14

ENGLISH

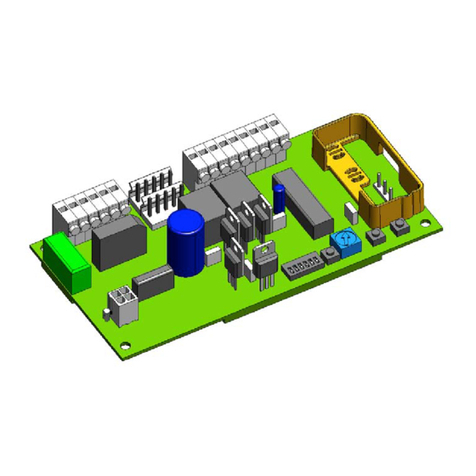

1. PROGRAMMING THE MICROSWITCHES

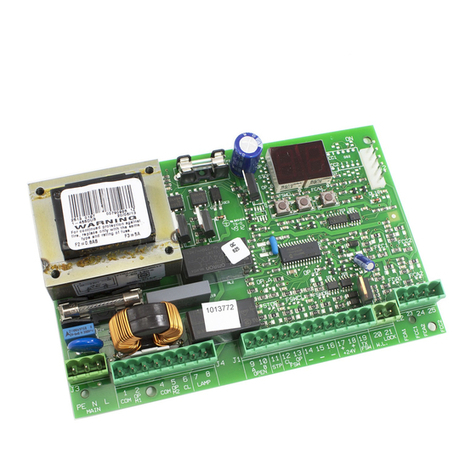

Automation programming is carried out by the microswitches

(fig. 1 - ref. 9) as shown in the diagram below.

If the gate closes, invert the motor wires on the control unit

(brown and black wires).

2.2. OPERATION TIME ADJUSTMENT

Opening/closing times are set by the OP/CL trimmer on the

control unit (fig. 1 - ref.7).

To reduce operation time, adjust the trimmer anticlockwise

To increase operation time, adjust the trimmer clockwise.

Maximum operation time is 120 seconds.

For 90° opening the approximate opening/closing time is 18

seconds.

For optimal system efficiency set the opening/closing time so

that the electric motor remains activated for a few seconds

after the leaf has reached the mechanical travel stop.

2.3. CLOSING LEAF DELAY ADJUSTMENT

Inthe case ofoverlapping leaves,it ispossible to delayclosing

of the leaf driven by motor M1 (see fig. 2) to ensure correct

closure of the gate.

SetthedelaybytheLEAFDELAYtrimmeronthe410MPScontrol

unit (fig. 1 - ref. 8).

To reduce delay time, adjust the trimmer anticlockwise.

To increase delay time, adjust the trimmer clockwise.

Maximum delay time is 28 seconds. If the operation time is

shorter, the delay time is reduced automatically.

2.4. SETTING PAUSE TIME

When A, S or AD logics are selected, the leaf momentary stop

time can be set using the PAUSE trimmer (fig. 1 ref. 6).

Turn the trimmer clockwise to increase the time.

Turn the trimmer anticlockwise to reduce the time.

The maximum pause time is 240 sec.

2.5. ANTI-CRUSHING SYSTEM ADJUSTMENT

The 410 MPS control unit has been designed for use on both

electromechanical and hydraulic operators.

Whenthe410MPScardisusedonelectromechanicaloperators,

the torque control device must be set by turning the TORQUE

trimmer (fig. 1 ref. 5).

To reduce torque, adjust the trimmer anticlockwise.

To increase torque, adjust the trimmer clockwise.

In any event, FAAC advises not to exceed a torque of 15 Kg

measured on the outer edge of the leaf.

Toensureprecisetorqueadjustmentusealineardynamometer.

When the 410 MPS card is used on hydraulic operators, the

torque control device must be set to the maximum value by

turning the TORQUE trimmer clockwise.

This device is already present inside the operator hydraulic

circuit (BY-PASS valves).

1.1. OPERATION LOGICS

There are four operating logics available:

A: “AUTOMATIC” E : “SEMI-AUTOMATIC”

S : “SAFETY” EP : “SEMI-AUTOMATICSTEP-BY-STEP”

AD: "AUTOMATIC TIMER"

Operationof the different logics isdescribed in tables 3/a-b-c-d-

e.

1.2. SAFETIES ON CLOSING

Thisfunctionservestoselecttheoperatingmodefortheclosing

safeties:

- OFF: immediate reverse of movement during gate closure

- ON: movement is stopped during closing and reversed on

opening when the safety is disengaged.

2. START-UP

1) Program the 410 MPS electronic control unit according to

specific requirements as shown in fig. 15.

2) Check led status as shown in table.

LEDfunctions

LEDS ON OFF

DL 1 (OPEN INPUT A) Commandactive Command not active

DL 3 (STOP) Command not active Commandactive

DL4 (FTSW OPEN) Safetiesdisengaged Safetiesengaged

DL5 (FTSWCLOSE) Safetiesdisengaged Safetiesengaged

N.B.: the bold text indicates led status with gate idle.

2.1. DIRECTION OF ROTATION

1) Switch off the power.

2) Manually move the gate to halfway.

3) Lock the operators.

4) Switch on the power.

5) Send an OPEN signal to input A (fig. 2) and check that the

leaf opens.

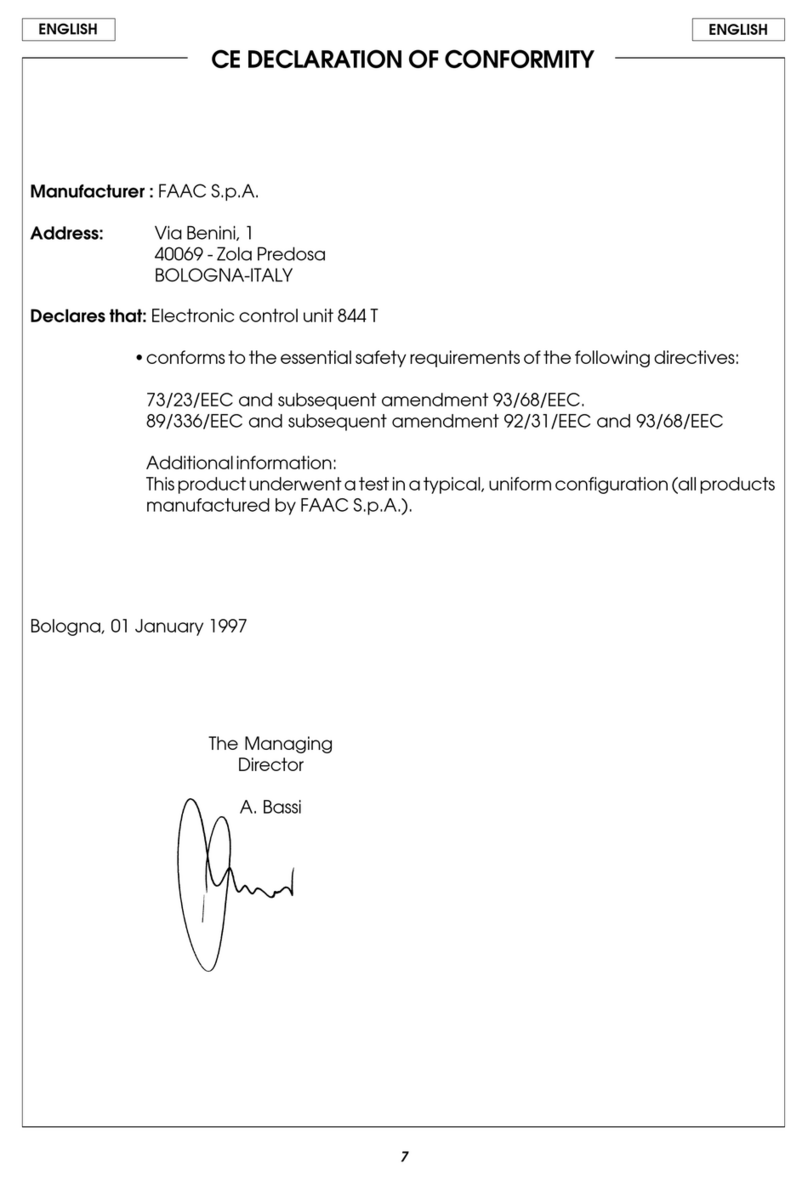

Fig. 15

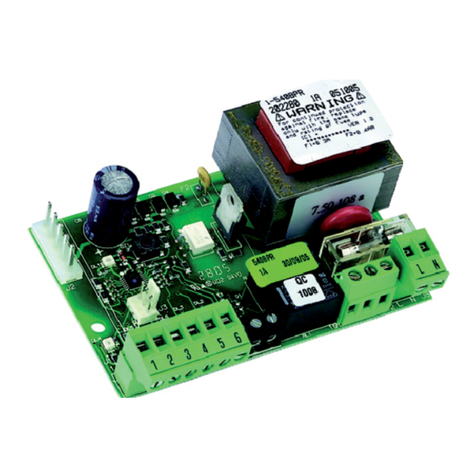

OPERATING

LOGICS SAFETIES ON CLOSING

INVERTS MOVEMENT

IMMEDIATELY

STOPS AND INVERTS

MOVEMENT ON

DISENGAGEMENT

AD

A

S

E

EP

OFF

ON

OFF

OFF

ON OFF OFF

OFF

OFF ON

ON OFF

SW1 SW2 SW3 SW4

OFF

ON

ON ON

OFF

123 4

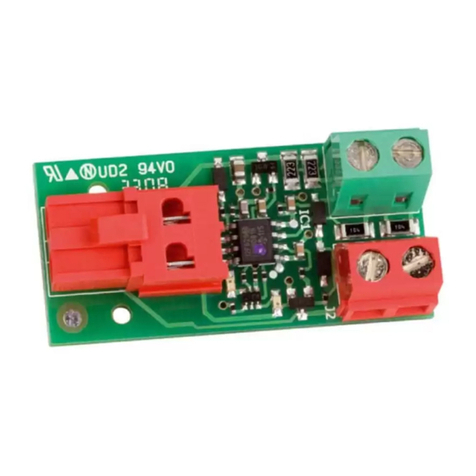

Fig. 14

Enable

Disable

DisableEnable

FAIL-SAFE

LEAF DELAY

Intelligent Security & Fire Ltd.