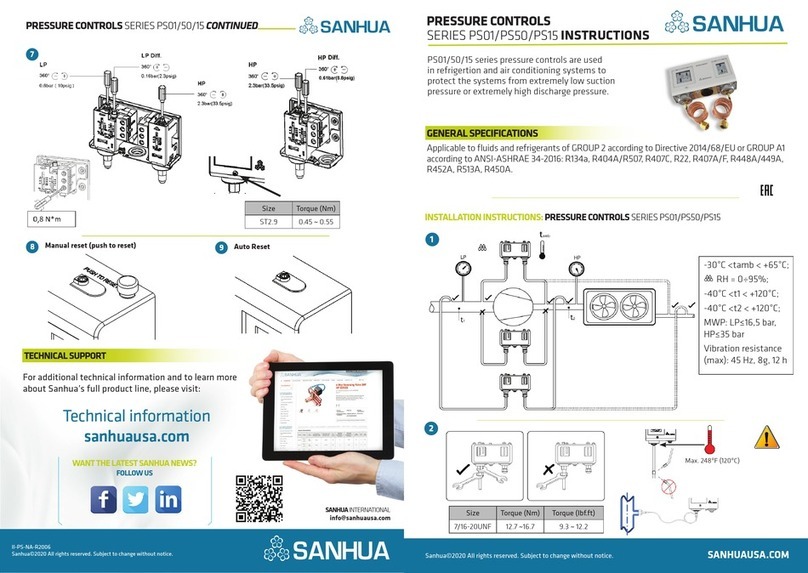

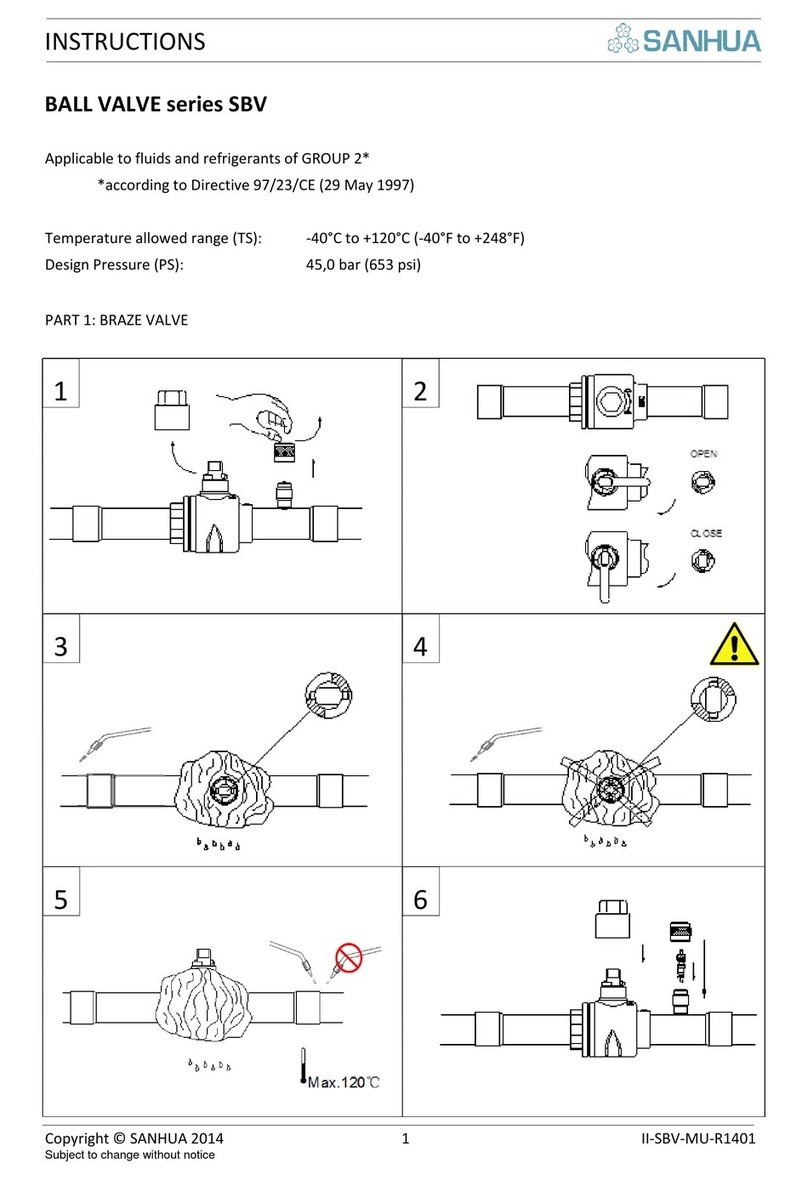

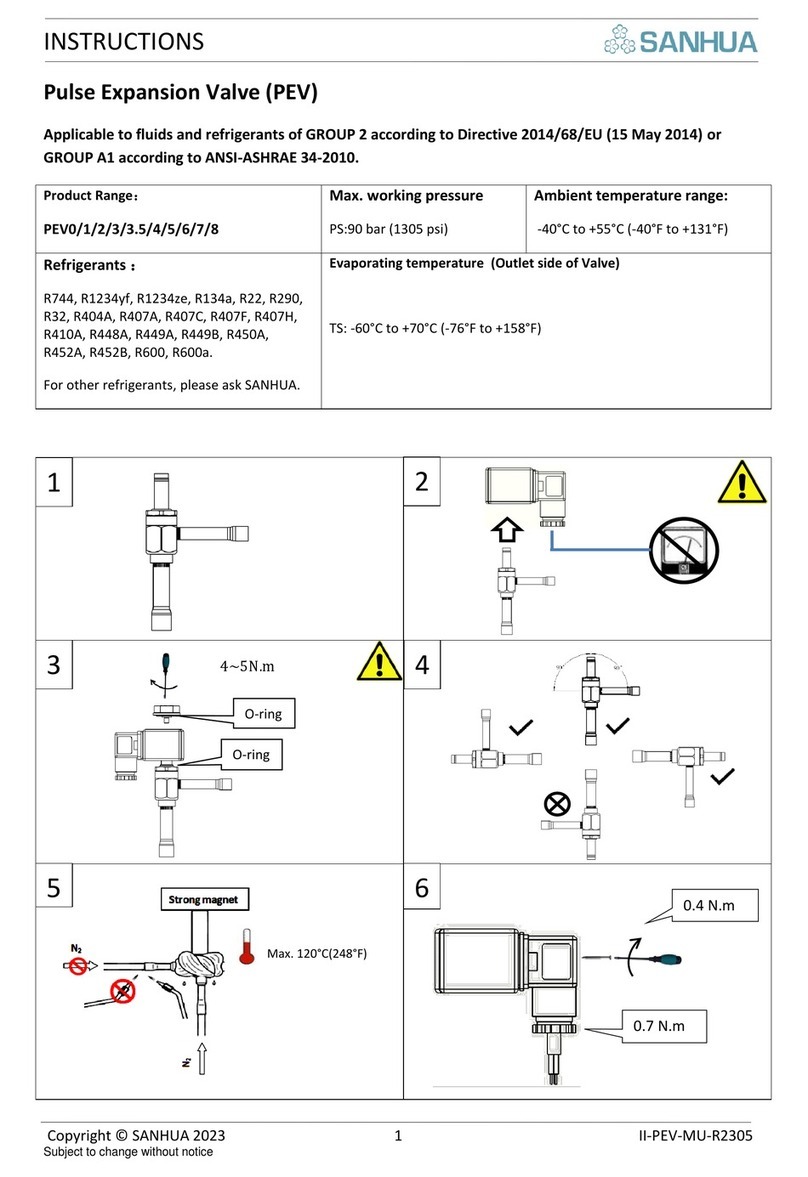

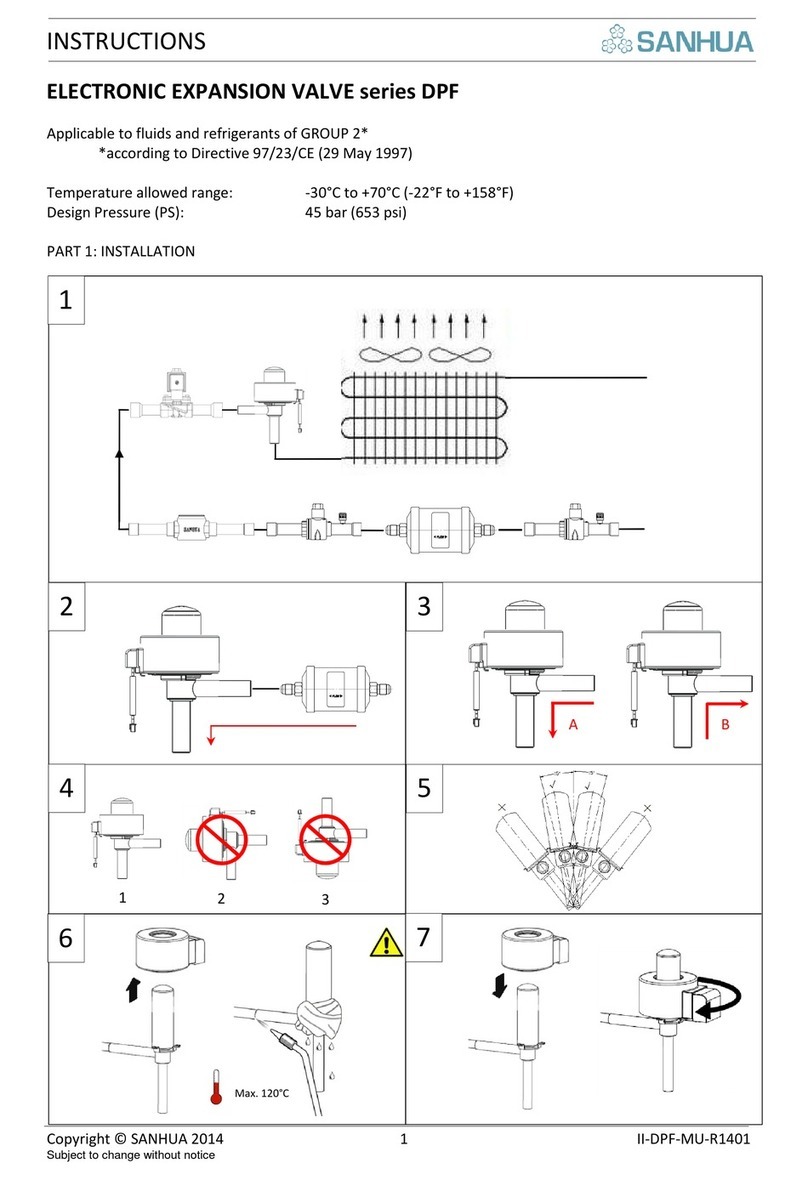

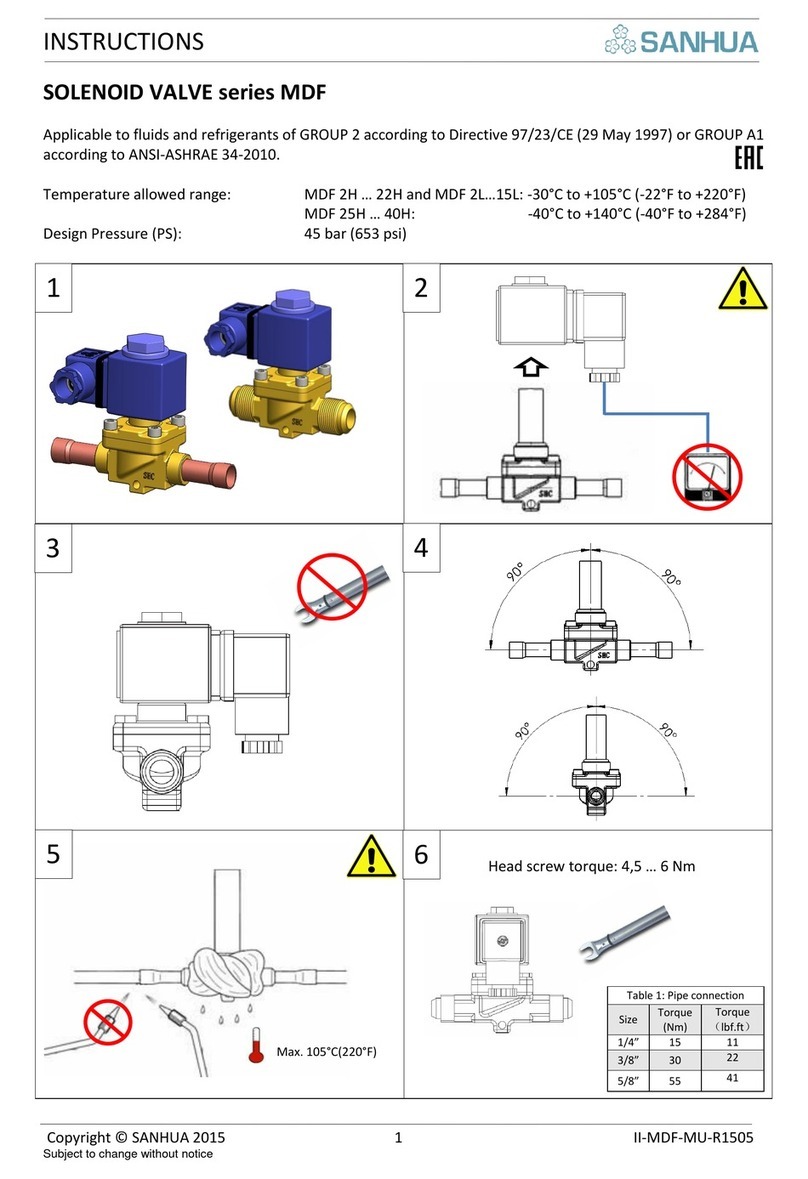

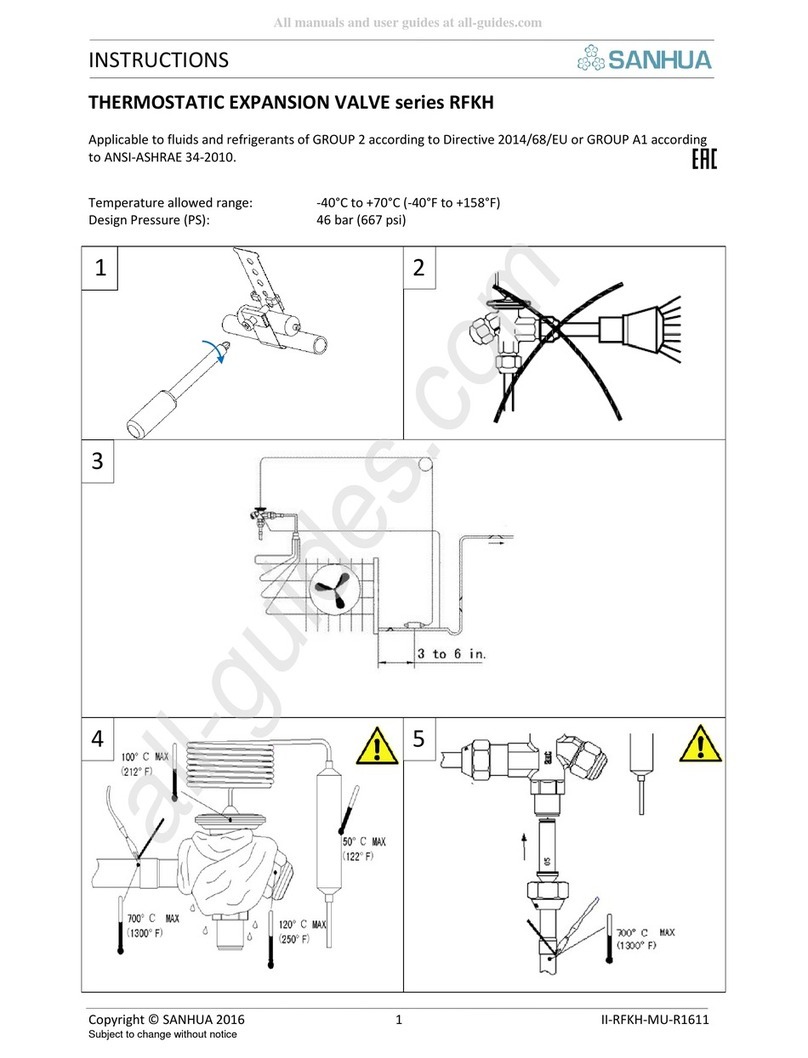

INSTRUCTIONS

Copyright © SANHUA 2015 II-RFGD-MU-R1504

Subject to change without notice

ACTION Chinese English Français Deutsch Italian Españ l

1

产品标识基本信息

Fix the bulb on the pipe (su tion

line) using a lamp as shown in

the pi ture

Fixer le bulbe sur la ligne

d’aspiration en utilisant un

ollier omme montré sur le

s héma

Thermofühler mit einer

S helle gemäß Bild am

Saugleitungsrohr befestigen.

Fissare il bulbo sul tubo della

linea di aspirazione usando un

morsetto ome in figura

Fijar el bulbo en el tubo de la

línea de aspira ión usando

una abrazadera omo en la

figura.

2

焊接时各部温度控

制

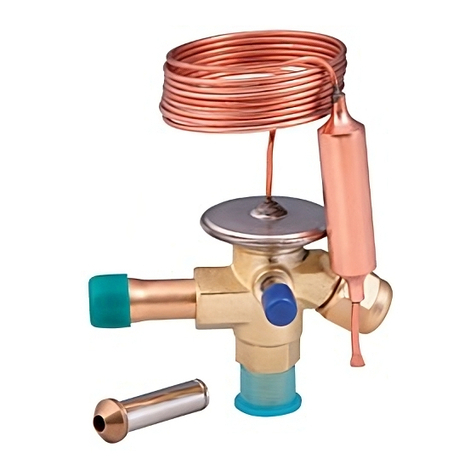

Respe t the orre t installing

position in the plant admitted for

the thermostati expansion valve

(TEV). Evaporators with liquid

distributors need TEV with

external equalization (fig.A)

Positionner orre tement la

vanne d’expansion

thermostatique dans

l’installation. Les

évaporateurs ave

distributeurs ont besoin de

TEV ave égalisation externe

Korrekte Einbaulage des

thermostatis hen

Expansionsventiles (TEV)

innerhalb der Anlage

bea hten. Verdampfer mit

Flüssigkeitsverteiler

benötigen TEV mit externem

Dru kausglei h

Rispettare la orretta

posizione di installazione

nell’impianto ammessa per la

valvola di espansione

termostati a (TEV). Gli

evaporatori on distributore

di liquido ne essitano di una

TEV on equalizzazione

esterna

Respetar la posi ión orre ta

de instala ión en el equipo

admitido por la válvula de

expansión termostáti a (TEV).

Los evaporadores on

distribuidor de líquido

ne esitan una TEV on

iguala ión externa

3

系统安装位置要

求,注意不要折弯

气箱盖连接的毛

细管

Install the bulb on the su tion

line a ording to the position

shown in the pi ture. Respe t

the minimum length L (verti al

distan e between the valve and

the liquid distributor). It must be

L > 7 x D (D= pipe diameter).

Install the bulbe lose to the

evaporator (from 3 to 6 in.)

Installer le bulbe sur la ligne

d’aspiration selon la position

indiquée sur le s héma.

Respe ter la distan e

minimum L (distan e verti ale

entre la vanne et le

distributeur). Elle doit

respe ter la règle L > 7xD (où

D est le diamètre du tube

uivre). Installer le bulbe près

de l’évaporateur (de 3 à 6

pou es)

Thermofühler gemäß Bild an

der Saugleitung befestigen.

Minimalen Abstand L

einhalten (vertikaler Abstand

zwis hen Ventil und

Flüssigkeitsverteiler). Es muss

L > 7 x D (D=

Rohrdur hmesser)

eingehalten werden. Den

Fühler nahe am Verdampfer

montieren (von 3 bis 6 in.;

von 75 bis 150mm)

Installare il bulbo sulla linea di

aspirazione se ondo la

posizione mostrata in figura.

Rispettare la lunghezza

minima L (distanza verti ale

fra la valvola e il distributore

di liquido). Deve essere

L > 7 x D (D= diametro del

tubo). Installare il bulbo vi ino

all’evaporatore (da 3 a 6

polli i)

Instalar el bulbo en la línea de

aspira ión según la posi ión

mostrada en la figura.

Respetar la longitud mínima L

(Distan ia verti al entre la

válvula y el distribuidor de

líquido). Debe ser L>7 x

D(D= diámetro) del tubo).

Poner el tubo er a de la

salida del evaporador ( de 3 a

6 pulgadas)

4

感温包安装位置及

固定

SOLDER VERSION: Braze inlet,

outlet and (if present) external

equalization onne tions of TEV

using spe ifi alloy (SilFos 15).

Use a wet rag on the valve

during the brazing pro ess

VERSION A BRASER: Braser les

onne tions d’entrée, de

sortie et (si présent)

d’égalisation externe en

utilisant un alliage spé ifique

(type SilFos 15). Pla er un

hiffon mouillé sur le orps de

la vanne pendant le brasage.

LÖTVERSION: Eingang,

Ausgang und (falls vorhanden)

externen Ausglei h einlöten

unter Verwendung spezieller

Legierung (SilFos 15).

Während des Lötvorgangs das

Ventil mit nassem Lappen

umwi keln.

VERSIONE A SALDARE:

Brasare le onnessioni di

ingresso, us ita e (se

presente) di equalizzazione

usando una lega spe ifi a

(SilFos 15). Usare uno stra io

bagnato sulla valvola durante

il pro esso di brasatura.

VERSION SOLDAR: Soldar las

onexiones de entrada, salida

y (si presente) de la iguala ión

usando una alea ión

espe ífi a (SilFos 15). Poner

un paño húmedo en ima de la

válvula durante el pro eso de

soldadura.

5

过热度的测量 计

算;注意

MOP

类产

品要求阀体所处的

环境温度要高于感

温包温度

THREAD VERSION: Braze the

inlet onne tion to a solder

adaptor using spe ifi alloy

(SilFos 15). Insert into the body

valve the internal orifi e

VERSION A VISSER:

Braser la onne tion d’entrée

à un adaptateur à souder en

utilisant un alliage spé ifique

(type SilFos 15). Insérer

l’orifi e interne dans le orps

de la vanne.

GEWINDEVERSION:

Eingangsverbindung mit

einem Lötadapter verlöten

unter Verwendung spezieller

Legierung (SilFos 15). Die

interne Düse in das

Ventilgehäuse einfügen.

VERSIONE AD AVVITARE

Brasare la onnessione di

ingresso ad un adattatore a

saldare usando una lega

spe ifi a (SilFos 15). Inserire

nel orpo valvola l’orifi io

interno.

VERSION ROSCAR: Soldar la

onexión ros ada a un

adaptador a soldar usando

una alea ión espe ífi a (SilFos

15). Introdu ir el orifi io

interno en el uerpo de la

válvula.

6a

逆时针调整调节杆

将过热度调小,蒸

发温度

5

℃调整一圈

过热度变化参考表

2

Tighten the adaptor to the

thread onne tion respe ting the

torque values. ATTENTION: use

the two wren hes as shown in

the pi ture.

Serrer l’adaptateur sur la

onne tion vissée en

respe tant les valeurs de

ouples.

ATTENTION : Utiliser 2 lés de

serrage omme illustré sur le

s héma.

Den Adapter mit der

Gewindeverbindung

befestigen unter

Berü ksi htigung der

Drehmomente. ACHTUNG :

Zwei S hlüssel benutzen wie

im Bild dargestellt.

Serrare l’adattatore alla

onnessione filettata

rispettando i valori di oppia

riportati.

ATTENZIONE: usare le due

hiavi ome mostrato in

figura.

Ajustar el adaptador a la

onexión ros ada repetando

los valores de Par de Ajuste.

ATENCION: Usar las dos llaves

omo se muestra en la figura.

6b

顺时针调整调节杆

将过热度调大,蒸

发温度

5

℃调整一圈

过热度变化参考表

2

After the TEV installation, he k

that: the evaporator inlet

temperature (t2) must be bigger

than the evaporator outlet

temperature (t1 = temperature

measured by the bulb)

Après avoir installé la vanne,

vérifier que la température

d’entrée de l’évaporateur (t2)

est supérieure à la

température de sortie de

l’évaporateur (t1 mesurée par

le bulbe)

Na h Installation des TEV

si herstellen, dass die

Verdampfereintrittstemperat

ur (t2) höher ist als die

Verdampferaustrittstemperat

ur (t1 = vom Fühler

gemessene Temperatur).

Dopo l’installazione della TEV

ontrollare he: la

temperatura di ingresso

all’evaporatore (t2) deve

essere maggiore della

temperatura di us ita

dall’evaporatore (t1 =

temperatura misurata dal

bulbo)

Después de la instala ión de

la TEV, omprobar que: la

temperatura de la entrada al

evaporador (t2) ha de ser

mayor que la temperatura de

salida(t1=temperatura

medida por el bulbo).

6

出厂设置(有或

无

MOP

功能)仅对

标准品提供。可以

自定义过热度值

(∆Tsh )

Fa tory presetting of TEV (with

or without MOP) is just provided

on standard produ ts. It is

possible to ustomize the

superheat value (∆Tsh ) setting:

Le préréglage d’usine des TEV

(ave ou sans MOP) est

uniquement effe tué sur les

omposants standards. Il est

possible de personnaliser la

valeur de désur hauffe

(∆Tsh)

Werkseinstellung von TEV

(mit oder ohne MOP) wird nur

bei Standardprodukten

vorgenommen.

Kundenspezifis he Einstellung

der Überhitzung (∆Tsh) ist

mögli h :

Nei prodotti standard è

fornito un pre-settaggio di

fabbri a della TEV ( on o

senza MOP). E’ possibile

personalizzare il settaggio del

surris aldamento ∆Tsh:

El produ to estándar de la

TEV ( on o sin MOP) lleva un

ajuste de fábri a. Es posible

personalizar el ajuste del

super alentamiento

∆Tsh:

6d

用螺丝刀顺时针拧

紧螺钉到需要的过

热度

∆Tsh

(具体见

表

2

)

Turn the regulation s rew in

lo kwise until the desired ∆Tsh

value (see table 2 for details)

Tourner la vis de régulation

dans le sens des aiguilles

d’une montre jusqu’à la

valeur désirée (∆Tsh). Se

référer à la table 2 pour les

détails.

Die Einstells hraube im

Uhrzeigersinn drehen, bis die

gewüns hte Überhitzung

∆Tsh errei ht wird (Siehe

Tab.2 für Details)

Girare in senso orario la vite

di regolazione fino al

raggiungimento del valore

ri hiesto di ∆Tsh (vedi tabella

2 per dettagli)

Girar el tornillo de regula ión

en el sentido del reloj hasta el

valor deseado (ver Tabla 2

para detalles) del ∆Tsh