REBUILD/REPAIR INSTRUCTIONS

Page 1 of 9

Roseville, MN

Ph: 1-800-444-2373

Fax: 651-645-7390

www.fastestinc.com

WP172 Rev A 08/2/2021

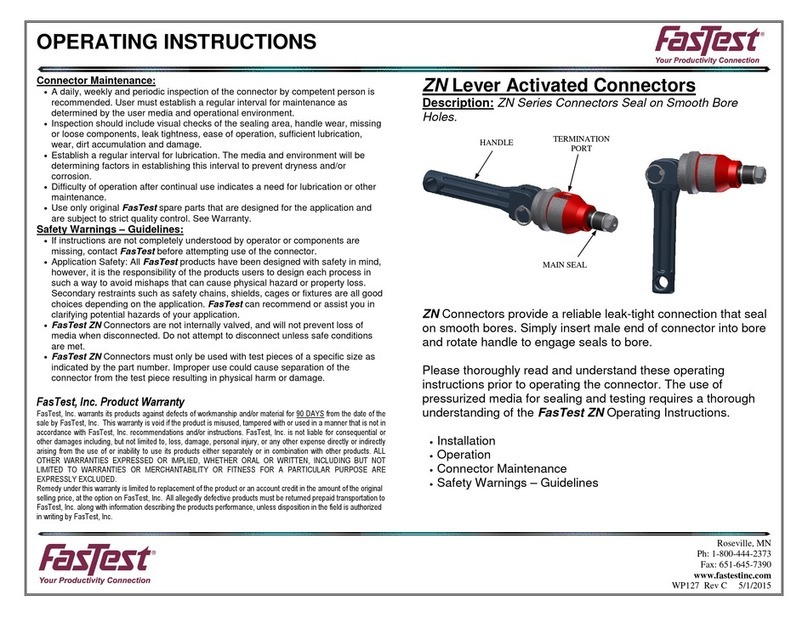

Connector Maintenance:

•A daily, weekly and periodic inspection of the connector by competent person is

recommended. User must establish a regular interval for maintenance as

determined by the user media and operational environment.

•Inspection should include visual checks of the sealing area, handle wear, missing

or loose components, leak tightness, ease of operation, sufficient lubrication,

wear, dirt accumulation and damage.

•Establish a regular interval for lubrication. The media and environment will be

determining factors in establishing this interval to prevent dryness and/or

corrosion.

•Difficulty of operation after continual use indicates a need for lubrication or other

maintenance.

•Use only original FasTest spare parts that are designed for the application and

are subject to strict quality control. See Warranty.

Safety Warnings – Guidelines:

•If instructions are not completely understood by operator or components are

missing, contact FasTest before attempting use of the connector.

•Application Safety: All FasTest products have been designed with safety in mind,

however, it is the responsibility of the products users to design each process in

such a way to avoid mishaps that can cause physical hazard or property loss.

Secondary restraints such as safety chains, shields, cages or fixtures are all good

choices depending on the application. FasTest can recommend or assist you in

clarifying potential hazards of your application.

•FasTest 60/70 Connectors are not internally valved, and will not prevent loss of

media when disconnected. Do not attempt to disconnect unless safe conditions

are met.

•FasTest 60/70 Connectors must only be used with test pieces of a specific size

as indicated by the part number. Improper use could cause separation of the

connector from the test piece resulting in physical harm or damage.

FasTest, Inc. Product Warranty

FasTest, Inc. warrants its products against defects of workmanship and/or material for 1 year from the date of the sale

by FasTest, Inc. This warranty is void if the product is misused, tampered with or used in a manner that is not in

accordance with FasTest, Inc. recommendations and/or instructions. FasTest, Inc. is not liable for consequential or

other damages including, but not limited to, loss, damage, personal in ury, or any other expense directly or indirectly

arising from the use of or inability to use its products either separately or in combination with other products. ALL

OTHER WARRANTIES EXPRESSED OR IMPLIED, WHETHER ORAL OR WRITTEN, INCLUDING BUT NOT

LIMITED TO WARRANTIES OR MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE ARE

EXPRESSLY EXCLUDED.

Remedy under this warranty is limited to replacement of the product or an account credit in the amount of the original

selling price, at the option on FasTest, Inc. All allegedly defective products must be returned prepaid transportation to

FasTest, Inc. along with information describing the products performance, unless disposition in the field is authorized

in writing by FasTest, Inc.

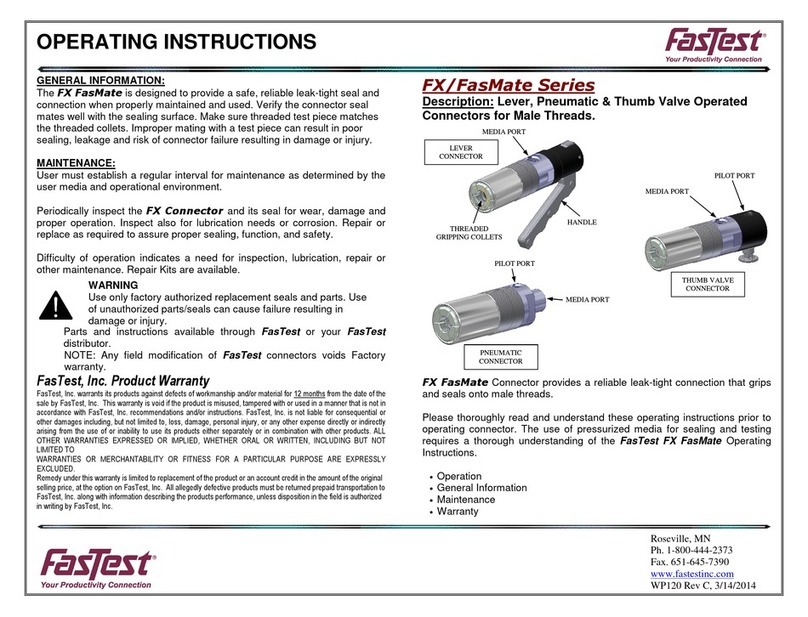

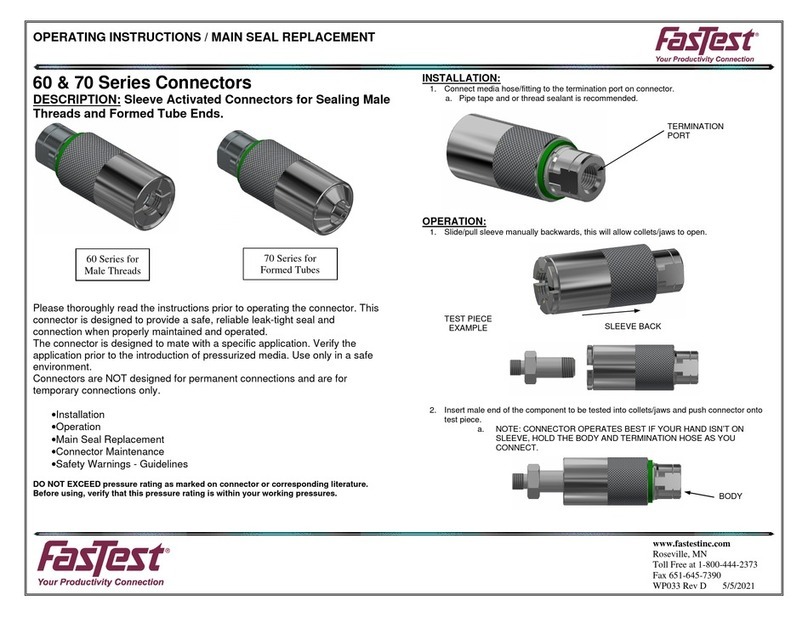

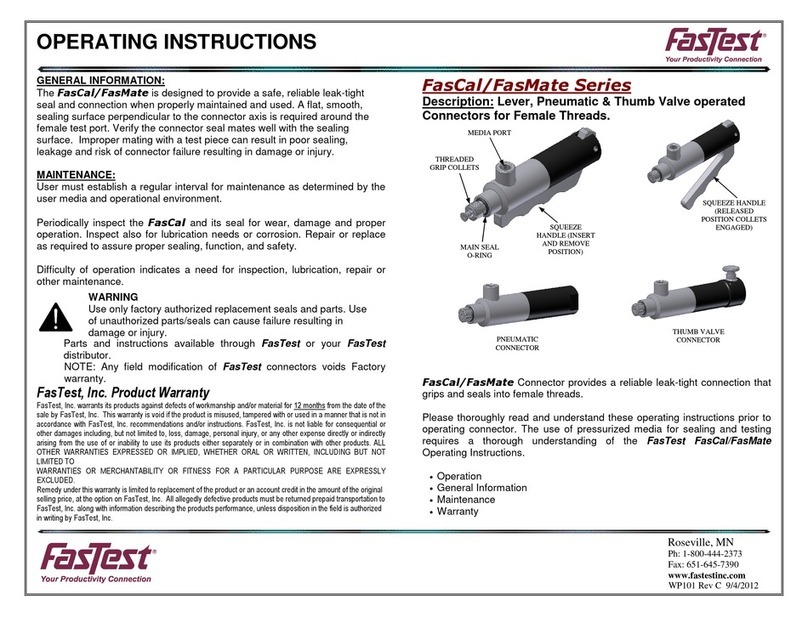

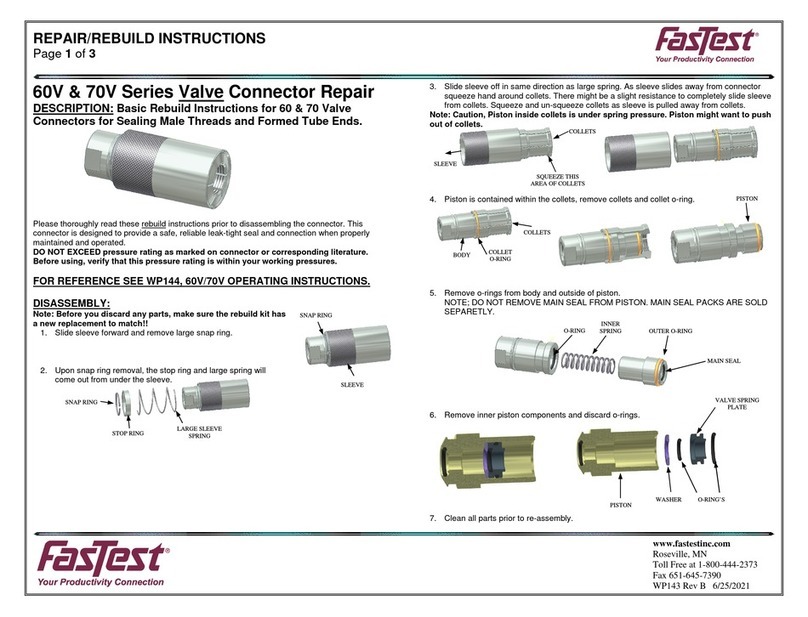

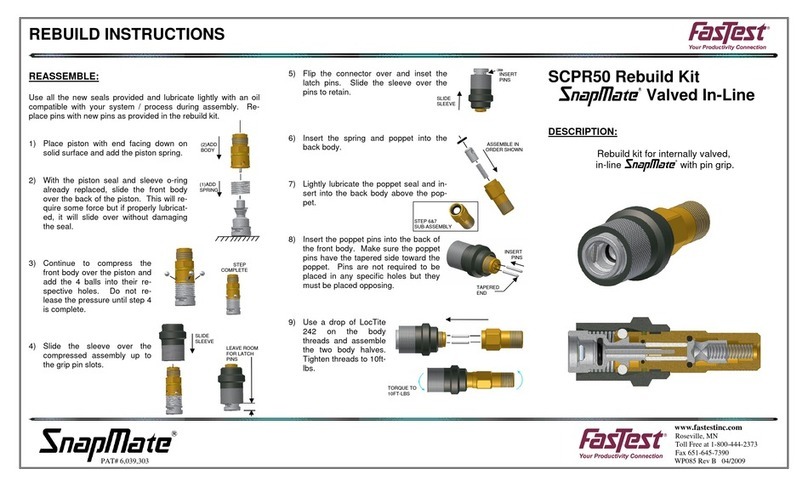

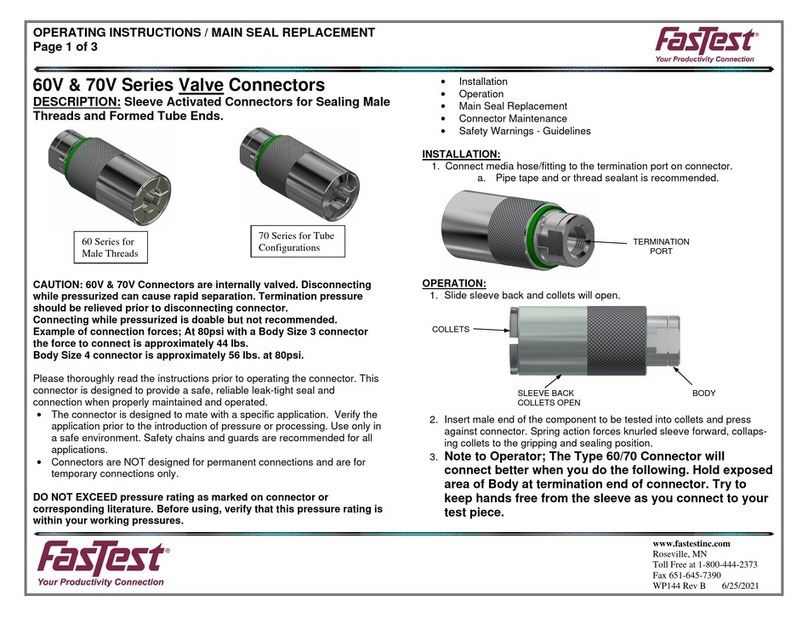

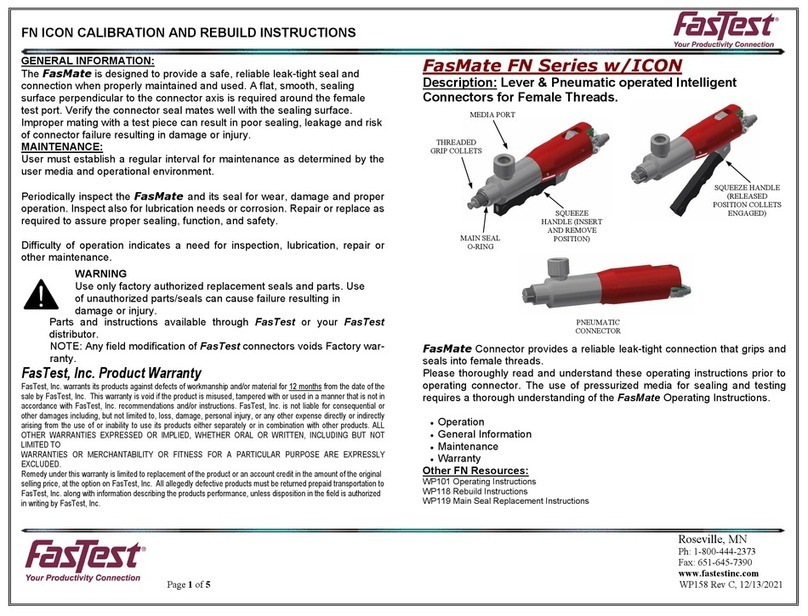

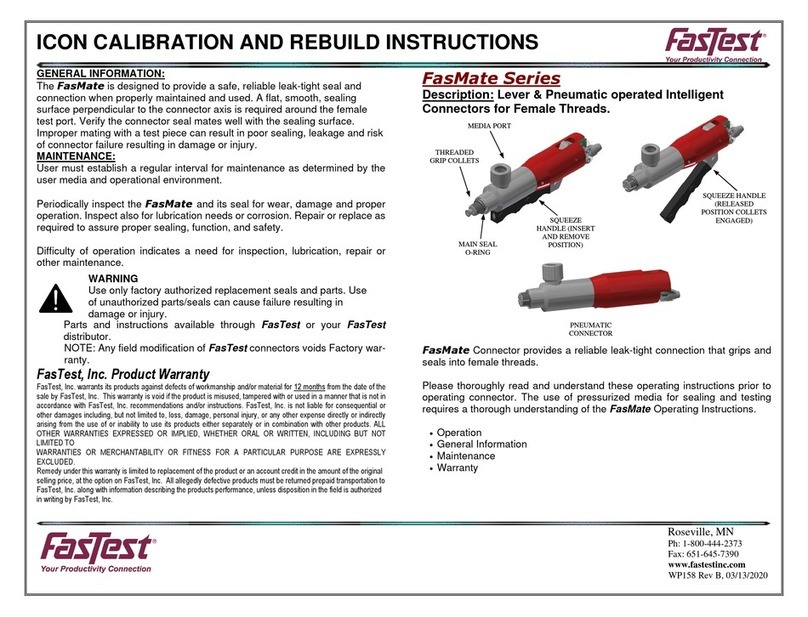

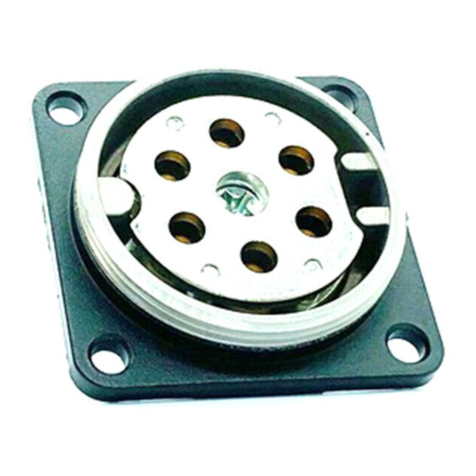

60/70 ICON™ Re-Build Instructions

Description: 60/70 Series Connectors to Grip and Seal Male

threads and Males Features with ICON™ CV04.

60/70 ICON™ Connectors provide a reliable leak-tight

connection that grips and seals male threads and male features.

Please thoroughly read and understand these repair instructions

prior to dis-assembling the connector.

Tools required are as follows:

Arbor press, hex wrench, sharp pic, small flat screw, Vaseline

Topics covered:

•Dis-assembly and Re-assembly Instructions

•Connector Maintenance

•Safety Warnings – Guidelines