REPAIR/REBUILD INSTRUCTIONS

Page 3of 3

www.fastestinc.com

Roseville, MN

Toll Free at 1-800-444-2373

Fax 651-645-7390

WP143 Rev B 6/25/2021

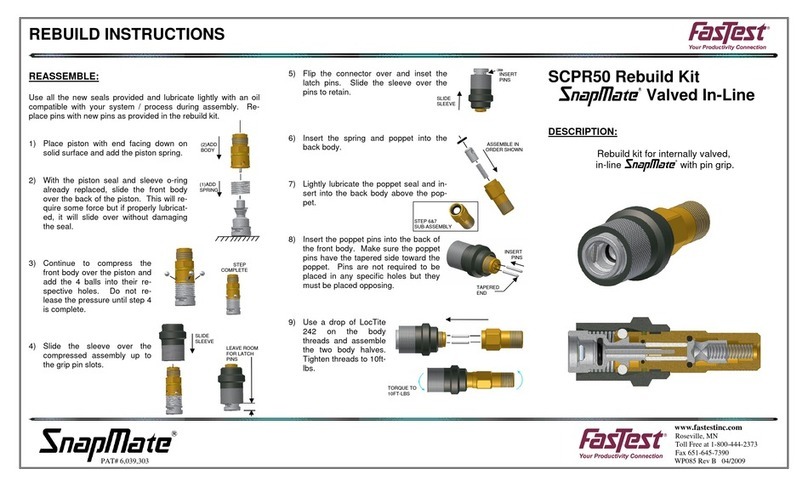

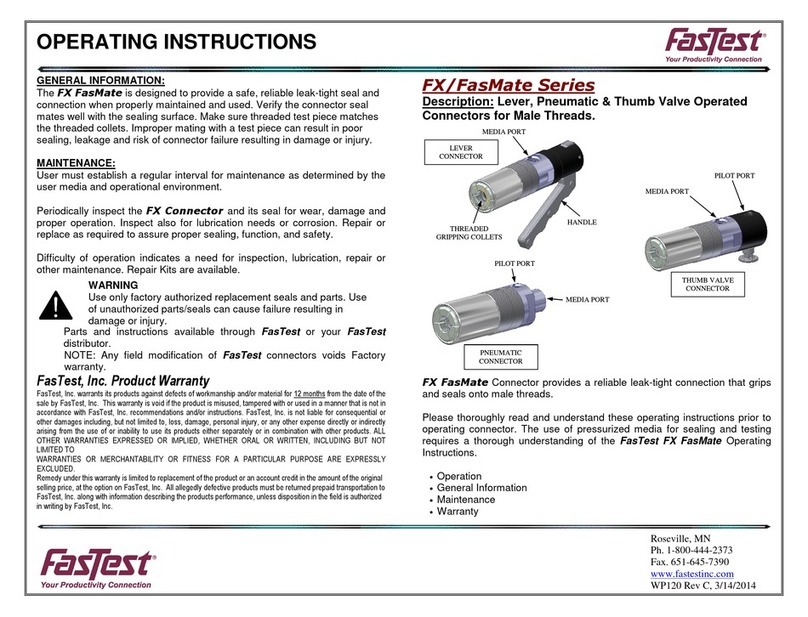

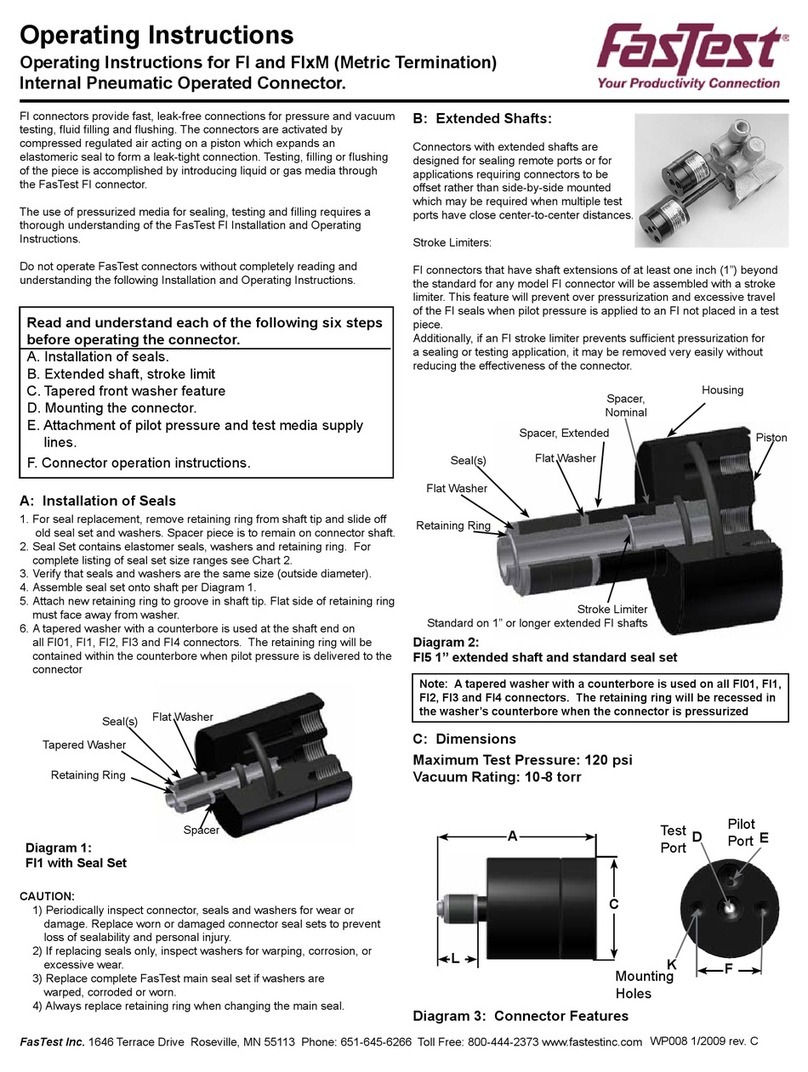

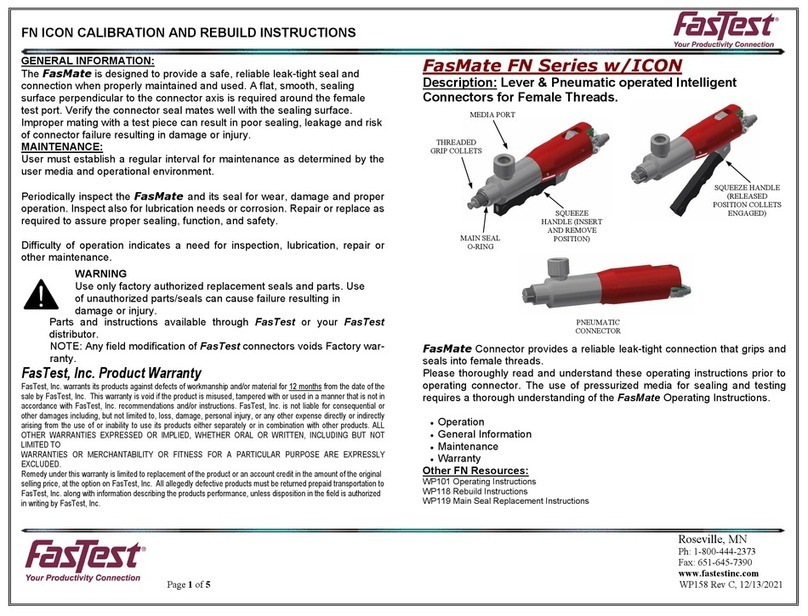

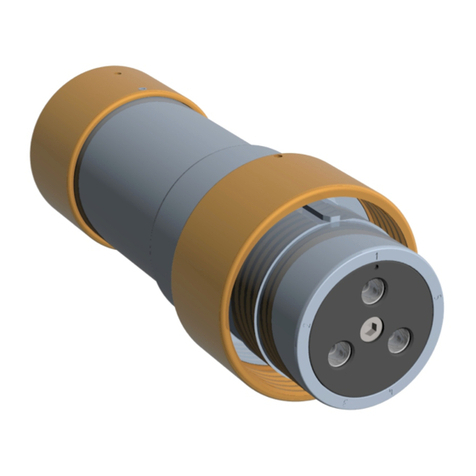

7. Slide sleeve over body and over collets. Slide on far enough to expose snap ring groove.

8. Place assembly with collets down on work surface. Using stop ring, push new large sleeve

spring down over body, followed by stop ring and the new snap ring.

9. Using some type of arbor press or hand tool, press the snap ring into snap ring groove on

body. Work press around snap ring until it snaps into groove. When snap ring is properly

seated the stop ring will be inside sleeve.

10. Before applying test pressure to connector, actuate connector several times onto test piece

to ensure proper function and movement of the collets.

FasTest, Inc. Product Warranty

FasTest, Inc. warrants its products against defects of workmanship and/or material for 12 months from

the date of the sale by FasTest, Inc. This warranty is void if the product is misused, tampered with or

used in a manner that is not in accordance with FasTest, Inc. recommendations and/or instructions.

FasTest, Inc. is not liable for conse uential or other damages including, but not limited to, loss, damage,

personal injury, or any other expense directly or indirectly arising from the use of or inability to use its

products either separately or in combination with other products. ALL OTHER WARRANTIES

EXPRESSED OR IMPLIED, WHETHER ORAL OR WRITTEN, INCLUDING BUT NOT LIMITED TO

WARRANTIES OR MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE ARE

EXPRESSLY EXCLUDED.

Remedy under this warranty is limited to replacement of the product or an account credit in the amount of

the original selling price, at the option on FasTest, Inc. All allegedly defective products must be returned

prepaid transportation to FasTest, Inc. along with information describing the products performance, un-

less disposition in the field is authorized in writing by FasTest, Inc.

SNAP RING

SNAP RING

LARGE SLEEVE

SNAP RING