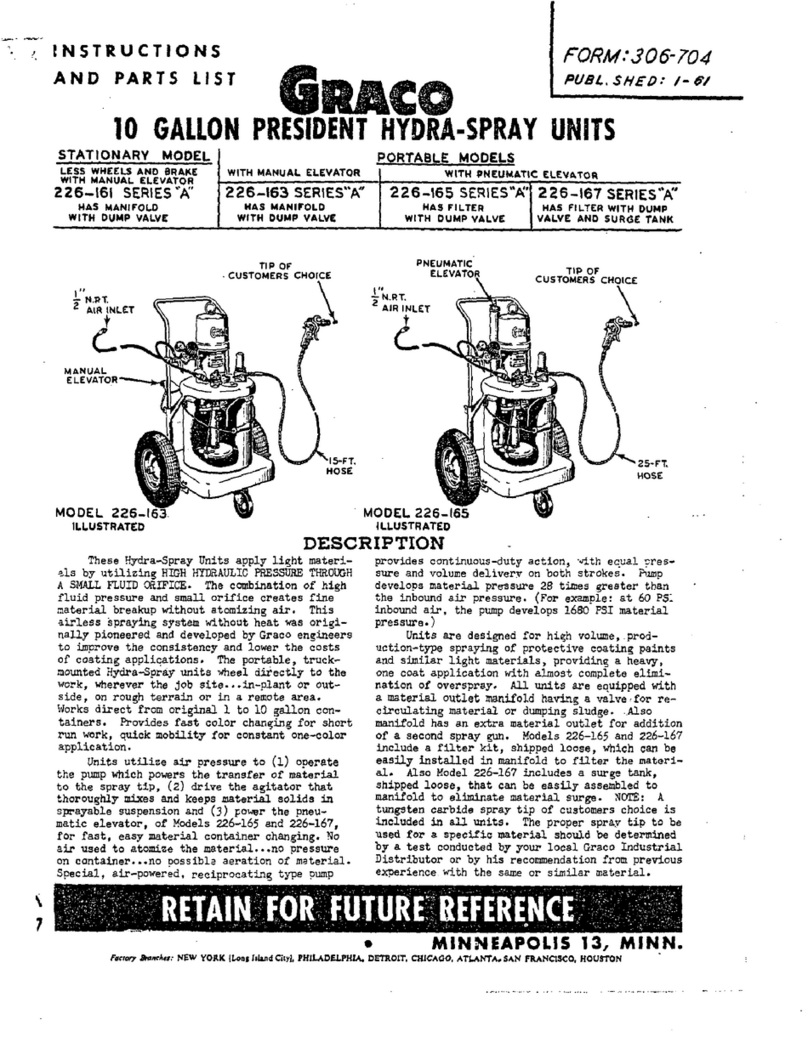

Graco EM 480 Hydra-Spray Manual

Graco

Graco 190ES 309063F Operating instructions

Graco

Graco 257025 Instruction Manual

Graco

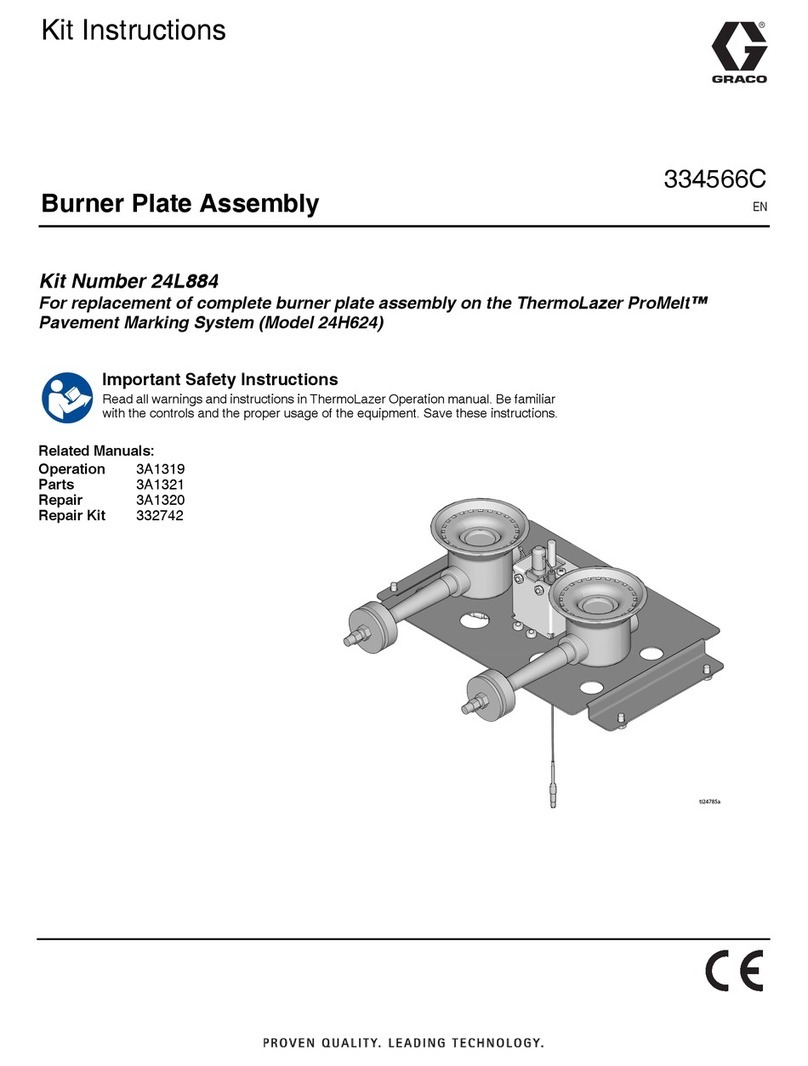

Graco 24L884 Manual

Graco

Graco MAGNUM PROJECT PAINTER PLUS Instruction Manual

Graco

Graco GM3500 SPRAYER 231-078 Operation manual

Graco

Graco HVLP 2500 Datasheet

Graco

Graco 17C301 Guide

Graco

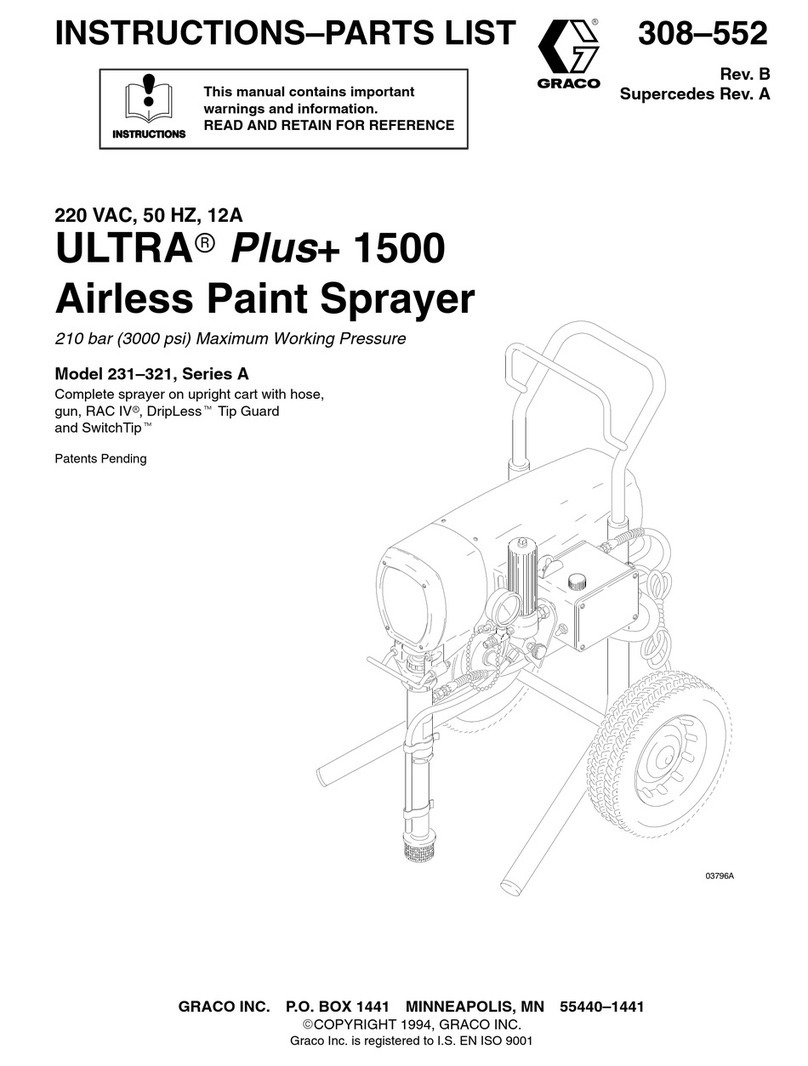

Graco ULTRA PLUS+ 1500 Parts list manual

Graco

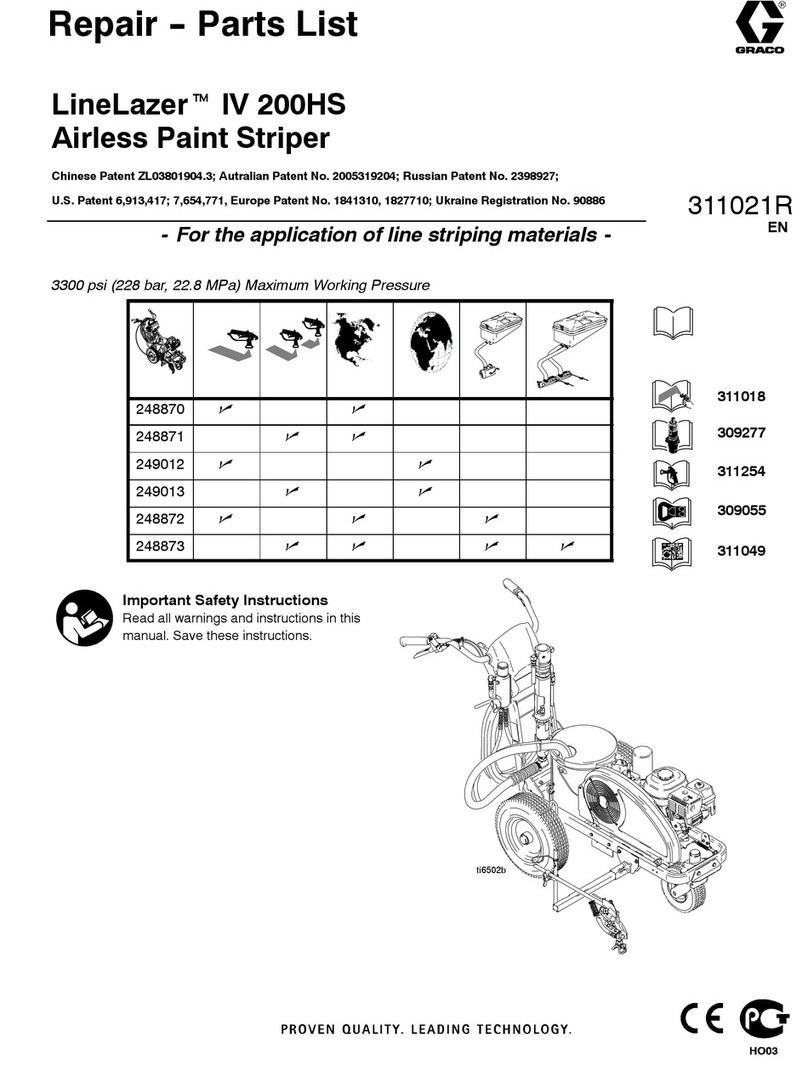

Graco LineLazer IV 200HS Use and care manual

Popular Paint Sprayer manuals by other brands

zogics

zogics Z-DAS instruction manual

KISANKRAFT

KISANKRAFT KK-KBS-165 Operation manual

Matrix

Matrix SG 650 Translation of the original instructions

Anest Iwata

Anest Iwata SGA-3 Installation, use & maintenance instruction manual

paasche

paasche VV Instructions and parts list

Carlisle

Carlisle DeVilbiss JGA-510 Service manual