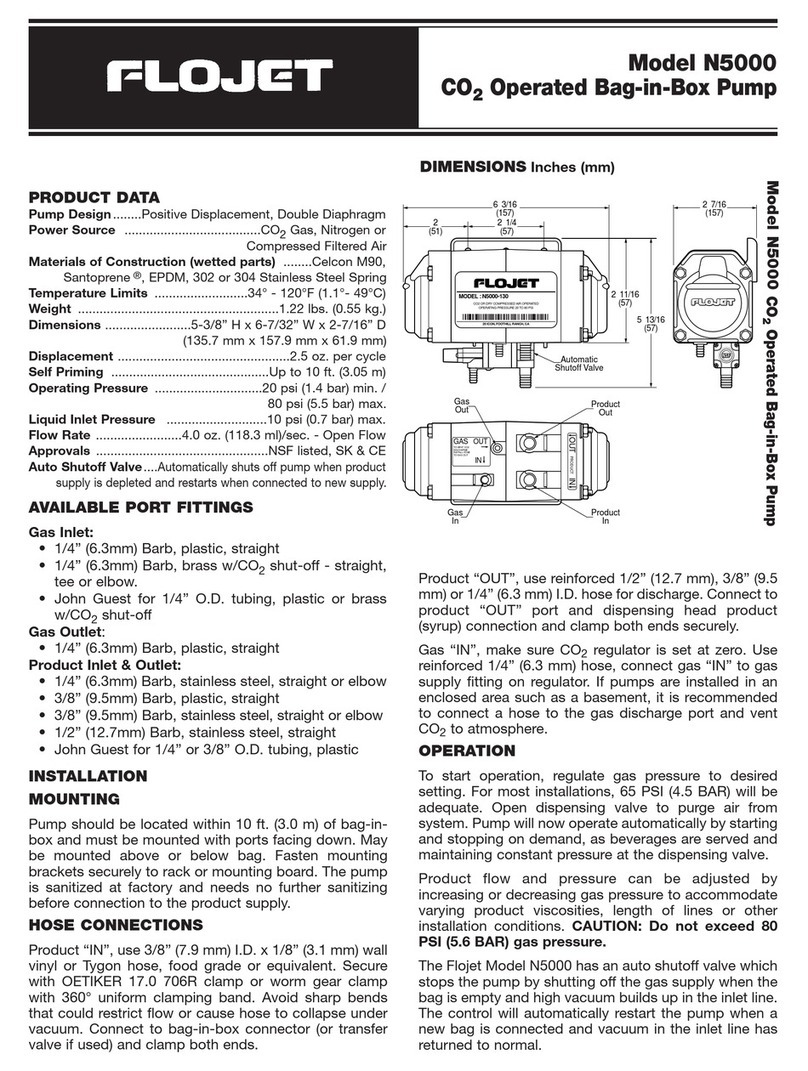

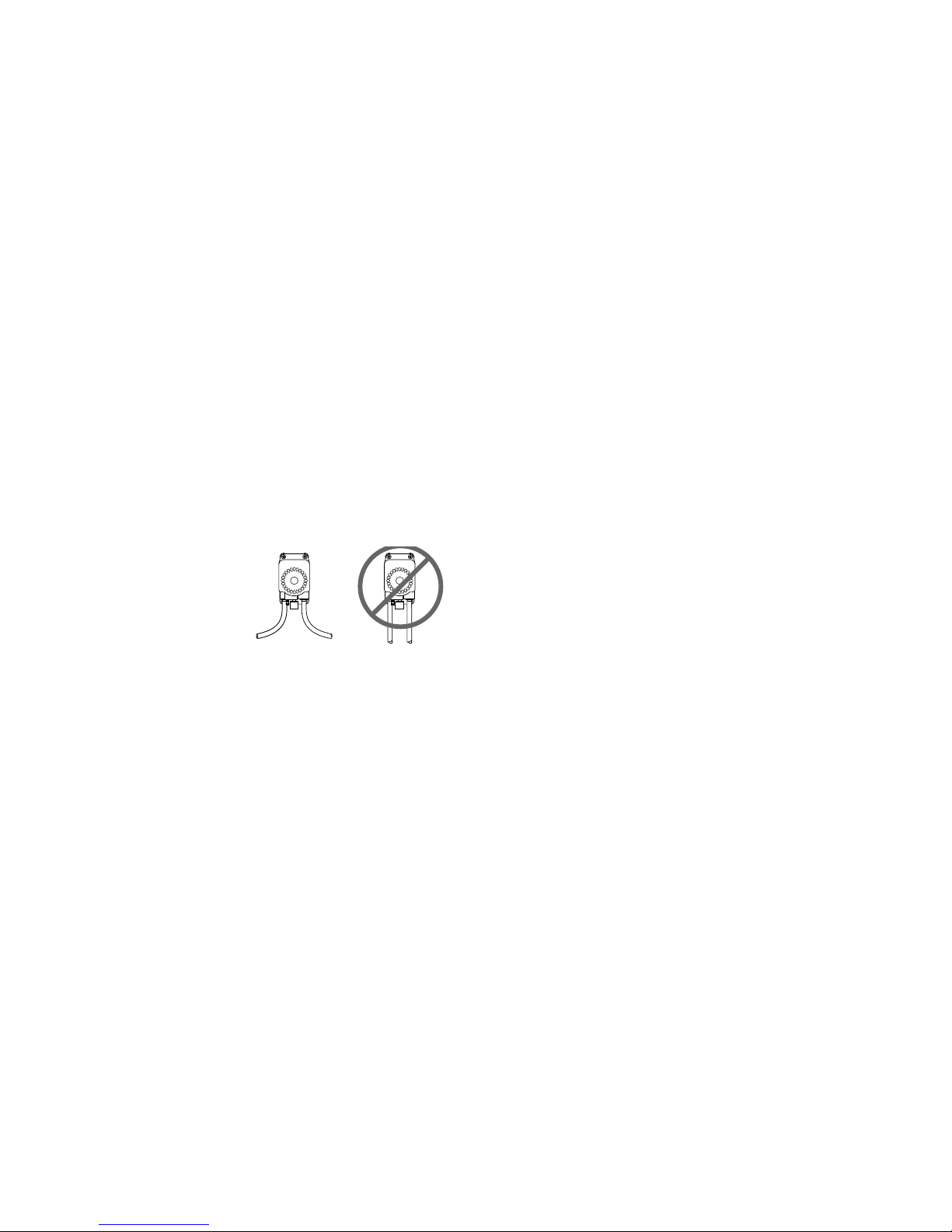

MOUNTING

The FLOJET G70C self-priming pump should be mounted in a

dry and adequately ventilated area. This pump can be mounted

several feet from the tank, above or below the fluid level. For

most applications, no more than 4 feet above the fluid level is

recommended. Note: This is not a subm rsibl pump.

Secure Pump to desired fixture by inserting screws through the

rubber grommets in the baseplate of the pump. Ports must b

facing down. The pump must be protected by a housing able

to withstand the impact of a steel half ball of 25mm with a mass

of 1Kg and an energy of 7J. Refer to EN 13463-1 Par 13 for

further details.

HOSE CONNECTIONS

Liquid n - Use 3/8”, 1/2”, or 3/4” .D. reinforced hose or

equivalent. Avoid sharp bends that could restrict flow or

cause hose to collapse under vacuum.

Liquid Out - Use 3/8”, 1/2”, or 3/4” .D. reinforced hose for

discharge tube. 3/4” .D. hose must use 90° elbows when

using large muffler.

Air n - Make sure air regulator is set at zero. Use reinforced

1/4” .D. hose. Connect “Air n” to air supply fitting on

regulator. f pumps are installed in an enclosed area, it is

recommended to connect a hose to the air discharge port

(exhaust) and vent air to atmosphere (Requires small

exhaust port PN# 20756103B not included).

PLUMBING

Use a flexible hose to avoid

excess stress on pump ports.

DO NOT crimp or kink hose.

All hose should be the same

size as the pump port fittings.

All fittings and hose must be

compatible with fluid being

pumped. t is recommended to use plastic fittings only.

The use of check valves in the plumbing system could

interfere with the priming ability of the pump. f unavoidable,

check valves in the pumping system must have a cracking

pressure of 2 PS or less.

Use a minimum 40 mesh strainer or filter in the tank or pump

inlet line to keep large foreign particles out of the system.

Liquid inlet port must be equal to or larger than the liquid

outlet port.

OPERATION

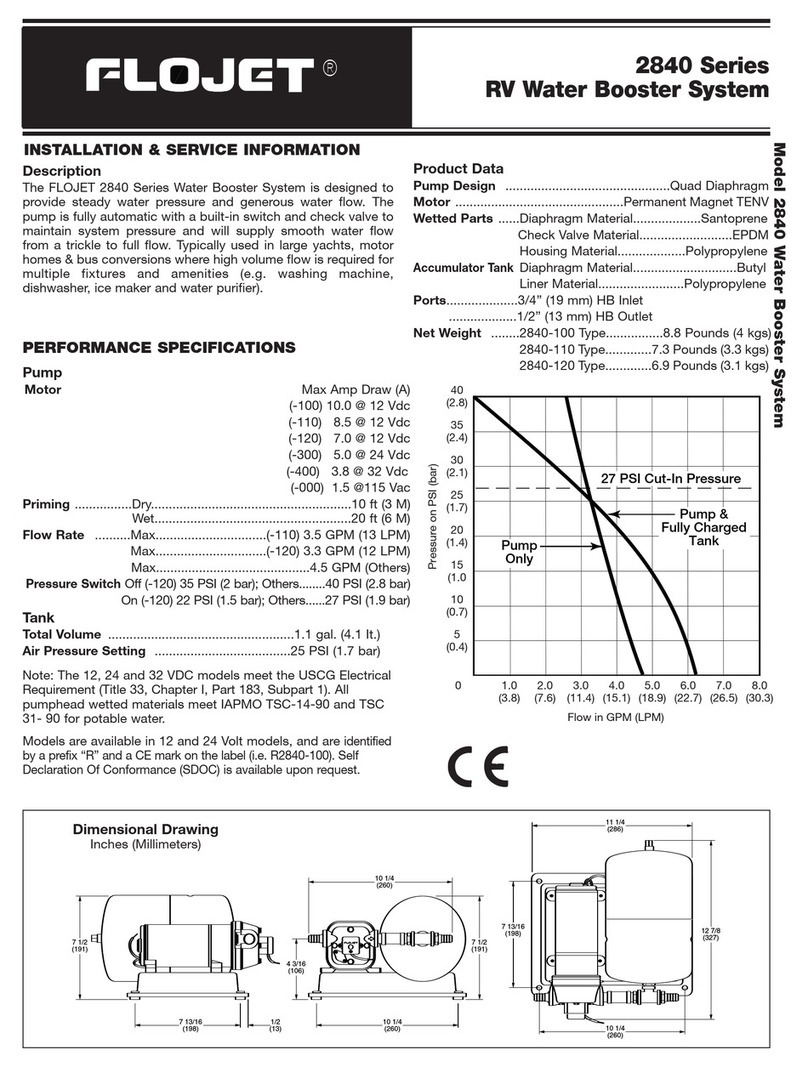

At start-up, regulate air pressure to desired setting. For

most installations 20 PS (1.4 bar) inlet will be adequate,

although DO NOT go below 20 PS . Pump will operate

according to air supply. Flow and pressure can be adjusted

by increasing or decreasing air pressure to accommodate

varying product viscosities, length of lines or other

installation conditions. Review flow curves located on page

1 for further assistance. High viscosi ty fluids and hose

length will limit priming distance.

Compressors must have dryers and/or a water separator in

the air distribution system. Pumps that fail due to water in

the air chamber will not be covered under the limited

warranty.

Plastic air inlet ports do not have a check valve. Prior to

cleaning or servicing, purge the pump by carefully tilting the

pump so ports are facing up and remove suction line from

source. Turn air off and disconnect air inlet line. (Standard

brass air inlet ports have a check valve).

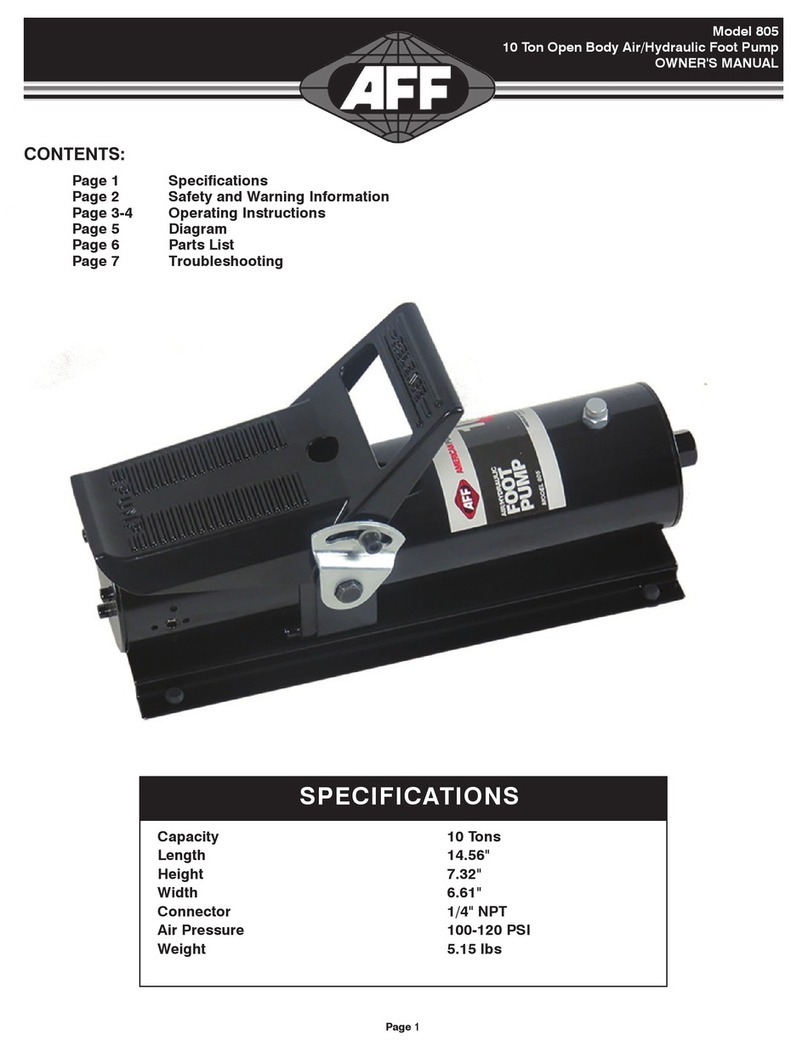

DISASSEMBLY PROCEDURE

First, remove inlet air line, muffler and suction/discharge

line from the pump. This is accomplished by using a flat-

bladed screwdriver to slide the retaining clips away from the

air inlet, muffler and suction/discharge fittings and pulling

the fittings away from the pump body. Now remove the muf-

fler by sliding the retaining clip away from the muffler base

and pulling the muffler out of the pump body.

Using a Phillips screw driver remove the seven (7) screws

from the front end cap followed by the (7) screws from the

rear end cap. With the front end cap facing up and the rear

end cap facing down on the workbench, position a flat blad-

ed screw driver into the slot located above the muffler port

and just below the pad marked Air/C02and lift off the front

end cap. The rear end cap can be removed by placing the

flat bladed screwdriver under the fully opened port retaining

clip and lifting off.

Note the position of the suction and discharge valves before

removing them from the pump body. The first diaphragm is

removed from the pump shaft by unscrewing in a counter

clockwise direction. The second diaphragm is removed by

placing the flat tip of a screwdriver into the exposed slot at

the end of the pump shaft and unscrewing the diaphragm

from the shaft. To remove the flange housing, place the tip

of the flat bladed screw driver into the air bleed hole on the

lower side of the flange housing and lift up the lower end

separating the flange housing from the pump body.

The slide valve assembly and pump shaft can be removed

by simply pulling them from the pump body. The pump shaft

then can be removed from the slide valve yoke assembly.

REASSEMBLE PROCEDURE

Assemble the slide valve and pump shaft with the yoke

placed between the (2) bumpers on the pump shaft. nstall

the slide valve/pump shaft assembly into the pump body

making sure the O-rings in the slide valve are in place. To

install the flange housing, prelube the o-ring with Parker

Super “O” Lube and install on flange housing and place

housing over the pump body aligning the flange housing

with the pump body ribs pressing it into place.

nstall the first diaphragm and O-ring on to the pump shaft

by threading on to shaft using a flat blade screwdriver to

hold the pump shaft until the diaphragm is tight. nstall the

second diaphragm and O-ring on to the pump shaft turning

clockwise until tight.

nstall the suction valves with springs facing into the pump

body and the discharge valves with the springs facing out.

See arrows on pump rear end cap below suction and

discharge ports.

nstall the port retainer clips (large) into the pump end cap

(mounting base) and install the seven (7) Phillips screws

into pump body and cross tighten until snug and then cross

torque to 22-24 inch pounds. nstall port retaining clips

(small) into the pump body with tabs facing out. Position the

front end cap and install the seven (7) Phillips screws into

pump body and cross tighten until snug and then cross

torque to 22-24 inch pounds.

nstall the muffler in the center port by pushing it in and

sliding the retainer clip into place. nstall the suction and

discharge ports and the air inlet port fitting and slide the

retainer clips in place. Check for leaks.