2 Safety

2.1 Intended Use

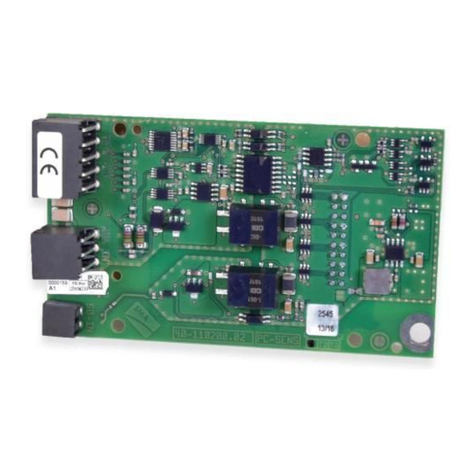

The SMA Sensor Module is a module for SMA inverters. The SMA Sensor Module has different

interfaces for connecting various sensors. The SMA Sensor Module converts the signals of the

connected sensors and transmits them to the inverter.

The SMA Sensor Module has the following interfaces:

• Two temperature inputs for connecting the temperature sensors

• One analog input for voltage or current signals (e.g. of an irradiation sensor)

• One supply voltage for a signal source (e.g. of an irradiation sensor)

• One S0 interface (e.g. for connecting an anemometer or energy meter)

The SMA Sensor Module must only be installed in the following SMA inverters:

• STP 50-40 (Sunny Tripower CORE1)

The inverter still complies with the standard after the product has been installed.

The product must only be operated with temperature sensors with a Pt100 measuring shunt or a

Pt1000 measuring shunt.

The product must only be operated with irradiation sensors that can output a current signal in the

range from 0mA to 20mA or 4mA to 20mA or a voltage signal in the range from 0V to +10V.

The product must only be operated with anemometers with impulse output for S0 impulses in

accordance with DINEN62053-31 (IEC62053-319).

The product must only be operated with energy meters with S0 interface in accordance with

DINEN62053-31 (IEC62053-31).

A list with SMA Sensor Module compatible products is available at www.SMA-Solar.com.

The product must only be used in countries for which it is approved or released by SMA Solar

Technology AG and the grid operator.

All components must remain within their permitted operating ranges at all times.

Use this product only in accordance with the information provided in the enclosed documentation

and with the locally applicable standards and directives. Any other application may cause

personal injury or property damage.

Alterations to the product, e.g. changes or modifications, are only permitted with the express written

permission of SMA Solar Technology AG. Unauthorized alterations will void guarantee and

warranty claims and in most cases terminate the operating license. SMA Solar Technology AG

shall not be held liable for any damage caused by such changes.

Any use of the product other than that described in the Intended Use section does not qualify as the

intended use.

The enclosed documentation is an integral part of this product. Keep the documentation in a

convenient place for future reference and observe all instructions contained therein.

The type label must remain permanently attached to the product.

2 Safety

SMA Solar Technology AG

Installation Manual 7MDSEN-40-IA-en-10