FLOJET 4105 Series User manual

Other FLOJET Water Pump manuals

FLOJET

FLOJET R3526144 User manual

FLOJET

FLOJET G70C Series Owner's manual

FLOJET

FLOJET 18555-000 User manual

FLOJET

FLOJET 4305-144 User manual

FLOJET

FLOJET R3B21 Series User manual

FLOJET

FLOJET 4300 Series User manual

FLOJET

FLOJET N5100 Series Guide

FLOJET

FLOJET 03526-144 User manual

FLOJET

FLOJET R4515-743 User manual

FLOJET

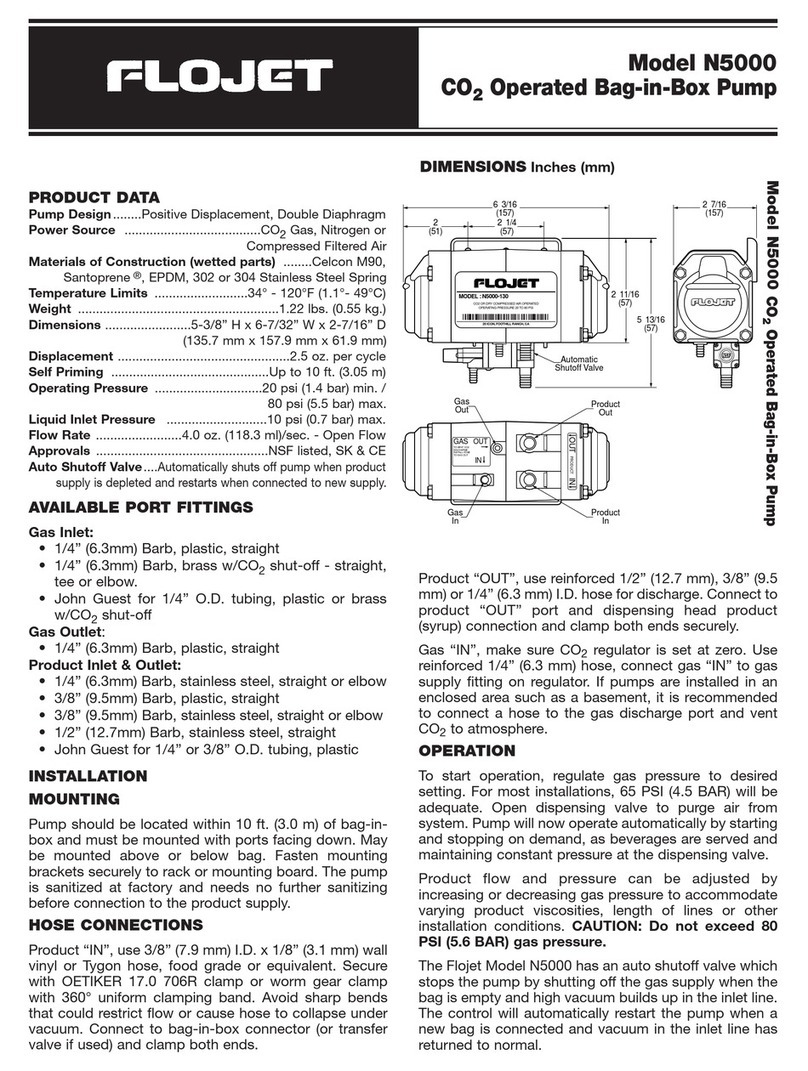

FLOJET N5000 User manual

FLOJET

FLOJET G573 User manual

FLOJET

FLOJET 2100-12 User manual

FLOJET

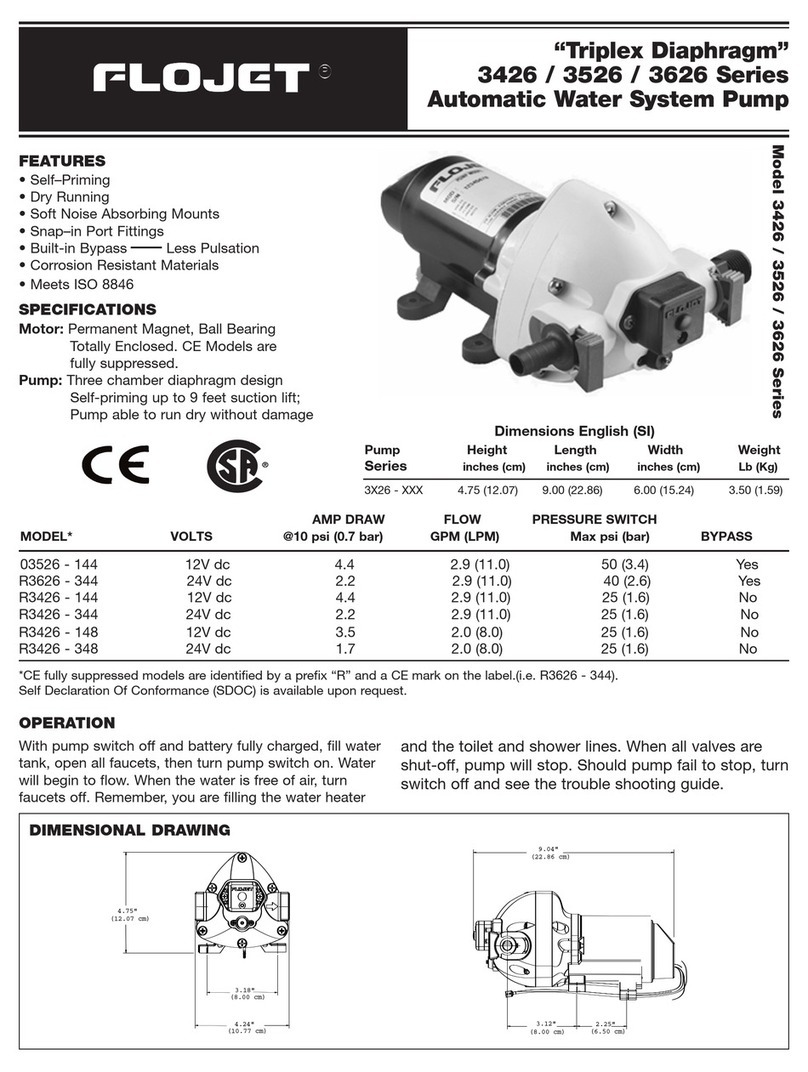

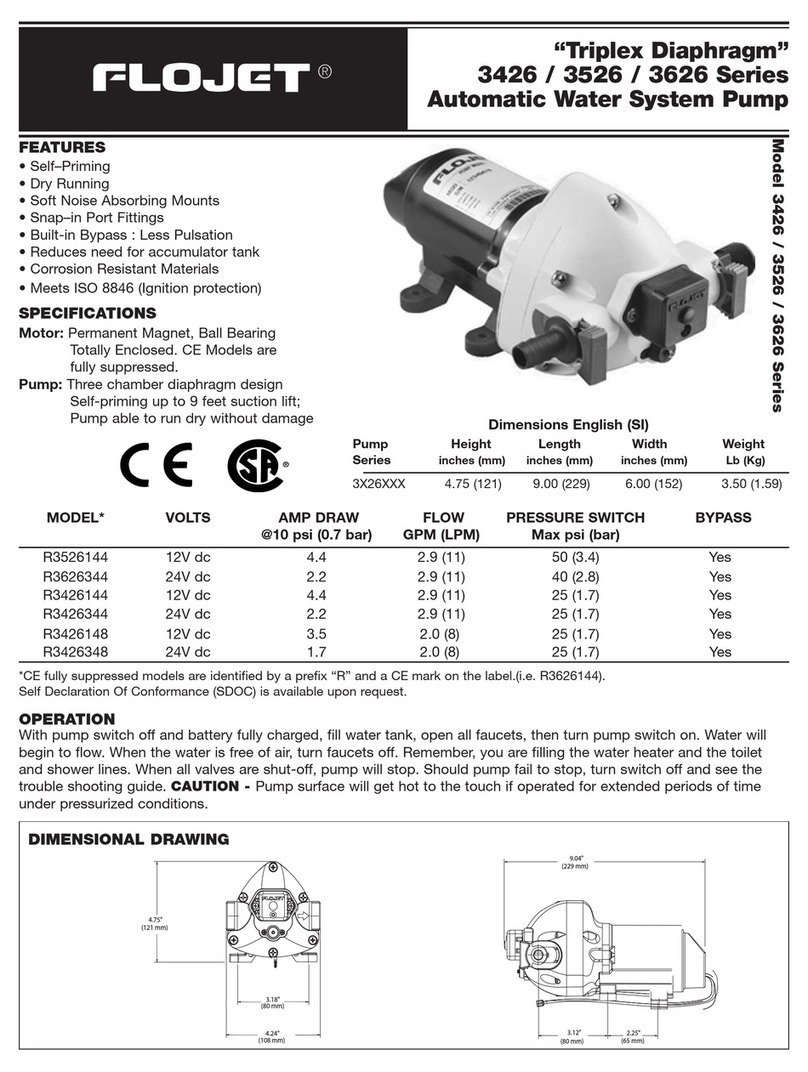

FLOJET Triplex Diaphragm 3426 Series User manual

FLOJET

FLOJET N5100-010 Guide

FLOJET

FLOJET quad II diaphragm 4125 series User manual

FLOJET

FLOJET BevJet Compact User manual

FLOJET

FLOJET G257 Series Guide

FLOJET

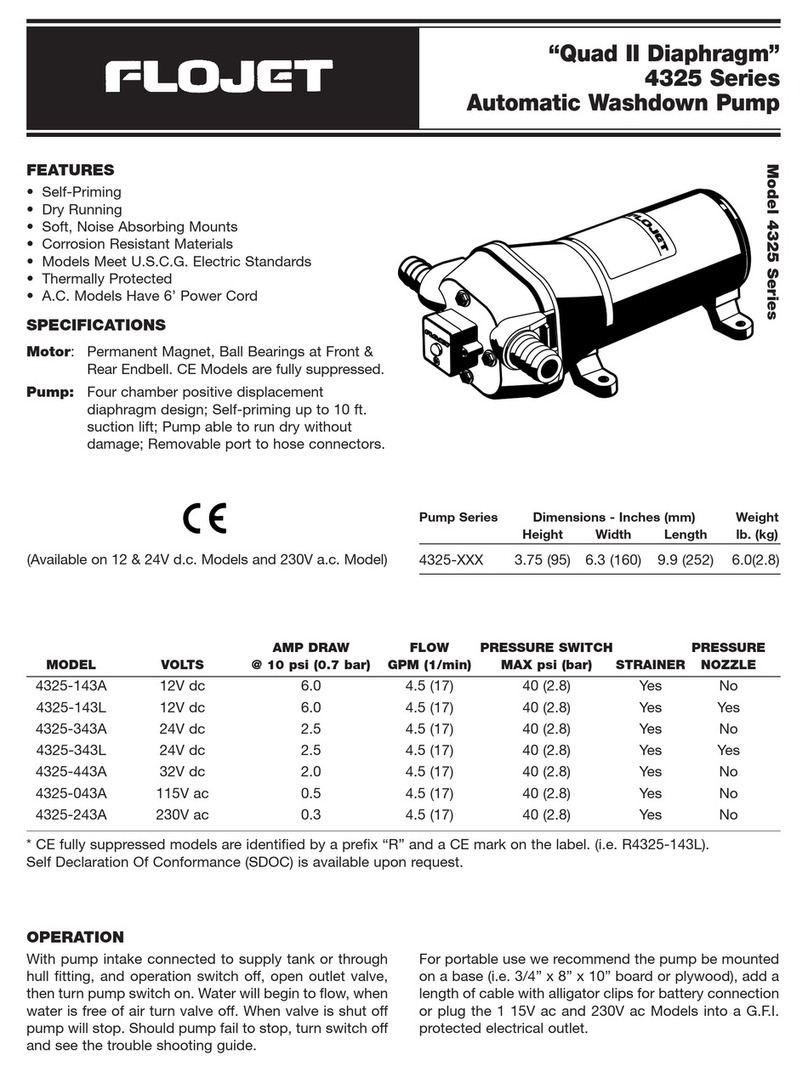

FLOJET 4325 Series User manual

FLOJET

FLOJET G56 User manual

FLOJET

FLOJET 2125 Series User manual

Popular Water Pump manuals by other brands

Agilent Technologies

Agilent Technologies TriScroll 300 Installation and operation manual

Stenner Pumps

Stenner Pumps ECON FP Series Installation and maintenance manual

BUSCH

BUSCH MINK MM 0084 A instruction manual

BUSCH

BUSCH RA 0165 D instruction manual

Denison Hydraulics

Denison Hydraulics P11S Series Service information

Sulzer

Sulzer XFP PE1 Installation, Operating and Maintenance Instruction

Crane

Crane BARNES PRESSURE SYSTEMS omni GRIND plus ULTRA GRIND OGP2022AUE... installation manual

Wright flow

Wright flow Cocept SQ Installation, operation and maintanance manual

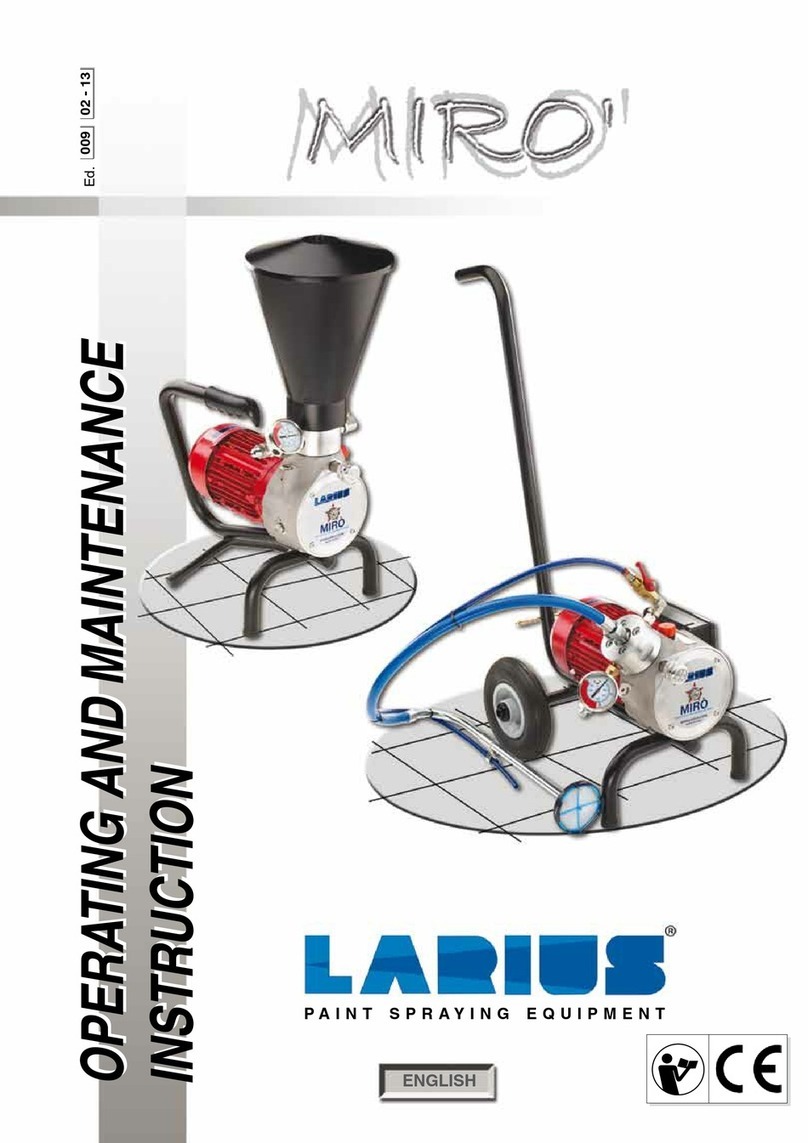

Larius

Larius MIRO Series Operating and maintenance instruction

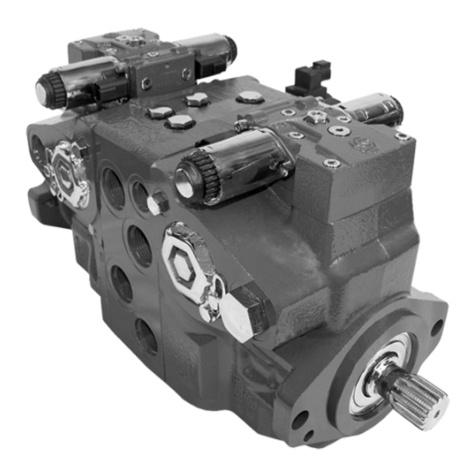

Danfoss

Danfoss H1 Series technical information

EBARA

EBARA DLFU instruction manual

RICE HYDRO

RICE HYDRO EL Series quick start guide

Harrop

Harrop ZL1 installation guide

Gotec

Gotec HIGH-LIFT Instruction manual and maintenance

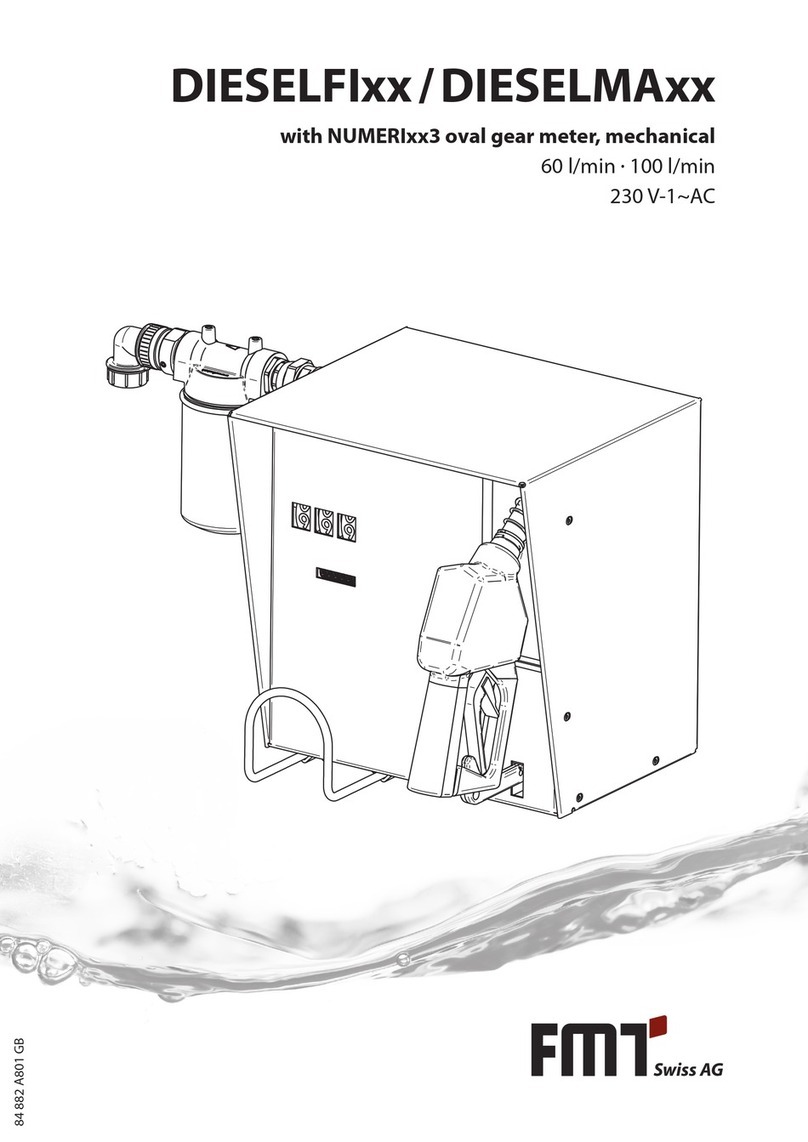

FMT

FMT DIESELFI Series operating instructions

Pentair

Pentair Sta-Rite DMC Series Installation and operation manual

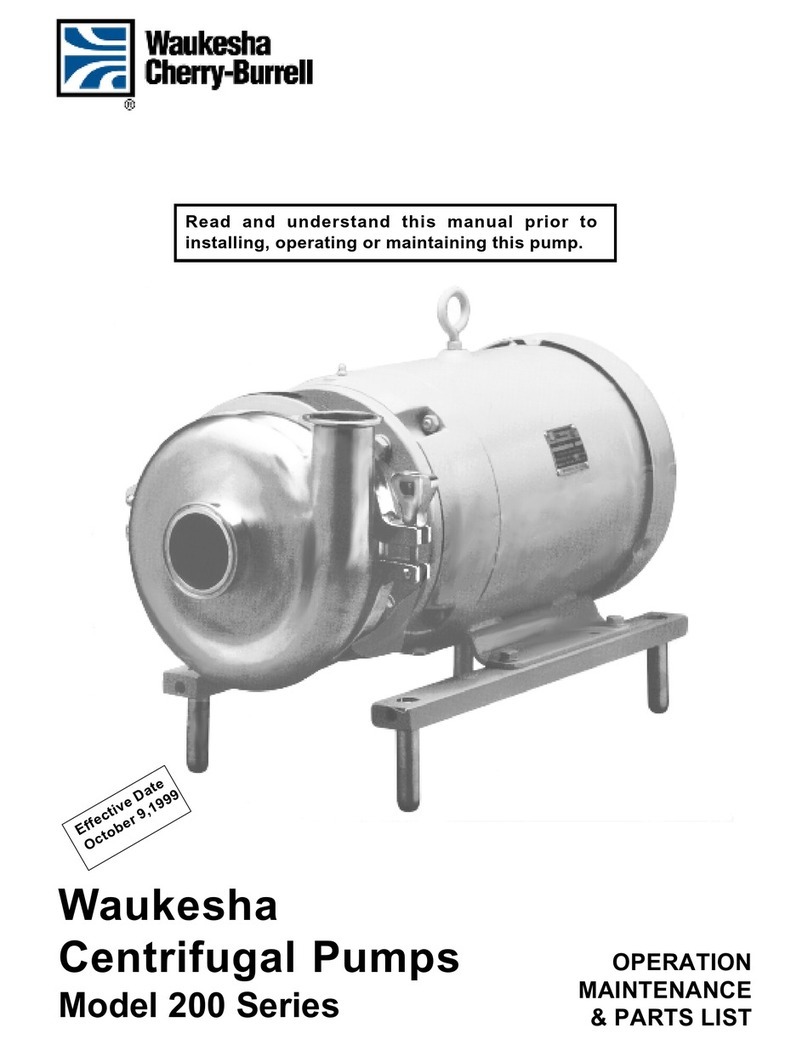

Waukesha

Waukesha 200 series Operation, maintenance and parts manual

Grundfos

Grundfos SCALA Installation and operating instructions