NOTICE!

The supplied plastic blanking plugs are intended exclusively for protection

against contamination during transport and handling. During operation, these

should be replaced by cable connectors and/or blanking plugs approved for use

in explosion protection areas.

WARNING!

Use cable connectors of type of (ignition) protection Ex-d and a degree of protec-

tion of at least IP67. Seal unused cable entries with blanking plugs.

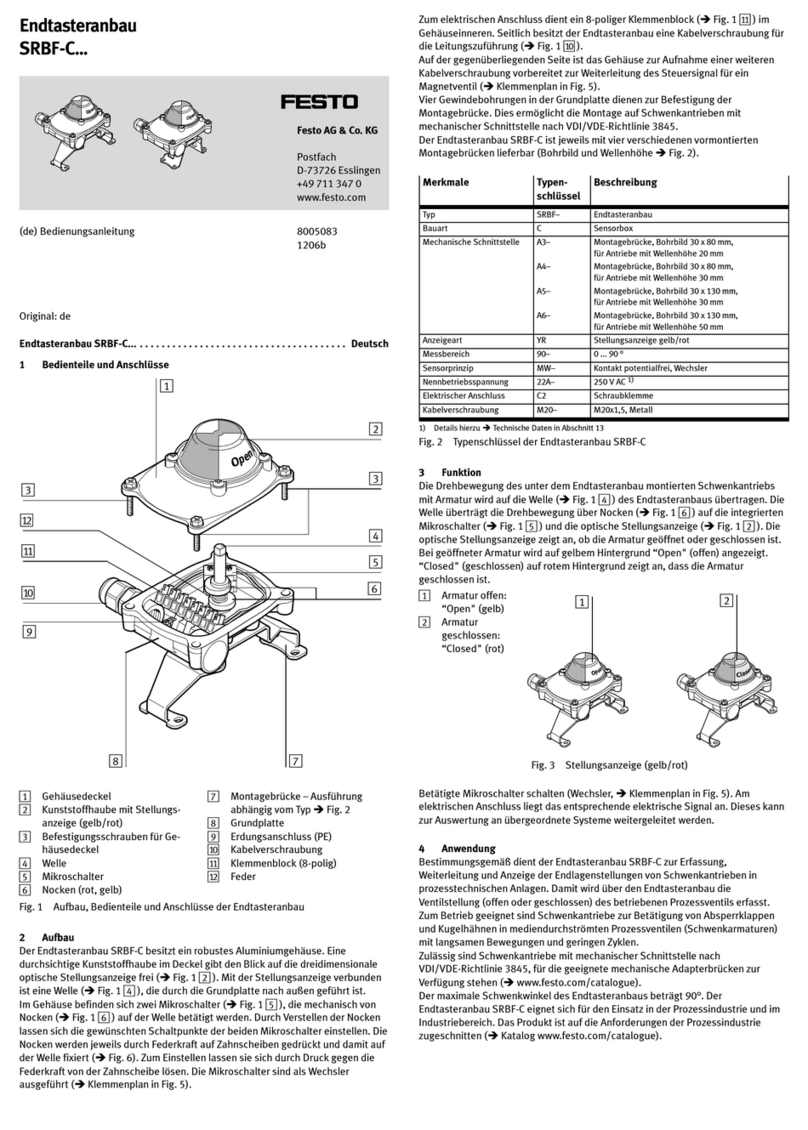

1. Loosen the housing screws3on the housing cover2.

2. Screw the cable fitting into the cable inlet8. Guide the electrical connecting

cable through the cable fitting to the terminal block6.

3. Wiring connections è 8.1 Terminal plan

4. Connect the earth terminal7 with low impedance (short cable with large

cross section) to the earth terminal.

5. Place the housing cover in position and tighten the housing screws.

– Note the correct position of the seal.

8.1 Terminal plan

SRBE-Cxx-YR90-MW-22A-1W-…/SRBE-Cxx-YR90-R-2A-1W-…

Fig. 2 Two SPDT micro-switches, mechanical or magnetic

SRBE-Cxx-YR90-N-20N-ZC-…/SRBE-Cxx-YR90-N-1-ZU-…

Fig. 3 Two-wire proximity switches, inductive

SRBE-Cxx-YR90-N-1-P-…/SRBE-Cxx-YR90-N-1-N-…

Fig. 4 Three-wire proximity switches, inductive

SRBE-Cxx-YR90-MW-22A-2W-…

Fig. 5 Four SPDT micro-switches, mechanical

9 Switching point adjustment

The switching points are preset è 4 Product overview.

Fig. 6

1. Close process valve.

ÄPosition indicator: “closed”.

2. Loosen the housing screws on the housing cover and remove the housing

cover.

3. Lift the red cam against the spring and turn until the lower proximity switch

switches.

4. Release the red cam.

Ä– The spring presses the red cam into the ring gear.

– The switching point for “closed” is set.

5. Open process valve.

ÄPosition indicator: “open”.

6. Press down the green cam against the spring and turn until the upper proxim-

ity switch switches.

7. Release the green cam.

Ä– The spring presses the green cam into the ring gear.

– The switching point for “open” is set.

8. Place the housing cover in position and tighten the housing screws.

10 Maintenance and care

The device is maintenance-free. Repairs are not possible.

Avoid contact with aggressive substances.

– Only clean the device with a damp cloth. Do not use the following agents:

– Abrasives

– Alcohol

– Solvents

– Protect surfaces from excessive heat.

11 Fault clearance

Fault description Cause Remedy

Wire break Replace cable

Position of the switching points

incorrect

Setting switching points

Incorrect or unexpected signal

Proximity switch defective Replace limit switch box

Tab. 2

12 Technical data

SRBE-...

Angular detection setting range [°] 0…90

Cable entry

SRBE-…-M20 2 x M20x1.5

SRBE-…-N12 2 x 1/2 NPT

Electrical connection

SRBE-Cxx-YR90-MW-22A-1W-…

SRBE-Cxx-YR90-N-20N-ZC-…

SRBE-Cxx-YR90-N-1-P-…

SRBE-Cxx-YR90-N-1-N-…

SRBE-Cxx-YR90-N-1-ZU-…

SRBE-Cxx-YR90-R-2A-1W-…

10-pin, screw terminal

SRBE-Cxx-YR90-MW-22A-2W-… 14-pin, screw terminal

Conductor nominal cross section that

can be connected

[mm²] 0.25…2.5

Mounting position any

Operating voltage range AC

SRBE-Cxx-YR90-R-2A-1W-… [V] 0…220

SRBE-Cxx-YR90-MW-22A-1W-…

SRBE-Cxx-YR90-MW-22A-2W-…

[V] 0…250

Max. output current AC

SRBE-Cxx-YR90-R-2A-1W-… [A] 0.416 (220 V)

SRBE-Cxx-YR90-MW-22A-1W-…

SRBE-Cxx-YR90-MW-22A-2W-…

[A]

[V]

3 (250 V)

Operating voltage range DC

SRBE-Cxx-YR90-R-2A-1W-…

SRBE-Cxx-YR90-MW-22A-1W-…

SRBE-Cxx-YR90-MW-22A-2W-…

[V] 0…30

SRBE-Cxx-YR90-N-20N-ZC-… [V] 8.2

SRBE-Cxx-YR90-N-1-P-…

SRBE-Cxx-YR90-N-1-N-…

[V] 10…30

SRBE-Cxx-YR90-N-1-ZU-… [V] 5…60

Max. output current DC

SRBE-Cxx-YR90-R-2A-1W-… [A] 3 (300 V)