930426S0•816857•7995k0•18.04.2005We reserve the right to carry out improvements

2

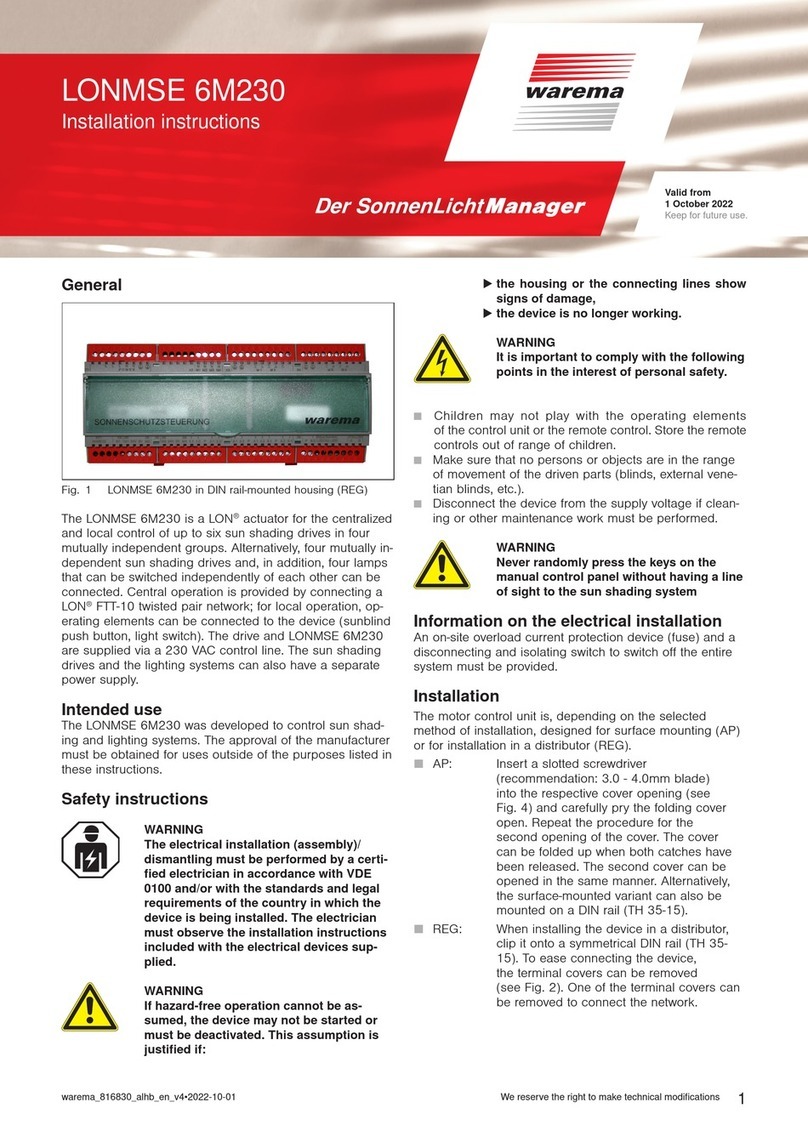

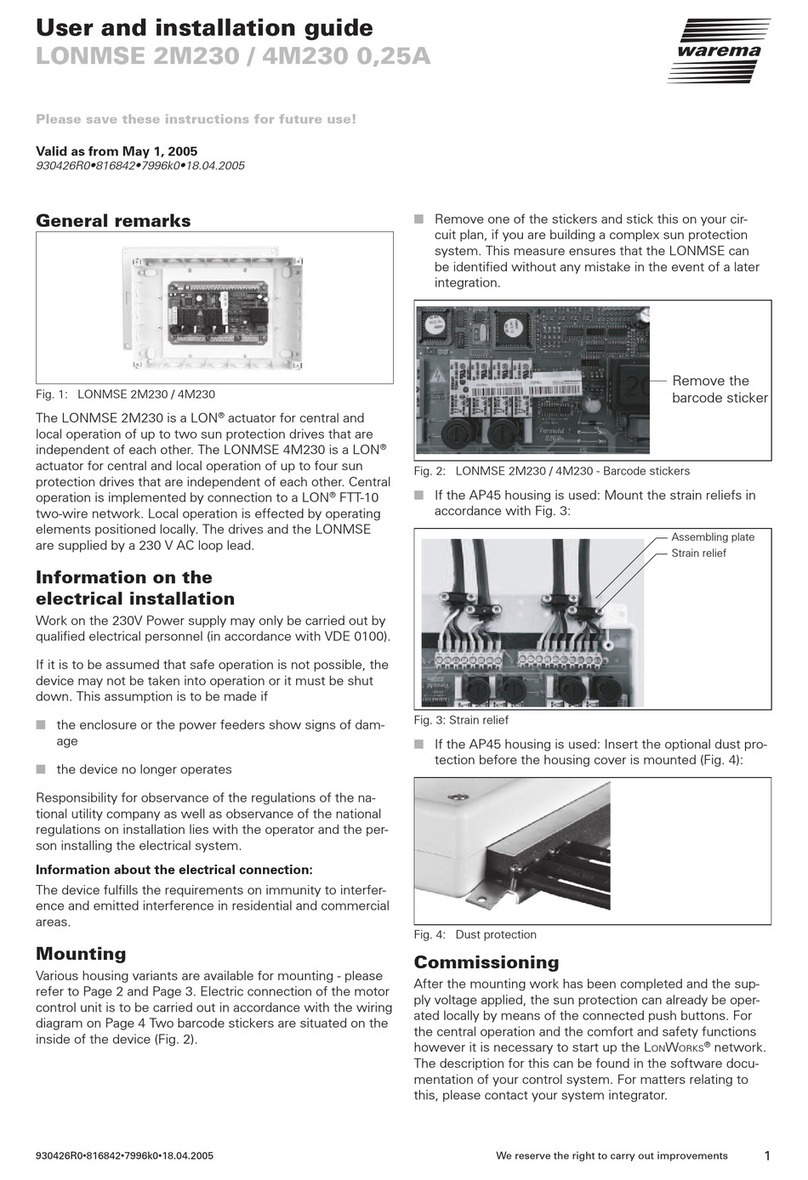

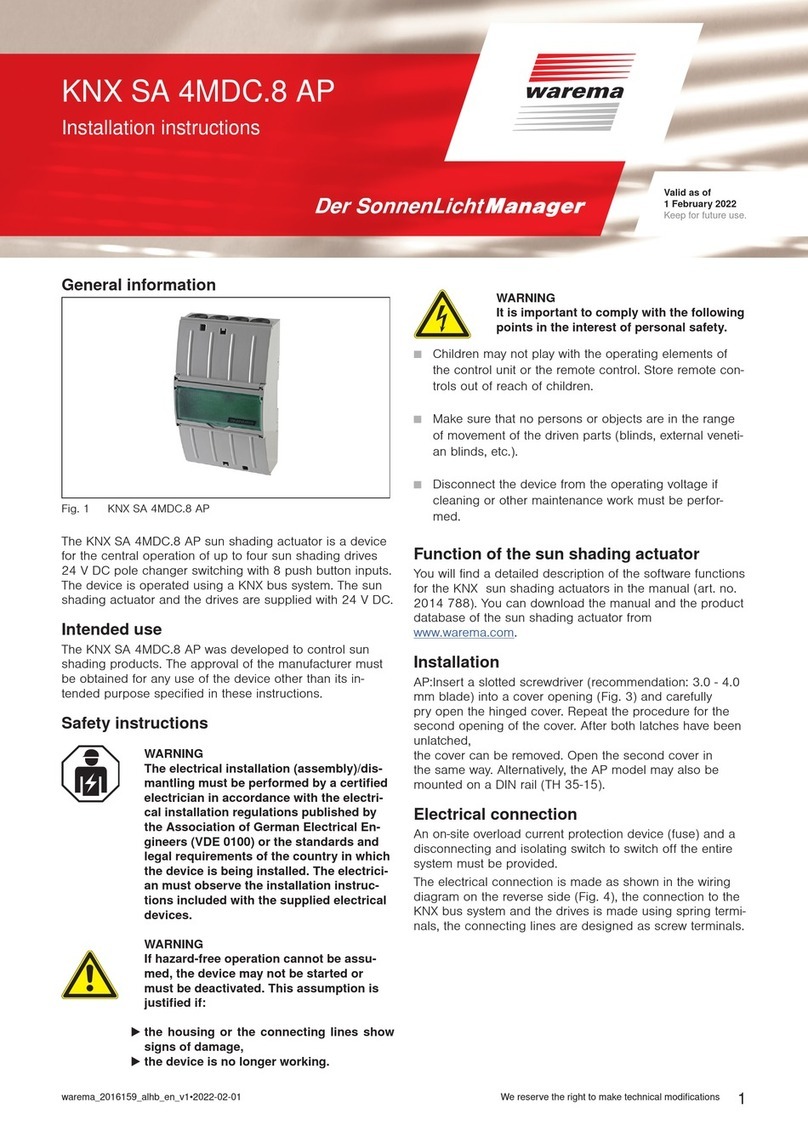

Status LED’s and service key: On the circuit board of the

LONMSE you will find a red and a green status LED as well

as a service key (see fig. 5). Carry out a simple function test:

After switching on the supply voltage or after a quick press

on the service key the green LED lights up for approx. 0.5

seconds and then goes out. A continuous lighting up indi-

cates a fault in the device. In this case, contact your system

integrator. The red LED then lights up for a duration of up to

20 seconds after the switching on of the supply voltage. As

soon as the device is ready for operation this LED begins to

flicker irregularly. A continuous light indicates a fault in the

device. Also contact your system integrator in this case.

Note: Take suitable precautions in order to avoid damage

through electrostatic discharges!

Network terminals

Service-key

Satus-LEDs

Fig. 5: LONMSE 2M230I / 4M230I

Function of the LONMSE

Comfort and safety functions

These functions have been integrated in your software and

adapted exactly to your wishes. A detailed description is

contained in the software documentation of your sun pro-

tection control unit.

Local operation

■Brief operation of the sun blind push button (< 0.6 sec-

onds) is used to set the sun blind in small steps.

■If the push button is pressed for between 0.6 and 2.6

seconds, a move command is triggered and the sun

blind moves for about as long as the button is pressed.

■If the push button is pressed for longer than 2.6 sec-

onds, the sun blind moves to the upper or lower end

position. In order to stop the movement, press the but-

ton of the opposite direction of movement briefly.

Maintenance

There are no parts to be maintained within the device. In

case of a malfunction the installed miniature fuses may only

be replaced by qualified electrical personnel. Note: The de-

vice has a thermal fuse which interrupts the power supply

when the operating temperature rises too high. After the

thermal fuse has been triggered, the device is unusable and

has to be sent in to the manufacturer to be repaired. Over-

heating of the device indicates a fault. Therefore switch off

the plant and check the correct installation.

Liability

The manufacturer can reject the warranty for damage to the

product if the product information given in these instructions

is not observed, if it is used for purposes other than those

specified or if used improperly. Liability for consequent dam-

age to persons or property is also excluded in this case. Ob-

serve the specifications in the operating instructions of your

sun blind. Liability for damage to the sun blind caused by

operation during icing or icy conditions is also excluded.

Technical data

LONMSE

2M230I/4M230I 0,25A min typ max unit

Supply 230 V AC

Operating voltage 207 230 253 V AC

Primary zero-signal cur-

rent 20 25 mA

Thermal-fuse (primary) 131 135 °C

Safety class I

Output (drive)

Operating voltage via re-

lais 230 V AC

Operating current 0,1 1 2,15 A

Switching capacity at

230 V AC/cos ϕ=0,2 460 VA

Current monitoring 0,25 A

Miniature fuse per drive 3,15 AT

Inputs incremental encoder

Control voltage active 10 12 30 V DC

Control voltage inactive 0 0 1 V DC

Operating frequency 80 100 120 Hz

Power supply for incre-

mental encoders, total

current max. 15 mA

10 16 26 V DC

Input LON®FTT-10

Inputs on local operating elements, (sun blind but-

tons, 1-pin) and signaling contact inputs

Local voltage active 8 24 36 V DC

Local voltage inactive -0,5 0 3 V DC

Housing variants Degree of protection

Dimensions see fig. 6,

7, 8 and 9.

AP45-housing with dust

protection IP10

AP45-Clip housing IP10

Clip housing for distribu-

tion cabinet IP20

AP60 housing IP31

AP60 housing with

screwed cable glands IP41

Connection

Power feeder, outputs,

buttons, signaling con-

tacts

Screwed terminals

Network Spring-load terminals

Terminals

Power supply, outputs 0,5...2,5 mm2

Network 0,6...0,8 mm2

Test standards

DIN EN60730-1: 2002

DIN EN50081-1: 1992

DIN EN50082-1: 1997