© Copyright 2001, ITT Industries Printed in U.S.A. All Rights Reserved Form: 81000-343 11/01

UNITED KINGDOM

Flojet, Unit 1, Avant Business Centre

Denbigh West Industrial Estate

Milton Keynes, Bucks, England MK1 1DL

Tel: 44 1908 370088

Fax: 44 1908 373731

U.S.A.

Flojet

20 Icon

Foothill Ranch, CA 92610-3000

Tel: (949) 859-4945

Fax: (949) 859-1153

Standard installation of a three pump / three

transfer valve assembly on a riser/spacer

(See front mount)

Fig. #9

Standard five pump assembly installation

Fig. #10

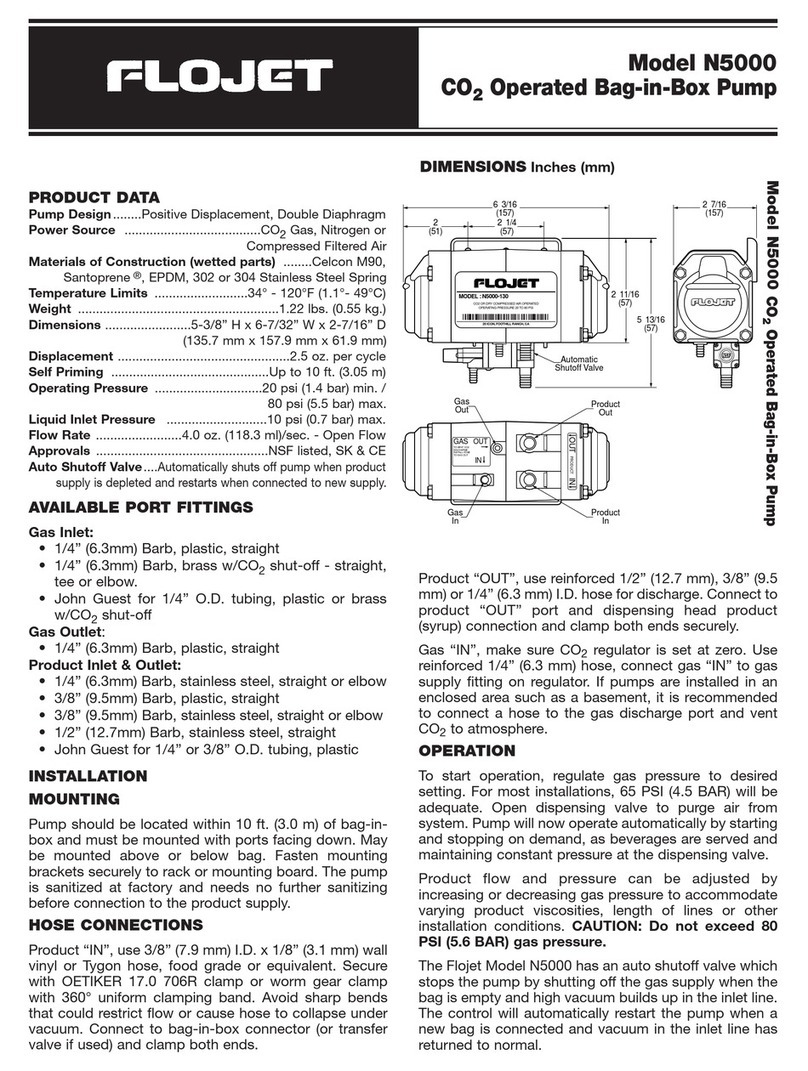

Model N5000 Specifications

Pump Design

................Positive Displacement, Double Diaphragm

Power Source

........CO2Gas, Nitrogen or Compressed Filtered Air

Materials of Construction (wetted parts) ....................Celcon M90,

Santoprene®, EPDM, 302 or 304 Stainless Steel Spring

Temperature Limits

..................................34˚ - 120˚ F (1.1˚ - 49˚ C)

Weight

....................................................................1.22 lbs. (0.55 kg.)

Dimensions

..................................5-3/8" H x 6-7/32" W x 2-7/16" D

(135.7 mm x 157.9 mm x 61.9 mm)

Displacement

..........................................................2.5 oz. per cycle

Self Priming

......................................................Up to 10 ft. (3.05 m)

Operating Pressure

....20 psi (1.4 bar) min. / 80 psi (5.5 bar) max.

Liquid Inlet Pressure

......................................10 psi (0.7 bar) max.

Flow Rate

..................................4.0 oz. (118.3 ml)/sec. - Open Flow

Approvals

..................................................................NSF listed & CE

Vacuum Shutoff

......Automatically shuts off pump at 21" Hg when

product supply is depleted. High altitude versions available for

installation where altitudes exceed 3,000 feet (914 m).

Features

1. Supplies up to two fast flow or four standard flow dis-

pensing valves at remote locations.

2. Fully automatic, operates only when beverage is

being dispensed and maintains constant pressure at

the dispensing valve.

3. Shuts off automatically when bag is empty and

restarts when a full bag is connected.

4. High suction capability empties the bag down to a

minimum residual.

5. Brass tee and elbow CO2shutoff valve quick-discon-

nect allows us to manifold CO2inlet line.

6. All pumps come with a stainless steel 3/8 inch (9.5

mm) product out barb port.

Accessories

Quantity Part No. Description

one 20590-000 Bracket for Pumps

one 20594-000 Bumper Guard

two 20595-000 Tube Hangers

one 1520-000 1/4 Inch (6.3 mm) Brass Tee

CO2Shutoff Valve

one 1521-000 1/4 Inch (6.3 mm) Brass Elbow

CO2Shutoff Valve

one 1500-030A Transfer Valve

IF USED WITH CO2OR N2BE SURE THE AREA IS

WELL VENTILATED

ONLY USE PUMPS WITH SPECIFIED PRODUCTS. DO

NOT PUMP FLAMMABLE LIQUIDS OR USE WHERE

FLAMMABLE VAPORS ARE PRESENT

WARNING

AVAILABLE PORT FITTINGS

Gas Inlet:

• 1/4” (6.3mm) Barb, plastic, straight

• 1/4” (6.3mm) Barb, brass w/CO2shut-off - straight, tee

or elbow.

• John Guest for 1/4” O.D. tubing, plastic or brass

w/CO2shut-off

Gas Outlet:

• 1/4” (6.3mm) Barb, plastic, straight

Product Inlet & Outlet:

• 1/4” (6.3mm) Barb, stainless steel, straight or elbow

• 3/8” (9.5mm) Barb, plastic, straight

• 3/8” (9.5mm) Barb, stainless steel, straight or elbow

• 1/2” (12.7mm) Barb, stainless steel, straight

• John Guest for 1/4” or 3/8” O.D. tubing, plastic