9

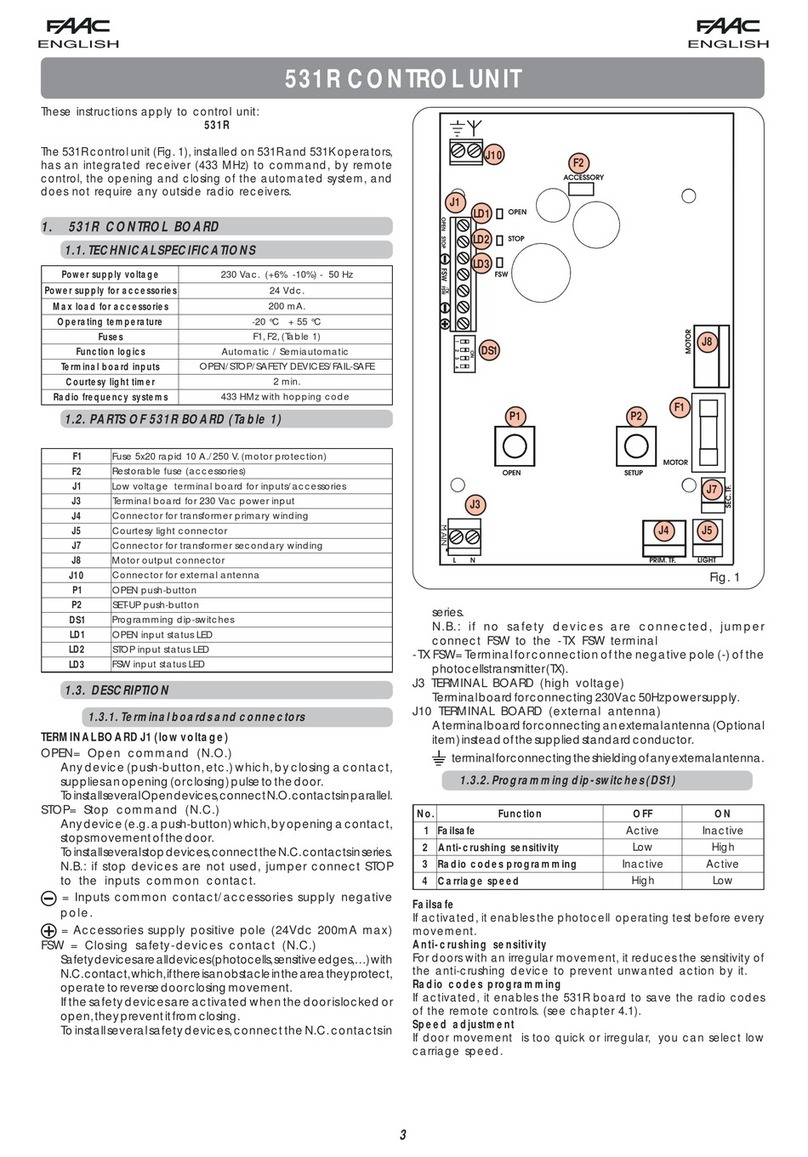

455 D Control Board

Figure U

The board has a two-digit display. When not in “PROGRAMMING”

mode, this display is used to indicate the status of inputs. Fig. U

shows how the LED segments of the display exactly correspond to

the inputs.

The table below shows the status of the LEDs in relation to the

status of the inputs.

Note the following: LED ON = closed contact

LED OFF = open contact

Operation of the Status Signaling LEDs

The status of the LEDs while the gate is closed at rest are shown in bold.

1. Program the functions of the 455 D control board according to

need, as previously shown.

2. Cut power to the electronic control equipment.

3. Release the operators and manually move the gate to the

mid-point of the opening angle.

4. Re-lock the operators.

5. Restore power.

6. Send and opening command on the OPEN A input (Fig.B)

and check if the gate leaves are being commanded to open.

N.B: If the rst OPEN A pulse commands a closing, cut power

and reverse the phases of the electric motor (red and black

wires) on the 455 D control board.

7.

Check force setting of the motors, modify if necessary (see

Section 13.5.1).

N.B: For hydraulic operators, like the 400, force should be pro-

grammed to maximum level (50)

8. Stop leaf movement with a STOP command.

9. Release the operators, close the leaves and re-lock the

operators.

Opening/closing time is established by a learning procedure which

varies slightly according to whether you are using Gatecoders or not.

13.6.3.1 LEARNING NORMAL TIMES

Normal learning (i.e. without limit-switches and Gatecoders) can be

accomplished in two ways:

- SIMPLE LEARNING (Without Slow Down):

Check that the leaves are closed. Enter “BASIC PROGRAMMING,”

select the TIME LEARNING function and then press the +push-

button for 1 second. The display begins ashing and the leaves

begin to open.

As soon as the leaves reach the opening contact point, provide an

OPEN A pulse (with the key operated push-button or with the radio

control) to stop the movement. The leaves stop and the display

stops ashing.

Press push-button Fto exit and save the programming. The

procedure is complete and the gate is ready to operate.

- COMPLETE LEARNING (With Slow Down):

Check that the leaves are closed. Enter “BASIC PROGRAMMING,”

select the TIME LEARNING function and then press the +push-

button for more than 3 seconds. The display begins ashing and

leaf 1 begins to open. The following functions can be performed by

sending OPEN A pulses (by key push-button or radio control):

1° OPEN - Slow down at opening of leaf 1

2° OPEN - Leaf 1 stops at opening and leaf 2 begins its opening

movement

3° OPEN - Slow down at opening of leaf 2

4° OPEN - Leaf 2 stops at opening and immediately begins its

closing movement

5° OPEN - Slow down at closing of leaf 2

6° OPEN - Leaf 2 stops at closing and leaf 1 begins its closing

movement

7° OPEN - Slow down at closing of leaf 1

8° OPEN - Leaf 1 stops at closing

When the display stops ashing, press push-button Fto exit and

save the programming. The procedure is complete and the gate is

ready to operate.

Notes:

• If you wish to eliminate deceleration in certain stages, wait for the

leaf to reach its stop-limit and supply 2 consecutive Open pulses

(by 1 second).

• If only one leaf is present, the entire sequence must nevertheless

be effected. When the leaf has nished opening, supply 5 Open

pulses until the leaf begins to close, and then resume normal

operation.

WARNING: During the learning procedure, safety

devices are disabled! Avoid crossing the leaf

movement area when this operation is carried out.

Make sure travel limit mechanical stops are present.

1.6 Start-Up

1.6.1 LED Check

1.6.2 Rotation Direction and Force Check

1.6.3 Learning Operating Times

Learning with the Gatecoder can be accomplished in two ways:

- SIMPLE LEARNING (With Slow Down):

Check that the leaves are closed. Access “BASIC PROGRAM-

MING,” select the TIME LEARNING function and then press the

+push-button for 1 second: the display begins ashing and the

leaves begin the opening movement.

The movement stops automatically when the opening stop limit is

reached. The display will stop ashing.

Press push-button Fto exit and save the programming. The proce-

dure is complete and the gate is ready to operate, using the default

slow down set at the factory.

- COMPLETE LEARNING (With Slow Down):

Check that the leaves are closed. Access “BASIC PROGRAM-

MING,” select the TIME LEARNING function and then press the +

push-button for more than 3 seconds. The display begins ashing

and leaf 1 begins to open. The following functions can be performed

by sending OPEN A pulses (by radio control or key push-button):

LEDs ON OFF

OP_A

Command activated Command inactive

OP_B

Command activated Command inactive

STOP

Command inactive Command activated

FSWCL

Safety devices clear Safety devices triggered

FSWOP

Safety devices clear Safety devices triggered

FCA1 (if used)

Flashes when Gatecoder 1 is in use

FCC1 (if used)

Flashes when Gatecoder 1 is in use

FCC2 (if used)

Flashes when Gatecoder 2 is in use

FCA2 (if used)

Flashes when Gatecoder 2 is in use

1.6.4 Learning Times with Gatecoder