FasTest FasMate Series User manual

ICON CALIBRATION AND REBUILD INSTRUCTIONS

Roseville, MN

Ph: 1-800-444-2373

Fax: 651-645-7390

www.fastestinc.com

WP158 Rev B, 03/13/2020

WARNING

Use only factory authorized replacement seals and parts. Use

of unauthorized parts/seals can cause failure resulting in

damage or injury.

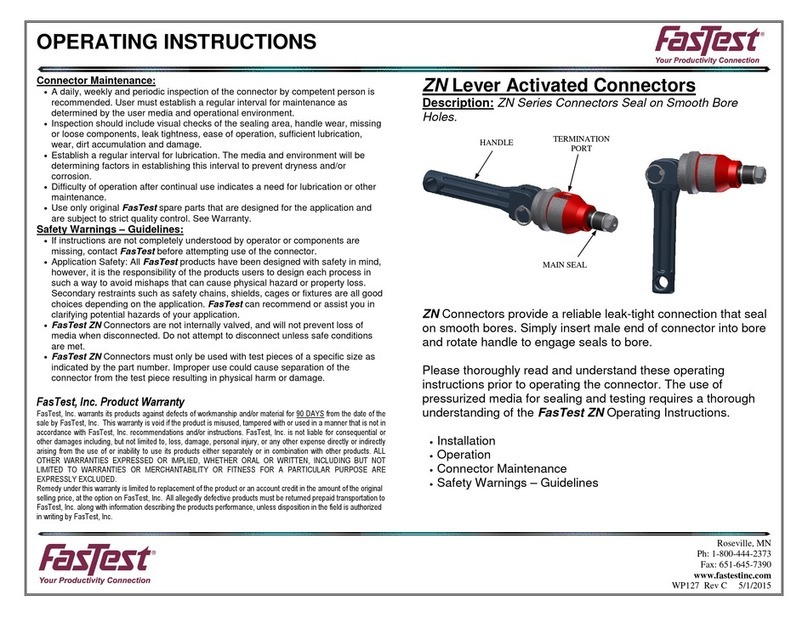

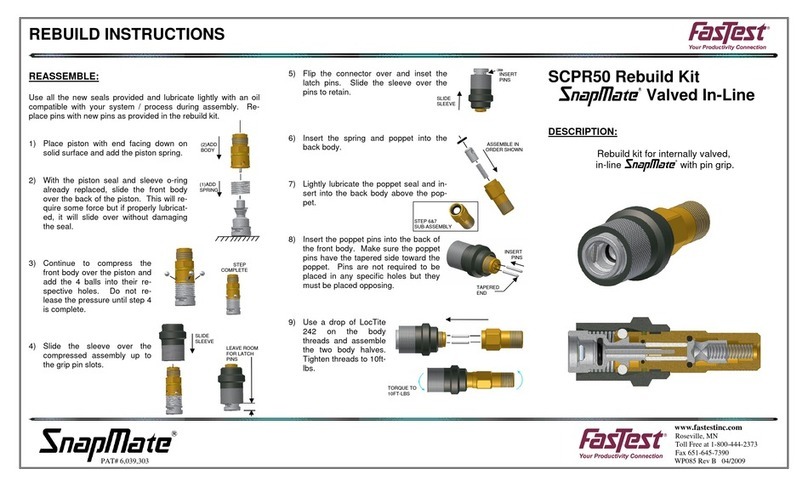

THREADED

GRIP COLLETS

SQUEEZE HANDLE

(RELEASED

POSITION COLLETS

ENGAGED)

PNEUMATIC

CONNECTOR

MEDIA PORT

MAIN SEAL

O

-

RING

SQUEEZE

HANDLE (INSERT

AND REMOVE

POSITION)

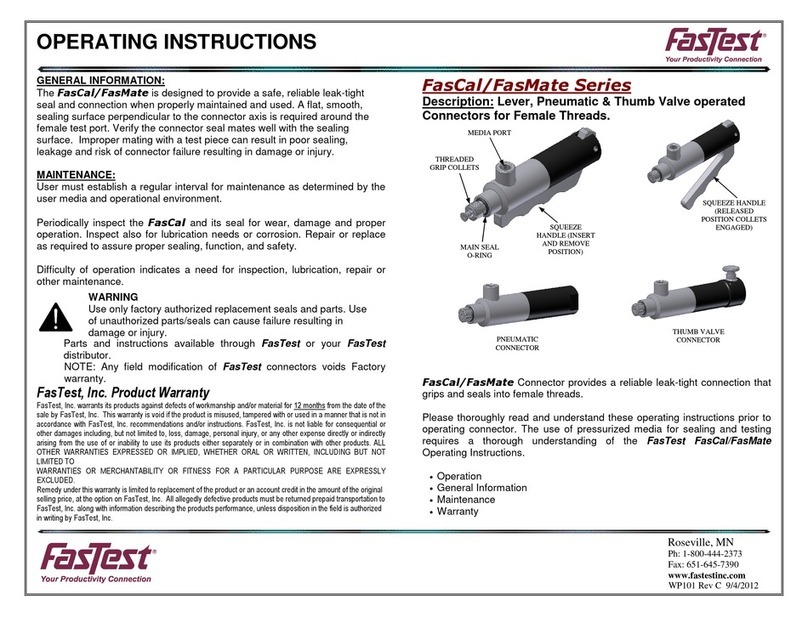

GENERAL INFORMATION:

The FasMate is designed to provide a safe, reliable leak-tight seal and

connection when properly maintained and used. A flat, smooth, sealing

surface perpendicular to the connector axis is required around the female

test port. Verify the connector seal mates well with the sealing surface.

Improper mating with a test piece can result in poor sealing, leakage and risk

of connector failure resulting in damage or injury.

MAINTENANCE:

User must establish a regular interval for maintenance as determined by the

user media and operational environment.

Periodically inspect the FasMate and its seal for wear, damage and proper

operation. Inspect also for lubrication needs or corrosion. Repair or replace as

required to assure proper sealing, function, and safety.

Difficulty of operation indicates a need for inspection, lubrication, repair or

other maintenance.

Parts and instructions available through FasTest or your FasTest

distributor.

NOTE: Any field modification of FasTest connectors voids Factory war-

ranty.

FasTest, Inc. Product Warranty

FasTest, Inc. warrants its products against defects of workmanship and/or material for 12 months from the date of the

sale by FasTest, Inc. This warranty is void if the product is misused, tampered with or used in a manner that is not in

accordance with FasTest, Inc. recommendations and/or instructions. FasTest, Inc. is not liable for conse uential or

other damages including, but not limited to, loss, damage, personal injury, or any other expense directly or indirectly

arising from the use of or inability to use its products either separately or in combination with other products. ALL

OTHER WARRANTIES EXPRESSED OR IMPLIED, WHETHER ORAL OR WRITTEN, INCLUDING BUT NOT

LIMITED TO

WARRANTIES OR MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE ARE EXPRESSLY

EXCLUDED.

Remedy under this warranty is limited to replacement of the product or an account credit in the amount of the original

selling price, at the option on FasTest, Inc. All allegedly defective products must be returned prepaid transportation to

FasTest, Inc. along with information describing the products performance, unless disposition in the field is authorized

in writing by FasTest, Inc.

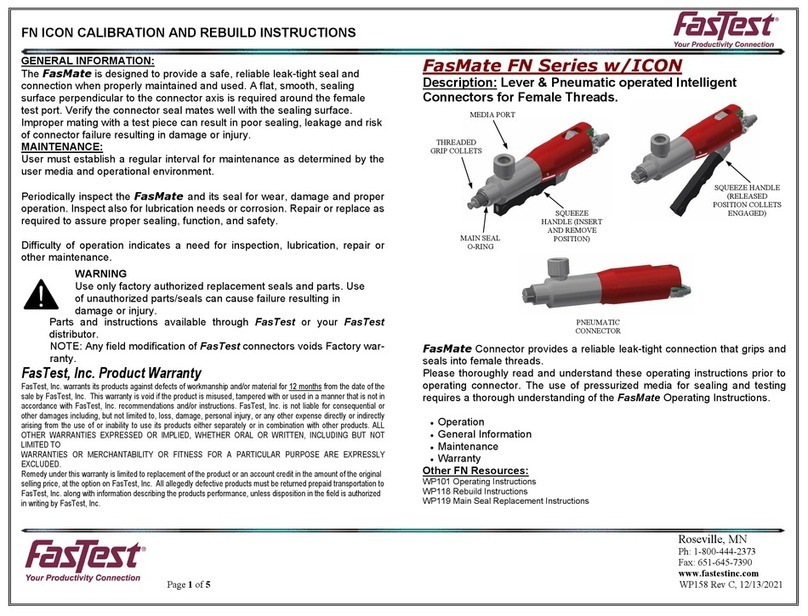

FasMate Series

Description: Lever & Pneumatic operated Intelligent

Connectors for Female Threads.

FasMate Connector provides a reliable leak-tight connection that grips and

seals into female threads.

Please thoroughly read and understand these operating instructions prior to

operating connector. The use of pressurized media for sealing and testing

requires a thorough understanding of the FasMate Operating Instructions.

•Operation

•General Information

•Maintenance

•Warranty

ICON CALIBRATION AND REBUILD INSTRUCTIONS

Roseville, MN

Ph: 1-800-444-2373

Fax: 651-645-7390

www.fastestinc.com

WP158 Rev B, 03/13/2020

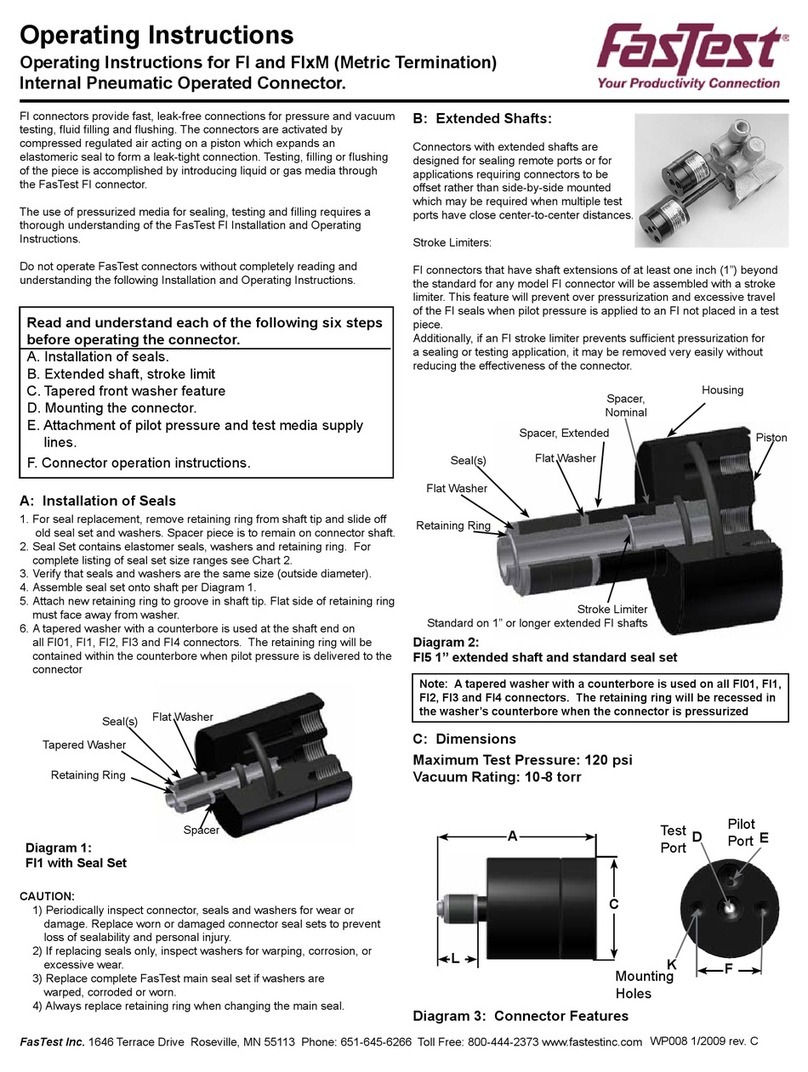

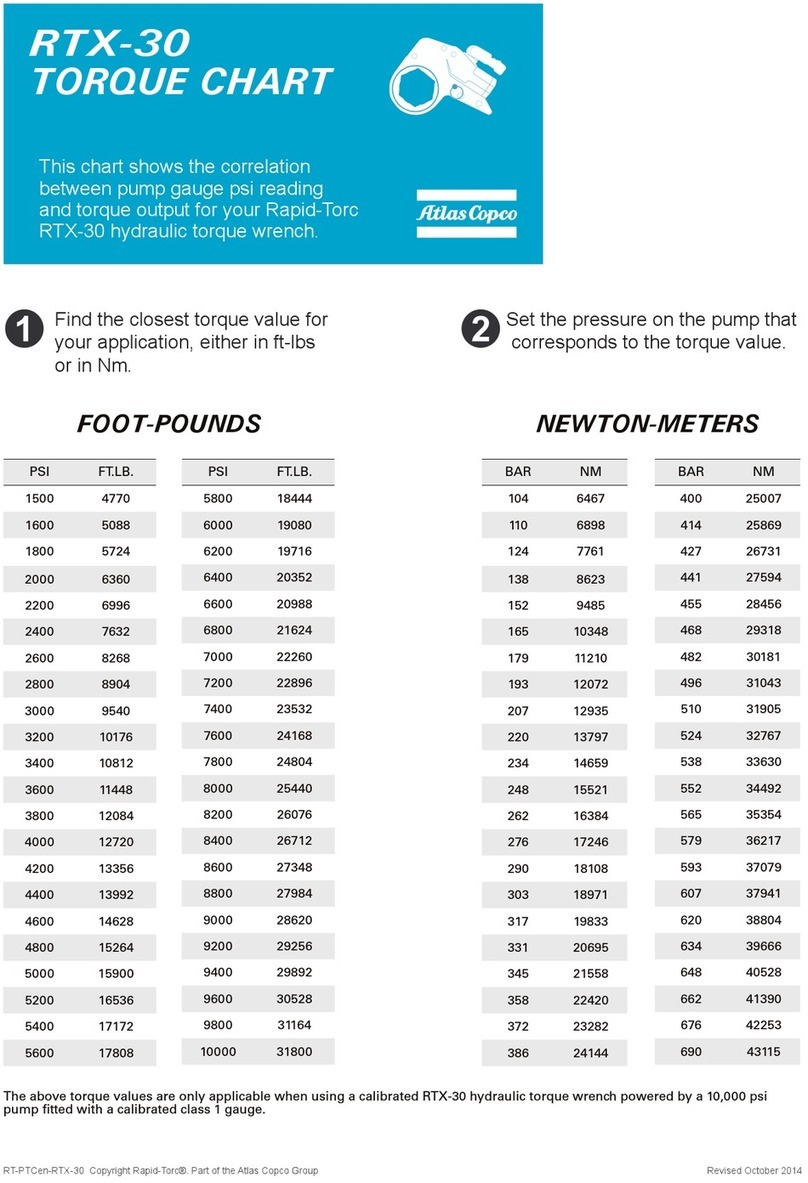

WIRING DIAGRAM:

SSR MODULE CALIBRATION (LEVER HANDLE TYPE ONLY):

Sure Seal™ enabled connectors need to be calibrated to each application. The FasMate con-

nector retains stored limit(s) even when power is removed. Due to the fine sensor resolution

and variations in seal height, limits may need to be set each time seals are replaced, or the con-

nector is re-built.

1. Rotate the red, back body to the desired location and lock it in place with the set screw. It

can be backed out up to one full turn.

2. Remove the main seal as shown in WP119.

STOP! READ STEPS 3-6 BEFORE STARTING CALIBRATION.

Note: Point A1 is a preset distance from the rest position (A). As the shaft is extended from

rest, it will begin flashing yellow within the good zone. A good connection is only indicated

when the shaft retracts from beyond the upper limit (B). If a good connection is made and

it’s just to the right of Point A1, it could travel through point A1 once test pressure is intro-

duced, and the light will change from green to flashing yellow. Cancel the test, reconnect,

and try again.

The input is asserted by applying 24V. This can be accomplished by pressing the button

on a FasTest Programming tool, or by using a 24V PLC signal or other 24V logic output.

3. Flash input 4 times quickly to enter programming mode. Connector will flash 3 times indi-

cating programming mode. Note: If the first calibration point is not set within about 30

seconds, the connector will return to operational mode.

4. Do not apply pressure to the handle. Hold input line high until indicator begins to flash,

about 2 seconds. The first calibration point will be recorded when the input is released.

Pinout/Standard M8 Cables

Pin Number

Wire Color

Description

1

BROWN

24 DC

2

WHITE

CALIBRATION

3

BLUE

GROUND

4

BLACK

NC

5

GREY

SSR CONTROL A

6

PINK

SSR CONTROL B

Pinout/Standard M8 Cables

Pin Number

Wire Color

Description

1

BROWN

24 DC

2

WHITE

LED GREEN

3

BLUE

GROUND

4

BLACK

ANALOG OUTPUT

5

GREY

LED RED

6

PINK

LED RETURN

STEPS 3-6 MUST BE COMPLETED WITHIN 30 SECONDS

CV04SSR Pinout

CV04SSR

Wiring Diagram

CV04

ANA

Pinout

CV04

ANA Wiring Diagram

ICON CALIBRATION AND REBUILD INSTRUCTIONS

Roseville, MN

Ph: 1-800-444-2373

Fax: 651-645-7390

www.fastestinc.com

WP158 Rev B, 03/13/2020

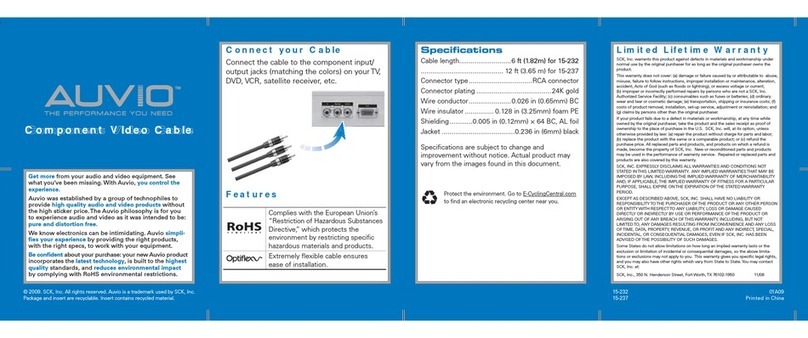

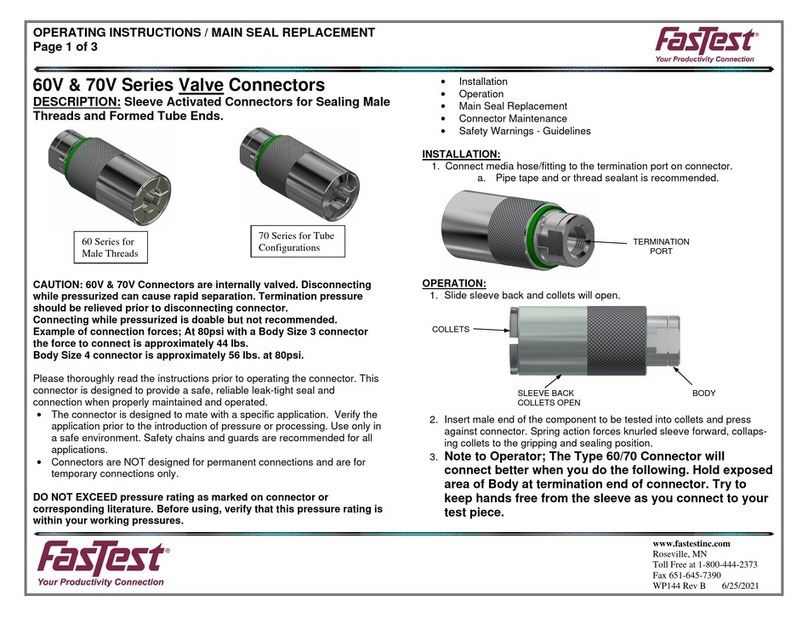

AT REST

EXTENDED WITH PILOT PRESSURE

TOO FAR

AT REST

PNEUMATIC

CONNECTOR

LEVER

CONNECTOR

5. Squeeze lever handle until the back of the main seal groove on the collet’s lines up with

the flat face of the front body. (See next section for pneumatic connectors)

Note: this location will change depending on thread size and fitting type.

6. Apply 24V signal to the input line until the indicator begins to flash, about 2 seconds. This

will set point B on the graph above. Release the input line to record the second calibration

point.

7. Release the handle.

8. Slowly squeeze the handle through its entire movement. Confirm that the proper output is

achieved. Refer to the graph above to see the LED output.

9. Re-install main seal.

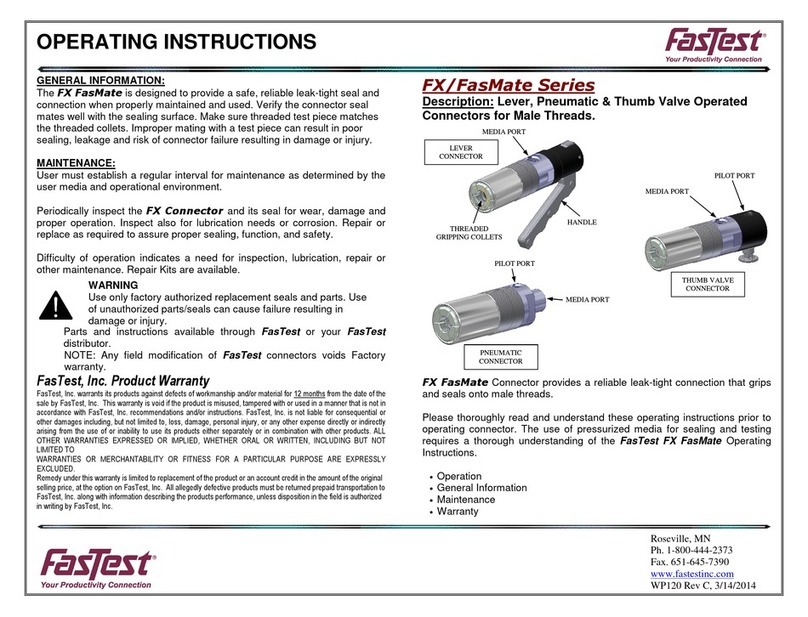

ANALOG CALIBRATION (LEVER HANDLE AND PNEUMATIC):

A FasMate will not make a good connection if cross-threaded or short-connected. If short-con-

nected, the piston will sit near or at rest position, and the voltage will be smaller than the voltage

for a good connection. If cross-threaded, the piston will be over-extended, and the voltage will be

larger than for a good connection. To detect a good connection on an analog Sure Seal

TM

Fas-

Mate, the voltage must be above the short-connect threshold voltage (V

SC

) and below the cross-

thread detection voltage (V

CT

). This calibration procedure is a guideline for determining these two

voltages, but exact values depend on the user application.

The pneumatic FasMate cannot be slowly moved into position like the lever handle. It is either at

rest or fully extended when pilot pressure in introduced.

1. Rotate the red, back body to the desired location and lock it in place with the set screw. It

can be backed out up to one full turn.

2. Record the connector’s voltage at rest. The short-connect voltage (V

SC

) will be approxi-

mately 0.8V larger than the voltage at rest but may vary depending on your application.

3. Activate connector by introducing pilot pressure. Note the voltage output at max travel.

4. Insert into test port and firmly hold it in place.

5. Remove pilot pressure to de-energize connector and verify that a good connection has been

made. Record the output voltage.

6. Repeat steps 3-5 several times and record the connector’s voltage. Use the distribution of

values to determine a cross-thread detection voltage (V

CT

) that is suitable for your pro-

cess, e.g. 2 standard deviations above the mean., or the largest voltage observed for

a good connection minus some safety margin.

7. A good connection is indicated by the output voltage settling in the range between V

SC

and

V

CT

8. Once the range is determined, a 24VDC signal may be applied to pins 2 and 5 to provide

red/yellow/green LED indication of connection quality.

* When using Analog, please note that the shielded cable improves noise (single termination); 0-

10VDC is used over operational range of the sensor.

Each time the connector is actuated, the threads can grip in a slightly different position. Therefore,

a range needs to be set during the calibration stage. It is suggested to try and short connect it

several times after the range has been set to ensure the range rejects bad connections. If the

connection falls outside of this range, the system can be setup to alert operators.

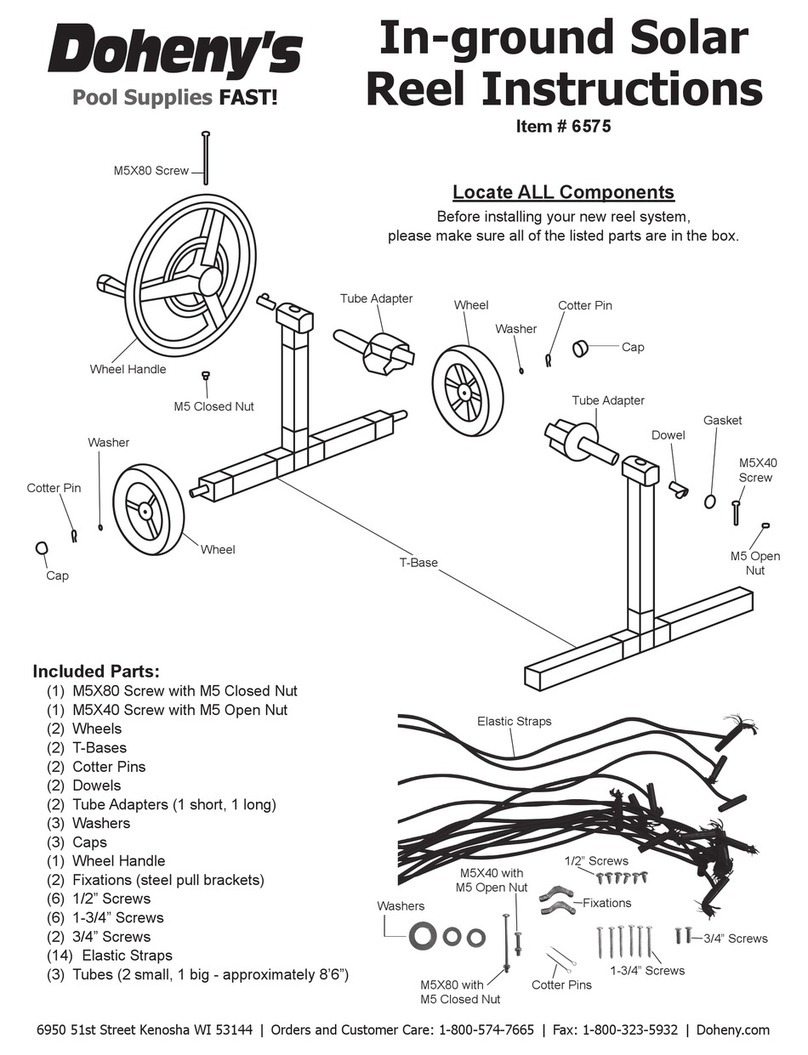

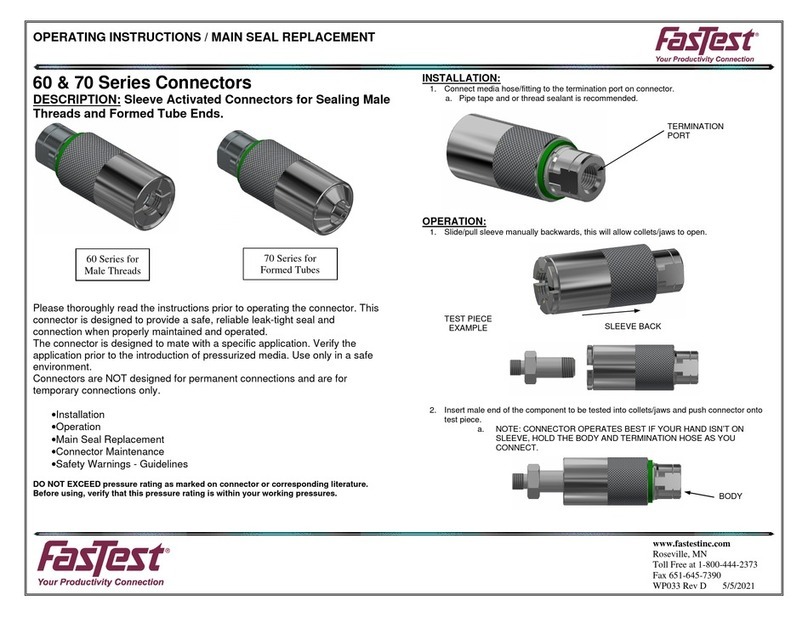

REBUILD:

1. Loosen set screw.

2. Unthread back actuator from front body.

3. Lever version:

a. Remove two screws securing PCA module.

b. Remove/replace PCA module, spring, and actuator.

CALIBRATION POINT

LINE UP GROOVE

ON COLLETS WITH

THIS FACE

PCA

MODULE

SCREWS

SPRING

ACTUATOR

ICON CALIBRATION AND REBUILD INSTRUCTIONS

Roseville, MN

Ph: 1-800-444-2373

Fax: 651-645-7390

www.fastestinc.com

WP158 Rev B, 03/13/2020

4. Pneumatic version:

a. Remove two screws and PCA module.

b. If needed, use a short blast of air at low pressure to remove the pressure piston. The

spring and actuator are located behind that.

5. Reverse the above steps to reassemble the connector.

a. Use a petroleum-based lubricant on the pressure piston o-ring for the pneu-

matic version.

6. Apply Loctite 242 to the screws that hold down the PCA module and tighten them to 5

in-lbs.

OTHER RESOURCES:

1. WP101: Operating Instructions

2. WP118: Rebuild Instructions

3. WP119: Main Seal Replacement Instructions

PCA

MODULE

SCREWS

SPRING

ACTUATOR

PRESSURE PISTON

O-RING

Other FasTest Cables And Connectors manuals

FasTest

FasTest 60V Series User manual

FasTest

FasTest 60 Series User manual

FasTest

FasTest SnapMate SCPR50 User manual

FasTest

FasTest FasCal Series User manual

FasTest

FasTest ICON 60 User manual

FasTest

FasTest FN Series User manual

FasTest

FasTest FasMate Series User manual

FasTest

FasTest 60V Series User manual

FasTest

FasTest FE001 Series Guide

FasTest

FasTest TWISTMATE Series User manual