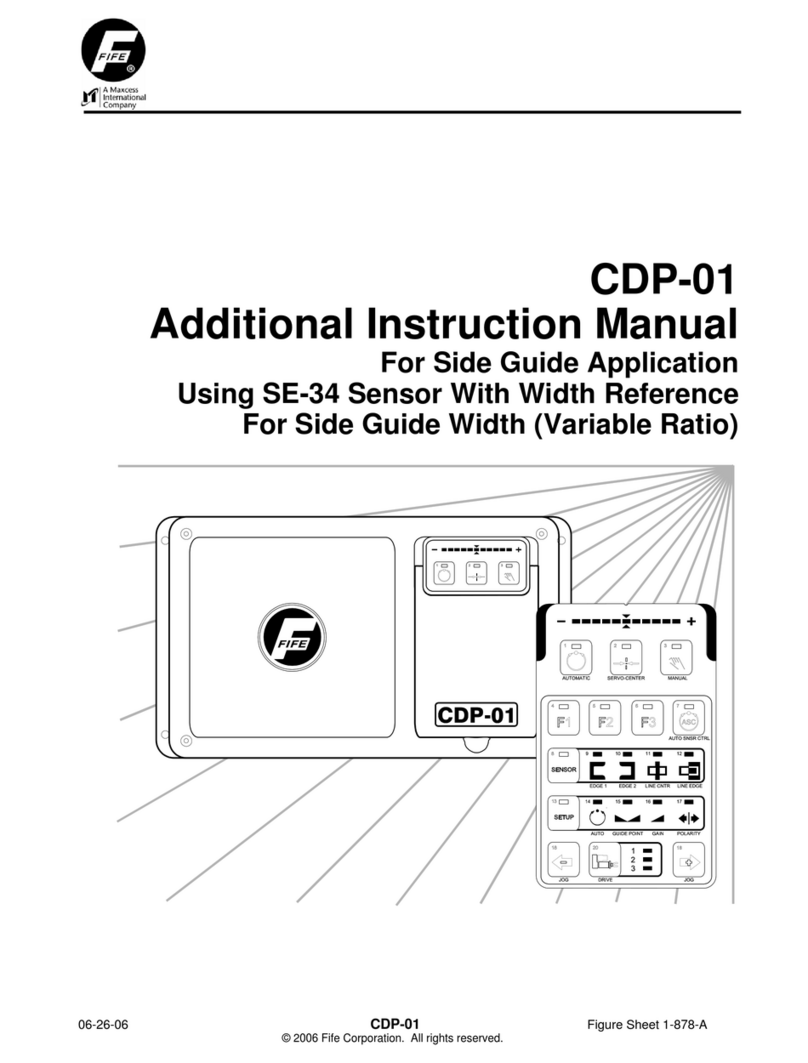

Fife CDP-01 User manual

02-17-03 CDP-01 Figure Sheet 1-860

CDP-01

Additional Instruction Manual

For Centerguiding Using Two(2) DAC-00X Sensors

02-17-03 CDP-01 Figure Sheet 1-860

SUPPLEMENTARY OPERATING MANUAL i

02-17-03 CDP-01 Figure Sheet 1-860

COPYRIGHT

NOTE

These additional instructions explain the special features of the system delivered to the customer. They

are intended for being used in conjunction with the CDP-01 Reference Manual. The CDP-01 Reference

Manual applies except as noted to the contrary in these instructions.

Copyright:

All rights reserved. Any reproduction of this Additional Instruction Manual, in any form, in whole or in part,

requires the prior written consent of FIFE.

The information given in this Additional Instruction Manual is subject to change without notice.

We have compiled this Additional Instruction Manual with the greatest possible care and attention:

however, the possibility of error can not be completely excluded. FIFE accepts no legal liability for

incorrect information given and the consequences arising therefrom.

Copyright 2002 FIFE Corporation, P.O. Box 26508, Oklahoma City, OK 73126, U.S.A.

FIFE GmbH,Postfach 1240, D-65762 Kelkheim/Ts., Germany

02-17-03 CDP-01 Figure Sheet 1-860

SUPPLEMENTARY OPERATING MANUAL iii

02-17-03 CDP-01 Figure Sheet 1-860

TABLE OF CONTENTS

GENERAL INTRODUCTION 1

APPLICATION DESCRIPTION..............................................................................................1-1

SOFTWARE PART NUMBERS.............................................................................................1-1

CONNECTING THE SYSTEM COMPONENTS....................................................................1-1

OVERVIEW OF FUNCTION 2

OPERATOR CONTROL OPTIONS.......................................................................................2-1

SPECIAL FEATURES OF EXTERNAL CONTROL ..............................................................2-1

INPUT MATRIX - EXTERNAL CONTROL.............................................................................2-2

EXPLANATION OF THE OPERATING MODES........................................................ 2-3 to 2-4

START UP / LEFT GUIDING SENSOR CALIBRATION.......................................................2-5

START UP / RIGHT GUIDING SENSOR CALIBRATION.....................................................2-6

START UP / SENSOR BANDWIDTH RATIO CALIBRATION..............................................2-7

START UP / GUIDE POLARITY............................................................................................2-8

TROUBLESHOOTING 3

FAULT DIAGNOSIS - FAULT RECTIFICATION...................................................................3-1

02-17-03 CDP-01 Figure Sheet 1-860

SUPPLEMENTARY OPERATING MANUAL 1

1-1

02-17-03 CDP-01 Figure Sheet 1-860

GENERAL INTRODUCTION

Application Description

Application is a Centerguide using 2 DAC sensors. A ratio calculation can be performed in the

case that the bandwidths of the 2 sensors are not equal.

Software Part Numbers

The software part numbers are located on the side of the CDP-01 housing. They include the

Matrix Setup no. (MS) , State Machine no. (SM) and firmware version ( Dx ).

CDP version: CDP-01-M or H D1:5650xx-02x MS: 100151.02x Please quote these

D2: SM: 100152.02x details with all inquiries.

D3: FIFEUSA

Connecting the System Components

The system components are to be connected according to the Cable Connection Diagram

contained in the documentation.

02-17-03 CDP-01 Figure Sheet 1-860

SUPPLEMENTARY OPERATING MANUAL 2

2-1

02-17-03 CDP-01 Figure Sheet 1-860

OVERVIEW OF FUNCTION

Operator Control Options

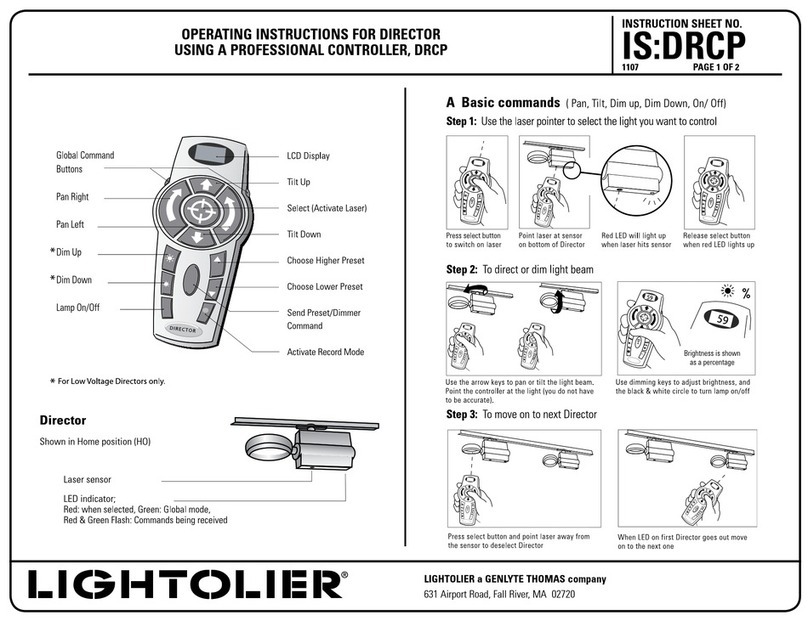

The CDP-01 signal amplifier can be operated by way of the CDP-01 control panel (internal

operation) or remotely through the Parallel port (external operation).

The symbols below are used for the various operator control options in the following:

Internal operation

External operation

Special Features of External Control

When the operation modes are being controlled via

external control, the Automatic, Servo-Center, Manual keys

of the CDP-01 control panel are disabled.

If the cable to the parallel port ( -X7 ) of the CDP-01 is

disconnected, the CDP-01 can be controlled via internal

control.

SUPPLEMENTARY OPERATING MANUAL 2

2-2

02-17-03 CDP-01 Figure Sheet 1-860

Input Matrix - External Control

Inputs CDP-01

Modes I5 I4 I3 I2 I1 I0

External Lock - - - - - H

Automatic - - L L H -

Manual - - L H L -

Servo Center - - H L L -

Jog Left L H - - - -

Jog Right H L - - - -

L = Low level

H = High level

- = any

SUPPLEMENTARY OPERATING MANUAL 2

2-3

02-17-03 CDP-01 Figure Sheet 1-860

Explanation of the Operating Modes

Note: All Start-up Procedures must be performed before Automatic and Servo

Center modes are used.

MANUAL

Press key 3 or Select ‘Manual’ via external control.

The active drives are switched to Manual.

Check: LED (3) lit.

Setup functions can be performed and sensor modes

selected, if desired.

‘Left’

‘Right’

Press the - or + key to set ‘Left’ or ‘Right’ to manually alter

the position of the drive.

JOG MANDREL LEFT / RIGHT

Select ‘Jog Left’ or ‘Jog Right’ via external control to

manually alter the position of the drive.

SUPPLEMENTARY OPERATING MANUAL 2

2-4

02-17-03 CDP-01 Figure Sheet 1-860

AUTOMATIC

The sensor mode must be pre-selected for Guiding.

’Automatic’

Press key 1 or Select ‘Automatic’ via external control.

The guide point or system gain can be altered, if desired.

Reference: CDP-01 Reference Manual, ‘Basic Settings’

section.

SERVO CENTER

‘Servo Center’

Press key 2 or Select ‘Center Mandrel’ via external

control.

The drive moves to the center of the stroke.

Check: LED 2 lit.

SUPPLEMENTARY OPERATING MANUAL 2

2-5

02-17-03 CDP-01 Figure Sheet 1-860

Start-up / Left Guiding Sensor Calibration

The following procedure must be performed while in Manual mode with all parallel inputs low.

Press the Setup key.

Press the Sensor key repeatedly until LED’s 8 and 9

light up.

Remove the web material fully out of the sensor field of

view.

Press the F1 key.

Bring web material fully into the sensor field of view.

Press the F2 key.

Press the Automatic key to store the settings.

or

Press the Manual key to abort the procedure.

SUPPLEMENTARY OPERATING MANUAL 2

2-6

02-17-03 CDP-01 Figure Sheet 1-860

Start-up / Right Guiding Sensor Calibration

The following procedure must be performed while in Manual mode with all parallel inputs low.

Press the Setup key.

Press the Sensor key repeatedly until LED’s 8 and 10

light up.

Remove the web material fully out of the sensor field of

view.

Press the F1 key.

Bring web material fully into the sensor field of view.

Press the F2 key.

Press the Automatic key to store the settings.

or

Press the Manual key to abort the procedure.

SUPPLEMENTARY OPERATING MANUAL 2

2-7

02-17-03 CDP-01 Figure Sheet 1-860

Start-up / Bandwidth Ratio Calibration

The following procedure must be performed while in Manual mode with all parallel inputs low.

Before proceeding, the bandwidth of the sensor and the stroke length of the mandrel must first be

determined.

NOTE: First, setup the sensor. Refer to documentation for connecting an oscilloscope. When

performing these steps, it is important that the strip be in the same plane as the production

material.

Press and hold the Left or Right Jog key until the web

material is located in the center of the 2 sensors.

Move the sensors out such that the web material is only

in a small portion of the bandwidth of each sensor.

Press and hold the F2 and F3 keys until LEDs 5 and 6

are lit (approximately 3 seconds).

Move each sensor in an equal distance such that the

web material covers most of the bandwidth of each

sensor.

Press the F2 key until LEDs 4 and 5 are lit.

After approximately 3 seconds, calculations will begin.

F2 and F3 LEDs will light and F1 LED will turn off.

Note: Approximately one minute is required for calculations

in this procedure. If it is desired to abort this procedure, press

and hold the Manual key until LEDs 5 and 6 turn off.

The previous calibration is retained.

Half way through the calculations (approximately 30

seconds), LED 6 will turn off.

Note: If it is desired to abort this procedure, press

and hold the Manual key until LED 5 turns off.

The previous calibration is retained.

When the calculations are complete (approximately 30

additional seconds), LED 5 will turn off.

SUPPLEMENTARY OPERATING MANUAL 2

2-8

02-17-03 CDP-01 Figure Sheet 1-860

Start-up / Guide Polarity

The following procedure must be performed with all parallel inputs low or the cable disconnected.

Press the Servo Center key. Verify that the guide moves

to the center of the stroke.

If the guide moves to either end, press the Manual key

and change the Servo Center polarity.

Reference: CDP-01 Reference Manual, Section “Servo

Center Polarity”.

Press the Sensor key repeatedly until LEDs 9 & 10 are

lit.

Press the Automatic key. Verify that the guide moves to

the center of the sensors.

If the guide moves to the end of stroke, press the

Manual key and change the guide polarity.

Reference: CDP-01 Reference Manual, Section

“Changing The Guide Direction”.

Press the Manual key to place the drive in Manual mode.

SUPPLEMENTARY OPERATING MANUAL 3

3-1

02-17-03 CDP-01 Figure Sheet 1-860

TROUBLESHOOTING

An incorrect setting on the CDP-01 is often the cause for incorrect or unwanted guiding

characteristics. Faults and the procedures for rectifying the faults are described in more detail in

the CDP-01 Reference Manual, Chapter ‘Frequent Setting Errors’. Application-specific faults are

explained below.

Fault Diagnosis - Fault Rectification

Fault: The sensor moves in the wrong direction in automatic mode.

Remedy: Select ‘Manual’ mode and change the polarity (guide direction) in EdgeR sensor mode

(LED 10 lit) for drive 1 if using a CDP-01-MH or for drive 3 if using a CDP-01-MHH.

Reference: CDP-01 Reference Manual, Section: “Changing The Guide Direction”

Fault: The mandrel moves to the end of stroke in automatic mode.

Remedy: Select ‘Manual’ mode and change the polarity (guide direction) in EdgeR sensor mode

(LED 10 lit) for drive 2.

Reference: CDP-01 Reference Manual, Section: “Changing The Guide Direction”

Fault: The mandrel moves an equal distance as the strip, but in the wrong direction in automatic.

Remedy: Select ‘Manual’ mode and perform the “Start-up / Position Transducer Calibration”

again, but reverse the directions of movement for the mandrel in the steps just before

pressing the ‘F1’ and ‘F2’ keys.

Fault: The sensor moves the wrong direction when placed in servo-center mode.

Remedy: Select ‘Manual’ mode and change the servo-center polarity for Drive 1 if using a CDP-

01-MH or for drive 3 if using a CDP-01-MHH.

Reference: CDP-01 Reference Manual, Section: “Servo Center Polarity”.

Fault: The mandrel moves to either end of the stroke instead of to the center of its stroke in

servo-center mode.

Remedy: Select ‘Manual’ mode and change the servo-center polarity for Drive 2.

Reference: CDP-01 Reference Manual, Section: “Servo Center Polarity”.

Fault: The mandrel does not accurately follow the strip while in automatic mode.

Remedy: Perform the procedure “Start-up / Sensor Positioner To Mandrel Ratio Calibration”

found in this document.

02-17-03 CDP-01 Figure Sheet 1-860

Other manuals for CDP-01

9

Table of contents

Other Fife Controllers manuals