Fireye MBCE-110UV Series User manual

This manual suits for next models

7

Table of contents

Other Fireye Control Unit manuals

Fireye

Fireye M4RT1 User manual

Fireye

Fireye BurnerLogiX YB110 User manual

Fireye

Fireye EP160 User manual

Fireye

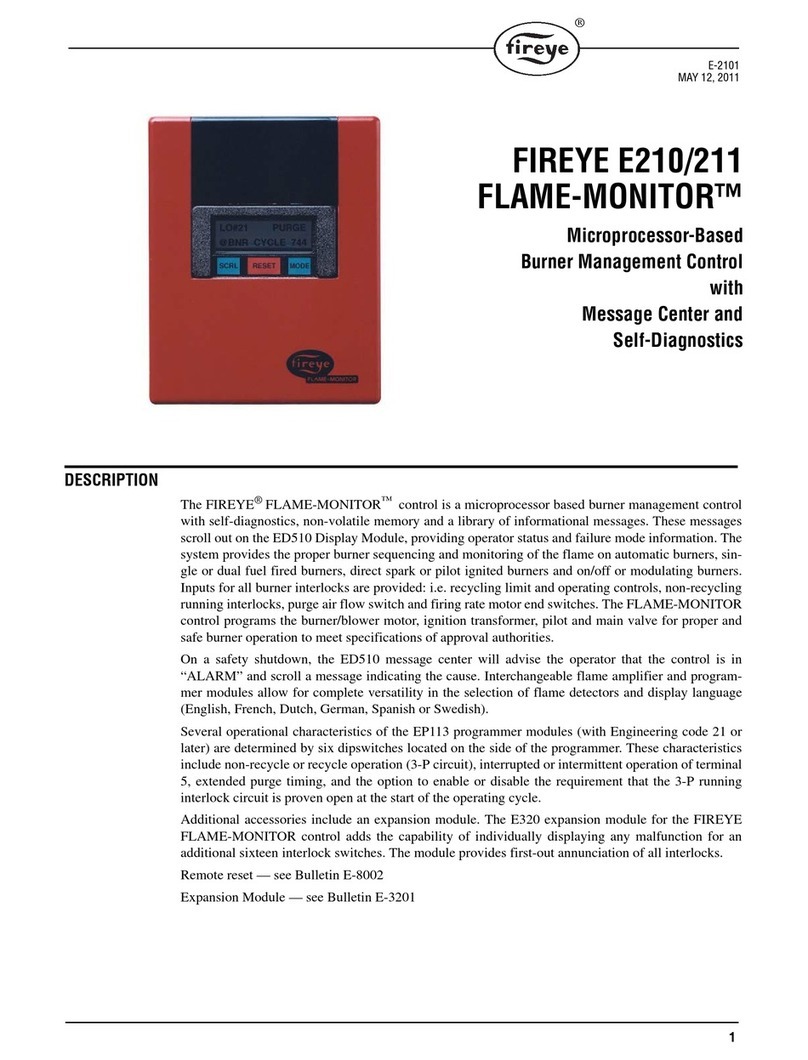

Fireye FLAME-MONITOR E210 User manual

Fireye

Fireye FlameWorx MBUV-100D User manual

Fireye

Fireye MicroM Series User manual

Fireye

Fireye MBCE-110FR User manual

Fireye

Fireye SureFire User manual

Fireye

Fireye E300 User manual

Fireye

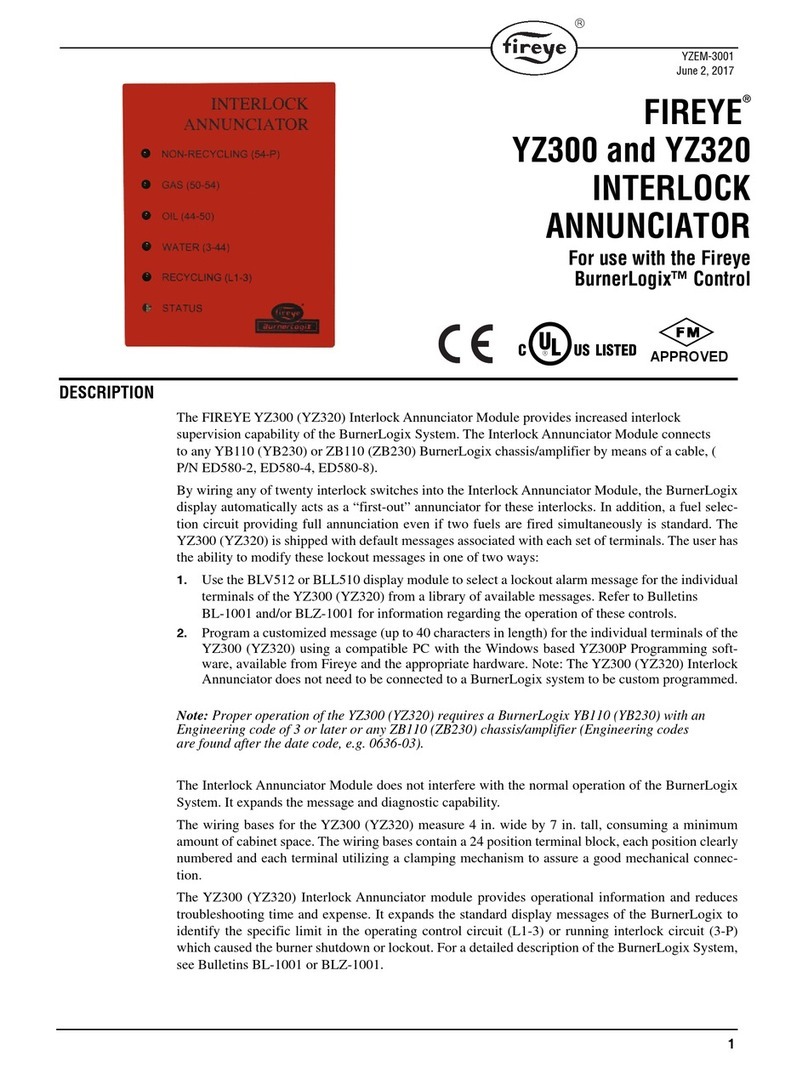

Fireye YZ300 User manual

Popular Control Unit manuals by other brands

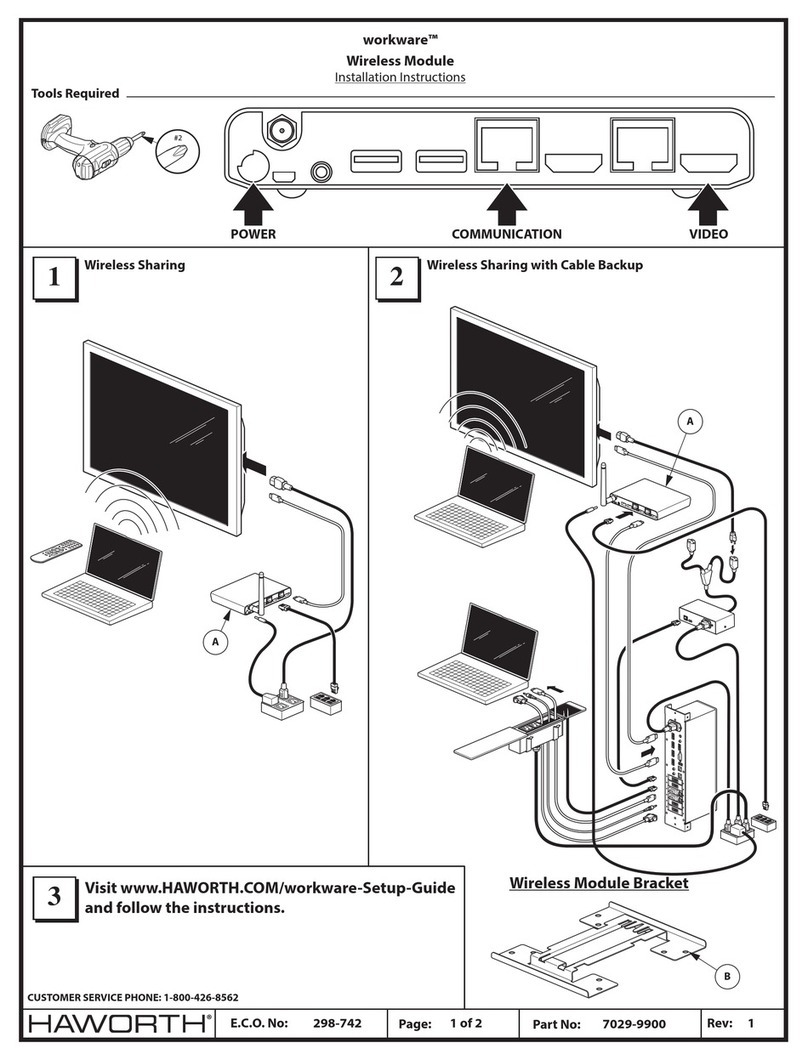

Haworth

Haworth workware installation instructions

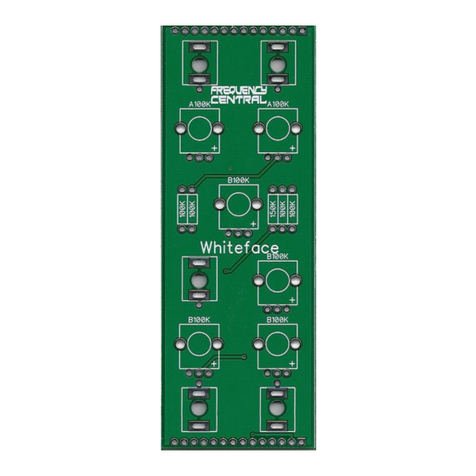

Frequency Central

Frequency Central Whiteface Build documentation

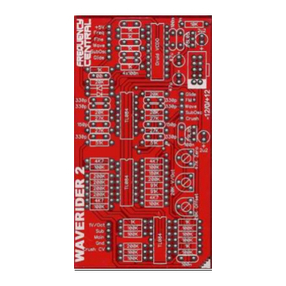

Frequency Central

Frequency Central Waverider VCDO MKii Build documentation

Metaltecnica

Metaltecnica 0080 Installation, operation & maintenance manual

Honeywell

Honeywell V48F Product data

Exhausto

Exhausto OJ GreenZone Module A instructions

ADLINK Technology

ADLINK Technology HSL-DI32-UD quick start guide

jbc

jbc NAU instruction manual

Sentiotec

Sentiotec Pro B2 Instructions for installation and use

Jetter

Jetter JXM-IO-E30 user manual

P.A.

P.A. VS 1200 FL instructions

Marshall Excelsior

Marshall Excelsior ME990-3F Installation and operating manual