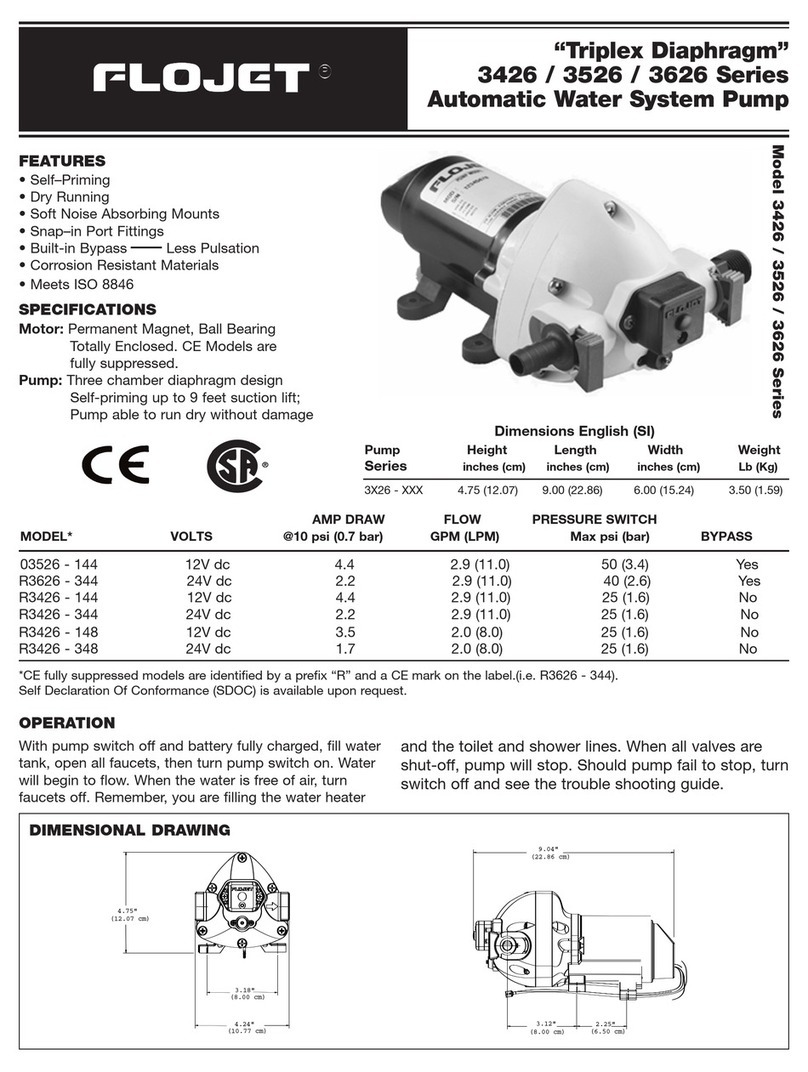

AUTOMATICWATERSYSTEMPUMPSEBVICEPARTS

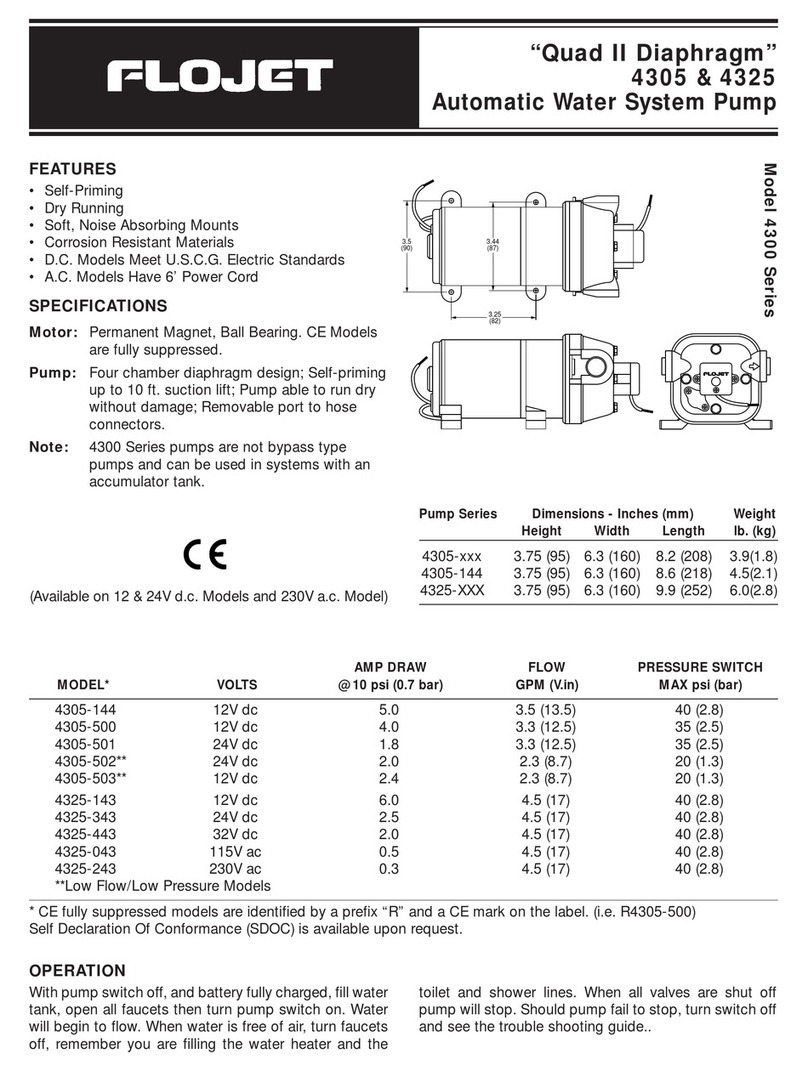

KEY# DESCRIPTION MODEL#

€05-lif4 4305-5004)05-501 4305-5024305-503

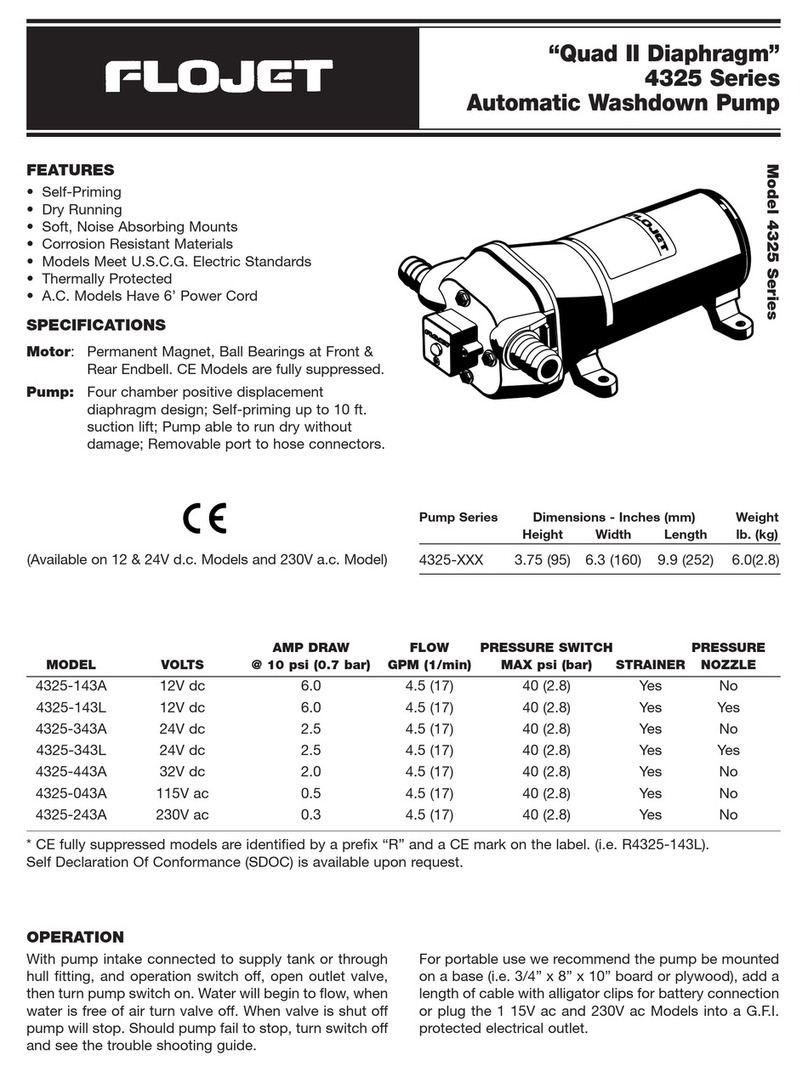

€25n€ $25-343 4325-4434325-0434325-243

0 Service

Kit- 20409-04320409-04320409-04320409-043

20409-04320409-04320409-04320409-04320409-04320409-043

1 Upper

HousingWith

Clips

20404-00320404-00820404-008

20404-012204A4-01220404-00320404-00320404-00320404-003

20404-003

2 Check

ValveAssembly 20407-03020407-03020407-03020407-030

20407-03020407-03020407-03020407-030

20407-03020407-030

3 DiaphragmAssembly

(ncludes

screv/s)20403-04020403-04020403"040

20403-04020403-04020403-04020403-04020403-040

20403-04020403-040

4 LowerHousingAssembly20419-00420419-00120419-001

20419-00020419-00020419-00220419-002

20419-00220419-00220419"002

5 l\,4otofs 2009-08742009-07342019-0234

2019-23A2009-074A2009-08042U9-A27A2049-A26A

l\,4otors

CE

Models 82009-0B74

F2009"0734R2009-023AR2019-023AR2009-074A

R2009-080AR2019-027A

lVotor115Volta.c./230Vol1a.c, 2029-091A

2039-0874

7 PurnpHeadAssembly 20406-015A20406"007A20406-007A

20406-012A20406-012A20406-002420406-002A

20406-002A20406-002A20406-002A

8 SideClips

(pa

r) 20408-00020408-00020408-00020408-000

20408-00020408-00020408"00020408-000

20408-0002040&000

I Pressure

SwitchAssembly2090-1182090-1042090-104

2090-1082090J082090-118

2090G-1182090-1182090-118

2090-118

-Service

Kitincludes

#2.#3.#Banddrivecamassemblv.

ACCESSORIES

QUICK COT{T{ECTPORT

SYSTEM rfilflF\

ul.lkj

F=

El

20381"009

OUAD

PORT

x

1/2'HOSEBARB

90'

ELBOW

_ Theabove

padnumbersare

packaged

with

2fittings

per

bag.

STRAIT{ERS

PumpSeries StrainerNumber Inlet Ou et Screen

1/2Bart)

1/2M Qest

Quad

Port

m381-000

OUADPOBTx

1/2 MALI

QEST.

STBAIGHT

20381-002

oUADP0RTx

1/2"HOSE

BARB

STMIGHT

1740-OO2

1740-OO4

1740-014

20381-007

oUADPoRTx

GARDEN

HOSE

ADAPTOR

ffim

20381-006

oUADPoBTx

3/4',H0SEBA88

STBAIGHT

2m81-008

OUADPORTx

1/2'I\4ALE

OEST

90'ELBOW

m381-t)t0

0UADPoRTx

3/4 HOSEBARB

90'ELBOW

1/2 Bart)

1/2M Qest

1/2 lvlQest

40Mesh

40lMesh

40N/esh

4305-144

4325-XXX

WARRANTY

1740-000 3/4 Batb 3/4 Bart)

RETURI{PROCEDURE

40l.4esh

FLOJET

warrantsthis product to be free of defects in material

and/orworkmanshipior a periodof two yearsafterpurchase

by

the customerfrom FLOJET.During

ths two year

warranty

period,

FLOJETwill at lts option,at no chargeto the customer,repair

or

replace

thisproductiffounddefectiven materialorworkmanship,

w1ha newor recond,t

oneo

product,

butnotto incluoe

costsot

removal or installation.

Thisisonlyanoverview

of our limitedwaffanty.lf youwouldlikea

copyof ourwarranty,

please

callorwriteFLOJET.

Priorto returning

anyproduct

to FLOJET,callcustomerservicefor

an authorizationnumber.Thisnumber

mustbe wrtten on the

outside

of the

shipping

package.

Place

a noteinsidethe pack

age w th an explanationregarding

the reasonfor returnas wel

as the authorizationnumber.Includeyour name, address and

pnone

numoer.

Flojet

ITT

lndustries

Ensineerc.t Ior tife

u.s.A.

Flojet

20lcon

FoothillRanch,

CA92610-3000

Tel:

(949)

859-4945

Fax:

(949)

859-1153

UNITED

KINGDO[/

Jabsco/Flojet

Bingley

Road,Hoddesdon

HertfordshreENl1

OBU

Tel:+44

(0)

1992450145

Fax:+44

(0)

1992467132

CANADA

Fluid

ProductsCanada

55RoyalRoad

Guelph,

OntarioNIH1T1

Tel:

(519)82'1-1900

Fax:

(519)

821-2569

JAPAN

NHKJabscoCompanyLtd.

3-21-10,Shin-Yokohama

Kohoku-Ku,

Yokohama,222

Tel:

045-475-8906

Fax:045-475-8908

GER[,1ANY

JabscoGmbH

Oststrasse28

22844Norderctedt

Tel:

+49-40-535373-0

Fax:+49-40-5353

73-11

@Copyrght2001,ITTndustes Form:81000-074 11/41

(713)-395-1508

Fax: (713) 893-6924

www.industrialzone.com

IndustrialZone

P.O. Box 667306

Houston, Texas 77266

United States