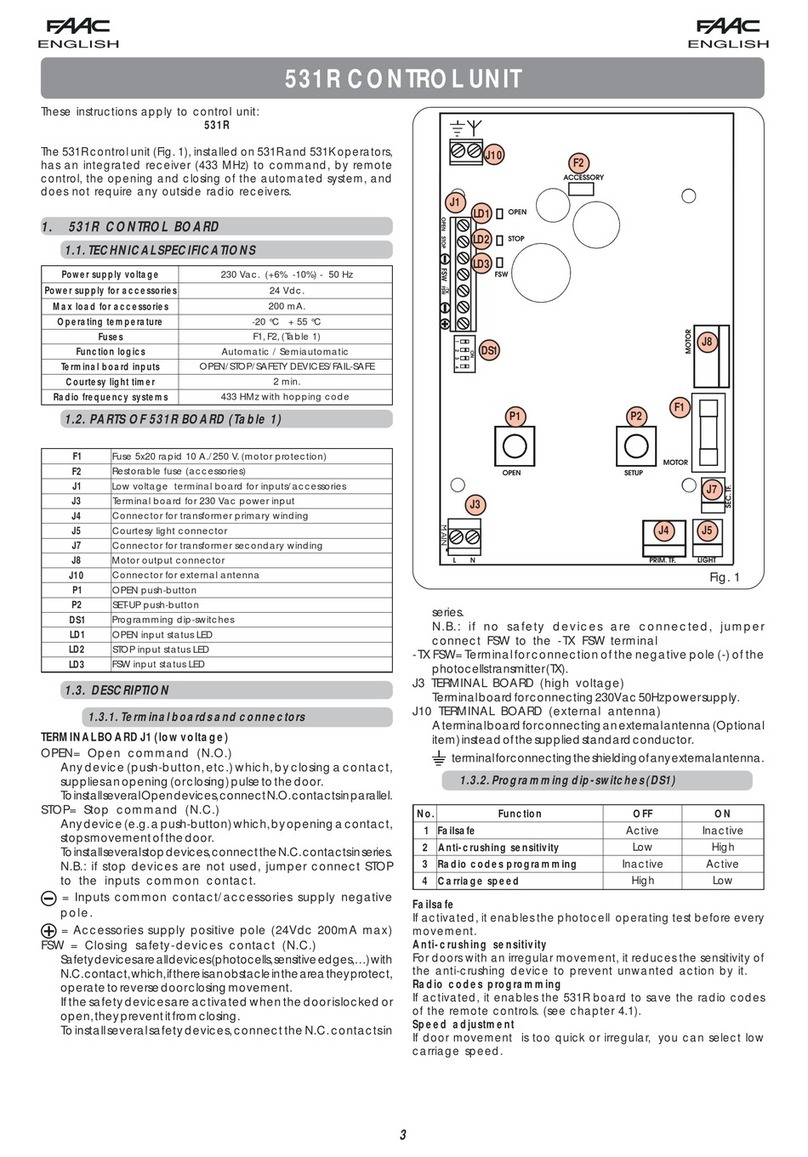

4

ENGLISH

8 = FSW CL = Closing Safety devices contact (N.C.)

Safety devices are all devices (photocells, sensitive ed-

ges,…) with N.C. contact, which, if there is an obstacle

in the area they protect, operate to reverse door closing

movement. They have no effect during the opening sta-

ge, except in the Ad function (see chap.7.4. - Advanced

programming).

If the closing safety devices are engaged while the door

is open, they inhibit any Open pulse.

To install several safety devices, connect the N.C. contacts

in series.

If no closing safety devices are connected,

jumper connect “FSW CL” to terminal 4.

9 = ENCODER = Input for encoder signal.

The signal received from the encoder must be connected

to this terminal. To supply power to the encoder, connect

the remaining two wires to terminals “1 - 3” observing the

polarity indicated on the lay-out of Fig. 2.

The control unit will not operate without an encoder.

For two-motor applications, the encoder must

be applied only to motor 1 (the one with the

board).

10 = OPEN = OPEN Command (N.O.)

Any device (push-button, detector,…) which, by closing a

contact, supplies an opening pulse to the door.

To install several Open devices, connect N.O. contacts

in parallel.

STOP = STOP command (N.C.)

A suitable device which, by opening a contact, immediately

stops door movement. Connect the STOP in series to the

common contact of the limit switches (see Fig 2) If a STOP

Push-button cannot be connected, connect the common

contact of the limit switches to terminal 2. To install several

STOP devices, connect N.C. contacts in series.

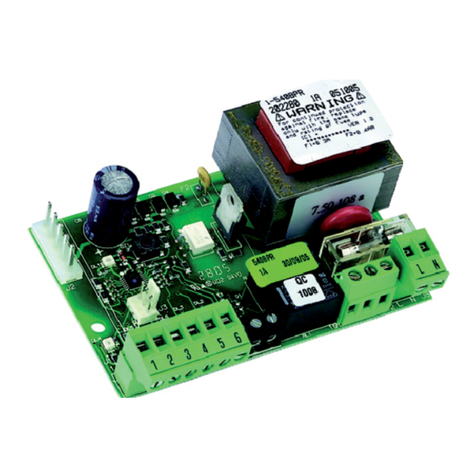

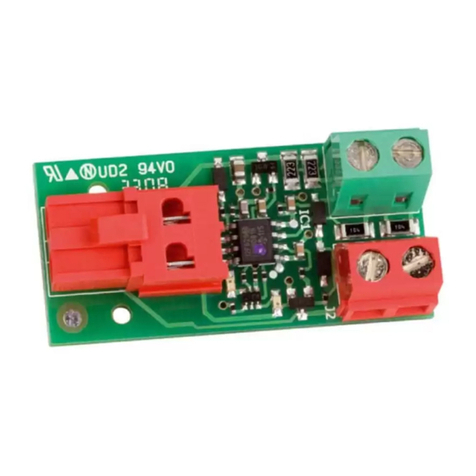

5.1.4. CONNECTOR J4 (low voltage)

Connector J4 (Fig. 4) is used for rapid connection of Minidec,

Decoder and RP Receivers. The receiver/decoding

board must be inserted with the components facing the

board.

Insert and remove the board ONLY after cutting

power.

A two-digit display is installed on the board. During normal

operation, it indicates the status of the inputs. We show

below the exact correspondence between the horizontal

segments (we will call them LEDs from now on) of the

display and the inputs.

The table below indicates the status of the LEDs in relation

to the status of the inputs.

Tab.1 STATUS OF LEDS

LED ON OFF

OPEN Opening command active Opening command

inactive

ENCODER LED flashes during operation

FSW OP Opening safety devices

released

Opening safety devices

engaged

FSW CL Closing safety devices

released

Closing safety devices

engaged

FCA Opening limit switch

free

Opening limit switch

engaged

FCC Closing limit switch free Closing limit switch

engaged

Led on = closed contact / led off = open contact

6 SIGNALLING LEDS (status of inputs)

An example of the

connection of the

radio receiver

Fig. 4

7 PROGRAMMING

Power up the system, checking that no pulse

generator is active and can send an OPEN

command.

With this control board, you can adjust the force, speed

and sensitivity parameters in compliance with what is

specified by current regulations to respect the impact

curve. (see paragraph 7.2).

To program the operation of the automated system, you

must access the “PROGRAMMING” mode.

Programming is in two parts: BASIC PROGRAMMING and

ADVANCED PROGRAMMING.

modification of the programming

parameters is immediately effective,

whereas definitive memory-storage

occurs only on exiting programming and

returning to the view of the status of the

automated system. If you cut power to

the board before returning to view the

status, all the modifications made will

be lost.

You can return to viewing the status from

any point of programming at any level,

by pressing keys F and - simultaneously.

: The statuses of the LEDs with door closed and

at rest are highlighted in bold.