The electronic control panel Elpro 15 Plus, new generation, is designed to operate the sliding gate operator Girri 130. Power supply is 230V 50Hz single-phase. Built in full

compliance with BT 93/68/CE Low Voltage and EMC 93/68/CE Electro-Magnetic Compatibility Regulations.

Fitting operations are recommended by a qualified technician in conformity to the existing safety standards.

The manufacturing company declines any responsability for incorrect handling and application; also, it reserves the right to change or update the control panel any time.

PLEASE NOTE:

- The control panel is fitted inside Girri 130.

- Make sure that the power supply to the electronic programmer is 230V ±10%

- Make sure that the power supply to the Electric Motor is 230V ±10%

- Fit the mains to the control panel with a 0.03A high performance circuit breaker.

- Use 1.5mm2section wires for voltage supply, electric motor and flashing lamp. Maximum recommended distance 50m.

Use 1mm2section wires for limit switches, photocells, push-buttons/key-switch and accessories.

- Bridge terminals 1 and 2 if no photocells are required.

- Bridge terminals 3 and 6 if no key- or push-button switches are required.

N.W: To fit extra accessories such as lights, CCTV etc. use only solid state relays to prevent damages to the microprocessor.

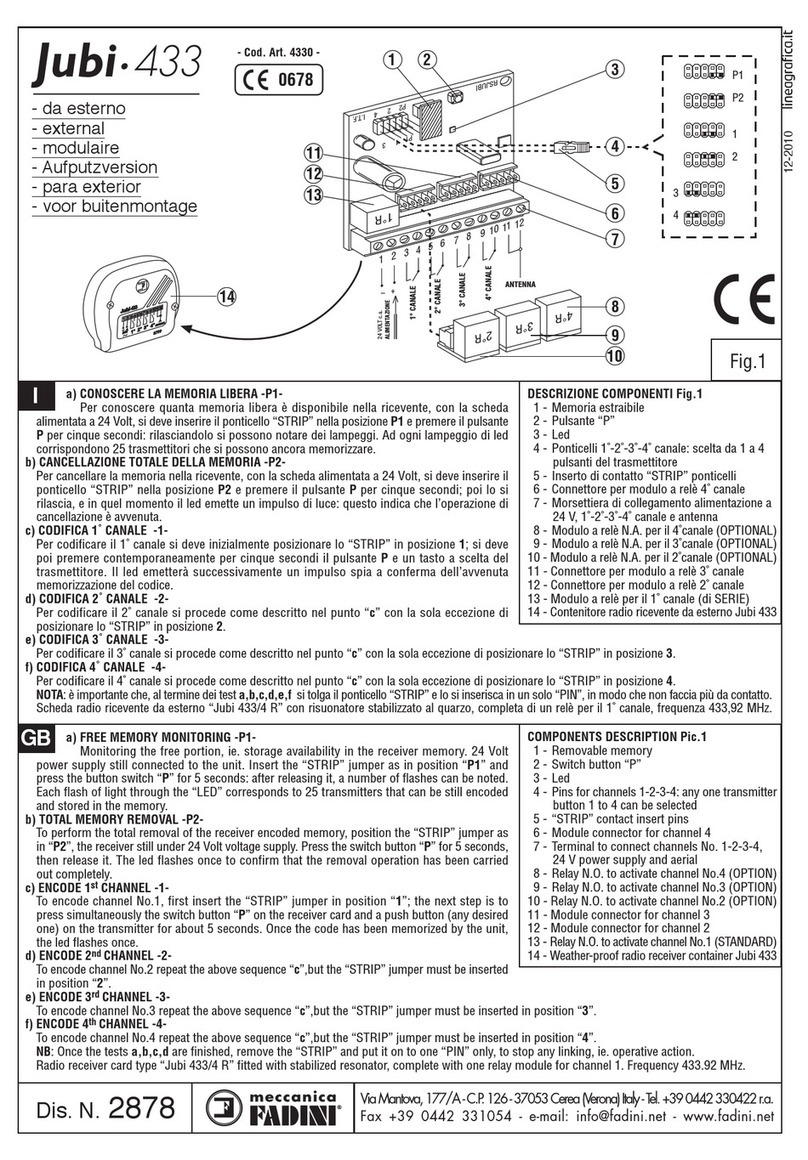

DIP-SWITCH

145678

2

ON

OFF

3

Dip-Switch:

1= ON. Photocells. Stop while opening

2= ON. Radio. No reversing while opening

3= ON. Automatic closing

4= ON. Preflashing activated

5= ON. Radio. Step by step. Stop in between

6= ON. Dead Man Control (Dip 4=OFF and Dip 3=OFF)

7= ON. No lamp on during dwell time

8= OFF. No function

In case of failure of the panel:

- Make sure that the power supply to the electronic programmer is 230V ±10%

- Make sure that the power supply to the Electric Motor is 230V ±10%

- Check fuses

- Check photocells if contacts are normally closed

- Check that no voltage drop has occurred from the control panel to the electric motor

Led Status Indication:

L1= 230V 50Hz power supply. Alight

L2= Photocells, if obstructed light goes off

L3= Open. Alight whenever an Open pulse is given

L4= Close. Alight whenever a Close pulse is given

L5= Stop. It goes off on pulsing Stop

L6= Radio. It goes on by pressing a transmitter button

L7= Gate Status; it flashes on gate moving

L8= Limit switch Close; off when gate is closed

L9= Limit switch Open; off when gate is open

112

213

COMMON

RADIO

CONTACT

7

3

26 27 28 3

NEUTRAL

Push Button Switch Pulin 3:

Photocells and Safety

Edge:

PHOTOCELLS

AND SAFETY

EDGE

24V (500 mA) OUTPUT

(MAX. LOAD:

2 PAIRS PHOTOCELLS

1 RADIO RECEIVER)

Light ON = Open gate

Light OFF = Close gate

Flashing (fast) 0.5s= Closing gate

Flashing (normally) 1s= Opening gate

Flashing (slowly) 2s= gate is stopped

24V 3W Indication Light:

311

Led to indicate

status of Open -

Stop - Close

switches

LOW VOLTAGE ELECTRICAL CONNECTIONS

1

DIP-SWITCH 1:

ON: Photocells stop gate while opening,

reverse it on closing once obstacle

is removed

OFF: Photocells do not stop gate while

opening, reverse it in case of an

obstacle on closing

Button switch:

3456

STOP

COMMON

OPOEN

CLOSE

Radio Contact:

- Open/Close (Standard)

- Travel reversing on

pulsing

- Step by step 2

ON: Gate is not reversed while opening

OFF: Any pulse reverses the gate

ON: Step by step. Stop in between

OFF: Standard operating mode

DIP-SWITCH 2 and 5 (NEVER set BOTH of them

ON at the same time): Limit switch:

LIMIT SWITCH

CLOSE

COMMON

10

89

LIMIT SWITCH

OPEN

8

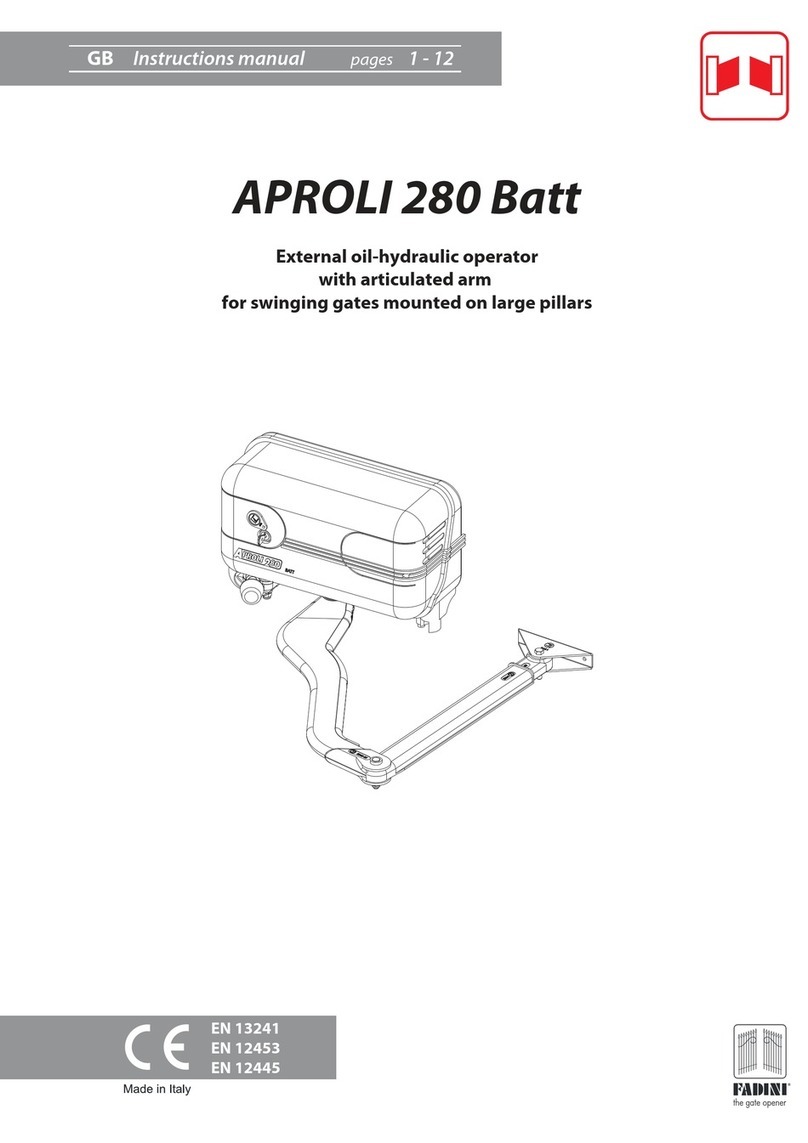

PIC. 12

PLUS

15

Drwg. No.4136

INDICATION LAMP 24V max 3W

M

F4 Fuse=630mA

24V Protection

PULIN 3

26 27 28 3

DIP-SWITCH ON

OFF

14567823

F1 Fuse=5A

230V Mains

RADIO PLUG-IN

CARD

CONNECTOR

MOTOR RUN

TIME

OPEN/CLOSE

from 2 up to

255s

DWELL

TIME from 2

up to 255s

PEDESTRIAN

OPENING

from 3 up

to 30s

T3

T1

ELPRO 15 PLUS

24V OUTPUT (max. load:

2 PAIRS PHOTOCELLS

1 RADIO RECEIVER)

174

10 11 12 13

285

396

STOP

COMMON

OPEN

CLOSE

PHOTOCELLS

RADIO CONTACT

LIMIT SWITCH CLOSE

LIMIT SWITCH OPEN

LIMIT SWITCH COMMON

L1

L2

L3

L4

L5

L6

L7

L8

L9

T2

2122

2324

EXT CAPACITOR

20µF

COURTESY LIGHT

230V max 100W

230V 25W max

FLASHING LAMP

14

16

230V 50Hz

SINGLE-PHASE

VOLTAGE SUPPLY

15

17

18

230V ±10% 50Hz

SINGLE-PHASE

ELECTRIC

MOTOR

19

20

F2 Fuse=5A

230V Mains

TRANSFORMER

F3 Fuse=315mA

Transformer

Protection

T4 MOTOR

TORQUE from

40% to 100%

COURTESY

LIGHT from 2

up to 255s

T5

-

+

-

+

-

+

-

+

-

+

ELPRO 15 Plus 1.4

MICROPROCESSOR

COMMON