2

WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.F

ELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.C

HVAC GUIDETM Tester

Field Manual

HG1 & HG2

Do it right the rst time!

Minimize call-backs. Reduce testing and diagno-

sis time. Improve the technician’s technical capability.

Minimize reliance on outside technical help. e HVAC

GuideTM Guided Probe Tester can do all that and more.

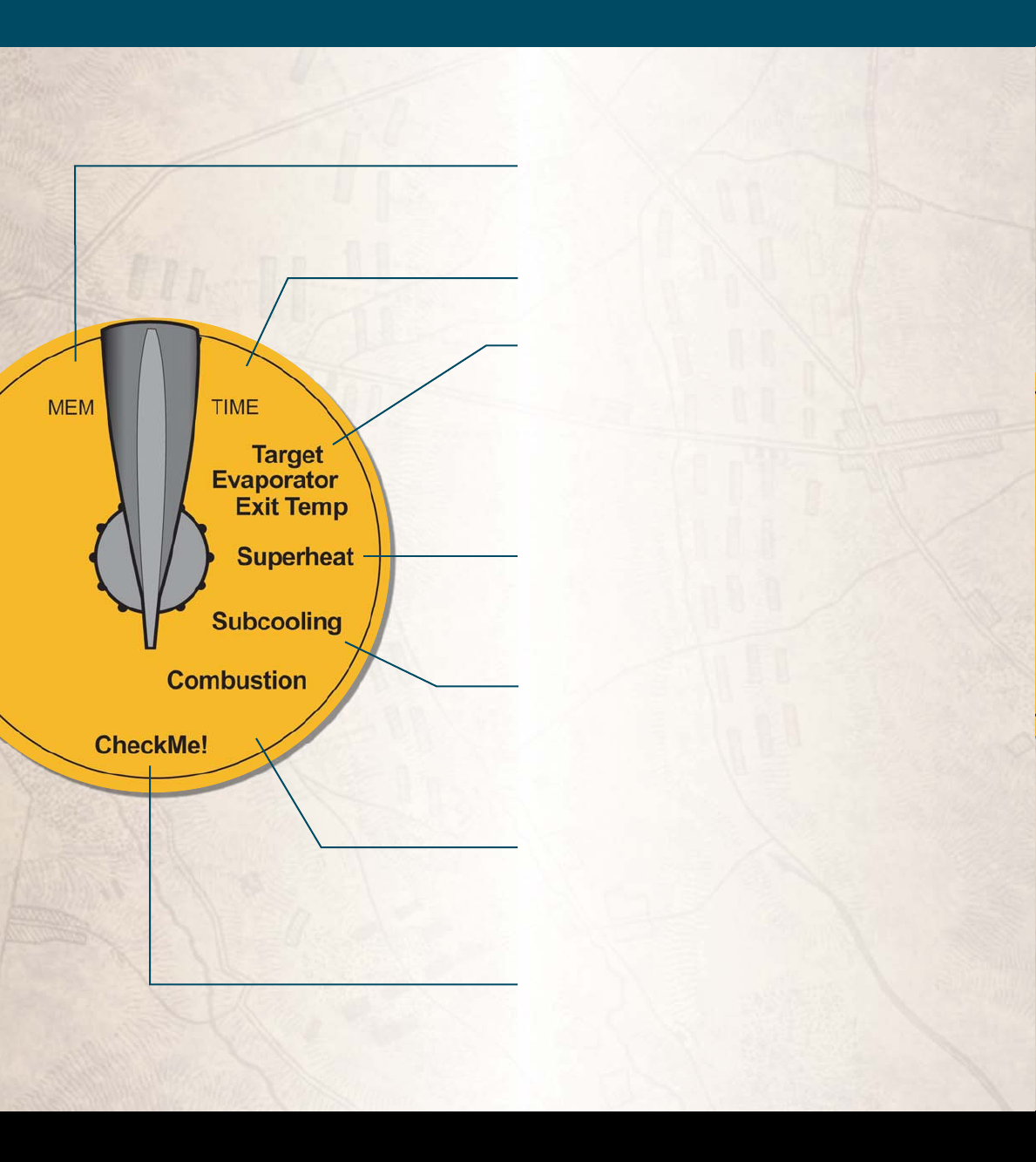

e display leads the technician step by step through

the most common HVAC tests. It then makes a diagno-

sis and recommends action. e HVAC GuideTM tester

makes the service call or installation faster, easier, clean-

er, and more complete.

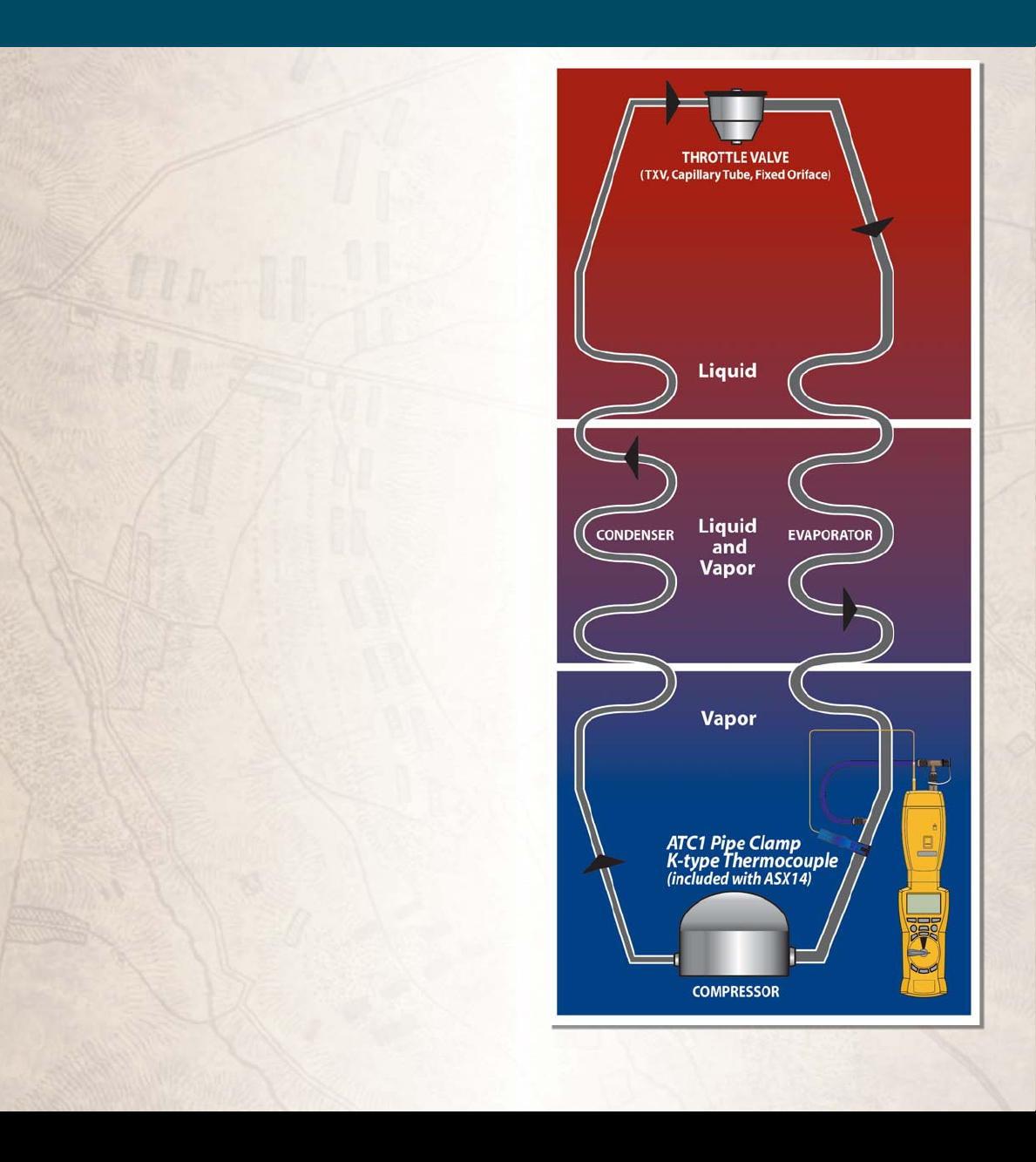

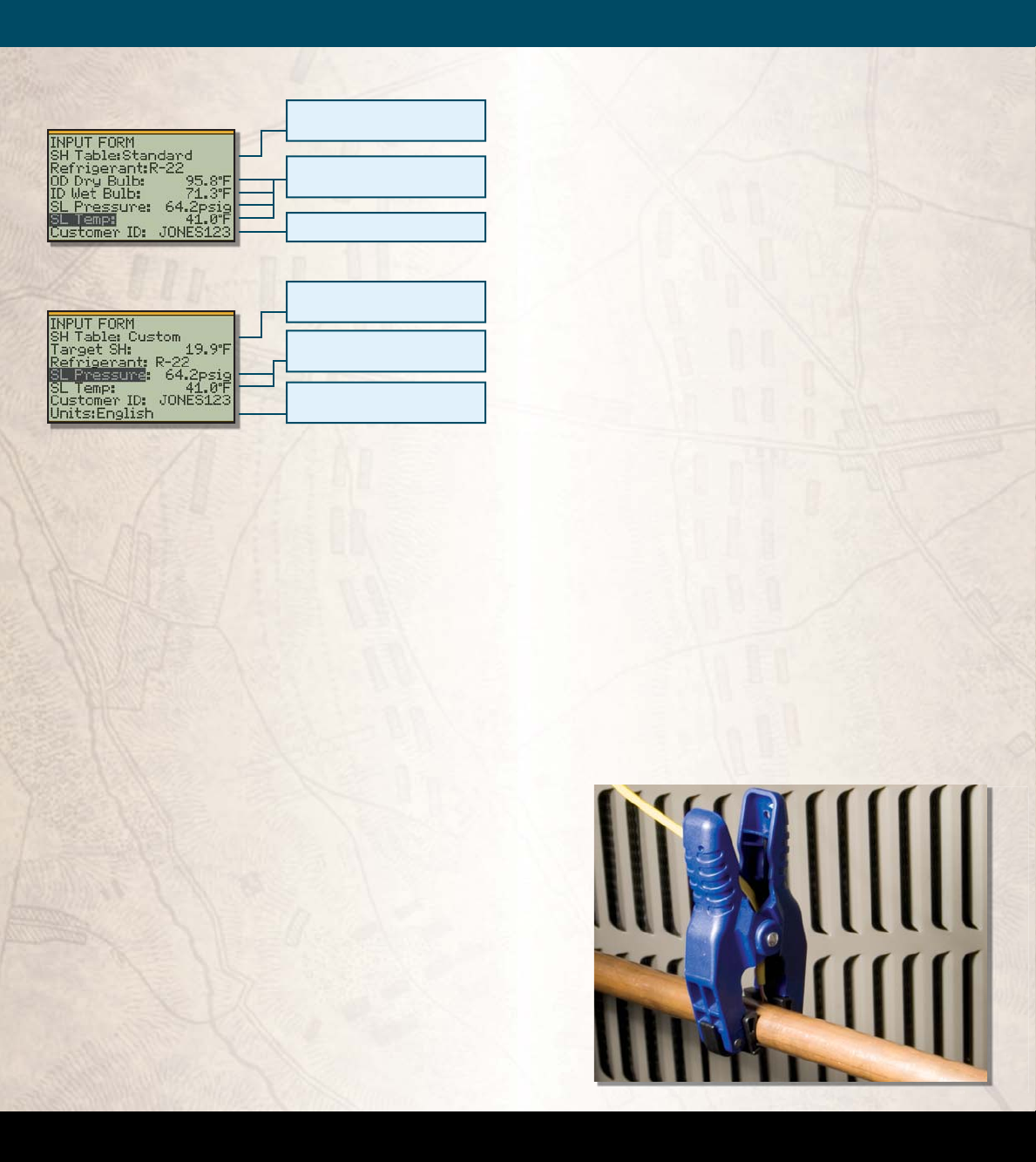

Improper refrigerant charge is one of the primary

reasons for call-backs. It can cause compressor noise,

shorten compressor life, and lower capacity. Using the

built-in Superheat and Subcooling tests, the HVAC

GuideTM tester leads the technician through a step by

step procedure to determine if the refrigerant charge

is correct. With the proper accessory heads, no calcula-

tions, charts, or data entry are needed.

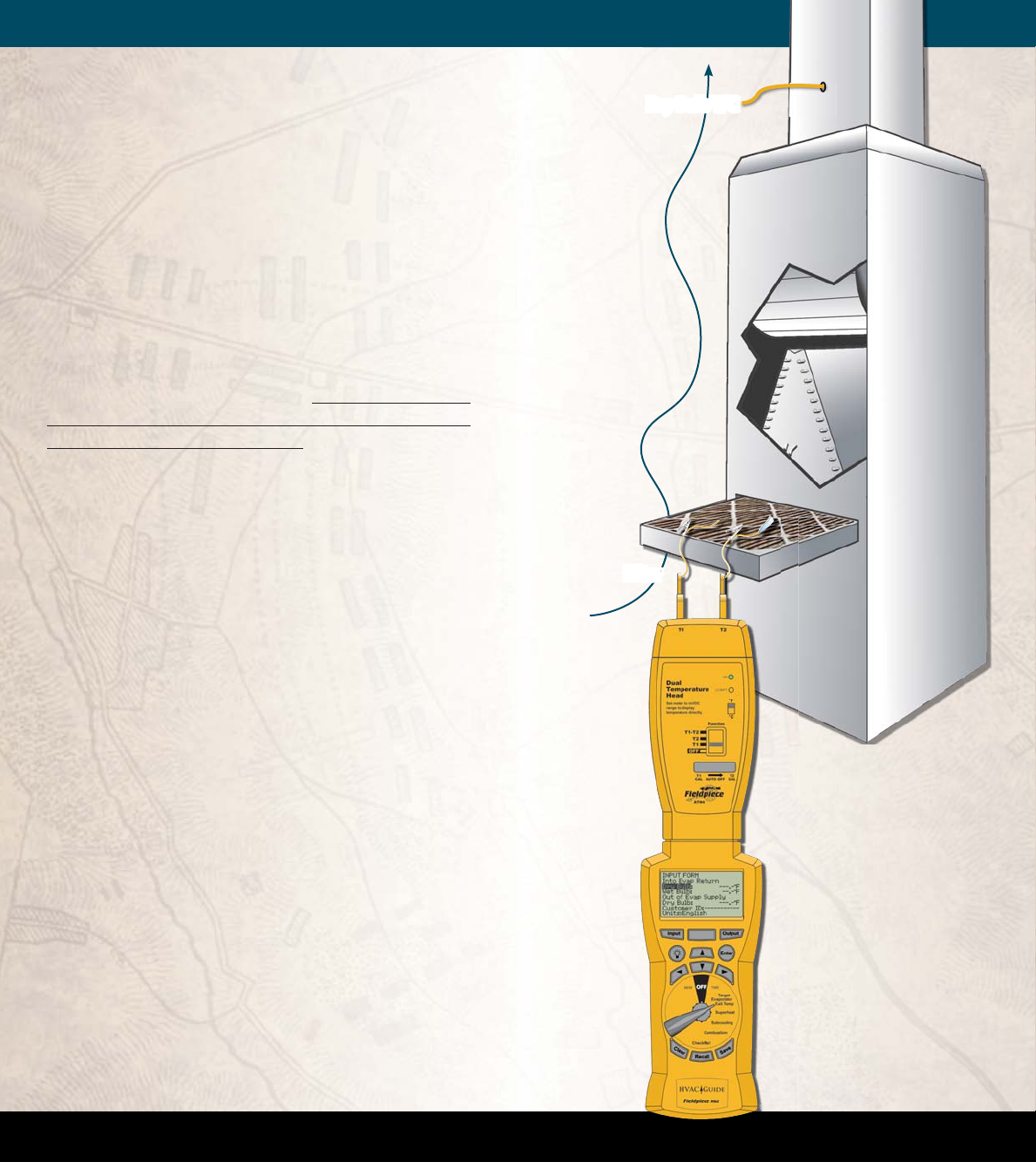

Improper airow can cause customers to complain

that they are too hot or too cold. Once you’ve checked

the duct system for restrictions and leaks, adjust the air-

ow with the Target Evaporator Exit Temperature pro-

cedure that’s built into the HVAC GuideTM tester.

An improperly adjusted furnace or water heater will

cause your customers to call you and complain about

the temperature being too cold or the hot water not be-

ing hot enough. Use the Combustion test built into the

HVAC GuideTM tester to determine if you have the right

air/fuel mixture by analyzing the combustion products.

You can then make adjustments to make sure the equip-

ment works as it should.

e CheckMe!® test (model HG2 only) is a much

more sophisticated air conditioner test procedure that

will help diagnose more complex problems by looking

at the air conditioning system as a whole.

Do it right the rst time, do it faster, do it easier, do

it more completely and avoid call-backs in the process.

Table of Contents

Do it Right the First Time! . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Table of Contents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

HVAC GuideTM Tester Controls . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Select the Test (Switch Positions) . . . . . . . . . . . . . . . . . . . . . . . 6

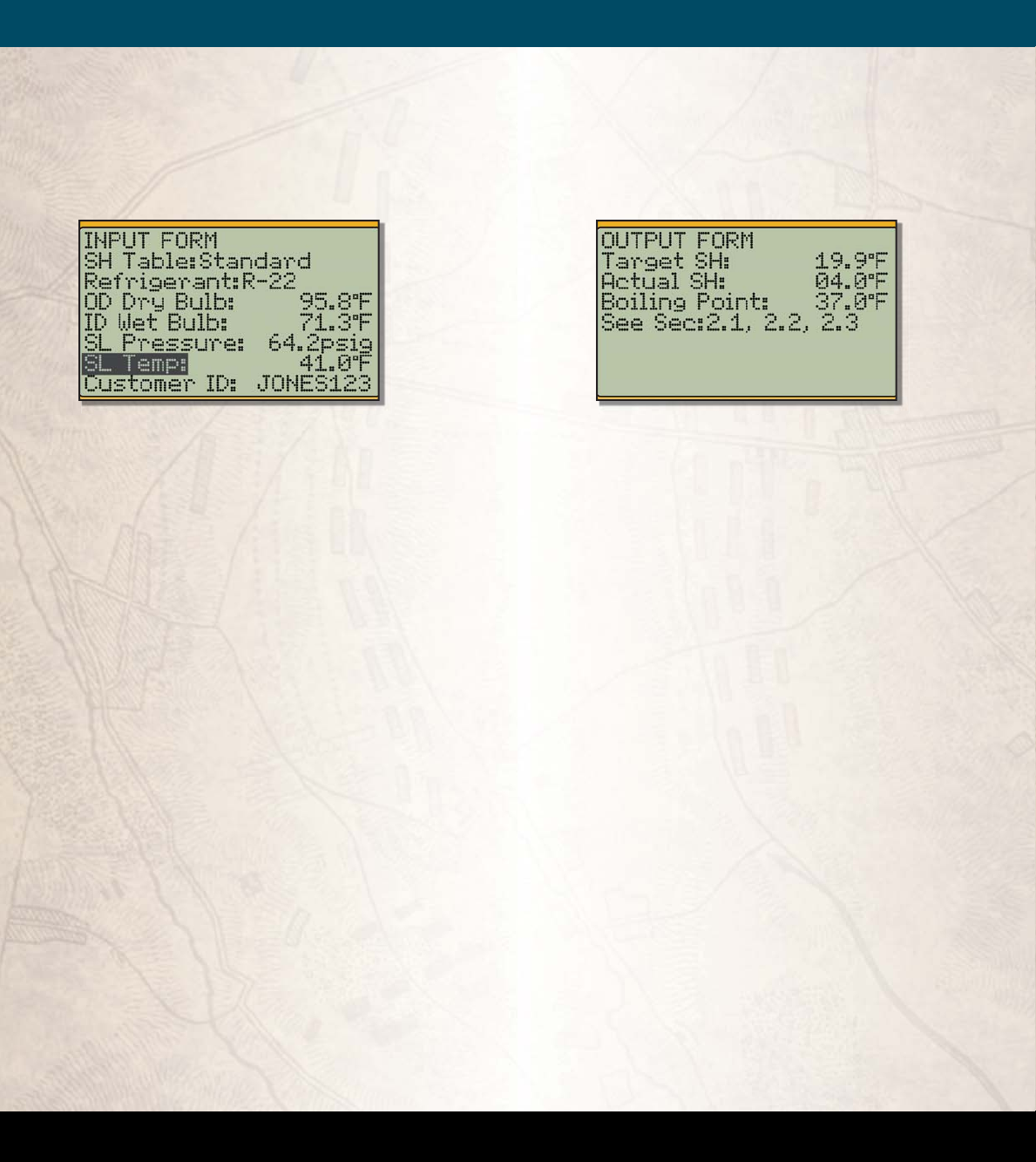

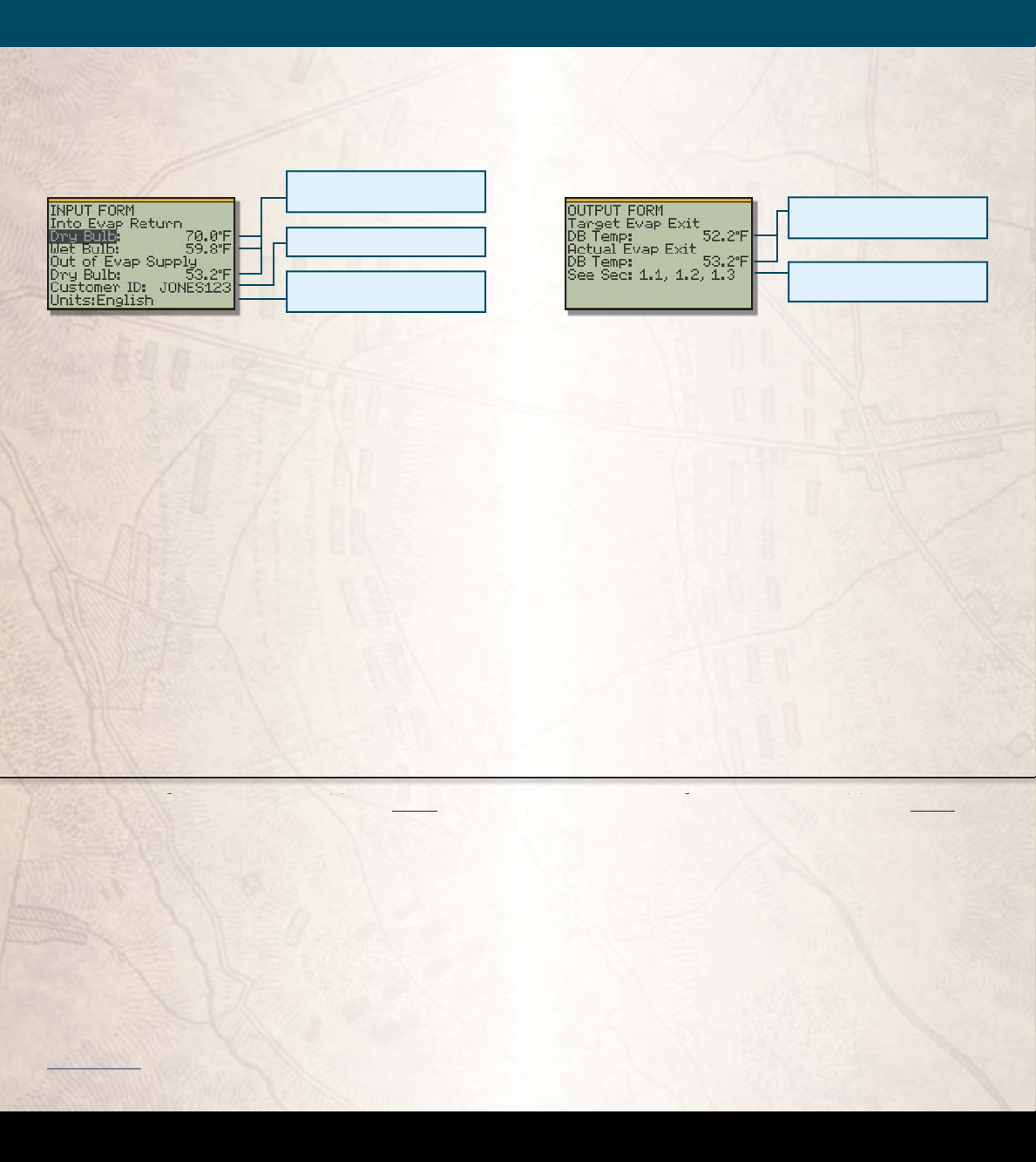

Fill in the INPUT FORM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Read the OUTPUT FORM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

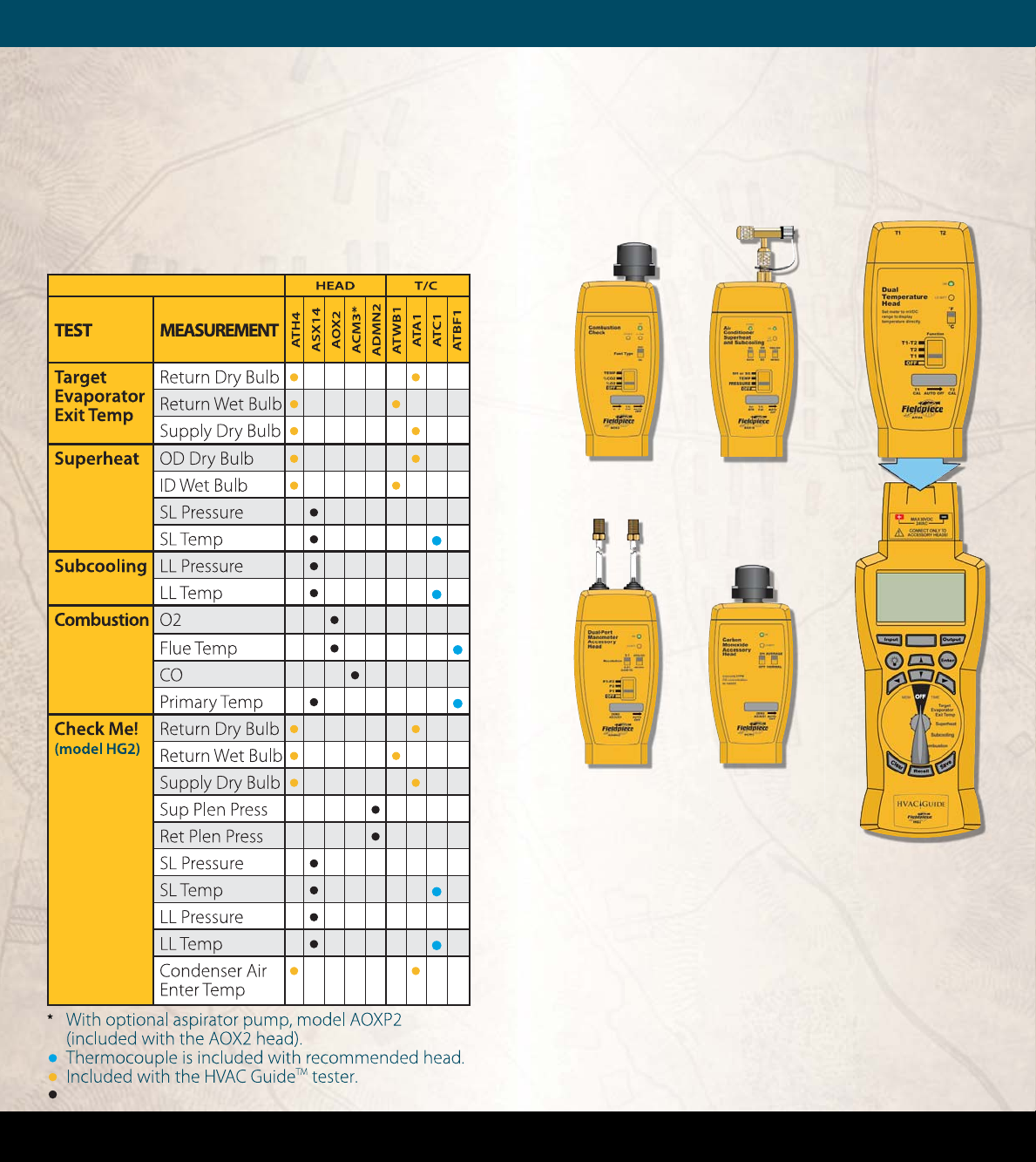

What Accessory Heads Do I Need? . . . . . . . . . . . . . . . . . . . . 10

How to Connect an Accessory Head . . . . . . . . . . . . . . . . . . . 11

Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Target Evaporator Exit Temperature . . . . . . . . . . . . . . . . . 12

Superheat. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Superheat and Subcooling FAQ part 1 . . . . . . . . . . . . 21

Subcooling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Superheat and Subcooling FAQ part 2 . . . . . . . . . . . . 27

Combustion. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

“CheckMe!®” . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Advanced Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Memory (MEM). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Units. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Customer ID. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Clearing a single input or INPUT FORM . . . . . . . . . . . . . . 52

Saving Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Recalling Saved Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Contrast Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

PC Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Installing the PC Software . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Communicating with a PC . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Transfer Tests from the HVAC GuideTM Tester to a PC. . 56

Transfer Tests From the PC to the HVAC GuideTM Tester. . 58

Looking at Downloaded Data. . . . . . . . . . . . . . . . . . . . . . . 60

Other Operations with PC Software . . . . . . . . . . . . . . . . . . . 61

Air Conditioning Basics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Combustion Basics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Product Specications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Limited Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Obtaining Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Disclaimer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

John Proctor and Title 24 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

© Copyright Fieldpiece Instruments 2007