IMPORTANT INFORMATION LEAFLET

Page 3

HA028256

Issue 3 Nov 12

HA028256

Issue 3 Nov 12Page 2

IMPORTANT INFORMATION LEAFLET

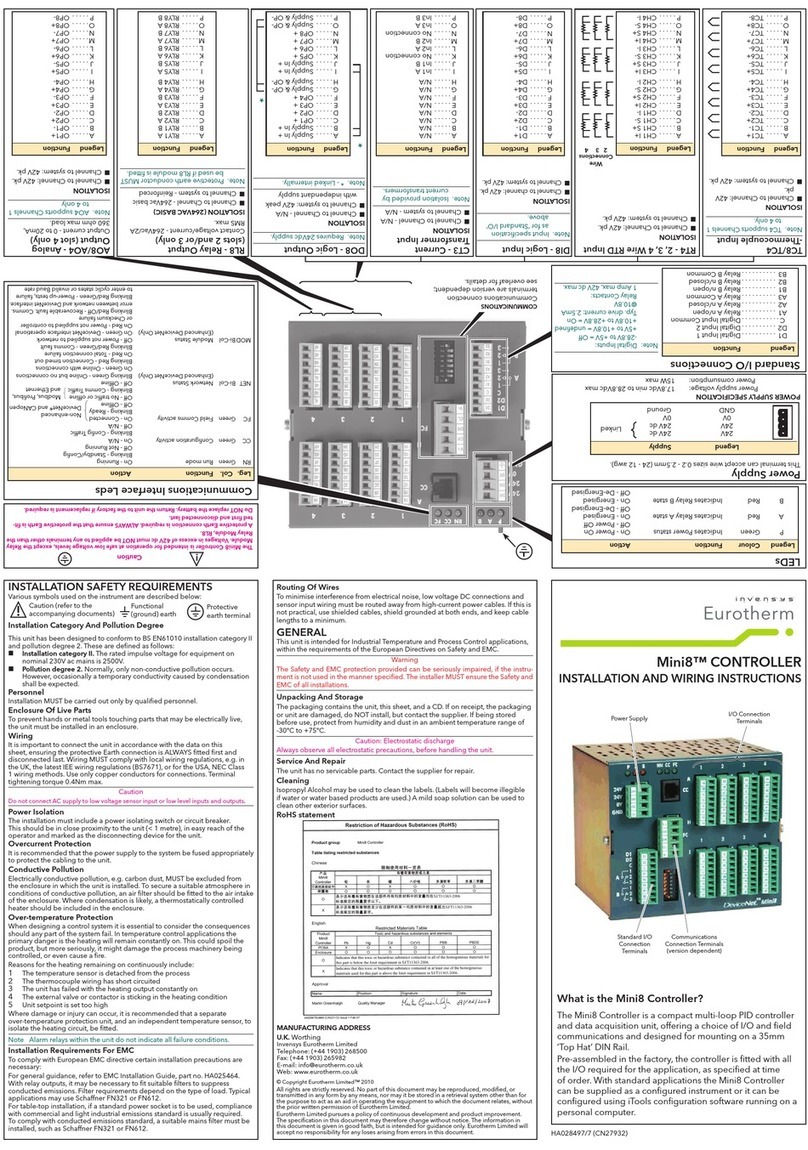

INSTALLATION & SAFETY REQUIREMENTS

Please read the following sections before installing the processor.

Note: This unit meets the requirements of the European Directives on Safety

and EMC. It is the responsibility of the installer to ensure the safety and EMC

compliance of any particular installation.

This product has been designed to conform to BS EN61010 pollution degree 2. This is defined

as follows:

Pollution degree 2

Normally, only non-conductive pollution occurs. Ocasionally, however, a temporary conduc-

tivity caused by condensation shall be expected.

Installation requirements for EMC and for safety.

This unit conforms with the essential protection requirements of the EMC Directive 89/336/

EEC, amended by 93/68/EEC and with the European Low Voltage Directive 73/23/EEC, by the

application of the safety standard EN61010-1:1993/A2:1995.

This unit satisfies the emissions and immunity standards for industrial environments.

To ensure compliance with the European EMC directive certain installation precautions are

necessary as follows:

Personnel

Installation must be carried out only by competent personnel, according to the instructions

given in the product manual applying to the instrument. The installation must comply with any

relevant national and local regulations in force.

a General guidance. For general guidance refer to the Manufacturer’s EMC Installation

Guide (Part No. HG083635U001).

b Relay outputs. When using the relay outputs it may be necessary to fit a filter suitable for

suppressing conducted emissions. The filter requirements depend on the type of load.

c Protective Earth. Before any other power input connection is made, the protective earth

terminal (see safety symbols section on page 4) shall be connected to an external protec-

tive earthing system.

Whenever it is likely that protection has been impaired, the unit shall be made inoperative

and advice should be sought from the nearest manufacturer’s service centre.

Mains supply wiring to the 24V power supply units must be terminated in such a way that,

should it slip in the cable clamp, the earth wire is the last wire to become disconnected.

WARNING!

Any interruption of the protective earthing system, or disconnection of the protective earth

terminal, is likely to make the unit dangerous under some fault conditions. Intentional in-

terruption is prohibited.

Wiring

It is important to connect the unit in accordance with the wiring data given in the product

manual. Wiring installations must comply with all local wiring regulations. Any wiring that is

‘Hazardous Live’ (as defined in EN61010) must be adequately anchored. To minimise the

pickup of electrical noise, low voltage DC connections and sensor input wiring must be routed

away from high-current power cables. Where it is impractical to do this, suitably grounded

shielded cables should be used for signal wiring.

Disconnecting device

In order to comply with the requirements of safety standard EN61010, the mains supply to the

24V supply shall have one of the following as a disconnecting device, fitted within easy reach

of the operator, and labelled as the disconnecting device for the equipment:

a. A switch or circuit breaker complying with the requirements of IEC947-1 and IEC947-3

b. A separable coupler that can be disconnected without the use of a tool

c. A separable plug, without a locking device, to mate with a socket outlet in the building.

Overcurrent protection

To protect the unit against excessive currents, the power supply to the unit and power outputs

must be wired through independent external fuses or circuit breakers. A minimum of 0.2 mm2

(20awg) wire is recommended. Independent fuses should be used for the instrument supply

and for each relay output. Suitable fuses are T type, (IEC 127 time-lag type) as follows:

a. Instrument supply (24Vdc nom. (18 to 36Vdc)). A 3 Amp Type T fuse must be fitted in

each positive supply line.

b. External battery back-up (4V nom.) A 500mA Type T fuse must be fitted in each positive

supply line.

c. Relay outputs: 0.5A (T).

Conductive pollution

Electrically conductive pollution (e.g. carbon dust, water condensation) must be excluded from

any cabinet in which the unit is mounted. To ensure the atmosphere is suitable, an air filter

should be supplied in the air intake of the cabinet. Where condensation is likely, for example at

low temperatures, a thermostatically controlled heater should be installed in the cabinet.

Ventilation

It should be ensured that any enclosure which houses the unit provides the ventilation/heating

required to maintain the operating temperature of the unit and the humidity level of its operat-

ing environment within its specified limits.

Safety symbols marked on the unit

Various safety/warning symbols are marked on the unit. These have the following meanings:

INSTALLATION & SAFETY REQUIREMENTS (CONT.)

Protective earth

terminal For use with Direct Current

(dc) supplies only