FLOJET 4325 Series User manual

Other FLOJET Water Pump manuals

FLOJET

FLOJET G257 Series Guide

FLOJET

FLOJET 2100-12 User manual

FLOJET

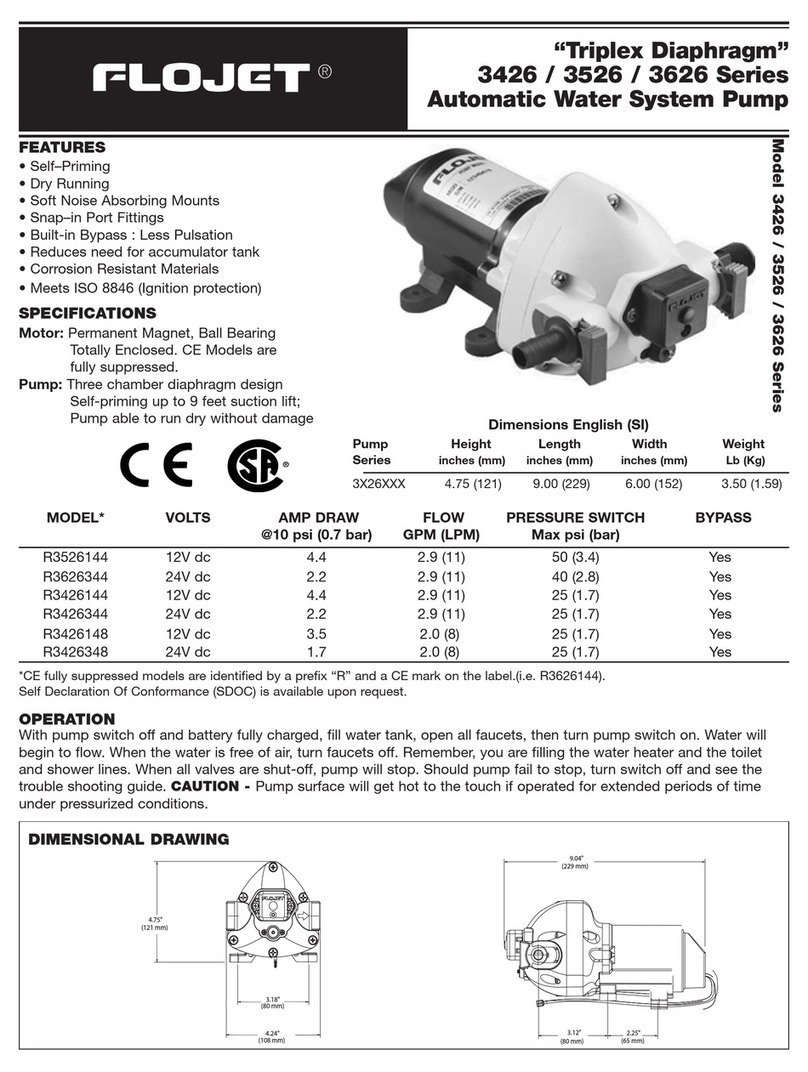

FLOJET 03526-144 User manual

FLOJET

FLOJET 2125 Series User manual

FLOJET

FLOJET G56 User manual

FLOJET

FLOJET G-57 Series Installation instructions

FLOJET

FLOJET G70C Series Owner's manual

FLOJET

FLOJET quad II diaphragm 4125 series User manual

FLOJET

FLOJET 4105 Series User manual

FLOJET

FLOJET N5100 Series Guide

FLOJET

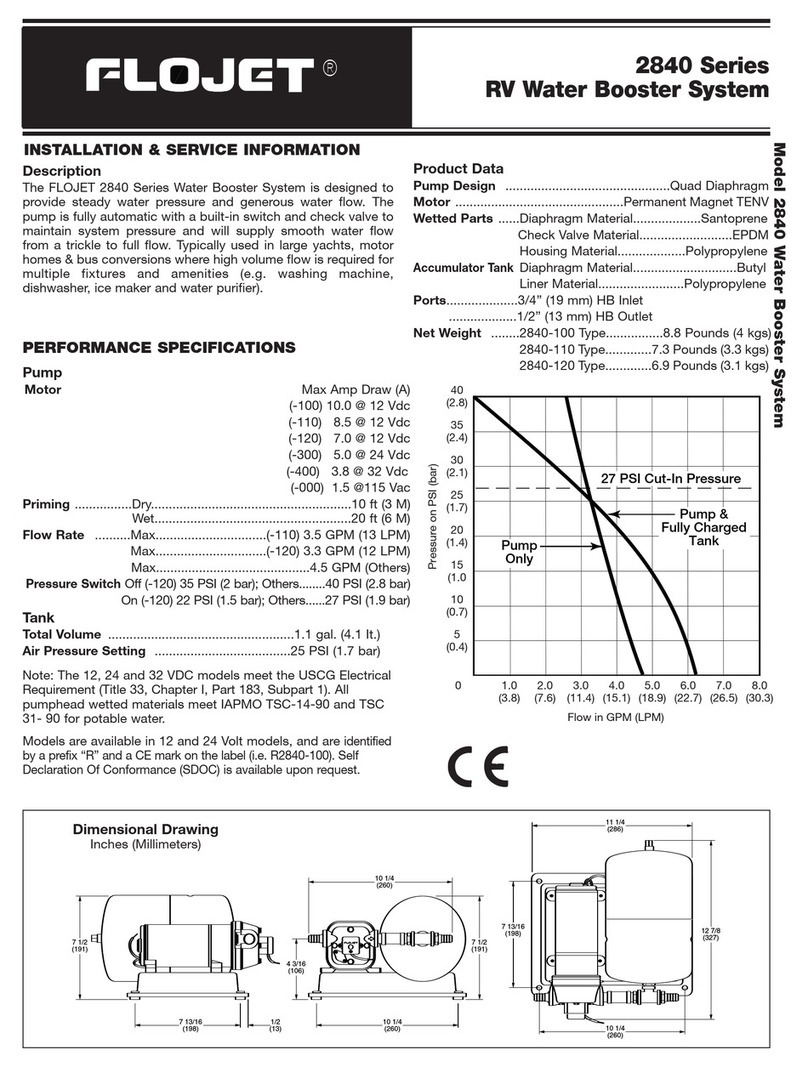

FLOJET 02840100A Operating and installation instructions

FLOJET

FLOJET 18555-000 User manual

FLOJET

FLOJET R3526144 User manual

FLOJET

FLOJET N5100-010 Guide

FLOJET

FLOJET 3426 series User manual

FLOJET

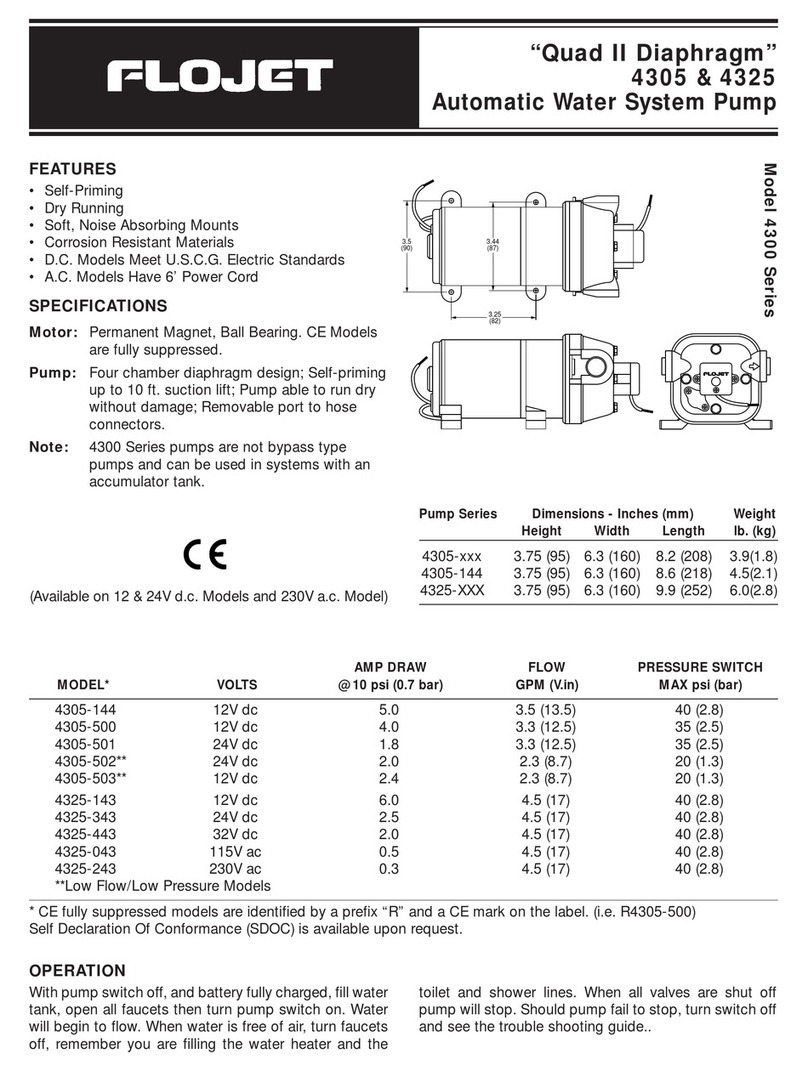

FLOJET 4300 Series User manual

FLOJET

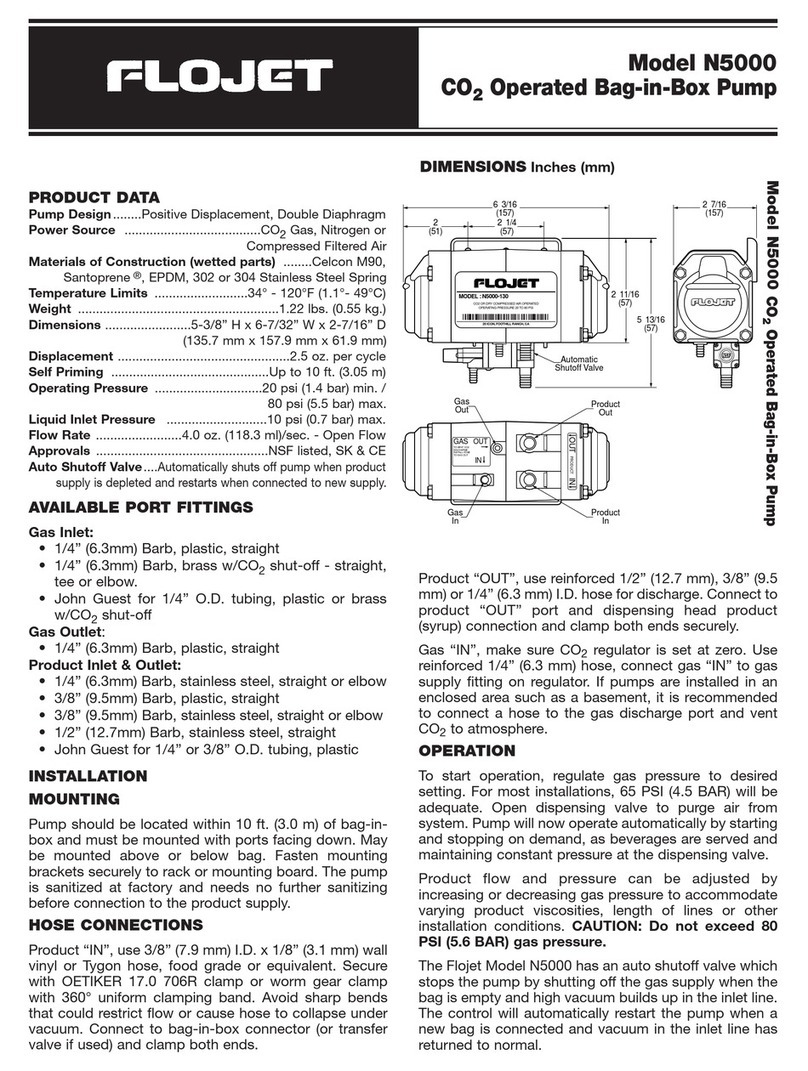

FLOJET N5000 Series Operation manual

FLOJET

FLOJET G573 User manual

FLOJET

FLOJET R4515-743 User manual

FLOJET

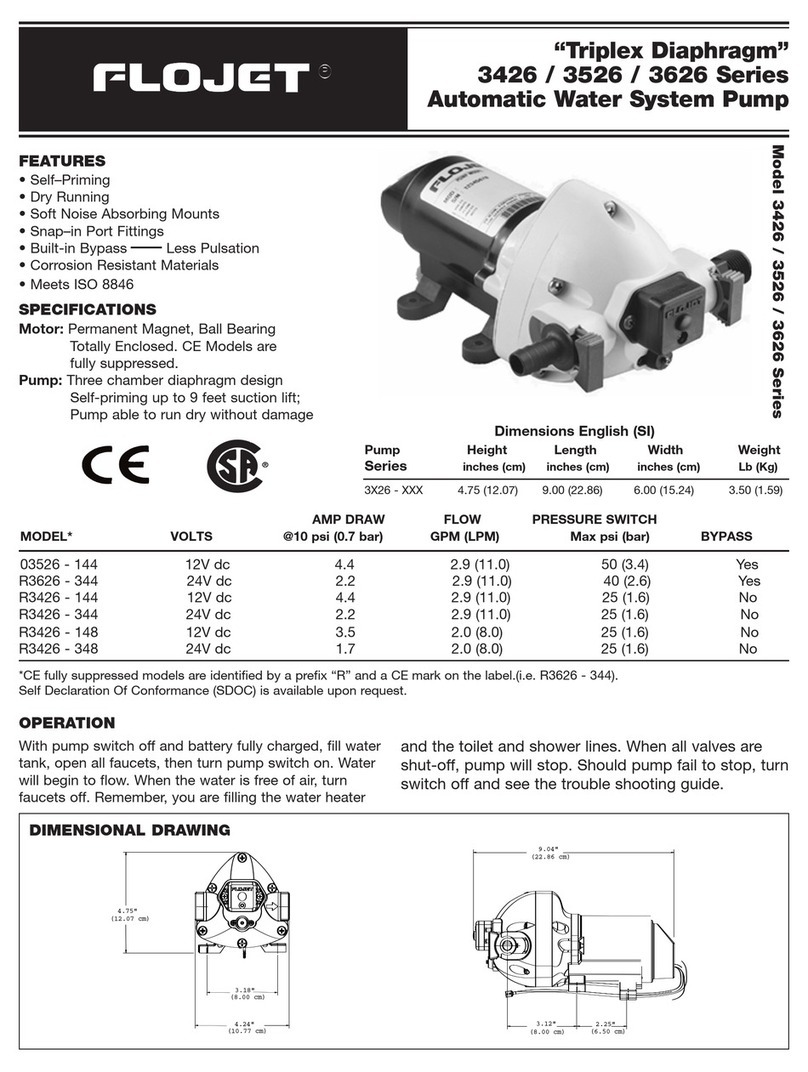

FLOJET Triplex Diaphragm 3426 Series User manual

Popular Water Pump manuals by other brands

Liberty Pumps

Liberty Pumps 240 Series installation manual

SKC

SKC QuickTake 30 operating instructions

Sealey

Sealey WPC100 instructions

Becker

Becker T 4.16 DV operating instructions

GORMAN-RUPP PUMPS

GORMAN-RUPP PUMPS O Series Installation, operation, and maintenance manual with parts list

Pentair

Pentair BERKELEY B4GPBHS Care manual

PFT

PFT SWING L operating manual

ZHT

ZHT AMPHIBIO user manual

SHURflo

SHURflo 316 Operating Instructions, Performance, Specifications and Parts Manual

Becker

Becker BASIC VASF 2.120/1-0.AC230 operating instructions

Cardinal Health

Cardinal Health Alaris GP Directions for use

Beckett

Beckett M250 owner's manual

Durapac

Durapac P-2200 instruction manual

Clarke

Clarke PSV5A Operation & maintenance instructions

GORMAN-RUPP

GORMAN-RUPP PA6F60 ---4045D Installation, operation and maintenance manual

Nakayama

Nakayama PRO NP1010 manual

GEL

GEL LONG LIFE SUPERFLUSH 40 user manual

KSB

KSB Delta Solo SVP Installation & operating manual