OPERATING INSTRUCTIONS/MAIN SEAL REPLACEMENT

Page 2 of 2

www.fastestinc.com

Roseville, MN

Ph 1-800-444-2373

Fax 651-645-7390

WP095 Rev C 5/5/2021

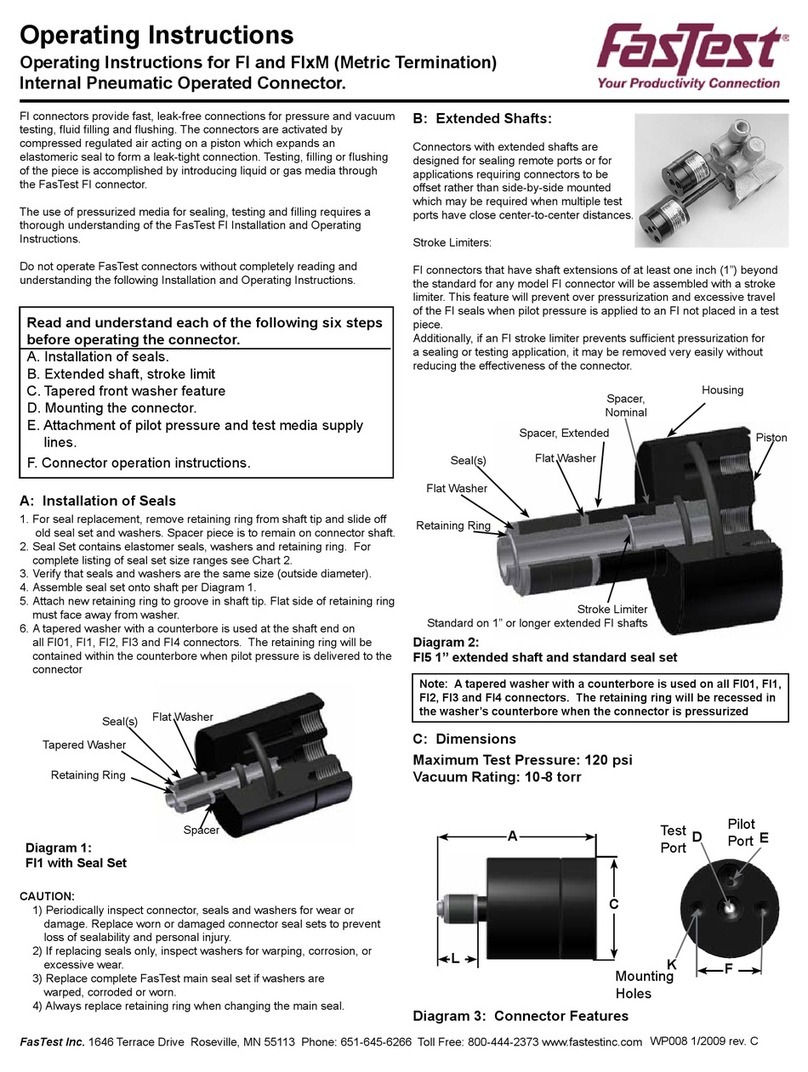

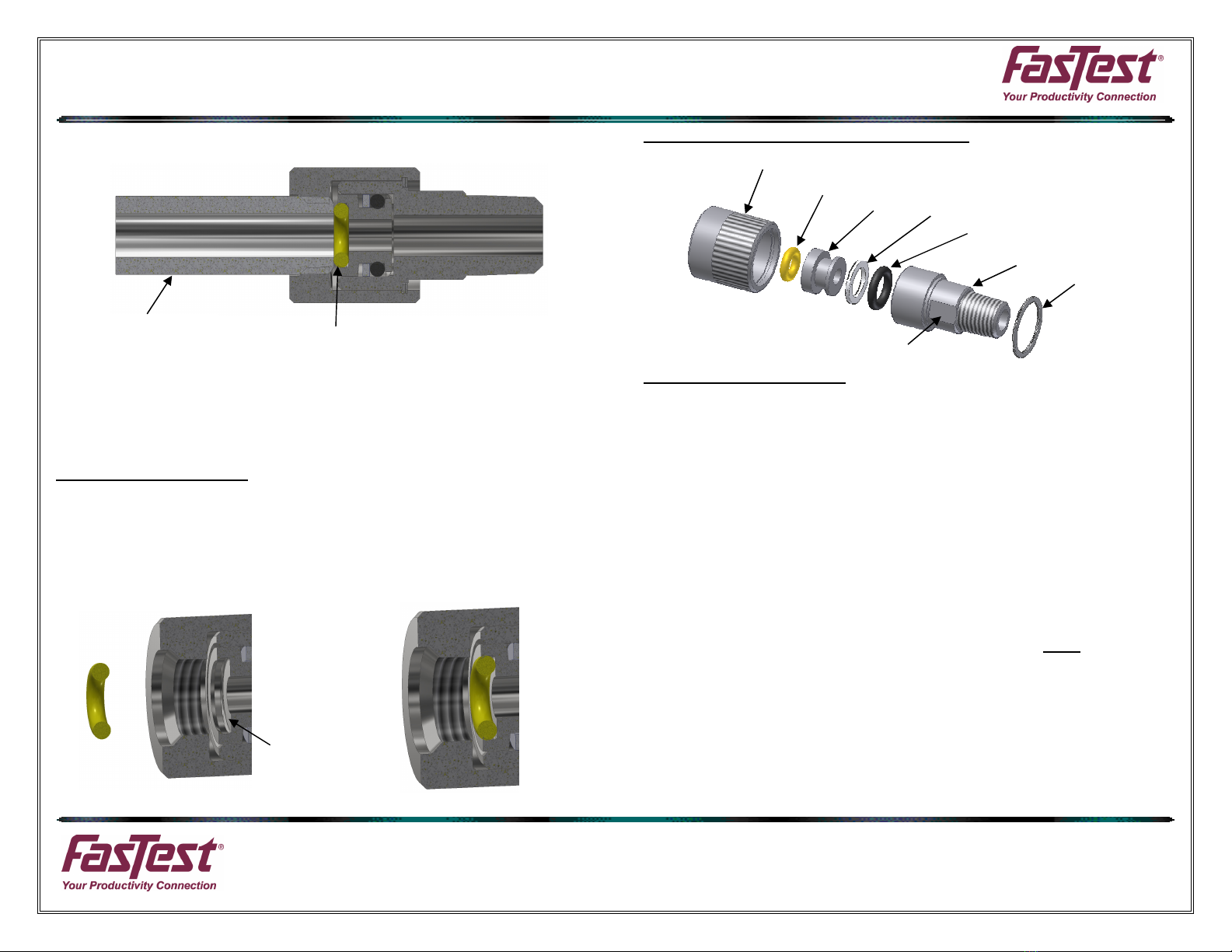

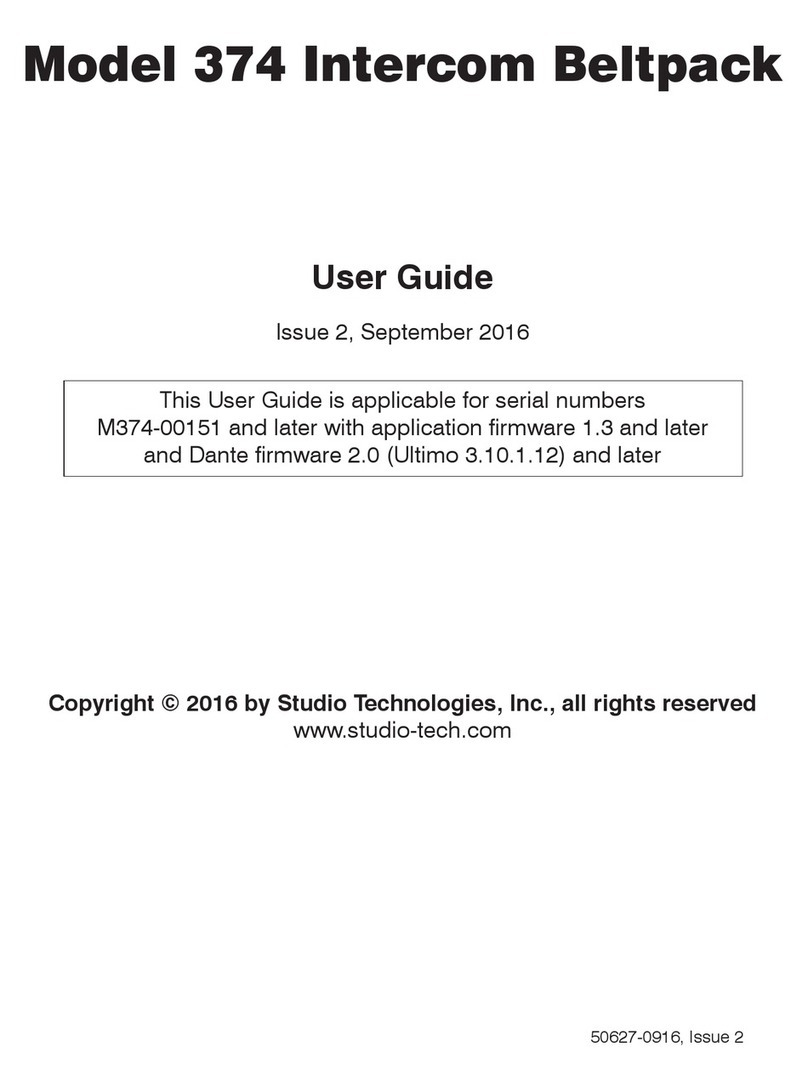

PISTON BACK-UP

BACK-UP

WRENCH FLATS

3. Activate test media and perform test. Test pressure will enhance the seal

between test piece and Twistmate.

4. When test process is complete, deactivate/relieve the media pressure.

5. To disconnect from test piece, un-thread the Twistmate from the test piece.

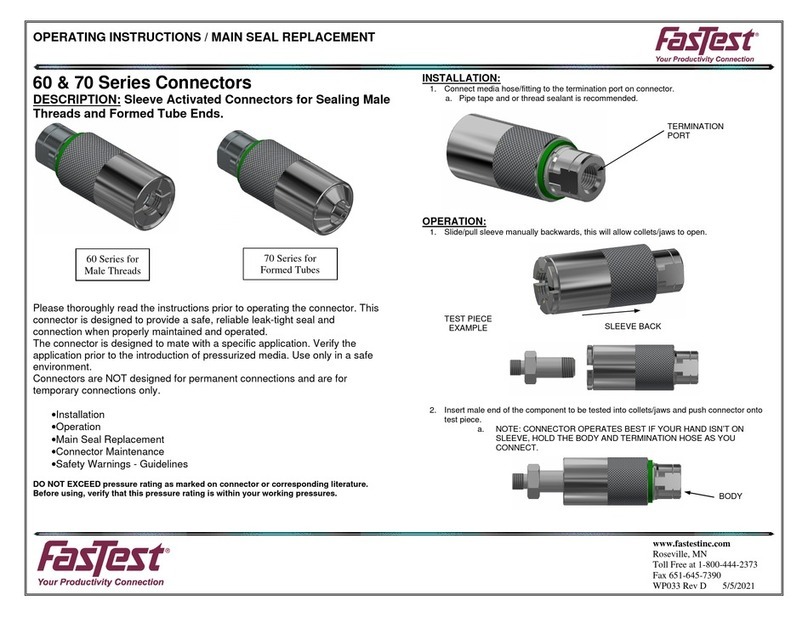

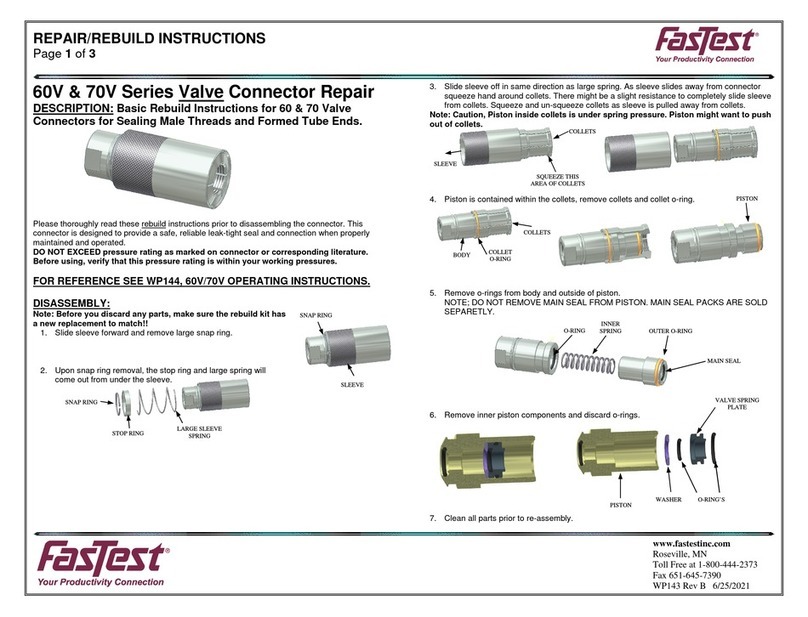

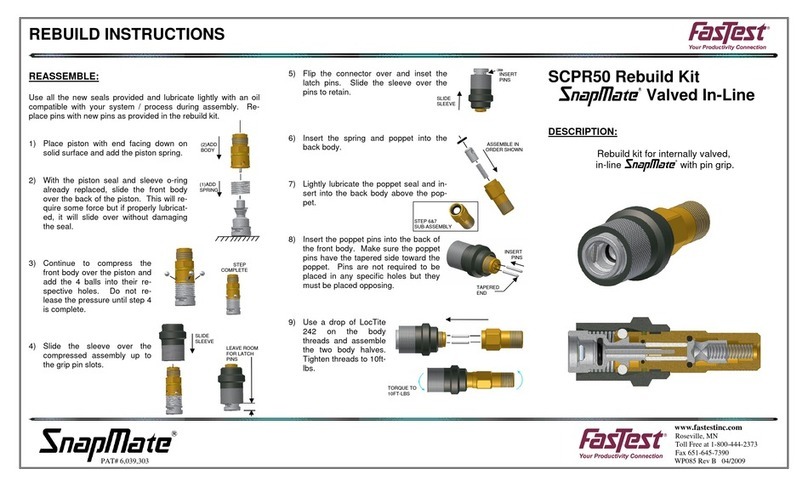

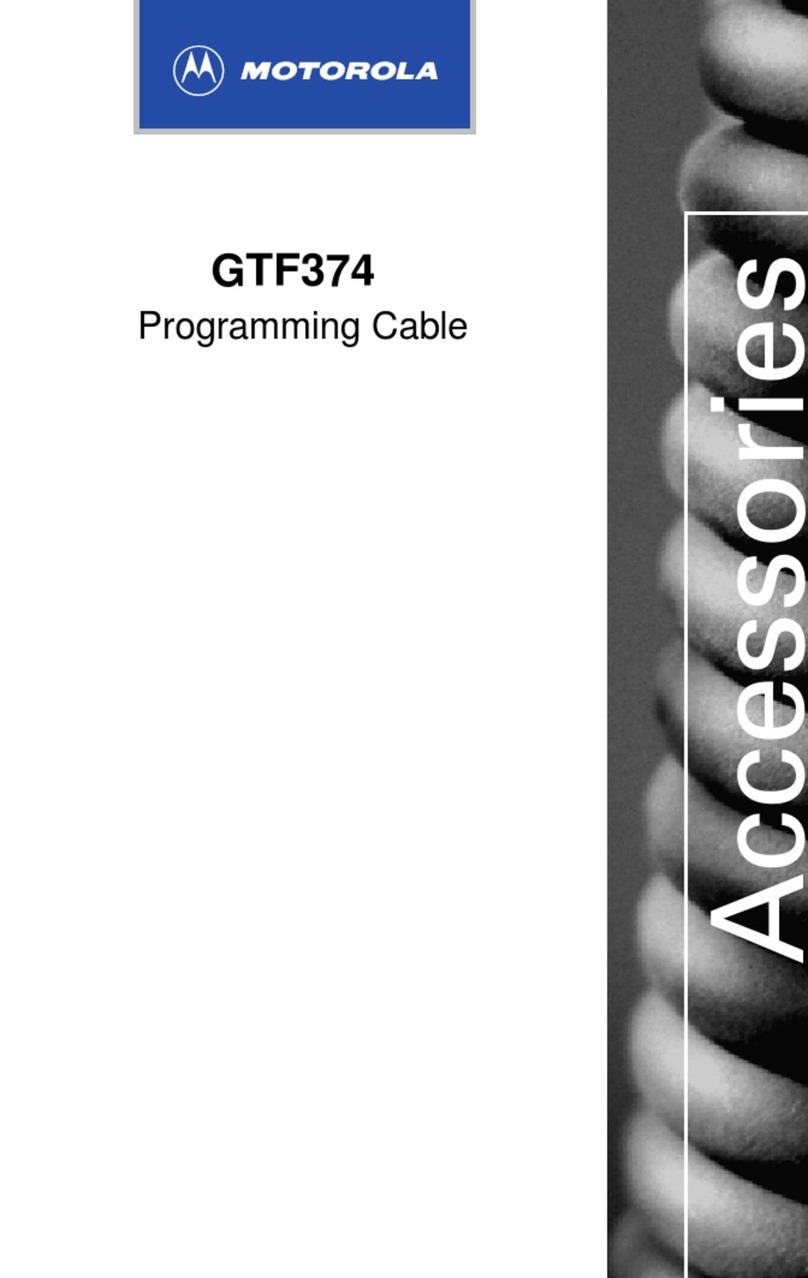

MAIN SEAL REPLACEMENT:

1. MET Twistmate connectors do not require dis-assembly to replace main

seal.

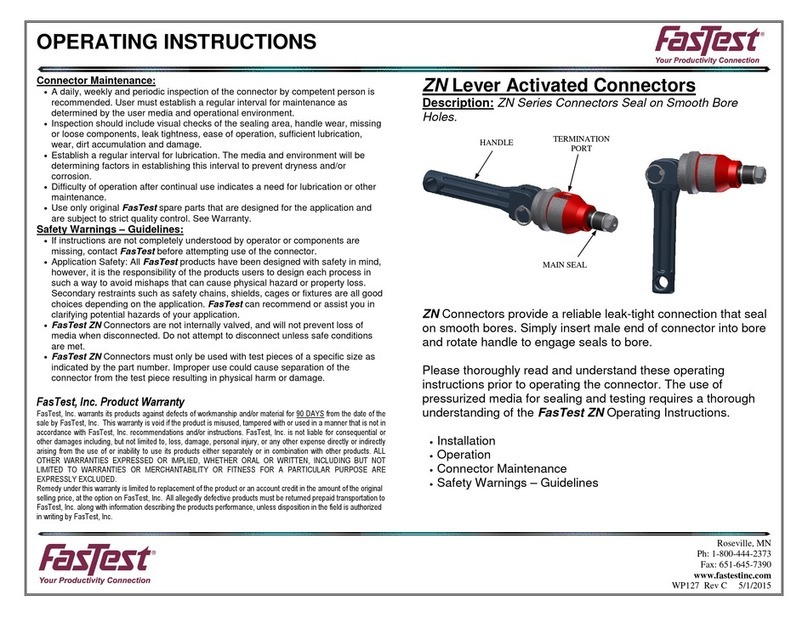

2. Using a pick like tool or small flat blade tool, remove main seal o-ring from

piston inside connector and discard.

3. Do not lubricate new main seal.

4. Place new o-ring inside sleeve and initially use your fingertip to install/press

the o-ring into the groove in the piston.

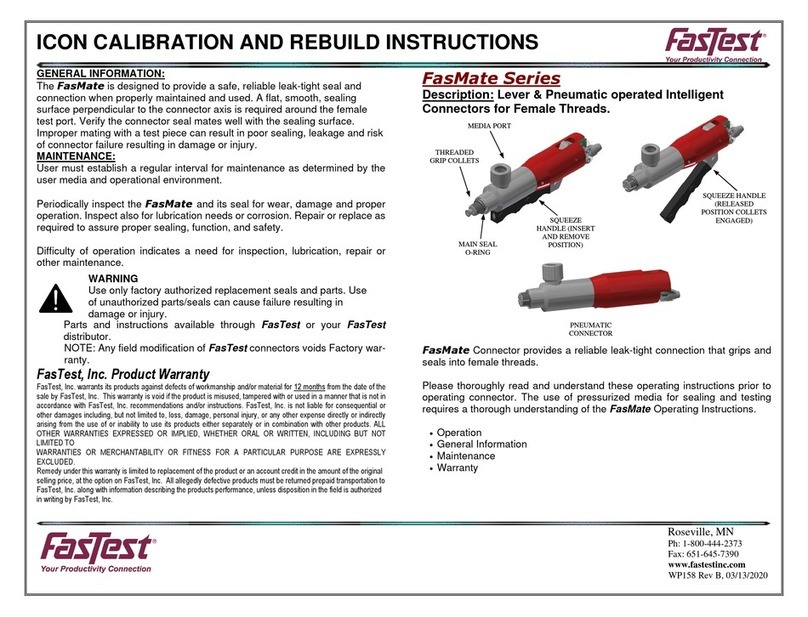

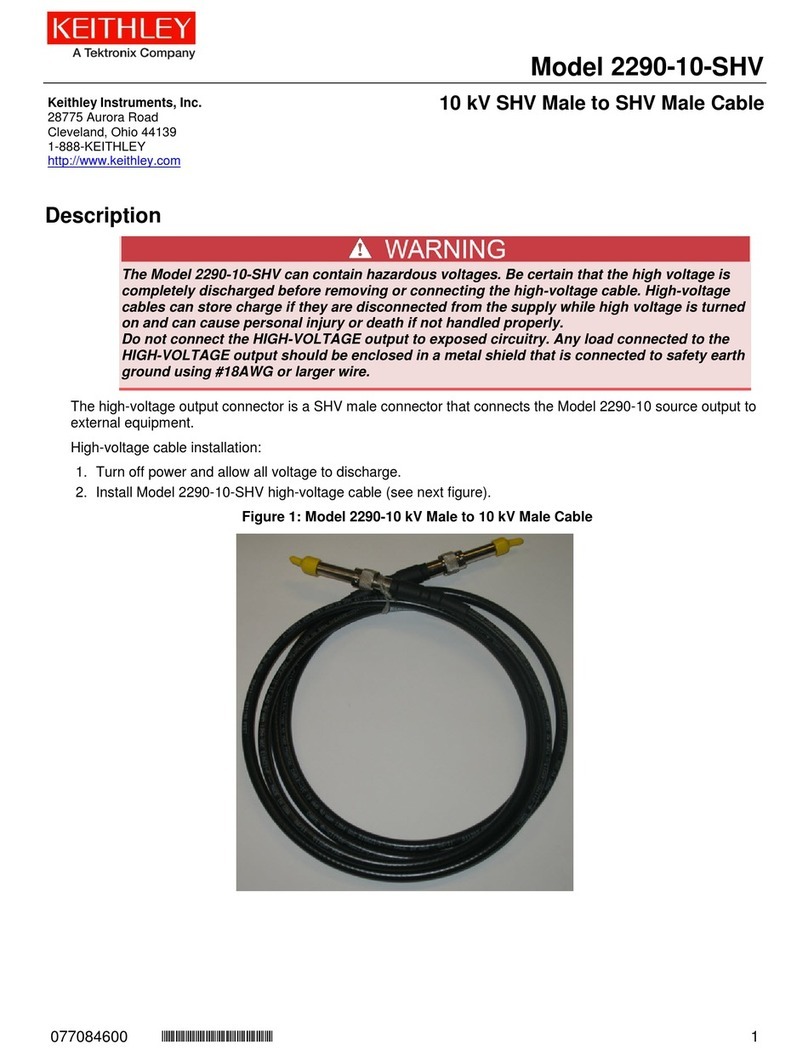

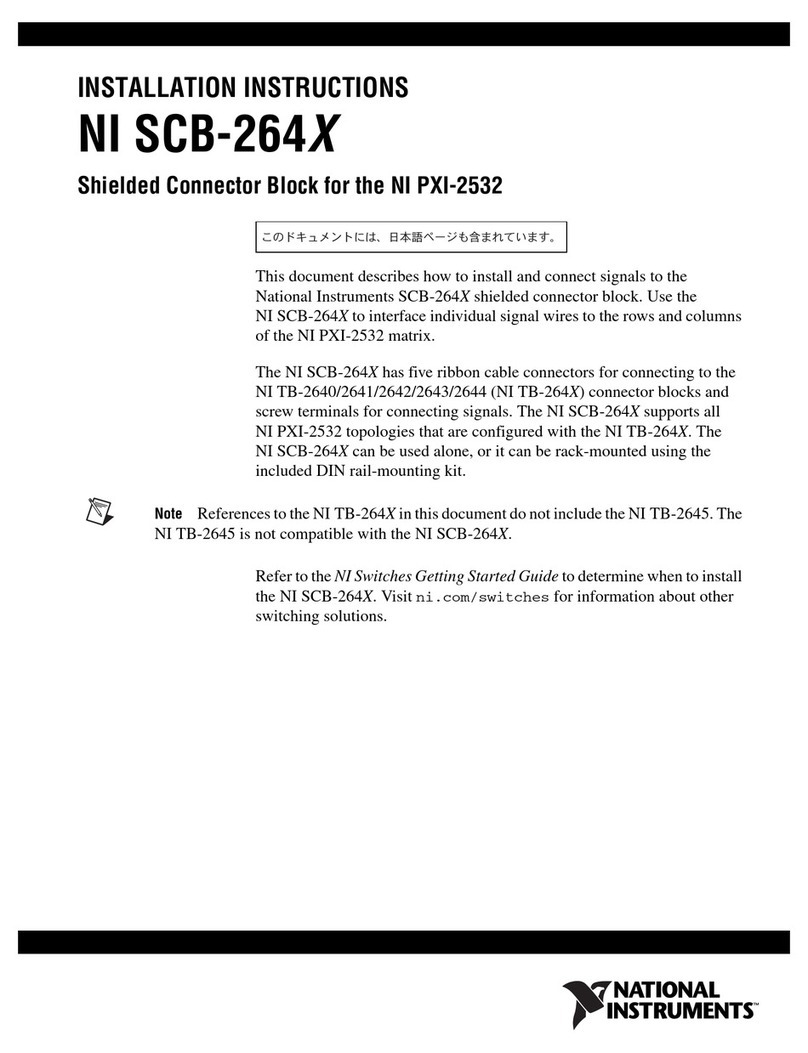

BASIC BREAK DOWN OF THE MET TWISTMATE:

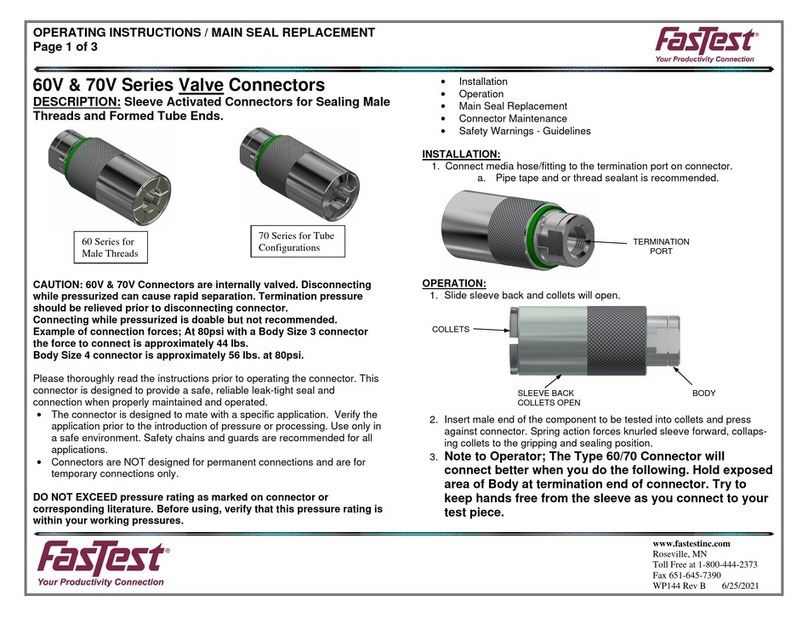

CONNECTOR MAINTENANCE:

•A daily, weekly, and periodic inspection of the connector by competent person is

recommended.

oUser must establish a regular interval for maintenance as determined by the user

media and operational environment.

oInspection should include damage to the body missing or loose components, leak

tightness, ease of operation, sufficient lubrication, wear, dirt accumulation and

damage.

•Inspect threads for wear.

•Use only original FasTest spare parts that are designed for the application and are

subject to strict quality control. See warranty.

•FasTest recommends a daily visual inspection of the main seal located in the front of

the piston. Inspect for tears or cracks in the seal surface. Replace the main seal if

tears or cracks are visible.

•Lubricate on regular intervals under normal operating conditions. Lubrication should

be compatible with user application.

FasTest, Inc. Product Warranty

FasTest, Inc. warrants its products against defects of workmanship and/or material for 1 YEAR from the date of the

sale y FasTest, Inc. This warranty is void if the product is misused, tampered with, or used in a manner that is not in

accordance with FasTest, Inc. recommendations and/or instructions. FasTest, Inc. is not lia le for consequential or

other damages including, ut not limited to, loss, damage, personal injury, or any other expense directly or indirectly

arising from the use of or ina ility to use its products either separately or in com ination with other products. ALL

OTHER WARRANTIES EXPRESSED OR IMPLIED, WHETHER ORAL OR WRITTEN, INCLUDING BUT NOT

LIMITED TO WARRANTIES OR MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE ARE

EXPRESSLY EXCLUDED.

Remedy under this warranty is limited to replacement of the product or an account credit in the amount of the original

selling price, at the option on FasTest, Inc. All allegedly defective products must e returned prepaid transportation to

FasTest, Inc. along with information descri ing the products performance, unless disposition in the field is authorized

in writing y FasTest, Inc.

RETAINING RING

SLEEVE

MAIN SEAL

BODY

MAIN SEAL

CONTACTING FACE

TEST PIECE

THREADED INTO

O-RING