MOUNTING

The FLOJET N5100 Series self-priming pump should be

mounted in a dry and adequately ventilated area. This

pump can be mounted several feet from the tank, above

or below the fluid level. For most applications, no more

than 4 feet above the fluid level is recommended. This

is not a submersible pump.

Secure Pump to desired fixture by screws through the

mountng bracket. Ports must be facing down.

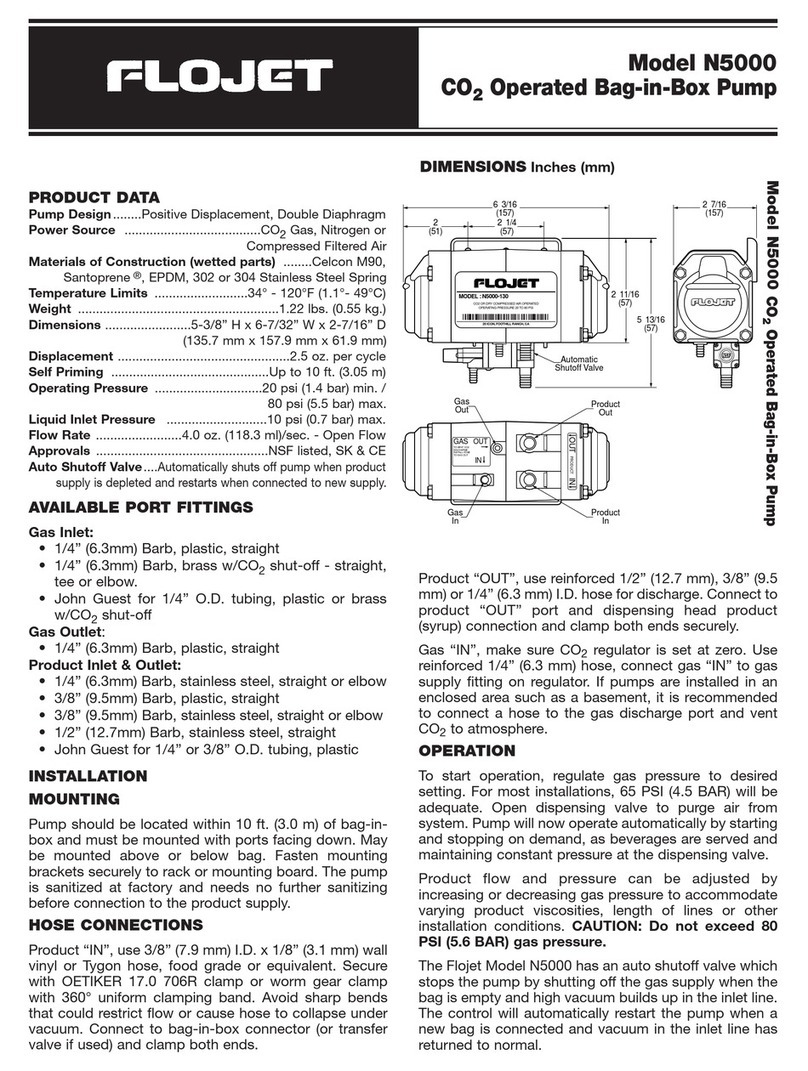

HOSE CONNECTIONS

Product In - Use 3/8”. reinforced, flexible, non-

collapsible hose or equivalent. Avoid sharp bends that

could restrict flow or cause hose to collapse under

vacuum.

Product Out - Use reinforced 3/8”. I.D. hose for

discharge tube.

Gas In - Make sure gas regulator is set at zero. Use

reinforced 1/4” hose. connect “Gas In” to gas supply

fitting on regulator. If pumps are installed in an enclosed

area, it is recommended to connect a hose to the gas

discharge port (exhaust) and vent gas to atmosphere.

(Requires ‘small’ exhaust port)

PLUMBING

Use a flexible hose to avoid excess stress on pump

ports. DO NOT crimp or kink hose. All hose should be

the same size as the pump port fittings.

All fittings must be compatible with fluid being pumped.

It is recommended to use plastic fittings only.

The use of check valves in the plumbing system could

interfere with the priming ability of the pump. If

unavoidable, check valves in the pumping system must

have a cracking pressure of 2 PSI or less.

Use a minimum 40 mesh strainer or filter in the tank or

pump inlet line to keep large foreign particles out of the

system.

OPERATION

At start-up, regulate gas pressure to desired setting. For

most installations 20 PSI (1.4 bar) inlet will be adequate,

although DO NOT go below 20 PSI. Pump will operate

according to air supply. Flow and pressure can be

adjusted by increasing or decreasing gas pressure to

accommodate varying product viscosities, length of

lines or other installation conditions. Review flow curves

located on page 1 for further assistance. High viscosity

fluids and hose length will limit priming distance.

IF PUMP IS T0 BE USED IN HIGH FLOW, LOW

PRESSURE APPLICATIONS, ADJUST GAS PRESSURE

TO 20 PSI (1.38 BAR) ABOVE DISCHARGE PRESSURE.

CAUTION: DO NOT EXCEED 80 PSI (5.6 bar) GAS INLET

PRESSURE.

CONTINUOUS OPERATION AT 120°F (48.9°C) WILL

REDUCE PUMP LIFE.

AIR MUST BE DRY AND OIL FREE.

Compressors must have dryers and/or a water

separator in the air distribution system. Pumps that fail

due to water in the air chamber will not be covered

under the limited warranty.

GENERAL SAFETY INFORMATION

Protect yourself and others by observing all safety

information. Follow all safety codes and the

Occupational Safety and Health Act (OSHA).

DO NOT PUMP GASOLINE OR

FLAMMABLE LIQUIDS OR USE WHERE

FLAMMABLE VAPORS ARE PRESENT.

If used with C02or N2be sure the area is

well ventilated.

CAUTION:

Do not clean or service FLOJET pumps, hoses or valves

while the system is pressurized. Plastic CO2air inlet

ports do not have a check valve. Prior to cleaning or

servicing, purge the pump by carefully tilting the pump

so ports are facing up and remove suction line from

source. Turn air off and disconnect air inlet line. (Brass

air inlet ports have a check valve)

PREVENTIVE MAINTENANCE TIPS

Tips to help prolong your pump’s life.

• If pumping liquid other than water. pump should be

flushed with water (if applicable) after every use.

•

Before freezing conditions occur. pump must be liquid free.

• If mounting pump in an outdoor environment. shield

pump from environmental extremes (i.e. sunlight.

water from washdown spray, rain, etc.).

• When using an air compressor. use an inline air dryer

before the pump to limit water build-up.

WARNING