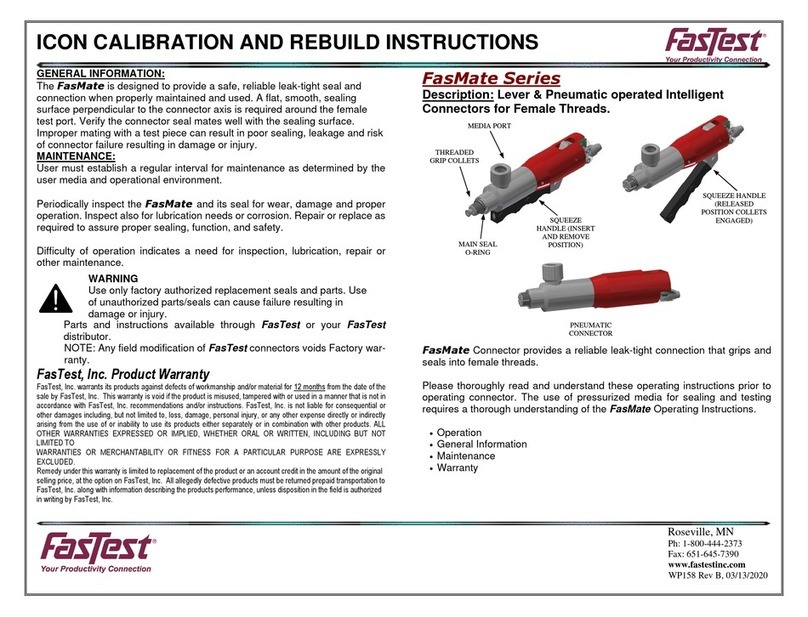

REBUILD INSTRUCTIONS

www.fastestinc.com

Roseville, MN

Toll Free at 1-800-444-2373

Fax 651-645-7390

PAT# 6,039,303 WP085 Rev B 04/2009

PUSH

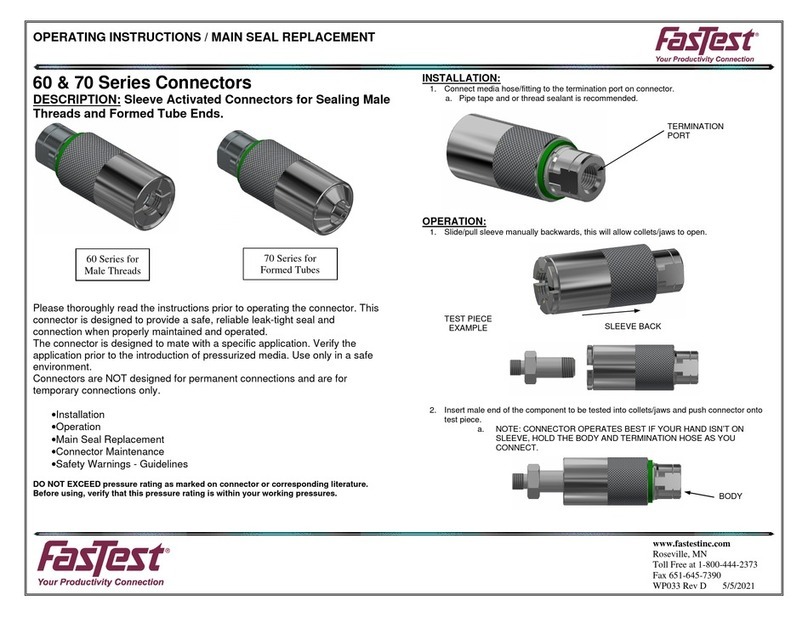

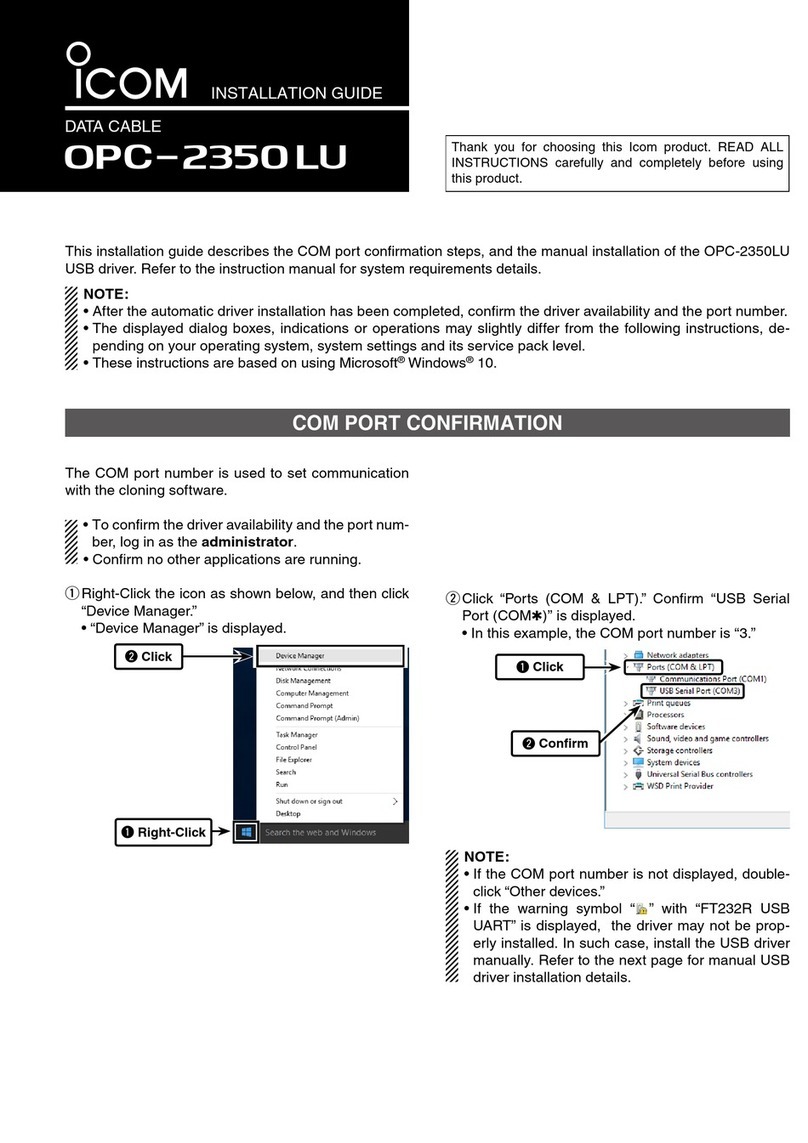

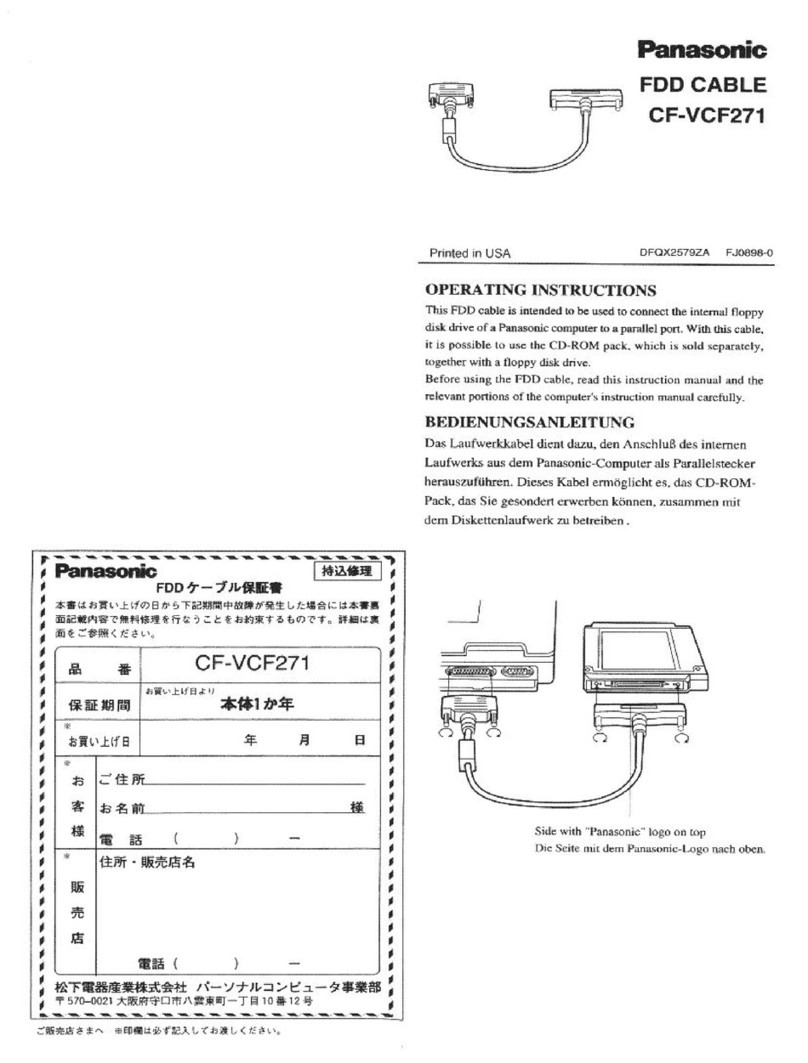

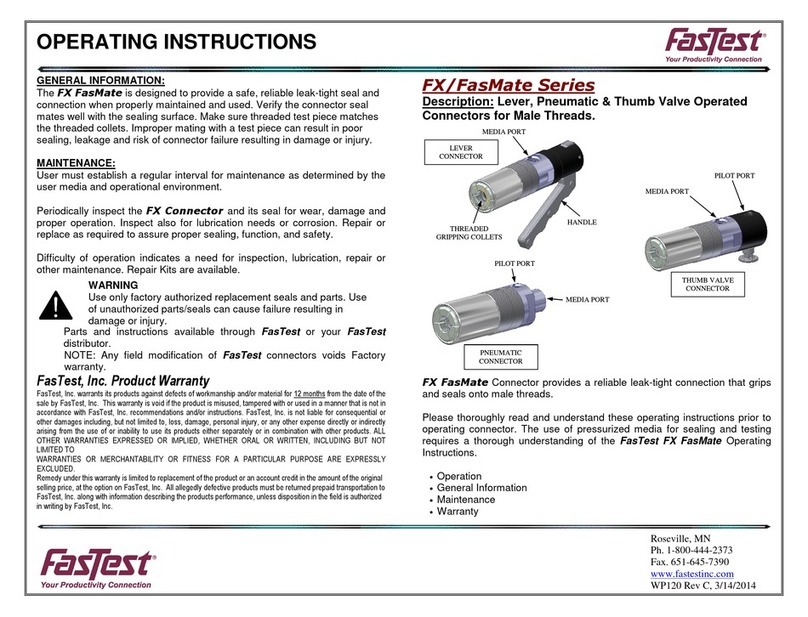

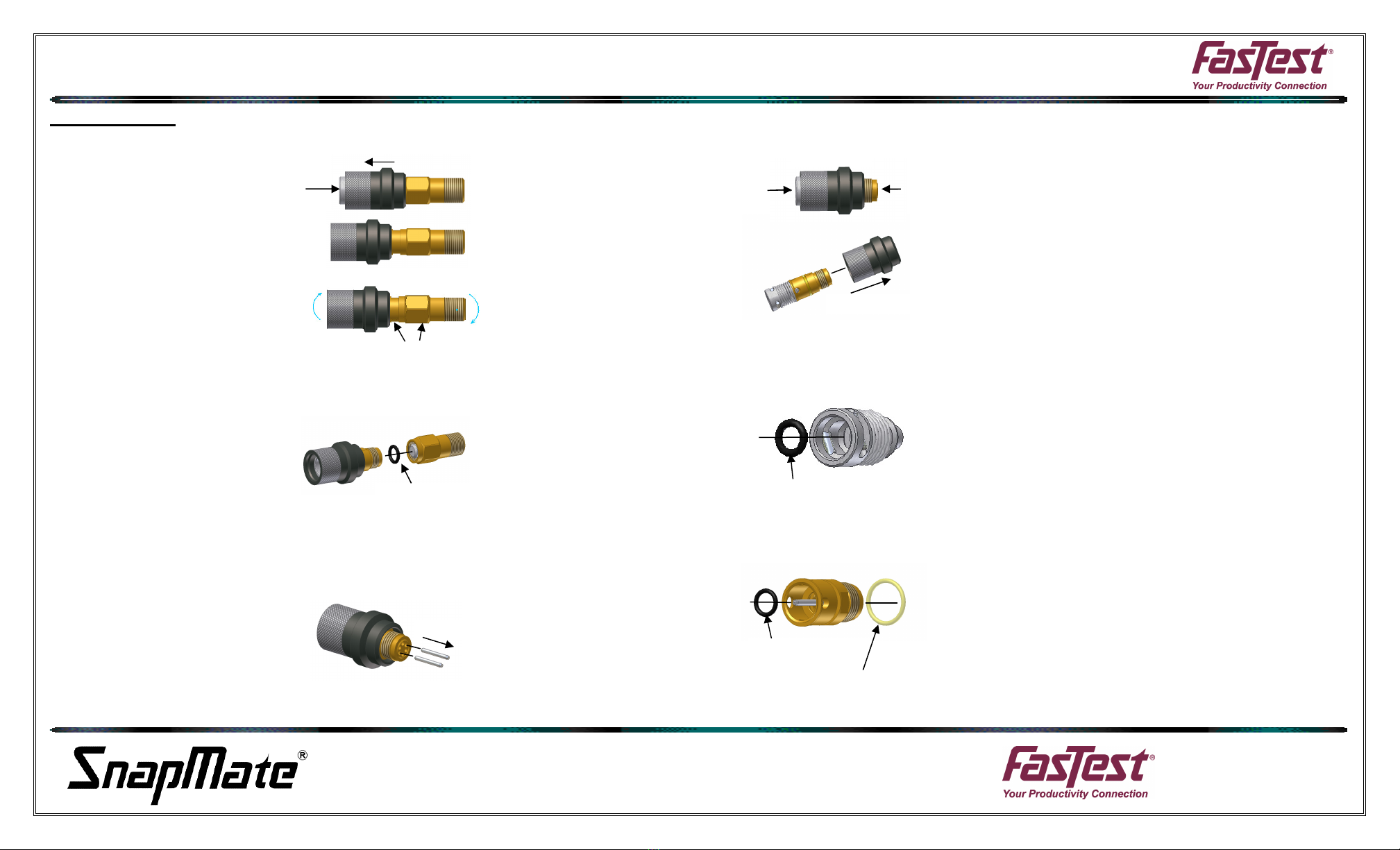

DISASSEMBLY:

1) Push against the piston and slide the

sleeve forward. Similar movement

as actual connection. This will ex-

pose the wrench flats on the front

body.

2) Thread apart the two halves of the

body by counter rotating the wrench

flats. Use caution when taking apart

body as internal components may

fall out.

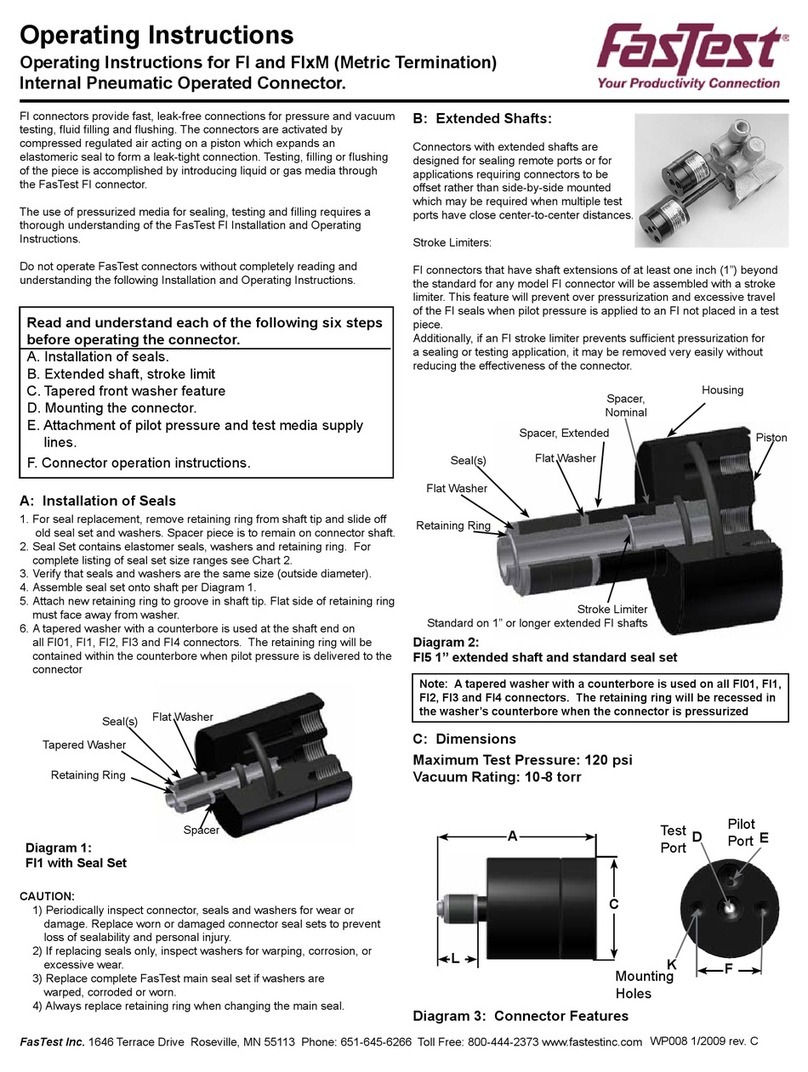

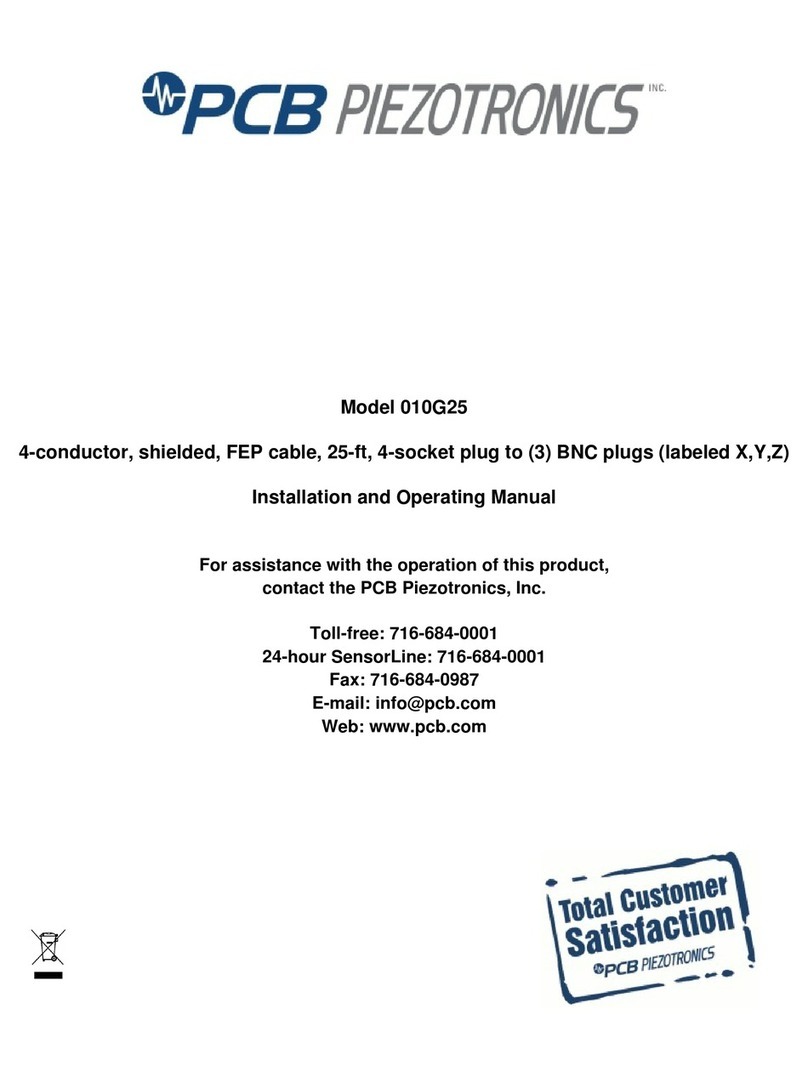

3) Once the two halves of the body are

apart, remove the poppet seal using

a repair pick, or similar tool. If the

seal remains below the poppet, re-

move poppet by pushing through

from termination end. It may not be

necessary to remove the poppet

and spring if the seal is easily ac-

cessible. Exercise caution so as not

to scratch or deform the seal

groove. This could cause a poten-

tial leak path.

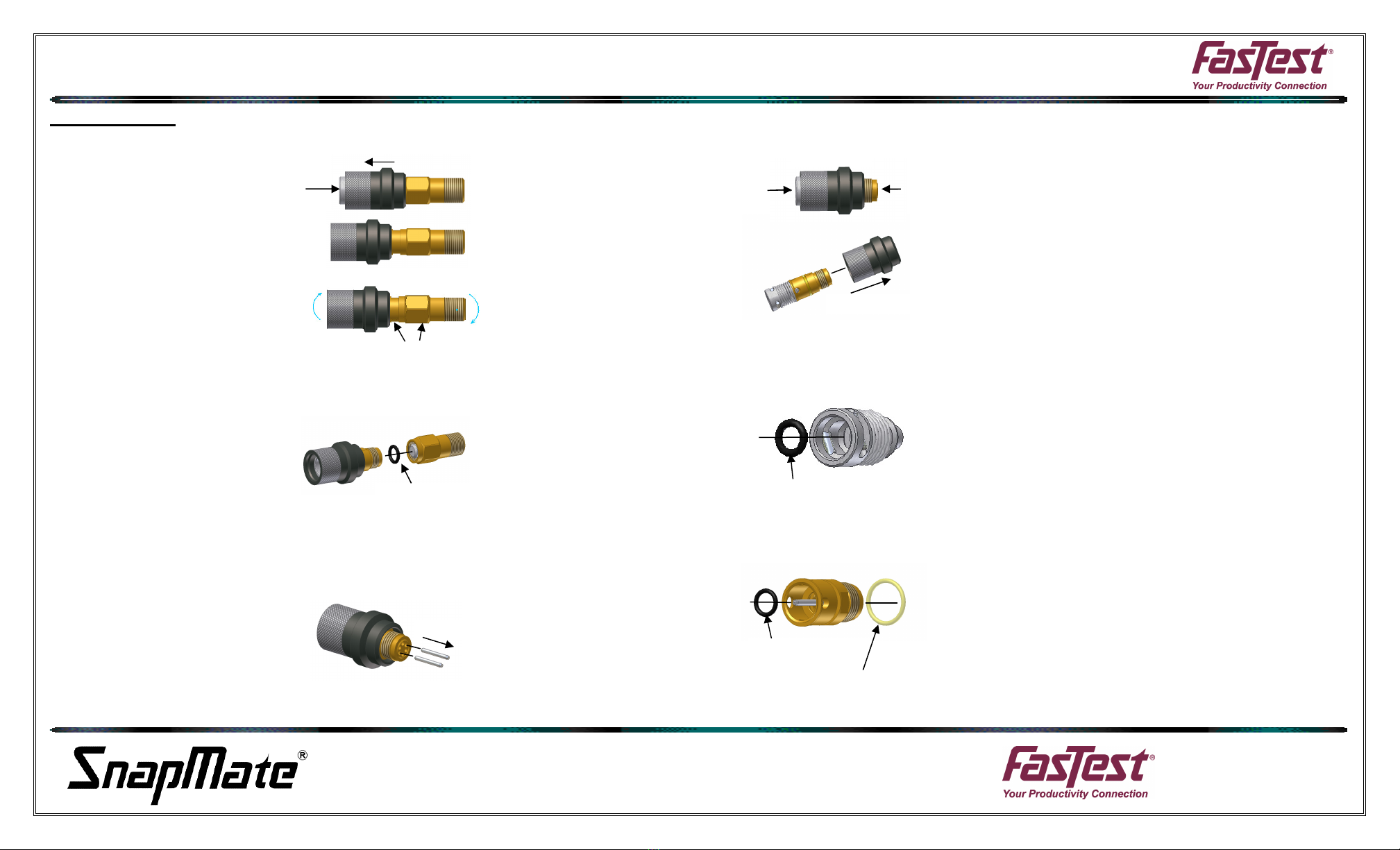

4) Remove the poppet activation pins. If

the pins are not easily removed, the

connector could require repair and

should be inspected for unusual

wear.

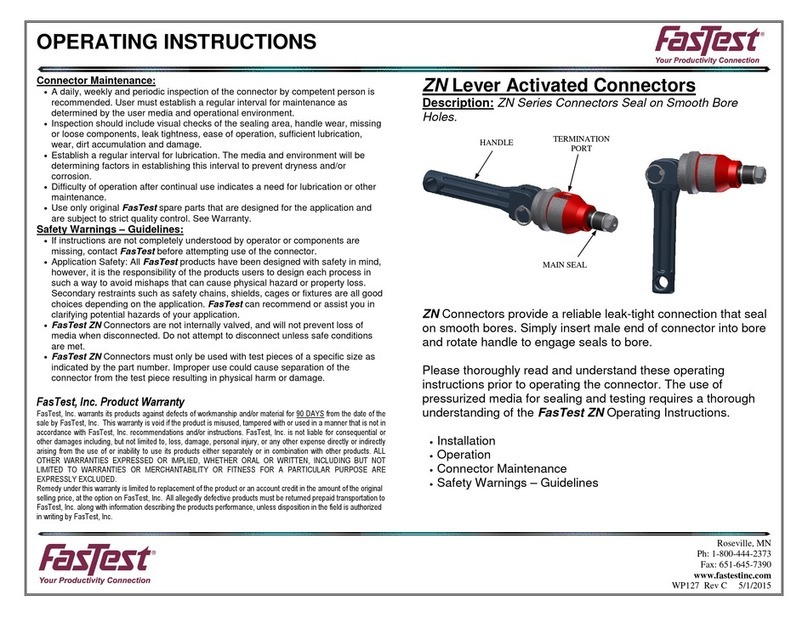

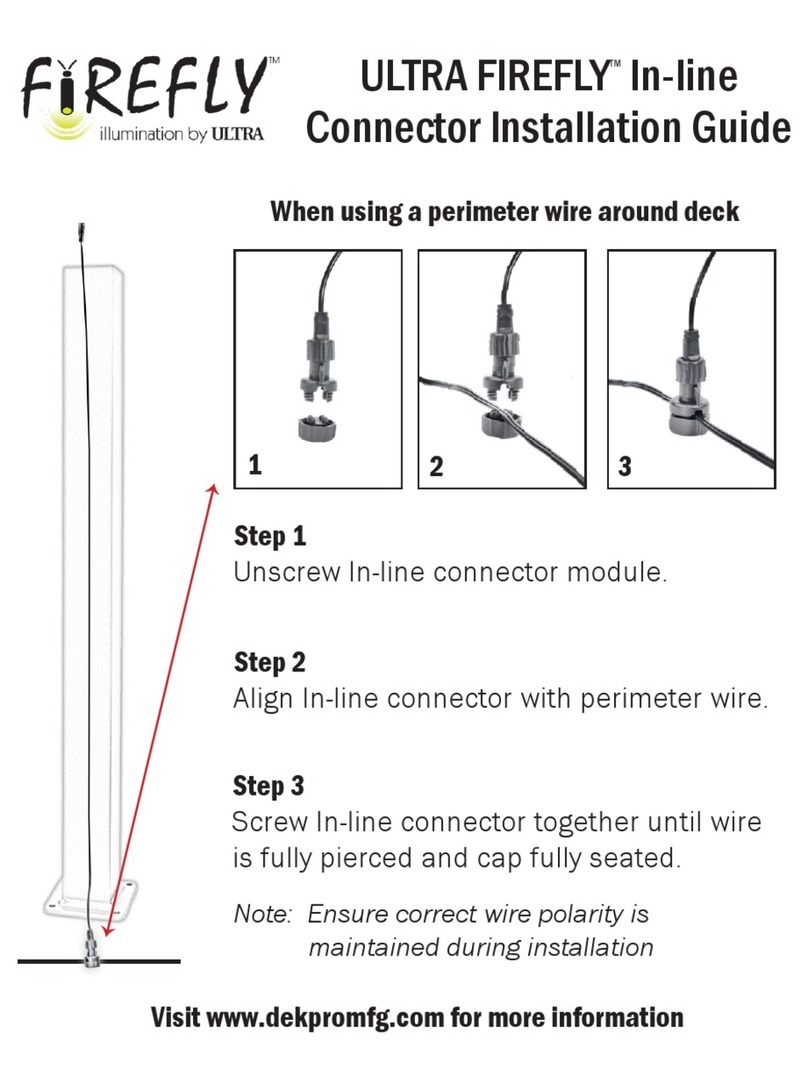

5) Remove the front sleeve. To remove

the sleeve, the front assembly must

be compressed. (Can be finger

compressed.) Once compressed,

the sleeve will slide off the back of

the assembly. Hold compression

while removing the sleeve. Once

compression is removed, the inter-

nal balls will be forced out of their

respective holes. Use caution when

taking apart the assembly as in-

ternal components may fall out. A

catch basin or cloth is recommend-

ed.

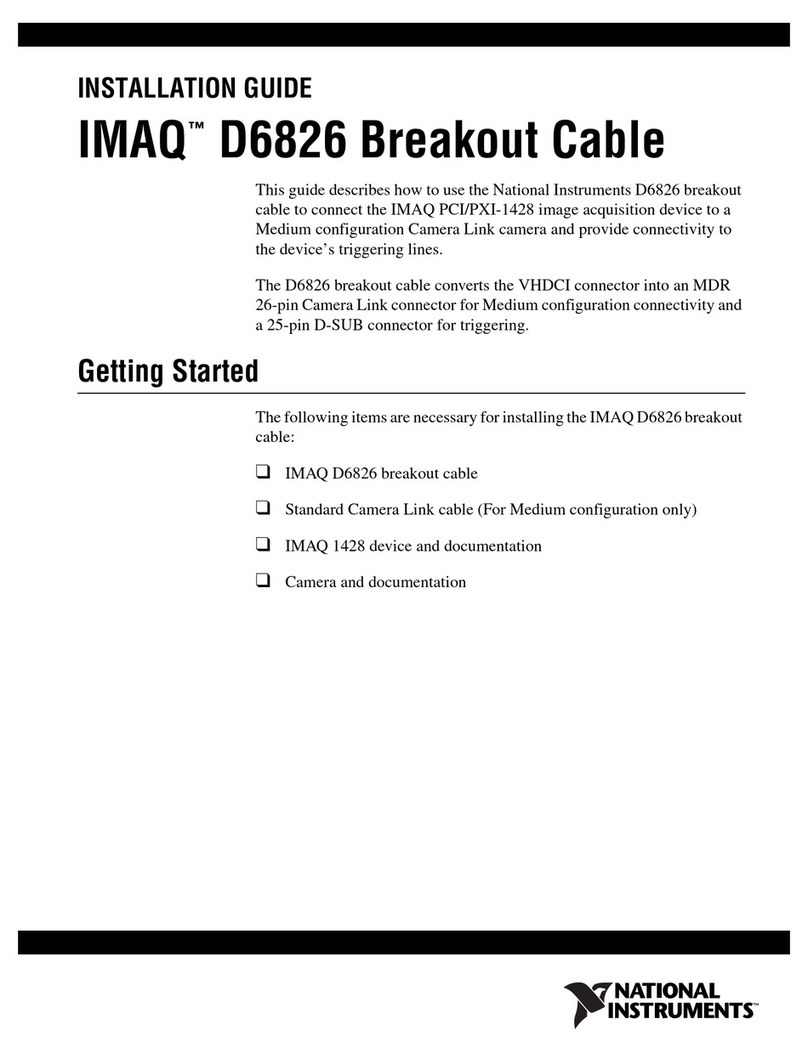

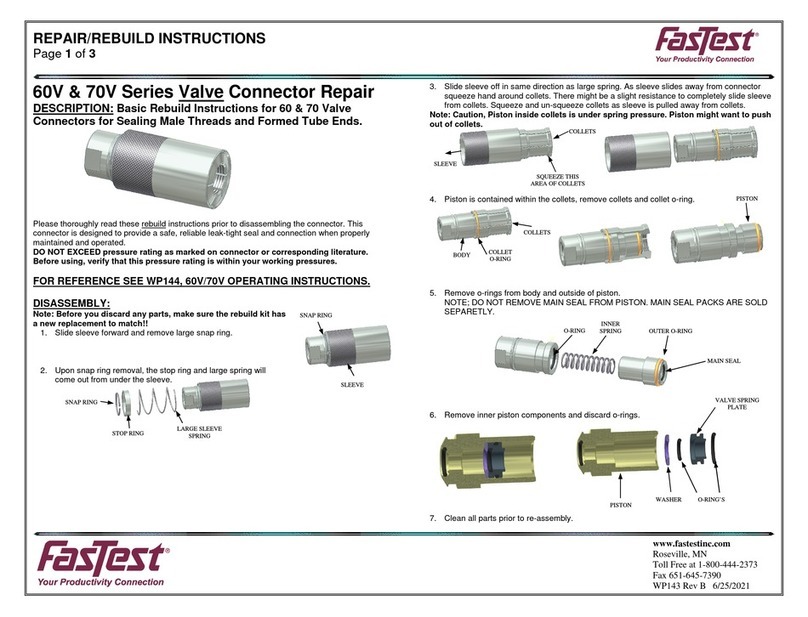

6) Remove the main seal from the pis-

ton. Using a repair pick, or similar

tool, remove the main seal. Exer-

cise caution so as not to scratch or

deform the seal groove. This could

cause a potential leak path.

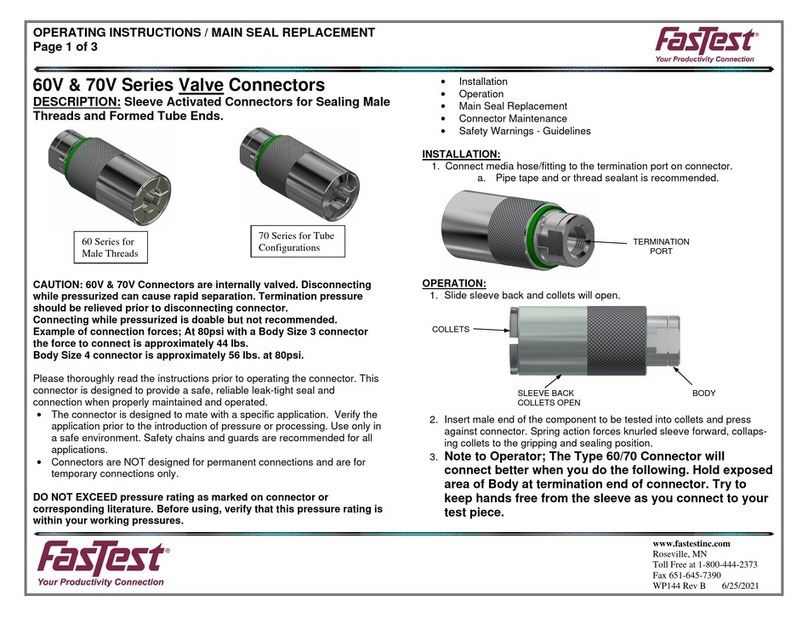

7) Remove the internal piston seal and

the external sleeve o-ring from the

front body. Using a repair pick, or

similar tool, remove the seal. Exer-

cise caution so as not to scratch or

deform the internal seal groove.

This could cause a potential leak

path.

FasTest, Inc. Product Warranty

FasTest, Inc. warrants its products against defects of workmanship and/or ma-

terial for 12 months from the date of the sale by FasTest, Inc. This warranty is

oid if the product is misused, tampered with or used in a manner that is not in

accordance with FasTest, Inc. recommendations and/or instructions. FasTest,

Inc. is not liable for consequential or other damages including, but not limited

to, loss, damage, personal injury, or any other expense directly or indirectly

arising from the use of or inability to use its products either separately or in

combination with other products. ALL OTHER WARRANTIES EXPRESSED

OR IMPLIED, WHETHER ORAL OR WRITTEN, INCLUDING BUT NOT

LIMITED TO WARRANTIES OR MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE ARE EXPRESSLY EXCLUDED.

Remedy under this warranty is limited to replacement of the product or an account credit in the

amount of the original selling price, at the option on FasTest, Inc. All allegedly defecti e products

must be returned prepaid transportation to FasTest, Inc. along with information describing the

products performance, unless disposition in the field is authorized in writing by FasTest, Inc.

WRENCH FLATS

POPPET SEAL

MAIN SEAL

REMOVE

SLEEVE

INTERNAL PISTON SEAL