8

Display Function Default

o4 OUTPUT 4:

See output 1

, except to functions 00, 11 ,

12

that in this case have not effect.

02

P4

OUTPUT 4 POLARITY:

for configuring the output polarity status.

Y

= N.C. polarity

n o

= N.O. polarity

no

AS

ASSISTANCE REQUEST (coupled to the

next two functions):

If activated at the end of the count-down

(settable with the next two functions under

“Cycle programming”), it activates LAMP

output for 4 sec every 30 sec. (assistan-

ce request). Can be useful for setting

scheduled maintenance

Y= Active

no = Excluded

no

nc

CYCLE PROGRAMMING IN THOUSANDS:

For setting a count-down of the system

operating cycles. Settable value from 0to 99

(thousands of cycles). The displayed value is

reset as the cycles progress, interacting with

the n C value (99 n c decrementing steps

correspond to one n C decrement).

The function can be used combined with

n C , to check the use of the system and to

make use of the “Assistance request”.

00

n C

CYCLE PROGRAMMING IN HUNDREDS OF

THOUSANDS:

For setting a count-down of the system

operating cycles. Settable value from 0

to 99 (hundreds of thousands of cycles).

The displayed value is reset as the cycles

progress, interacting with the n c value

(1 decrement of n C corresponds to 99

decrements of n c ).

The function can be used combined with

n c to check the use of the system and to

make use of the “Assistance request”.

0 1

h 1 NO EFFECT oo

h 2 NO EFFECT oo

S t AUTOMATED SYSTEM STATUS:

Exit from programming, storage of data

and return to gate status view (see par.

5.1.).

To access 3rd LEVEL PROGRAMMING, press push-button Fand, while holding

it down, press push-button +for about 10 seconds:

• if you release the push-button +, the display shows the name

of the first function.

• if you also release the push-button F, the display shows the value

of the function, which can be changed with keys +and -.

• if you press the push-button F(and hold it down), the display

shows the name of the next function; if you release it, the

values is shown and can be modified with keys +and -.

• when you reach the last function, press the push-button F

to exit programming, and the display resumes showing the

inputs status.

The following table indicates the sequence of functions accessible in 3rd

LEVEL PROGRAMMING:

3rd LEVEL PROGRAMMING 10sec

Display Function Default

/ setting

0 1

If you enable this function, automatic closure

occurs after pause time.

.

Y

= automatic

closure

no

= disables

02

If you enable this function, operation is with

two different inputs: OPEN for opening and

CLOSE for closing

Y

= operation

on two inputs

no

= disables

03

Activation of recognition of input levels OPEN

and CLOSE (command maintained), i.e. the

board recognises the level (e.g. with OPEN

maintained and STOP pressed, when the

latter is released, the automated system

continues to open). If

03

is disabled, the

board commands a manoeuvre only if the

input is varied.

Y

= recognition

of input level

no

= recognition

of input variation

04

Activation of DEAD MAN opening (command

always pressed). If the OPEN command is

released, operation is stopped.

Y

= enables

no

= disables

05

If you enable this function, an OPEN command

during opening stops the movement.

If parameter

06

is

no

the system is ready for

opening

If parameter

06

is

Y

the system is ready for

closing

Y

= OPEN at

opening stops

movement

no

= disables

06

If you enable this function, an OPEN command

during opening reverses movement.

If parameters

05

and

06

are

no

, OPEN has no

effect during opening

Y

= OPEN

at opening

reverses

no

= disables

07

If you enable this function, an OPEN command

during the pause stops operation

If parameters

07

and

08

are

no

, OPEN

recharges pause time

Y

= OPEN during

pause stops

movement

no

= disables

08

If you enable this function, an OPEN command

during the pause causes closure

If parameters

07

and

08

are

no

, OPEN

recharges pause time.

Y

= OPEN in

pause closes

no

= disables

09

If you enable this function, an OPEN command

during closure, stops operation, otherwise it

reverses movement.

Y

= stops

movement

no

= reverses

10

DEAD MAN closing enabled (command always

pressed). If you release the CLOSE command,

operation is stopped.

Y

= enables

no

= disables

1 1

If you enable this function, a CLOSE command

has priority over OPEN, otherwise OPEN has

priority over CLOSE.

Y

= enables

no

= disables

12

If you enable this function, a CLOSE command

commands closure when it is released.

Until CLOSE is enabled, the unit remains in

closure pre-flashing.

Y

= CLOSE

closes when

released

no

= CLOSE

closes at once

13

If you enable this function, a CLOSE command

during opening stops operation, otherwise

the CLOSE command commands reversing

immediately or at end of opening (also see

parameter

14

)

Y

= CLOSE stops

movement

no

= CLOSE

reverses

14

If you enable this function, and if parameter

13

is

no

, the CLOSE command commands

immediate closure at end of opening cycle

(memory stores CLOSE)

If parameters

13

and

14

are

no

, CLOSE

commands immediate closure.

Y

= immediate

closure at end of

opening

no

= immediate

closure

15

If you enable this function, when the system

is stopped by a STOP, a subsequent OPEN

command moves in the opposite direction.

If parameter

15

is

no

it always closes.

Y

= OPEN moves

in opposite

direction

no

= OPEN

always closes

16

If you enable this function, during closing, the

CLOSING SAFETY DEVICES stop movement

and allow resumption of movement when

disengaged, otherwise they immediately

reverse at opening.

Y

= closure at

disengagement

no

= immediate

reversing

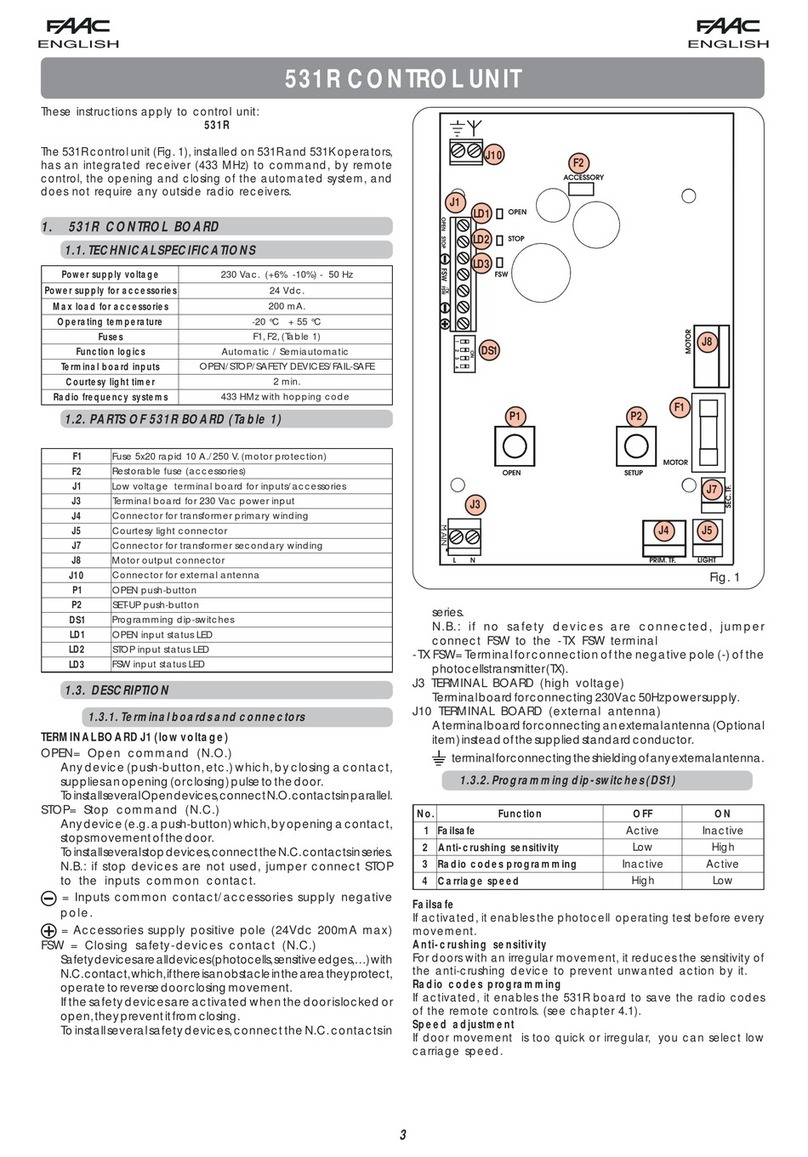

5.3. 3rd LEVEL PROGRAMMING

ENGLISH