E1SL 3 53225804 - Rev. B

Translation of the original instructions ENGLISH

TABLES

1 Assigning the Operating mode ...................................... 8

2 Configurable inputs ...............................................10

3 Configurable inputs programming..................................10

4 Configurable outputs ..............................................12

5 Programming Configurable Outputs ................................ 12

6 BASIC Programming............................................... 16

7 ADVANCED programming ..........................................18

8 Pre-set ID associations.............................................29

9 Upload/Download Menu........................................... 33

10 Status of the automation ..........................................35

11 Errors and Warnings ............................................... 36

12 Troubleshooting guide.............................................39

13 LED Error Coding on Function selectors ..............................41

14 LED Warning coding - LK EVO....................................... 41

15 FW version LED coding - LK EVO .................................... 41

16 FUNCTIONS menu ........................................... 46

CONTENTS

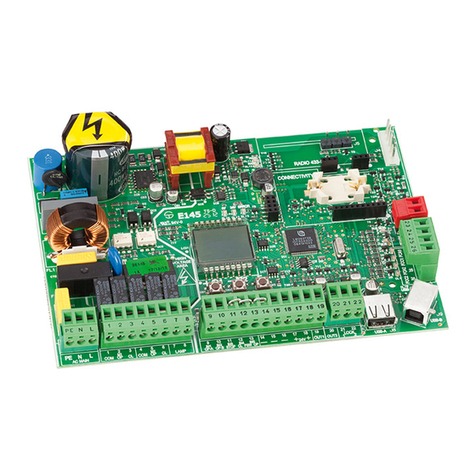

1. ELECTRONIC MODULE E1SL ............................................. 4

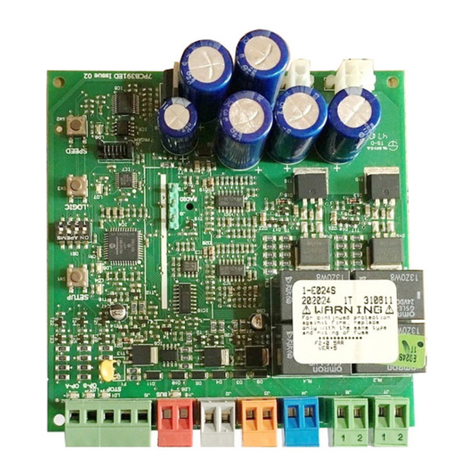

Board E1SL ........................................................... 4

Status LEDs on the board.............................................. 5

Terminal boards and connectors ....................................... 5

2. DM BOARD.............................................................. 6

Installing the DM board ............................................... 6

Connecting the second motor ......................................... 6

Enabling the DM KIT .................................................. 6

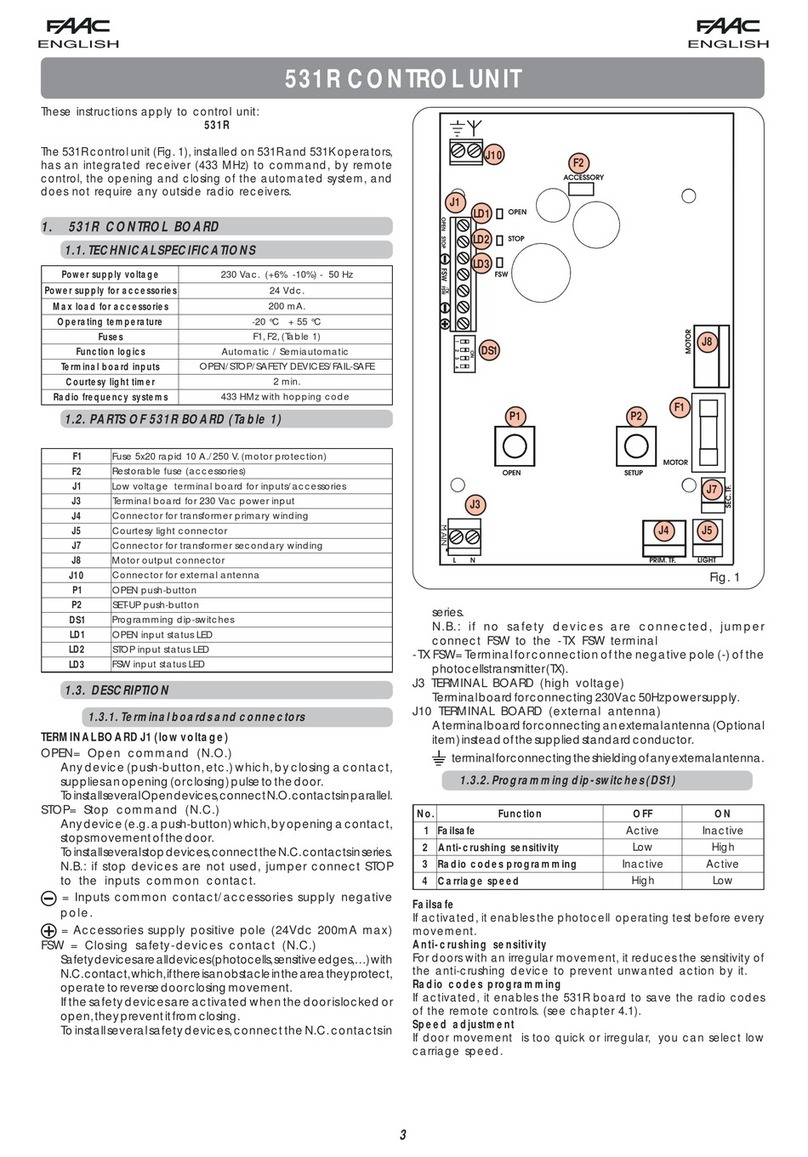

3. OPERATING MODE MODFUN........................................... 8

4. CONNECTIONS .......................................................... 9

5. CONFIGURABLE INPUTS................................................ 10

PROGRAMMING ..................................................... 10

Connections......................................................... 10

Automatic Opening Inputs ........................................... 11

SEMI-AUTOMATIC OPEN input......................................... 11

Safety inputs........................................................ 11

Operating mode inputs .............................................. 11

TIMER input ......................................................... 11

RESET input ......................................................... 11

6. CONFIGURABLE OUTPUTS.............................................. 12

PROGRAMMING ..................................................... 12

Connections......................................................... 12

7. STARTUP.............................................................. 13

Set-up procedure .................................................... 13

7.1 Turn the power on .................................................... 13

7.2 SETUP ............................................................... 14

7.3 Restoring factory settings ............................................. 14

7.4 Programming the board .............................................. 15

7.5 Movement parameters................................................ 20

7.6 Obstacle detection.................................................... 20

7.7 Low Energy .......................................................... 20

7.8 Intrusion............................................................. 20

KEEP CLOSED ........................................................ 20

PULL & GO........................................................... 20

7.9 Energy Saving ....................................................... 20

7.10 Timing and partial opening .......................................... 20

7.11 Date and Time....................................................... 21

7.12 Cycle counter - Scheduled maintenance ............................... 21

7.13 TIMER .............................................................. 22

WEEKLY PROGRAMMING ............................................. 22

JOLLY PROGRAMMING................................................ 22

ENABLING/DISABLING THE TIMER ..................................... 22

8. ACCESSORIES .......................................................... 23

Emergency battery .................................................. 23

XB LOCK motor block and monitoring (optional) ....................... 23

XM LOCK motor block and monitoring................................. 24

ELASTIC Kit.......................................................... 24

One Dual Technology entry and exit detector .......................... 25

2 Dual Technology entry and exit detectors............................ 26

Infrared detector for safety in opening ................................ 27

XFA button photocells................................................ 28

9. INTERCOM ............................................................. 29

Installing INTERCOM ................................................. 29

Assigning an ID...................................................... 29

Operation ........................................................... 29

Temporarily disabling a board ........................................ 29

INTERCOM diagnostics ............................................... 29

9.1 INTERLOCK ........................................................... 30

Installing INTERLOCK................................................. 30

Enabling / disabling INTERLOCK....................................... 30

9.2 AIRSLIDE............................................................. 31

Installing AIRSLIDE .................................................. 31

9.3 INTERLEAVES......................................................... 32

Installing INTERLEAVES .............................................. 32

10. FW UPDATES AND FILE DOWNLOAD USB............................. 33

AutoUpdate ......................................................... 33

Upload/Download Menu ............................................. 33

Bootloader and FW versions.......................................... 33

11. DIAGNOSTICS......................................................... 34

LEDs on the board ................................................... 34

Automation and configured inputs status ............................. 35

Errors and Warnings ................................................. 35

FW versions ......................................................... 35

11.1 Reset............................................................... 38

12. LK EVO................................................................ 40

LK EVO lock device ................................................... 41

13. KS EVO................................................................ 42

14. SDK EVO .............................................................. 43

SDK EVO lock device.................................................. 43

Home page.......................................................... 44

Reset - Lock/Release................................................. 44

PASSWORD (PSW) ................................................... 44

MODFUN ............................................................ 45

MENU ........................................................... 45

PROGRAMMING ..................................................... 45

Menu 1 language.................................................... 48

Menu 2 Programming................................................ 48

Menu 3 ERRORS ..................................................... 49

Menu 4 INDICATIONS................................................. 49

Menu 5 CYCLE COUNTER.............................................. 49

Menu 6 DATE / TIME.................................................. 49

Menu 7 TIMER ....................................................... 49

Menu 8 PASSWORD .................................................. 50

Menu 9 INFO ........................................................ 50