CONTENTS

CONTENTS......................................................................................................... 5

DEFINITION OF LEVELS OF WARNING........................................................... 6

GENERAL SAFETY REGULATIONS ................................................................. 6

GENERAL DESCRIPTION ................................................................................. 6

SYMBOLS USED IN THE MANUAL........................................................................................ 7

TARGET GROUP .................................................................................................................... 7

PURPOSE AND CONTENT OF THE USER AND MAINTENANCE MANUAL ....................... 7

STORING THE USE AND MAINTENANCE MANUAL ............................................................ 8

ON DELIVERY OF THE APPLIANCE ..................................................................................... 8

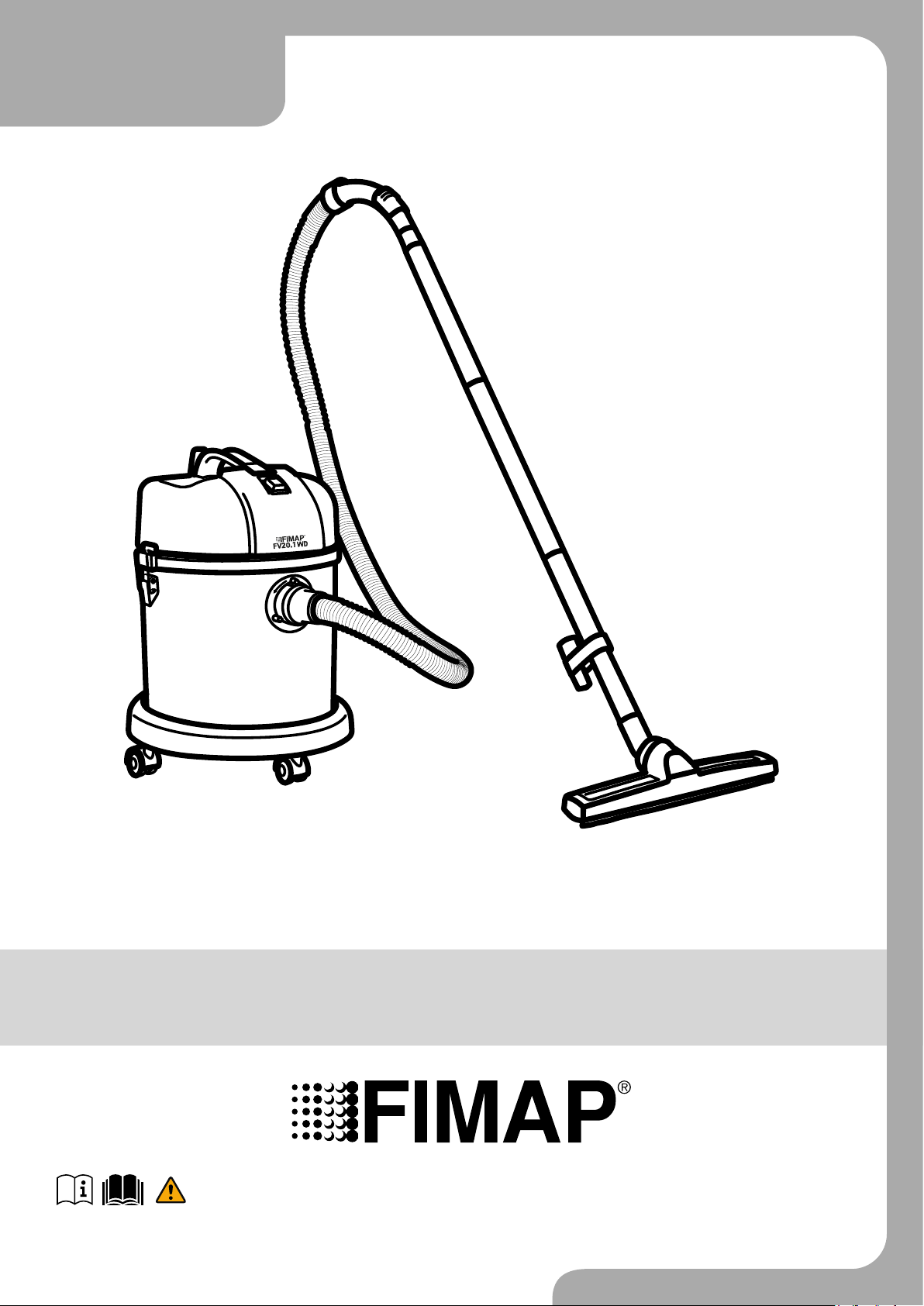

TECHNICAL DESCRIPTION................................................................................................... 8

INTENDED USE...................................................................................................................... 8

SAFETY................................................................................................................................... 8

SERIAL NUMBER PLATE ....................................................................................................... 9

TECHNICAL DATA ............................................................................................. 9

PREPARING THE APPLIANCE........................................................................ 10

HANDLING THE PACKED APPLIANCE ............................................................................... 10

HOW TO UNPACK THE APPLIANCE................................................................................... 10

HOW TO TRANSPORT THE APPLIANCE............................................................................ 10

APPLIANCE SAFETY.............................................................................................................11

INSERTING THE FILTER - COLLECTION BAG (OPTIONAL) ..............................................11

WORK PREPARATION CHECKLIST............................................................... 12

STARTING WORK (DRY VACUUM CLEANER) .............................................. 13

STARTING WORK (WET VACUUM CLEANER).............................................. 13

AT THE END OF THE WORK........................................................................... 14

EMPTYING THE COLLECTION TANK ................................................................................. 15

ROUTINE MAINTENANCE............................................................................... 16

EXTRAORDINARY MAINTENANCE................................................................ 17

REPLACING THE CARTRIDGE FILTER .............................................................................. 17

SELECTION AND USE OF THE ACCESSORY ............................................... 18

DISPOSAL ........................................................................................................ 19

TROUBLESHOOTING...................................................................................... 19

EC DECLARATION OF CONFORMITY ........................................................... 20

UKCA DECLARATION OF CONFORMITY ...................................................... 21

Page 5 of 24