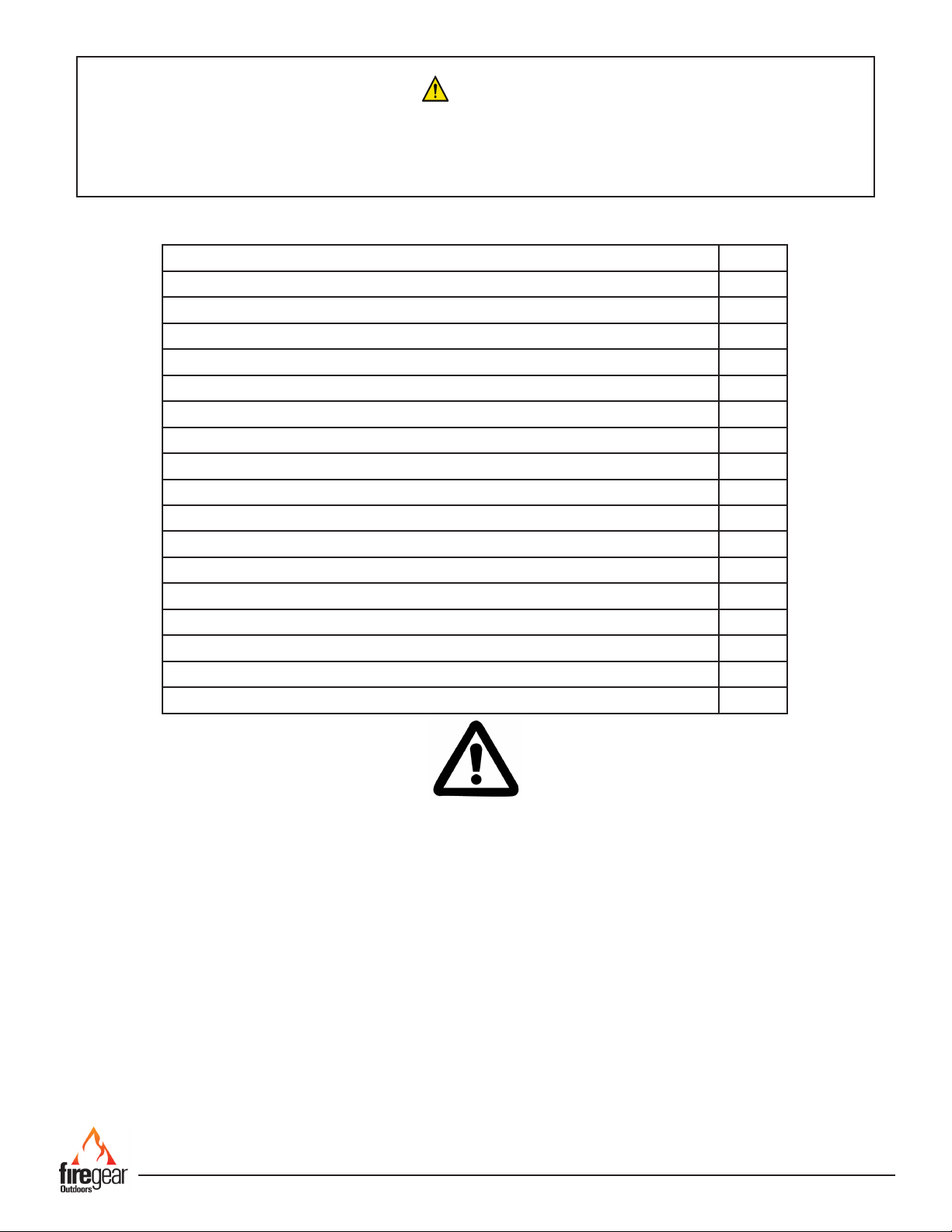

REFERENCE

GAS PIPE SIZING

Length of Pipe in Feet 1/2” 3/4” 1” 1 - 1/4” 1 - 1/2” 2” 2 - 2 1/2” 3” 4”

10 275 567 1071 2205 3307 6221 10140 17990 35710

20 189 393 732 1496 2299 4331 7046 12510 25520

30 152 315 590 1212 1858 3465 5695 10110 20620

40 129 267 504 1039 1559 2992 4778 8481 17300

50 114 237 448 913 1417 2646 4343 7708 15730

60 103 217 409 834 1275 2394 3908 6936 14150

70 89 185 346 724 1086 2047 3329 5908 12050

80 78 162 307 630 976 1811 2991 5309 10830

90 69 146 275 567 866 1606 2654 4711 9613

100 63 132 252 511 787 1496 2412 4281 8736

125 54 112 209 439 665 1282 2083 3618 7382

150 48 100 185 390 590 1138 1808 3210 6549

175 43 90 168 353 534 1030 1637 2905 5927

200 40 83 155 325 491 947 1505 2671 5450

300 37 77 144 303 458 887 1404 2492 5084

NATURAL GAS : PIPE SIZING CHART

•

Natural Gas (NG) flow is given in

thousands of BTU/hr. = 1cubic

foot of NG gas - 1000 BTU

•

Nominal pressure at the burner

for Natural Gas is 3.5” of water

column. (Typical machine supply

5”-7”)

•

Pipe length must include

additional length for all fittings.

Add approximately 5 feet of pipe

per fitting.

•

Natural Gas Example: A machine

with a burner that requires

440,000 BTU would need a 1 -1/4”

pipe for a 20” long run.

LIQUID PROPANE : PIPE SIZING CHART

NOTE: The sizing charts above list the specific pipe sizes required for the amount of BTU’s for a new gas line installations. If you

are using an existing gas line you must take into consideration the existing gas line capacities to ensure you will have proper

pressure. This chart is for reference only, we recommend you consult with a Licensed Plumber/Gas Fitter or NFPA54 (National Fuel

Gas Code - current edition) for more details.

Length of Pipe in Feet 1/2” 3/4” 1” 1 - 1/4” 1 - 1/2” 2” 2 - 2 1/2” 3” 4”

10 108 230 387 793 1237 2259 3640 6434 -

20 75 160 280 569 877 1610 2613 5236 9521

30 61 129 224 471 719 1335 2165 4107 7859

40 52 110 196 401 635 1143 1867 3258 6795

50 46 98 177 364 560 1041 1680 2936 6142

60 42 89 159 336 513 957 1559 2684 5647

70 38 82 149 317 476 896 1447 2492 5250

80 36 76 140 239 443 840 1353 2315 4900

90 33 71 133 275 420 793 1288 2203 4667

100 32 68 126 266 411 775 1246 2128 4518

125 28 60 117 243 369 700 1143 1904 4065

150 25 54 105 215 327 625 1008 1689 3645

175 23 50 93 196 303 583 993 1554 3370

200 22 47 84 182 280 541 877 1437 3160

300 17 37 70 145 224 439 686 1139 2539

•

Liquid Propane (LP) Gas flow is

given in thousands of BTU/hr. =

1cubic foot of LP gas - 2500 BTU.

•

This chart refers to low pressure LP,

after regulation, Standard nominal

pressure at the burner for Liquid

Propane Gas is 11” of water column.

•

Pipe length must include additional

length for all fittings. Add

approximately 5 feet of pipe per

fitting.

•

LP Example: A machine with a

burner that requires 440,000 BTU

would need a 1” pipefor a 20’ long

run.