English

7 EN

2.2 Installation Rules

• Before plugging in the appliance, make sure that the information on the nameplate (voltage, etc.)

matches that of the electrical and water systems.

• Check the condition of the power-supply cord; if it is damaged it must be replaced.

• Completely unwind the power-supply cable.

• The coee machine should sit on a at, stable surface at least 1 inch (20 mm) from walls and

from the counter. Keep in mind that the highest surface on the machine (the cup-warmer tray) sits

at a height of at least 47 inches (1.2 meters). Make sure there is a shelf nearby for accessories.

• Room temperature must range between 50 and 90 °F (10 and 32 °C).

• An electrical outlet, water connections, and a drain with siphon must be in the immediate vicinity.

• Do not install in rooms (kitchens) that are cleaned with jets of water.

• Do not obstruct openings or ventilation and heat vents.

• Do not install the appliance outdoors.

• Do not install or use the appliance in potentially explosive environments.

• Do not install the appliance in the presence of ammable substances.

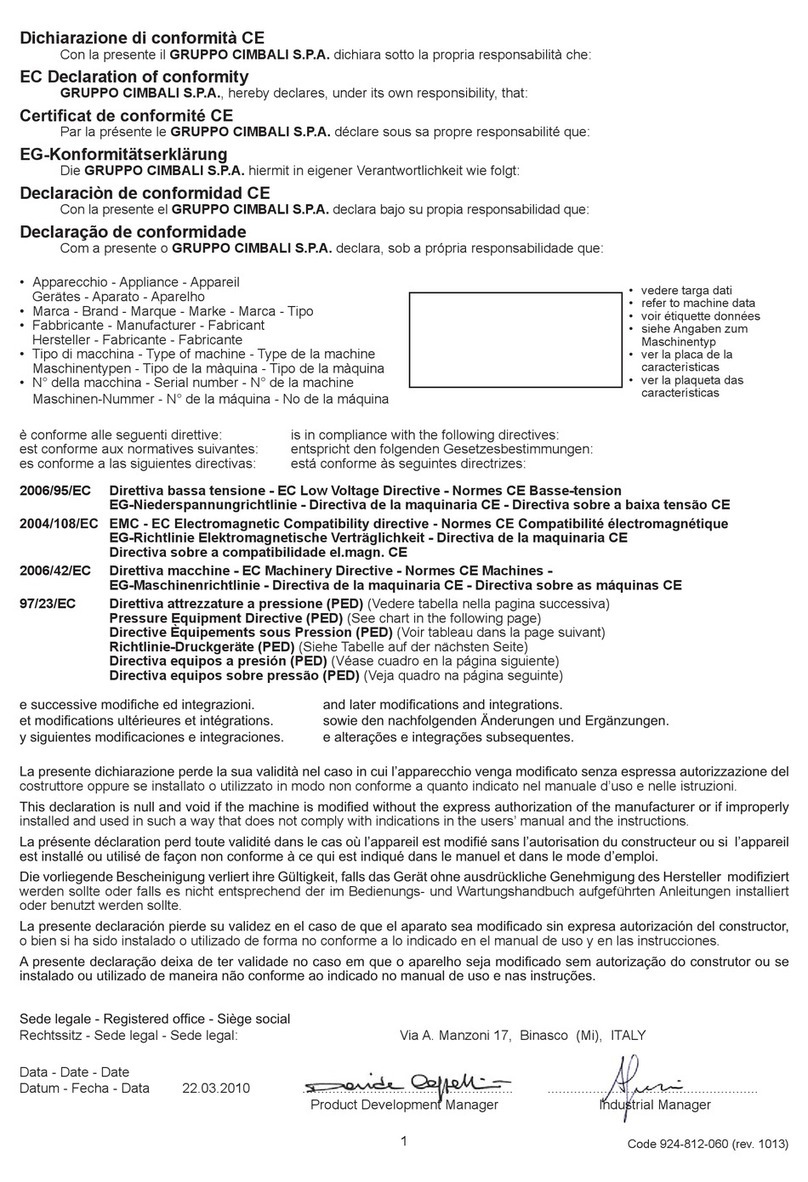

Prior to installation, make sure there is a circuit breaker installed with a distance between the contacts

that allows for complete disconnection when there is a category III overload and that provides

protection against current leakage equal to 30 mA. The circuit breaker must be installed on the

power-supply in compliance with installation rules.

If the power-supply is not working properly, the appliance can cause transitory voltage drops.

The electrical safety of this appliance is only ensured when it is correctly connected to an ecient earthing system in

compliance with the electrical safety laws in force. This fundamental safety requirement must be veried. If in doubt,

request that a qualied electrician inspect the system. The manufacturer cannot be held responsible for any damage

caused by the lack of an earthing system on the electrical supply.

Do not use adaptors, multiple plugs, and/or extension cords.

Check that the type of connection and voltage correspond with the information on the nameplate: see illustrations chapter,

Figure 1.

For machines with a single-phase connection: see illustrations chapter, Figure 2.

3. Electrical Installation Rules

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to part 15 of

the FCC Rules.

These limits are designed to provide reasonable protection against harmful interference when the equipment is operated

in a commercial environment.

This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance

with the instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful interference in which case the user will be

required to correct the interference at his own expense.