3/4

Our application examples are recommendations which have been tried and tested in

practice. However the different conditions are completely outside of our control. We

therefore do not provide any form of guarantee. Any legal claims arising out of this are

not to be made against Festool. Make sure you follow the safety directions and product

instructions provided with the product.

www.festool.co.uk

508/06

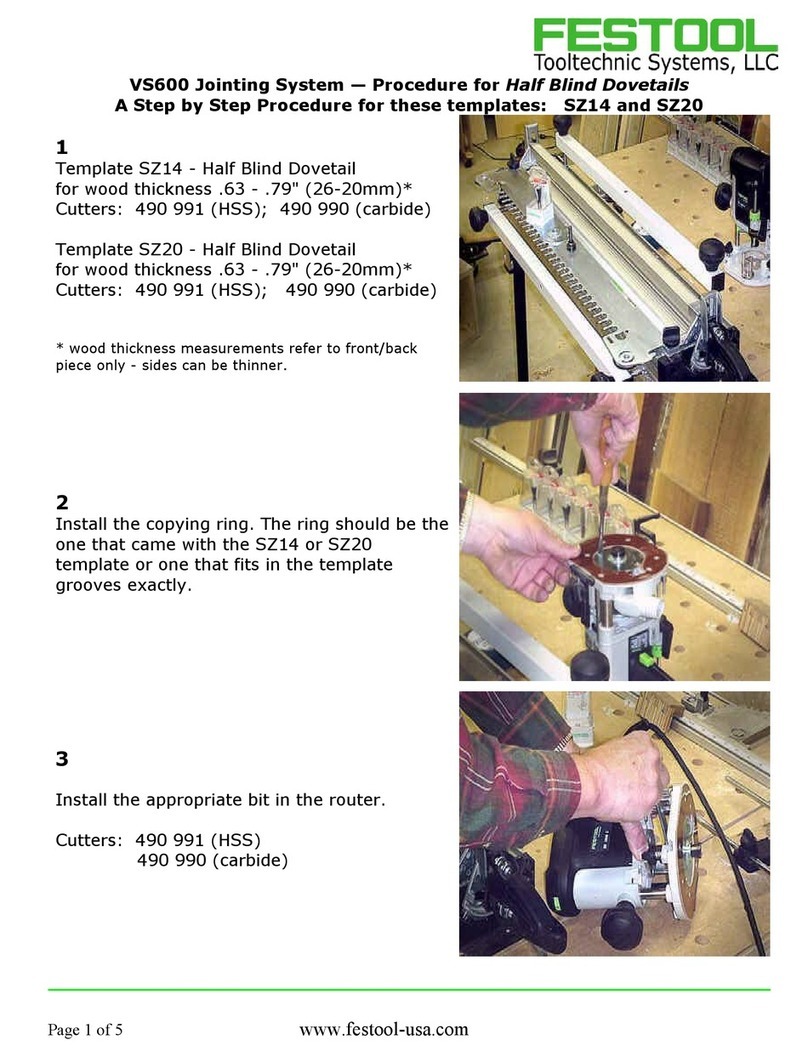

Setting the routing width:

Mount side stop with fine adjustment on tabletop.•

Push side stop against window sash.•

Make the rough adjustment of the cutter position using the linkage of the•

side stop.

Set the side stop with the fine adjustment (see Fig. 508/6) so that the•

cutter cleanly cuts out the putty in the glazing rebate.

Tip: On old windows, the wood can be recut until a straight putty rebate

edge guarantees perfect sealing.

508/07

508/08

D

Procedure

Switch on machine and plunge in. When routing, ensure that the side•

stop always makes contact with the window sash (see Fig. 508/7) and the

machine is flat on the surface of the window sash.

In order to cut right into the corner, in the area of the crossbar the•

chip protection is pulled upwards until it disappears in the router table

(see Fig. 508/8).

Always route in reverse direction to ensure to the longest possible•

service life of the cutters.

Windows with weatherboards at front

In order to cut right into the corner on windows with weatherboards, a

wooden base as high as the weatherboard must be fitted on the left and

right of the upright sash (see Fig. 508/9). Chip flutes are cut out at the

wooden bases to ensure that the fastening clamps do not obstruct the side

stop of the putty router (see Fig. 508/10). With this device, the putty can be

cut out comfortably and reliably from the two sashes and the weatherboard.

Upon completion of this work, corner areas can be reworked if necessary

with the firmer chisel and new putty can be applied.

508/9

508/10