A

C

B

ENGLISH

6

4 HOW TO USE THE RADIO CONTROLS

On the remote-control, every single pressure of

the rise or descent key commands a complete

movement. To stop a manoeuvre, press the STOP

push-button, otherwise the motor will continue

operating until the relevant travel-limit stop is

reached.

5 ADJUSTMENT OF THE TRAVEL-LIMIT STOPS

5.1 CORRELATION BETWEEN ROLLER ROTATION DIRECTION

AND TRAVEL-LIMIT ARROWS

4.3 DELETION OF INTERNAL RECEIVER MEMORY ( RESET )

According to the type of configuration of your instal-

lation (Fig.9), follow the instructions in the following

paragraphs.

1. Powerupthemotor.Thereceiverinstalledinthemotorgoes

into the programming phase, moving the motor in both

directionsfor1second.

2. PresskeyB(DESCENT)ofthetransmitterwithin15seconds.

3. Toconfirmcorrectprogramming,themotormovesagain

inbothdirectionsfor1second.

4. Runsomebriefrise,stopanddescentmanoeuvrestocheck

correctoperation.

TYPE 1 AND 4

TYPE 2 AND 3

1. Powerupthemotor.Thereceiverinstalledinthemotorgoes

into the programming phase, moving the motor in both

directionsfor1second.

2. PresskeyA(RISE)ofthetransmitterwithin15seconds.

3. Toconfirmcorrectprogramming,themotormovesagain

inbothdirectionsfor1second.

4. Runsomebriefrise,stopanddescentmanoeuvrestocheck

correctoperation.

4.2 ADDITION OF OTHER RADIO CONTROLS

1. Press and hold down for 5 seconds theSTOP key of the

transmitter(alreadystoredinthememory);themotormoves

for1secondinbothdirections.

2. PresstheRISEkeywithin5seconds,andpresstheDESCENT

Key within the next 5 seconds; the motor moves in both

directionsfor1second.

3. Press the RISE push-button of the NEW transmitter within 5

seconds.Ifthenewtransmitterwascorrectlymemory-stored,

themotormovesinbothdirectionsfor1second.

4. If the memory storage was not successfully performed,

repeattheprocedure.

Up to 32 transmitters can be memory-stored in

every receiver. If all the receiver’s memories

are occupied, the motor moves twice in both

directions.

4.1 HOW TO MEMORY-STORE THE FIRST TRANSMITTER

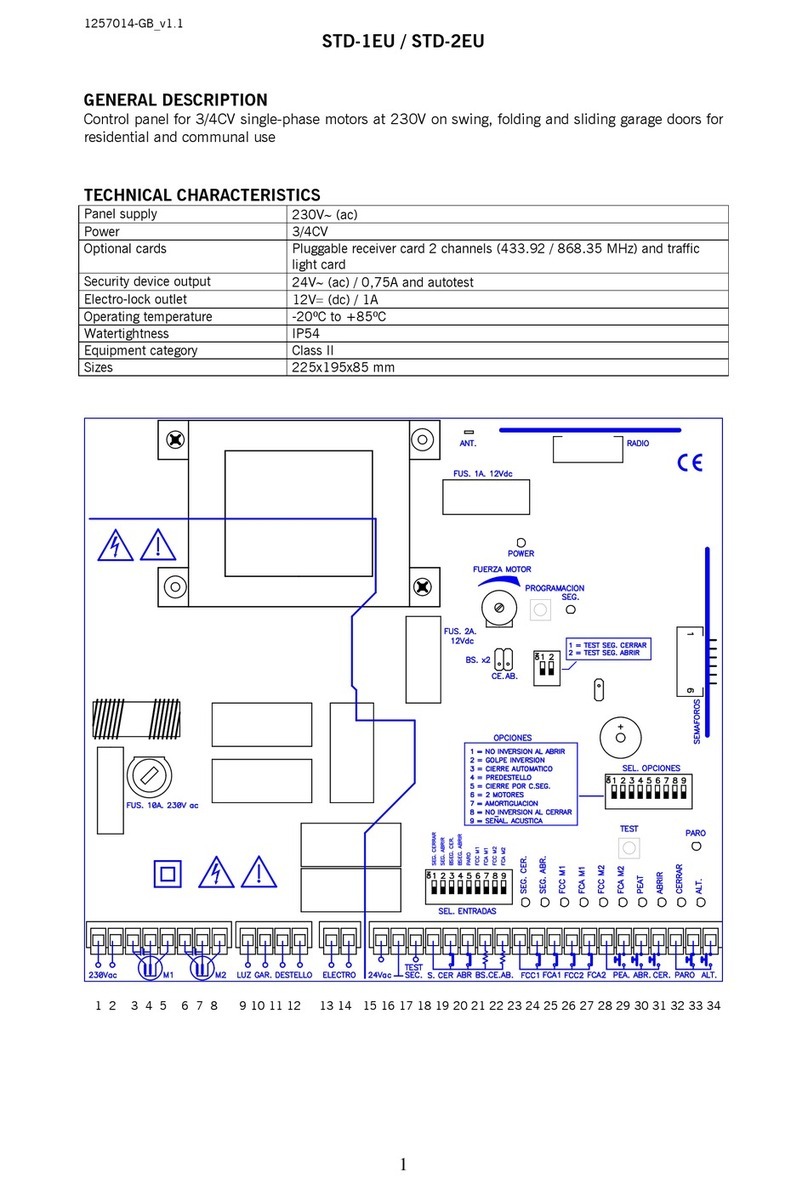

TYPE 1 TYPE 2

TYPE 3 TYPE 4

MOTOR HEAD SIDE

Fig.8

Asystemofelectro-mechanicaltravel-limitstopsishoused

insidetheFAACtubularmotors.Thesestopscutpowerto

themotor,whentheopeningorclosinglimitoftheroller-

shutterisreached.

Roller

rotation

direction

Relevant

travel-limit stop

Roller

rotation

direction

Relevant

travel-limit stop

KEYA:RISE

KEYB:DESCENT

KEYC:STOP

Fig.10

Fig.9

If memory storage is not successful, give a reset

command (CHAP. 4.3) and repeat the procedu-

re.

1) Cut power to the motor, wait for 10 seconds and

connecttheRED(orblack)wiretothebrownwire.

(Ifa“step-by-step”push-buttonisavailable,justholditdown

withoutmakingtheconnection.)

2)Supplypowertothemotor,afterapprox.10secondsthe

motoroperatesinbothdirectionsfor1secondsignalling

thatthememoryhasbeencompletelydeleted.

3) Cut power again to the motor. Disconnect

the black and the brown wires. (Release the

push-buttonifthe“step-by-step”push-buttonisavailable)