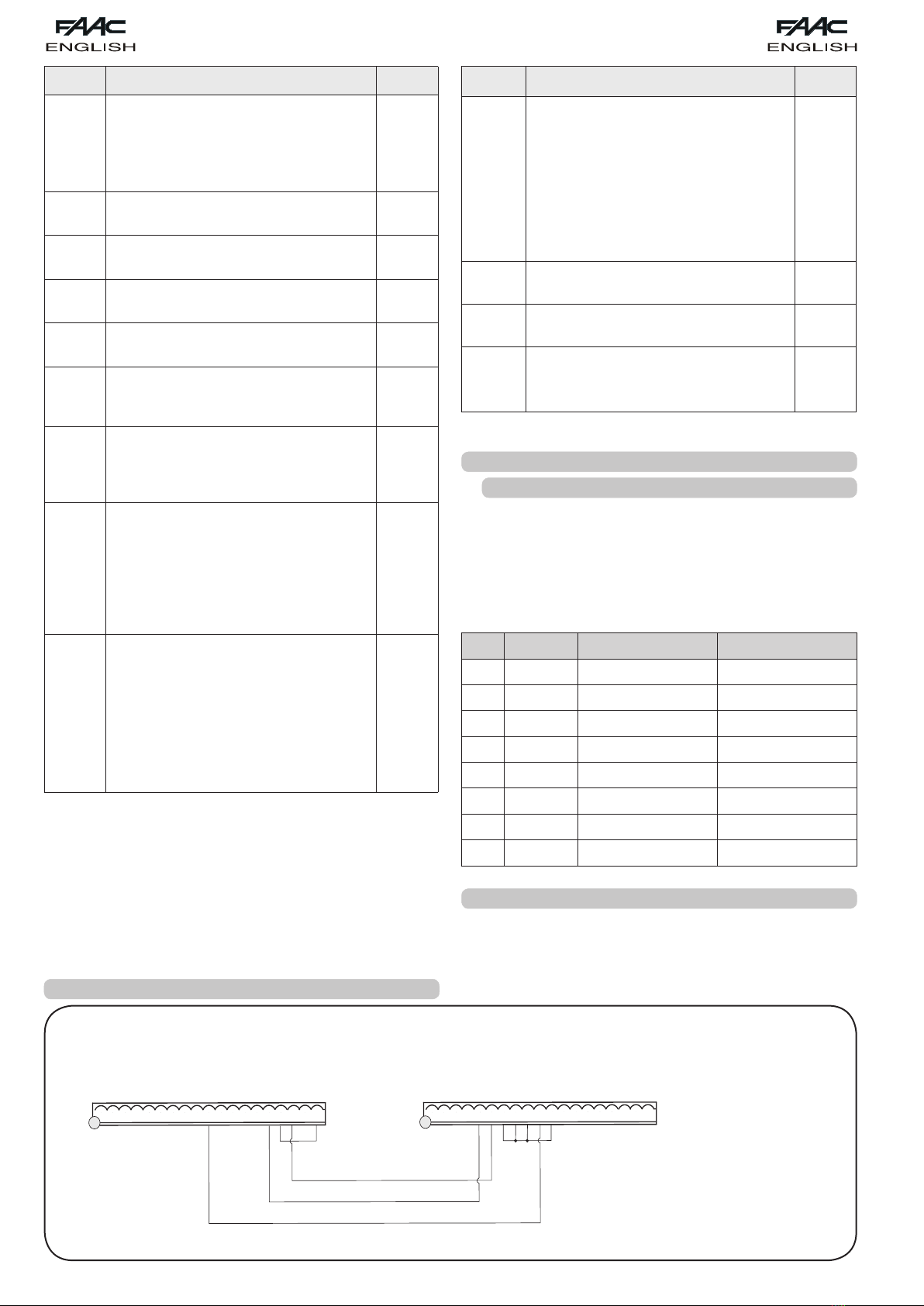

14

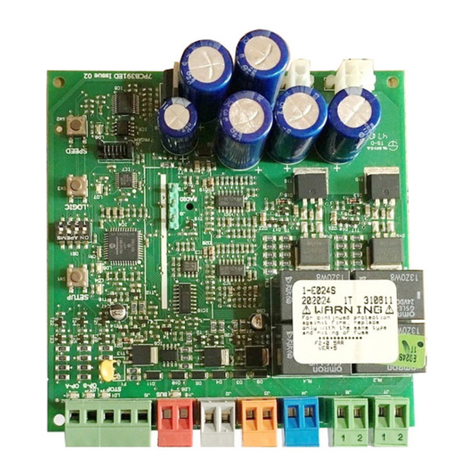

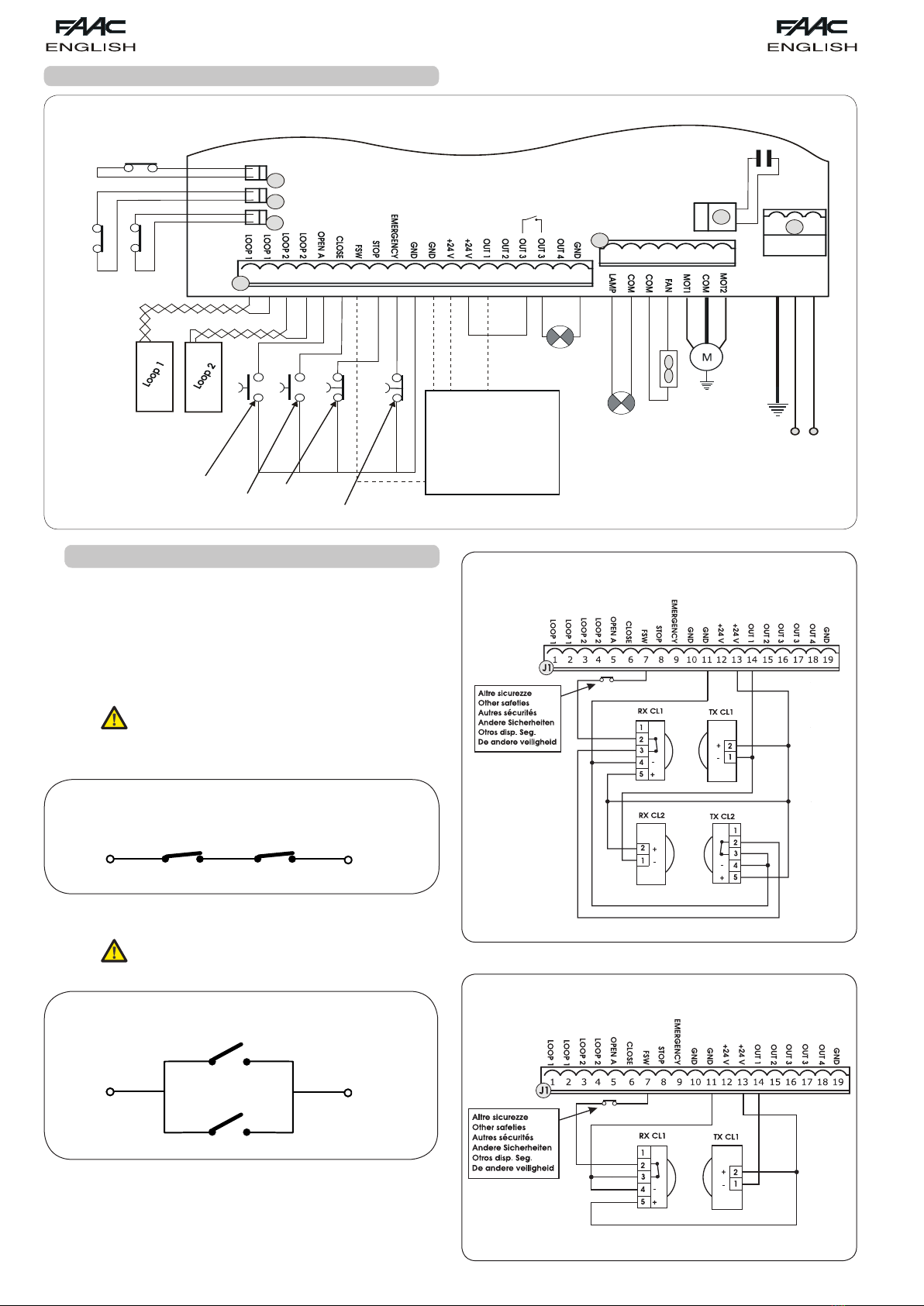

191816 17151412 1310 118 96 74 52 31

OPEN A

STOP

LOOP 1

LOOP 2

LOOP 2

LOOP 1

CLOSE

FSW

EMERGENCY

OUT 1

OUT 2

OUT 4

OUT 3

GND

GND

GND

+24 V

+24 V

OUT 3

J1

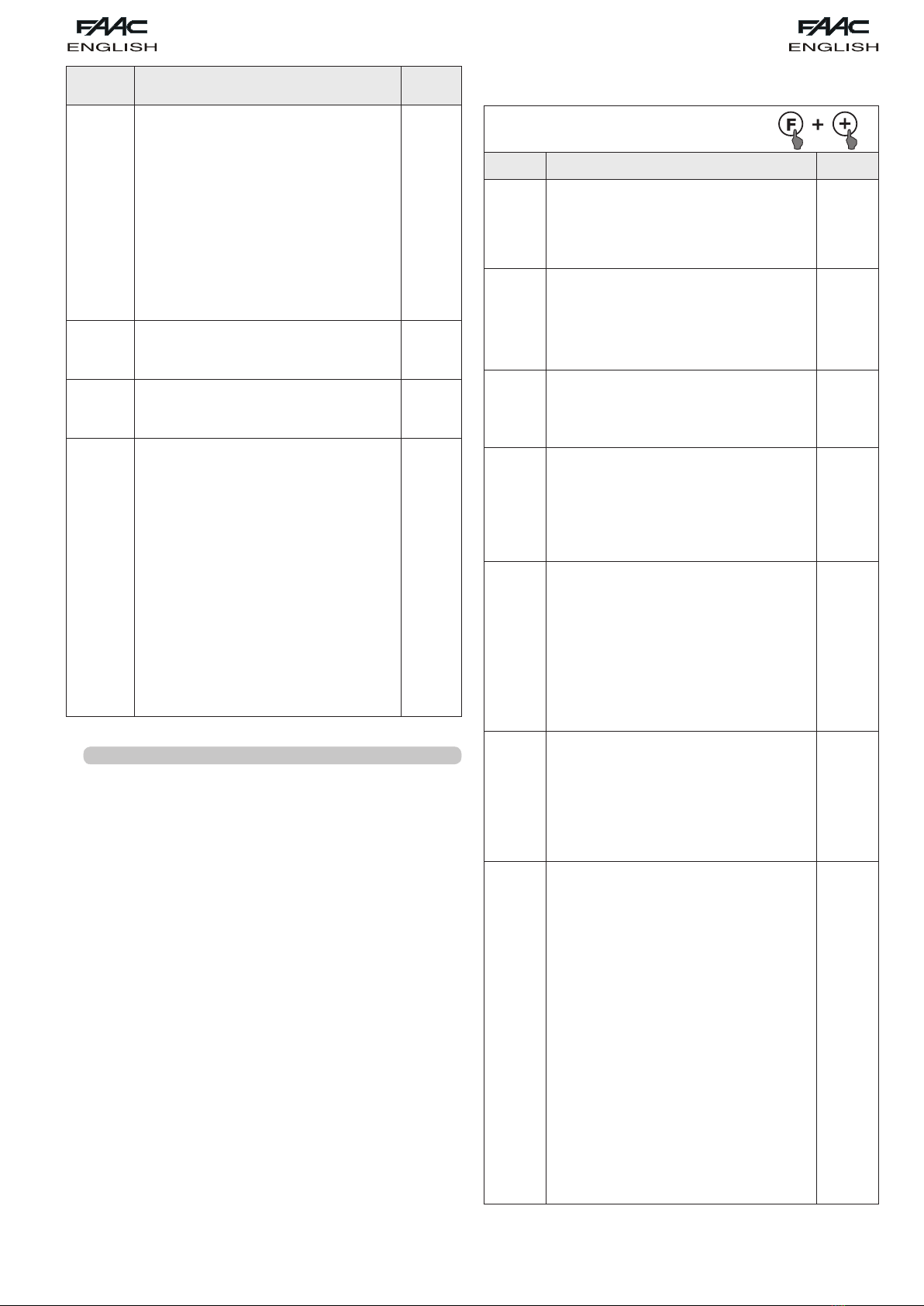

191816 17151412 1310 118 96 74 52 31

OPEN A

STOP

LOOP 1

LOOP 2

LOOP 2

LOOP 1

CLOSE

FSW

EMERGENCY

OUT 1

OUT 2

OUT 4

OUT 3

GND

GND

GND

+24 V

+24 V

OUT 3

J1

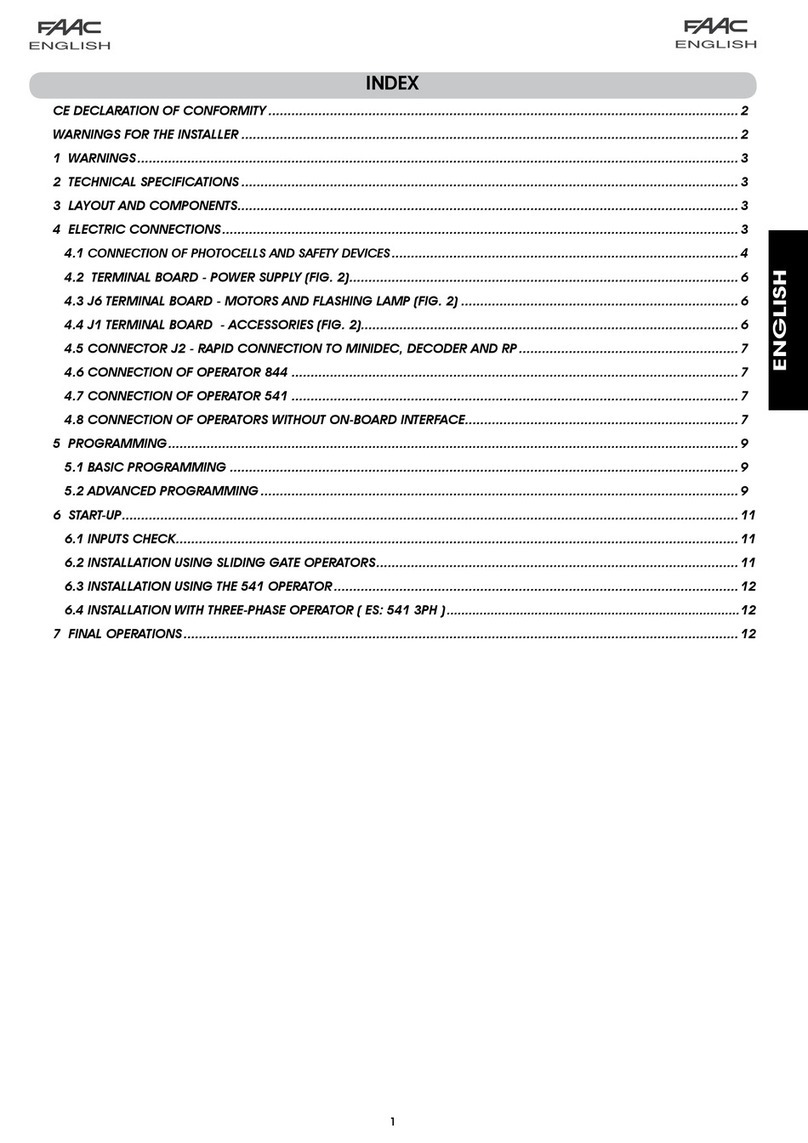

4.2. J1 TERMINAL-BOARD - ACCESSORIES (FIG.2)

LOOP 1 - Power supply to loop1 (OPEN - terminals 1-2): use these

terminals to connect the loop you wish to use as an OPEN pulse

generator.

LOOP 2 - Power supply to loop2 (SAFETY/CLOSE - terminals 3-4):

connect between these terminals the loop you wish to use as a

SAFETY/CLOSE pulse generator.

OPEN - “Opening” Command (N.O. - terminal 5): this refers to any

pulse generator (e.g.: push-button) which, by closing a contact,

commands the barrier to open and/or close.

To install several total opening pulse generators,

connect the N.O. contacts in parallel (see fig. 4)

CLOSE - “Closing” Command (N.O. - terminal 6): this refers to any

pulse generator (e.g.: push-button) which, by closing a contact,

commands the barrier to close.

To install several total opening pulse generators,

connect the N.O. contacts in parallel (see fig. 4)

FSW - Closing safety-devices contact (N.C. -. terminal 7) The purpose

of the closing safety devices is to protect the barrier movement

area during closure, by reversing motion. They are never tripped

during the opening cycle. If the closing safety devices are

engaged when the automated system is in open status, they

prevent the closing movement.

To install several closing safety devices, connect the

N.C. contacts in series(fig. 3).

If closing safety devices are not connected, jumper

connect the FSW and FAIL SAFE terminals (fig. 8).

STOP - STOP contact (N.C. - terminal 8): this refers to any device

(e.g.: push-button ) which, by opening a contact, can stop the

motion of the automated system.

To install several STOP devices, connect the N.C.

contacts in series (fig. 3.).

If stop safety devices are not connected, jumper

connect the STOP and GND terminals (fig. 8).

EMERGENCY - EMERGENCY contact (N.C. - terminal 9) this refers to

any switch which, by being activated in emergency state, opens

the barrier and stops its movement until the contact is restored.

If emergency safety devices are not connected,

jumper connect the EMERGENCY and GND

terminals (fig. 8).

GND (teminals 10-11-19) - Negative contact for feeding

accessories

24 Vdc (terminals 12-13) - Positive contact for feeding

accessories

Max. load of accessories: 500 mA. To calculate

absorption values, refer to the instructions for

individual accessories.

OUT 1 - Outout 1 (terminal 14): the output can be set to one of the

functions described in 2nd level Programming (see parag. 5.2).

The default value is FAILSAFE.

OUT 2 - Output 2 (terminal 15): the output can be set to one of the

functions described in 2nd level Programming (see parag. 5.2).

The default value is beam CLOSED.

OUT 3 - Output 3 (terminal 16-17): the output can be set to one of

the functions described in 2nd level Programming (see parag.

5.2). The default value is INDICATOR LIGHT.

Connect 24 Vdc - 3 W max. indicator light , if any, to these

terminals, following the instructions in fig. 2.

To avoid endangering correct operation of the

system, do not exceed the indicated power.

OUT 4 - Output 4 (terminal 18): the output can be set to one of the

functions described in 2nd level Programming (see parag. 5.2).

The default value is Beam LIGHTED.

Connection of one safety device

Connection of no device with NC contacts.

Fig. 7

Fig. 8

4.3. J2 TERMINAL-BOARD - MOTOR - FLASHING LIGHT AND

FAN (FIG.2)

M (COM-MOT1-MOT2): Motor connection

LAMP (LAMP-COM): Flashing light output ( 230 V ~)

FAN (FAN-COM): Fan output ( 230 V ~)

4.5. J9 TERMINAL-BOARD - POWER SUPPLY (FIG.2)

PE : Earth connection

N : Power supply 230 V~ ( Neutral )

L : Power supply 230 V~ ( Line )

To ensure correct operation, the board must be

connected to the earth conductor in the system.

Install an adequate differential thermal breaker

upstream of the system.

4.4. J8 CONNECTOR - MOTOR CAPACITOR (FIG.2)

Rapid connector for connecting the motor thrust capacitor.