FLOJET 2100-12 User manual

Other FLOJET Water Pump manuals

FLOJET

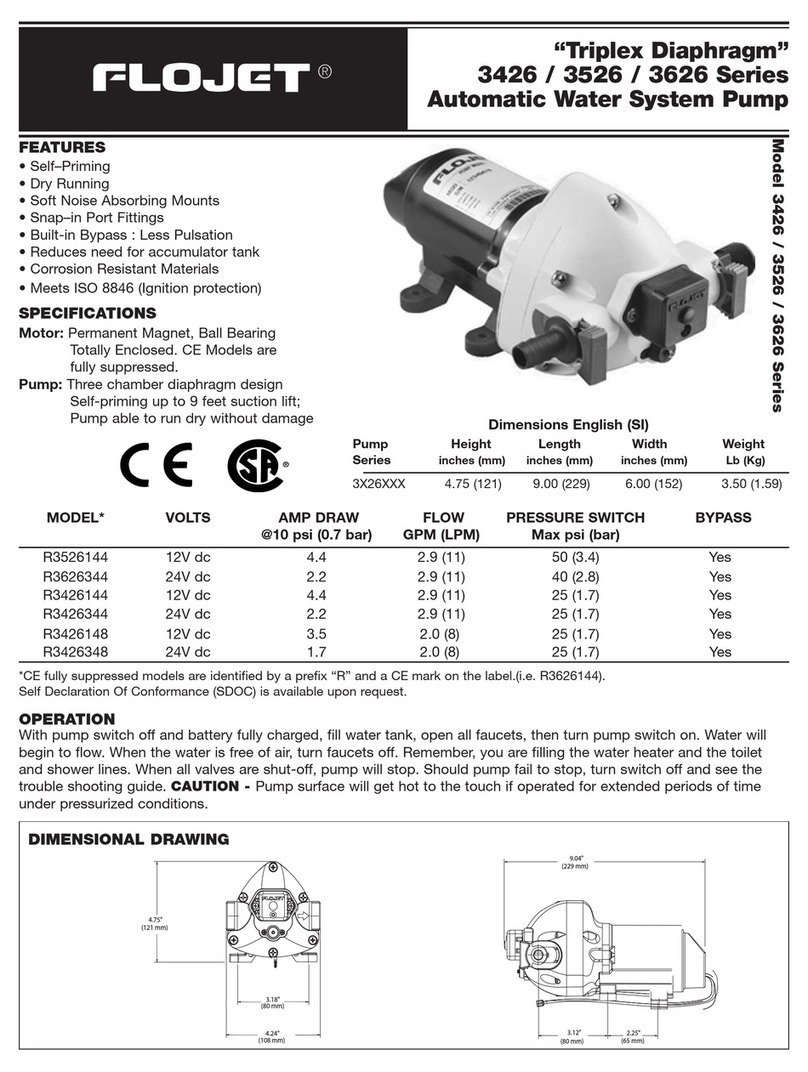

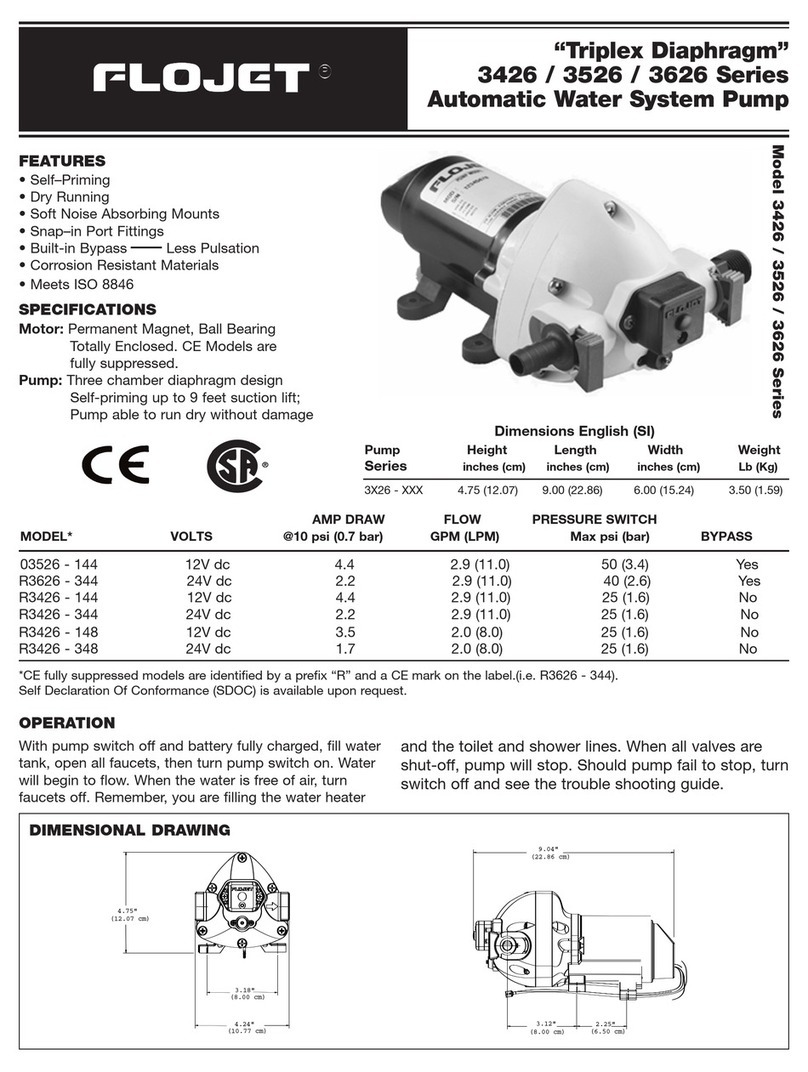

FLOJET Triplex Diaphragm 3426 Series User manual

FLOJET

FLOJET G257 Series Guide

FLOJET

FLOJET 03526-144 User manual

FLOJET

FLOJET G70C Series Owner's manual

FLOJET

FLOJET R3B21 Series User manual

FLOJET

FLOJET 2125 Series User manual

FLOJET

FLOJET 18555-000 User manual

FLOJET

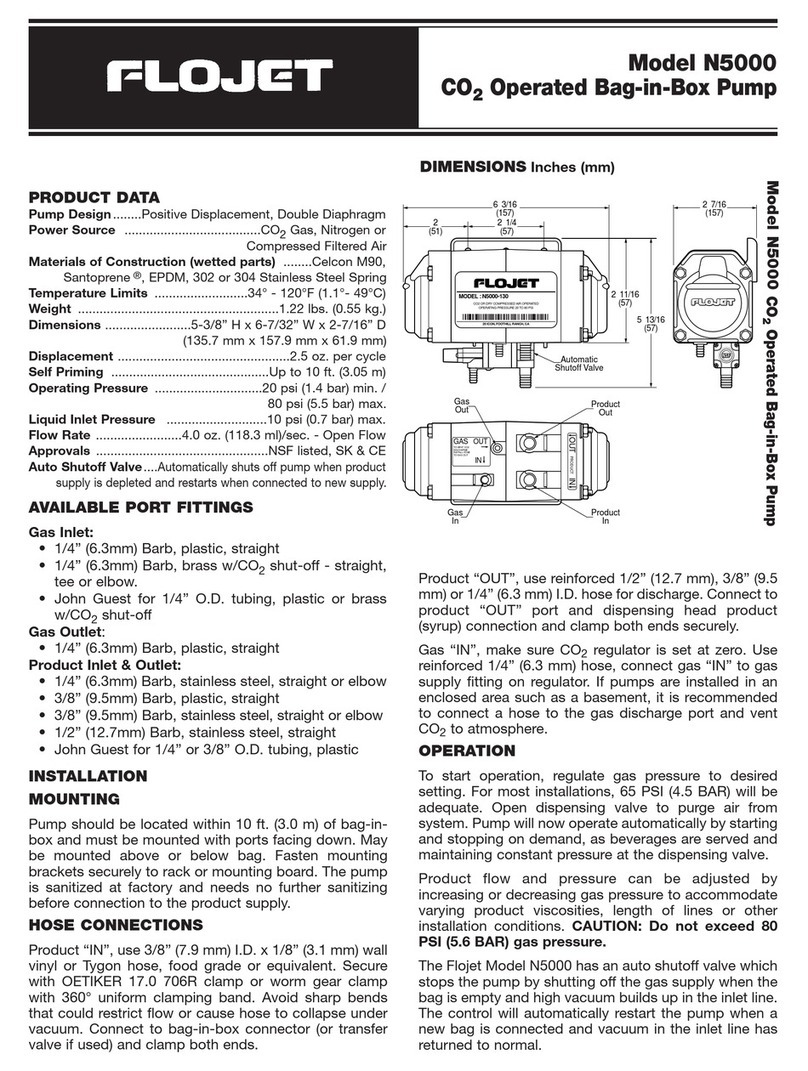

FLOJET N5000 Series Operation manual

FLOJET

FLOJET N5000 User manual

FLOJET

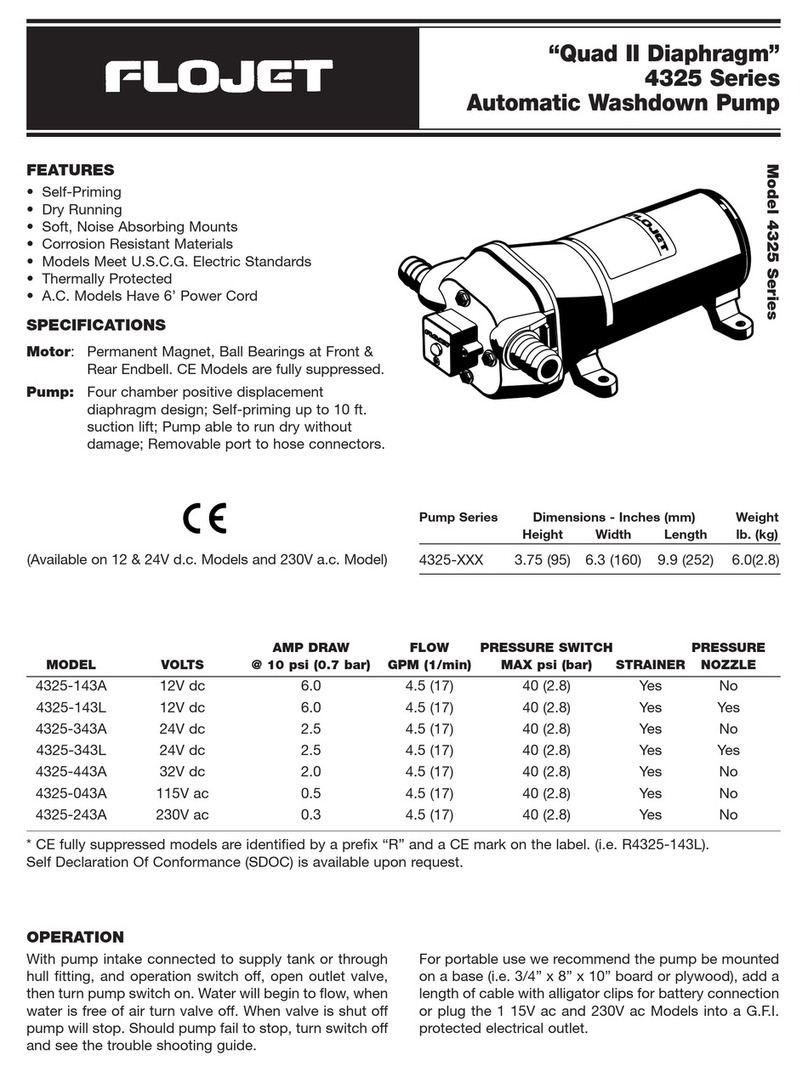

FLOJET 4325 Series User manual

FLOJET

FLOJET G-57 Series Installation instructions

FLOJET

FLOJET 4105 Series User manual

FLOJET

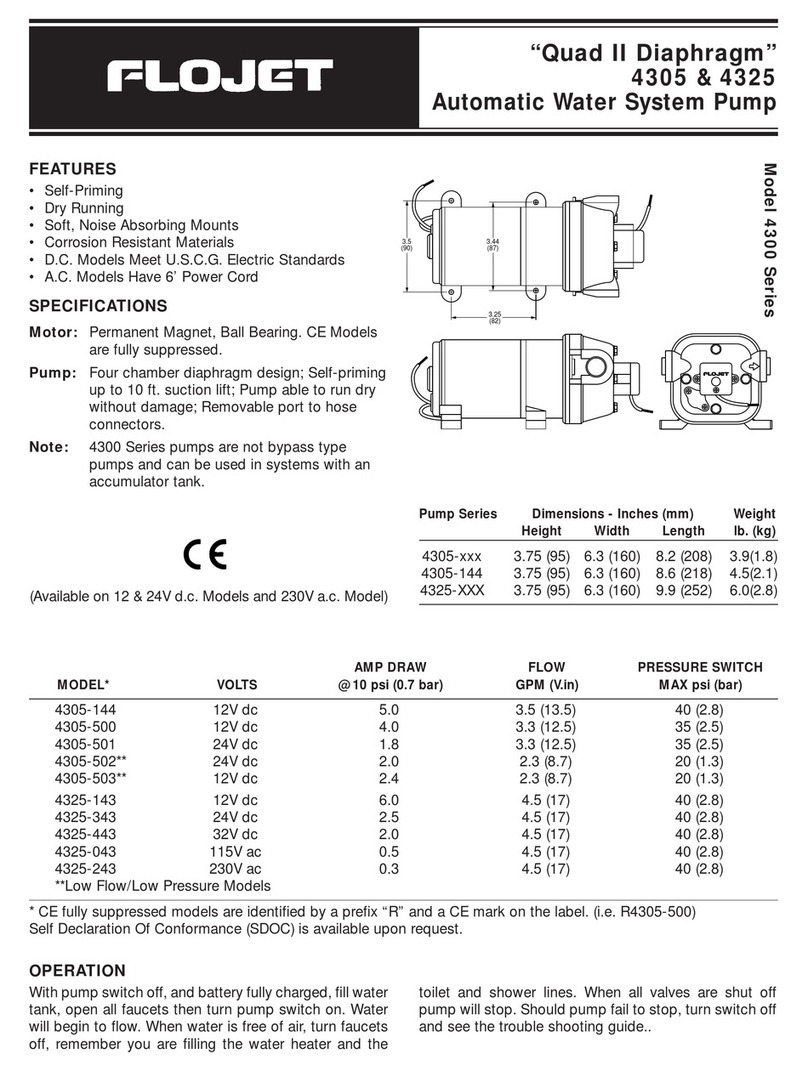

FLOJET 4300 Series User manual

FLOJET

FLOJET quad II diaphragm 4125 series User manual

FLOJET

FLOJET R4515-743 User manual

FLOJET

FLOJET G573 User manual

FLOJET

FLOJET G56 User manual

FLOJET

FLOJET R3526144 User manual

FLOJET

FLOJET BevJet Compact User manual

FLOJET

FLOJET 4305-144 User manual

Popular Water Pump manuals by other brands

Sandpipper

Sandpipper S05 Operating and service manual

MATO

MATO CMiNDTEK EP 100 operating instructions

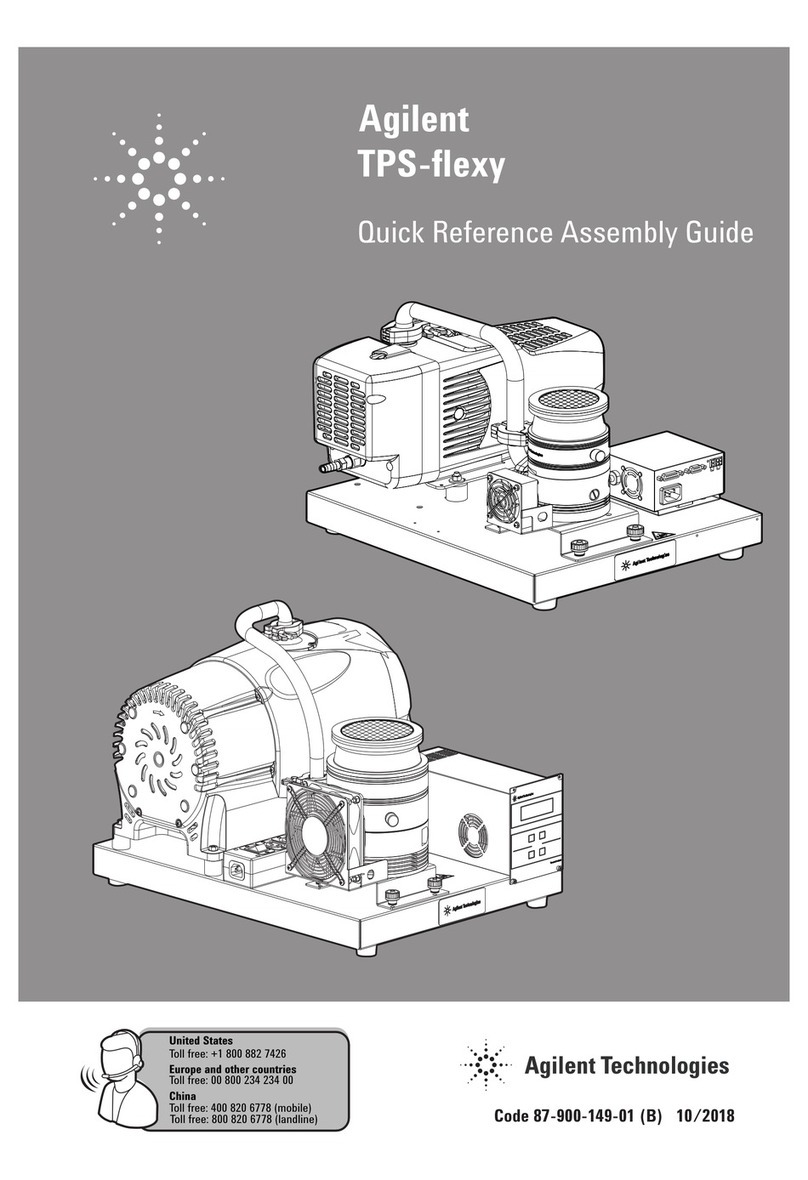

Agilent Technologies

Agilent Technologies TPS-flexy Quick Reference Assembly Guide

Ceco

Ceco Sethco P90S quick start guide

Reefe

Reefe RPS57E Exploded View & Instruction Manual

GORMAN-RUPP PUMPS

GORMAN-RUPP PUMPS T4B65-B Installation, operation, and maintenance manual with parts list

IWAKI AMERICA

IWAKI AMERICA Walchem EWN-Y Quick start programming guide

pumpa

pumpa BLUE LINE PMC1004P.1 manual

Nippon Oil Pump

Nippon Oil Pump Cyclone Filter Pump User instruction manual

GORMAN-RUPP

GORMAN-RUPP SUPER T SERIES Installation, operation and maintenance manual

Dekker

Dekker Maxima-K 1 Series Installation, operation and maintenance manual

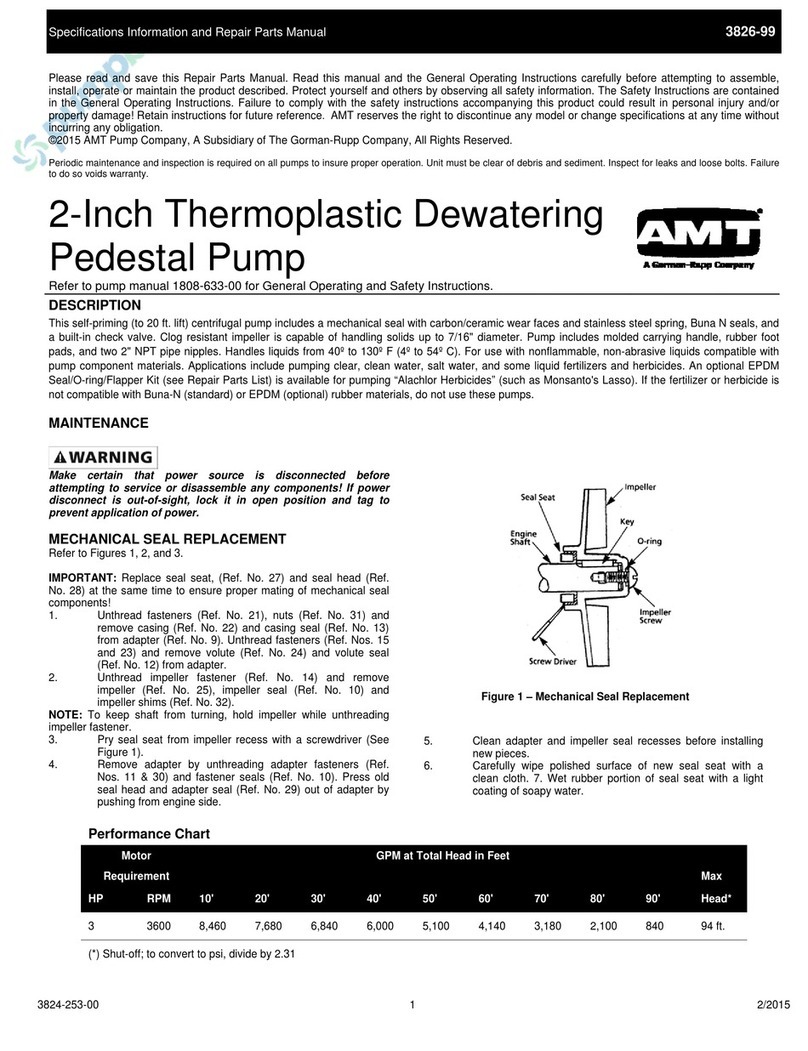

AMT

AMT 3826-99 Specifications information and repair parts manual

Hilti

Hilti DWP 10 operating instructions

Danfoss

Danfoss 45 Frame K2 Series Service manual

GORMAN-RUPP PUMPS

GORMAN-RUPP PUMPS GMS Series Installation, operation and maintenance manual

ESPANGO

ESPANGO IPCR6 Installation and maintenance instructions

Grundfos

Grundfos SCALA 2 Service instruction

SHUR-DRI

SHUR-DRI SD-520C-T7-01 installation manual