(

MSio

870

To be handed to the workshop!

Operating instructions

for the High Frequency Angle Grinders

Type MSfo

870d,

c, b

and MSfo

870dK,

cK,

bK

(42

Volts)

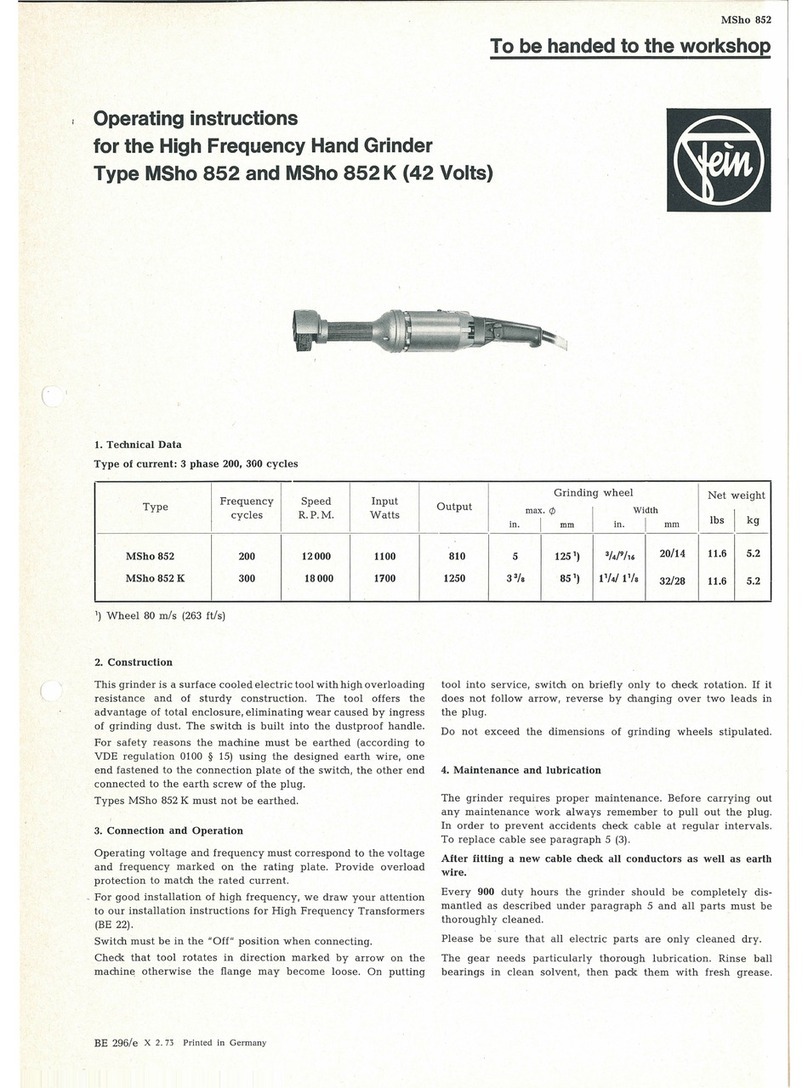

1. Technical

Data

Type

of

current: 3 ph.

A.

C. 200/300

Cycles

Fre-

Grinding

wheel

Admissib

le

Thread

Speed

Input

Output

Net

weight

I I I I

pe

ripheral

qu~~cy

R.P.M.

Watts

Watts

lbs. I

kg

in~~:~m

in~F~m

in.

~;;

I

Type

ft

./

ssp

~

e~/s

spi~~le

1

------------+------+--

----~-----r

----~----+----+

----T-

---T

----

~

-----r----+-

----+-------

~--------

~~

----

---

Type

~~::

:~~:K

I 300 I 8600 I 3300 I 2420 I

!~.

6

~

~:~

I 7 1 178 1 3

/s

110 I 7

/s

122 I

:~i~!~~

I 260 I 80 I M

14

--

----

------

T-----

~

--

-

----

:

------T-----~--~----

~------

--

:

I 200 I 8600 I 2200 11620 I

!~.

6

~

~:~

I 7 1 178 1

3fs

I 10 I 7/s 122 I

:~i~!~~

I 260 I 80 I M

14

MSfo B70d

MSfo B70dK

MSfo

B70c

I

300

I 6600 I 3300 I 2420 11

1

:61

~:~

I 9

123

0 I

3fs

I 10 I 7/s 122 I

i~i~!~~

I 260 I 80 I M 14

MSfo B70cK

MSfo B70c I 200 I 6500 I 2200

11620

I

!~.

6

~

~:~

I 9 1230 I 3/s I 10 I 7

/s

122 I

:~i~!~~

I 260 I 80 I M

14

MSio

B70cK

MSfo

870b

MSfo

870bK

I 200 I 4400 I 2200

11620

I

!~.

6

~

~

:

~

18

5/a 1220 I -- I -- I 9

/,6

114,2 I

elastic

di

sc

I 260 I 80 I M

14

~--------~----~--~----~----~--~--~--~--~----~--~--~

2.

Construction

The

High

Frequency

Grinder

MSfo

870

is

a

high

capacity

tool

with

earth

cable

according

to

the

VDE

regulations

0740.

For

safety

reasons

the

machine

is

provided

with

an

earth

wire,

which

is

yellow

and

green.

At

one

side

it

is

connected

to

the

metal

housing

of

the

tool

and

at

the

other

side

it

must

be

con-

nected

to

the

protecting

contact

of

the

plug

.

Machines

for

42

Volts

(Class III)

have

no

earthing

conductor.

Gears

are

lapped

for

accurate

meshing;

both

parts

to

be

supplied

as

pairs

only.

Gears

and

bearings

are

protected

against

dust

and

loss

of

grease.

Part

of

the

cooling

air

is

led

by

conducts

through

the

gearing

in

the

gear

head

for

additional

cooling.

3.

Connection

and

Operation

First

check

that

details

on

rating

plate

correspond

to

those

of

the

high

frequency

supply.

To

avoid

overloading

of

the

grinder

we

recommend

the

installation

of

a

safety

switch.

Switch

must

be

in

the

"Off"

position

when

connecting.

Check

that

the

tool

rotates

in

direction

marked

by

arrow

on

the

machine,

otherwise

the

tool

may

become

loos

e.

To

check

rota

tion

switch

on

tool

briefly

.

If

it

does

not

follow

arrow,

reverse

by

changing

over

two

lead

s

in

the

plug.

BE

315 e

EW

2. 73

Printed

in

Germany

Please

see

instruction

BE

22

for

the

high

fr

eq

uency

installation

.

To

avoid

overloading

of

the

gri

nder

we

recommend

the

installa-

tion

of

a

safety

switch

(see

also

separate

inst

ruction

B 22).

Do

not

exceed

the

dimensions

of

grinding

wheels

stipulat

ed.

When

wo

r

king

with

crank

wheel

hold

tool

in

such

a

position

that

the

grinding

wheel

wo

r

ks

under

an

angle

of

15

-

30

°.

For

cutting

off

stone

use

our

wheel

guard

with

adjus

t

able

support

.

4.

Maintenance

and

Lubrication

The

ang

le

grinder

require

s

adequate

main

te

n

ance.

Before

star-

ting

any

maintenance

work

pull

plug

from

socke

t. To

replac

e

cable

see

instru

ct

ions

.

of

pa

ragr

aph

5,

sectio

n

2.

After

fitting

new

cable

check

con

nection

of

co

nductor

as

well

as

of

earth

wire.

The

gearing

should

be

particularly

well

greased.

E

ve

ry

300

working

hours

renew

gear

grease.

Use

only

the

prescribed

qualit

y FG 9.

To

prevent

mi

xture

of

greases

,

lubricate

the

roller

bearings

in

the

gear

head

also

with

our

special

grease

FG

9.

When

checki

ng

or

ren

ewing

t

he

grease,

take

out

sc

r

ews

(48)

on

bearing

cap

(3

5)

.

Take

of

f

complete

cap

with

drive

s

haft

(42)

and

remove

old

grease.