33

Contents

1.0 Important safety information ......................................4

2.0 General...........................................................................5

2.1 Using the Technical Instructions.....................................5

2.2 Correct usage .................................................................5

2.3 Ambient conditions .........................................................5

3.0 Function .........................................................................6

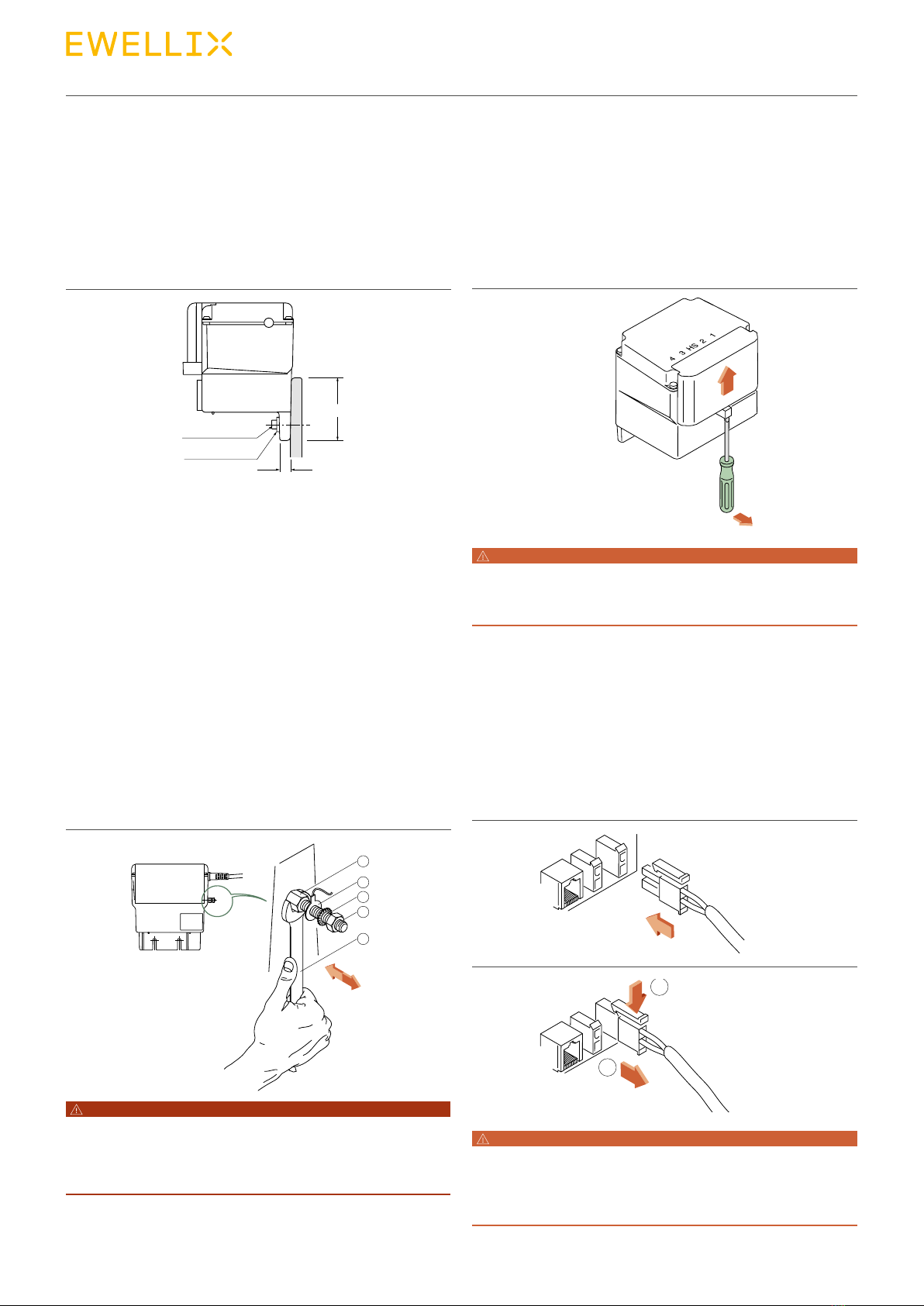

4.0 Installation and startup................................................7

4.1 Scope of delivery.............................................................7

4.2 Installation.......................................................................7

4.2.1 Mounting position ....................................................7

4.2.2 Mounting the control unit on the actuator (ECO

2/3/6/7 only)........................................................................7

4.2.3 Removing the control unit........................................7

4.2.4 Fastening the control unit externally .......................8

4.2.5 Installing / uninstalling the earth cable (option).......8

4.3 Startup.............................................................................8

4.3.1 Opening the control box cover ................................8

4.3.2 Connecting / disconnecting the actuator cable on

the control unit....................................................................8

4.3.3 Connecting / disconnecting the control device ......9

4.3.4 Closing the control box cover..................................9

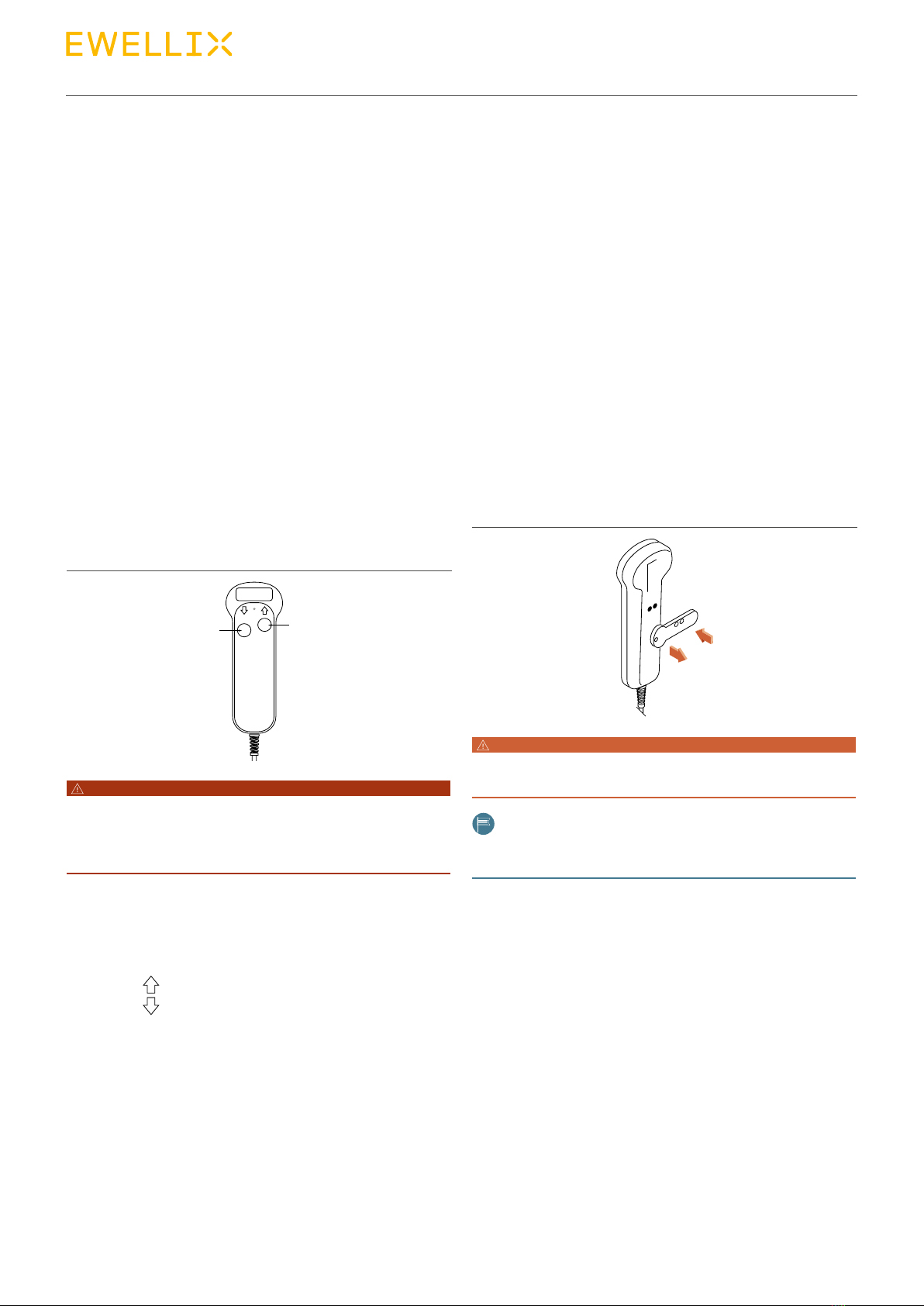

5.0 Operation..................................................................... 10

5.1 Controlling an actuator.................................................. 10

5.1.1 Fastenin g hook....................................................... 10

5.2 Locking device .............................................................. 10

5.2.1 Locking the handswitch......................................... 10

5.2.2 Unlocking the handswitch ..................................... 10

5.3 "Emergency lowering" in the event of a power failure

(option) ................................................................................. 11

5.3.1 Changing the batteries .......................................... 11

5.4 Rapid adjustment (optional).......................................... 11

5.4.1 Function ................................................................. 11

5.4.2 Usage ..................................................................... 12

6.0 Maintenance and Care............................................... 13

6.1 5.1 Mainte na nce ............................................................ 13

6.1.1 Dut y cyc le .............................................................. 13

6.1.2 Thermofuse ............................................................ 13

6.2 Care............................................................................... 13

6.2.1 Protection from water, cleaning, disinfecting........ 13

6.3 Disposal ........................................................................ 13

6.4 Liability .......................................................................... 14

6.5 Troubleshooting ............................................................ 15

7.0 Appendix ......................................................................16

WAINTING

Read this manual before installing, operating or maintaining this

actuator. Failure to follow safety precautions and instructions

could cause actuator failure and result in serious injury, death or

property damage.