DISASSEMBLE

Pressure Switch (9)

1. Disconnect power to pump and open a faucet or valve to

relieve system pressure.

2. Remove the two visible Pressure Switch Screws located on

each side of the Pressure Switch (9). DO NOT ADJUST

ALLEN HEAD SCREW IN CENTER OF SWITCH.

Upper Housing (1)

3. Loosen but DO NOT remove the four Pump Head Screws and

carefully remove Upper Housing Assembly (1).

4. Slide Port Clip (8) back and unplug from Tank Plumbing.

5. Remove Check Valve (2) and inspect for debris.

Check Valve Assembly (2) Follow Steps 1, 3 & 4

6. Inspect Check Valve (2) and O-Ring

Lower Housing (4) Follow Step 1

7. Remove pump from both Base and Tank Plumbing.

8. Remove Rubber Feet by pulling out and sliding to the rear

and follow step 3.

9. Rotate Lower Housing (4), so access Rubber Grommet foot

notch is aligned with Cam Bearing Set Screw (4-C), loosen

set screw with a 1/8” Allen Wrench and slide pump head off

motor shaft.

Diaphragm (3-B)

10. Loosen four cam piston screws with Phillips head screw

driver and pull apart cam (4-B) from Inner Pistons (3-A). (Both

pistons (3-A & C) should be replaced when a new Diaphragm

(3-13) is installed.)

Motor (5) Follow Steps 1, 7, 8 & 9

REASSEMBLE

Diaphragm (3-B)

1. Insert Outer Pistons (3-C) into Lower Housing (4-A) by

bending pistons at center fold.

2.

Placing the Diaphragm (3-B) (flatter side of Diaphragm facing the

motor) on the Lower Housing (4-A). Press each Inner Piston (3-A)

through the Diaphragm and Lower Housing (4-A) into Outer

Piston (3-C). Hex stem of Inner Pistons (3-A) must be aligned into

hex holes in Outer Pistons (3-C). Tighten cam piston screws

partially, center piston in diaphragm, and tighten screws securely

(18 in. lbs. torque). Also, the Outer Pistons (3-C) must be aligned

with alignment slots on Cam Assembly (4-B) making sure screw

holes align in cam assembly, otherwise diaphragm will leak.

Cam Bearing (4-B)

3. Place Cam Bearing (4-B) over Inner Pistons (3-C) and tighten

down with four Phillips Head Screws. (18 in. lbs. torque)

Lower Housing (4) to Motor (6)

Coat motor shaft with grease prior to installing Cam Bearing

(4-B).

4. When installing the Lower Housing (4), rotate mounting foot

notch to align with Cam Bearing Set Screw (4-C).

5. Attach Cam Bearing (4-B) to motor shaft indentation with

Cam Bearing Set Screw (4-C). (35 in. lbs. torque)

6. Reinsert Rubber Feet.

Check Valve (2)

7. Place Ferrules (Rubber Cones) in the Upper Housing (1)

coned side first.

8. Properly seat O-Ring in Check Valve (2) and insert Check

Valve (2) into the Upper Housing (1).

Upper Housing (1)

9. Place Upper Housing (1) on top of the Lower Housing (4-A)

and tighten Hex Bolts (30 in. lbs. torque) through the Upper

Housing (1) to the Motor.

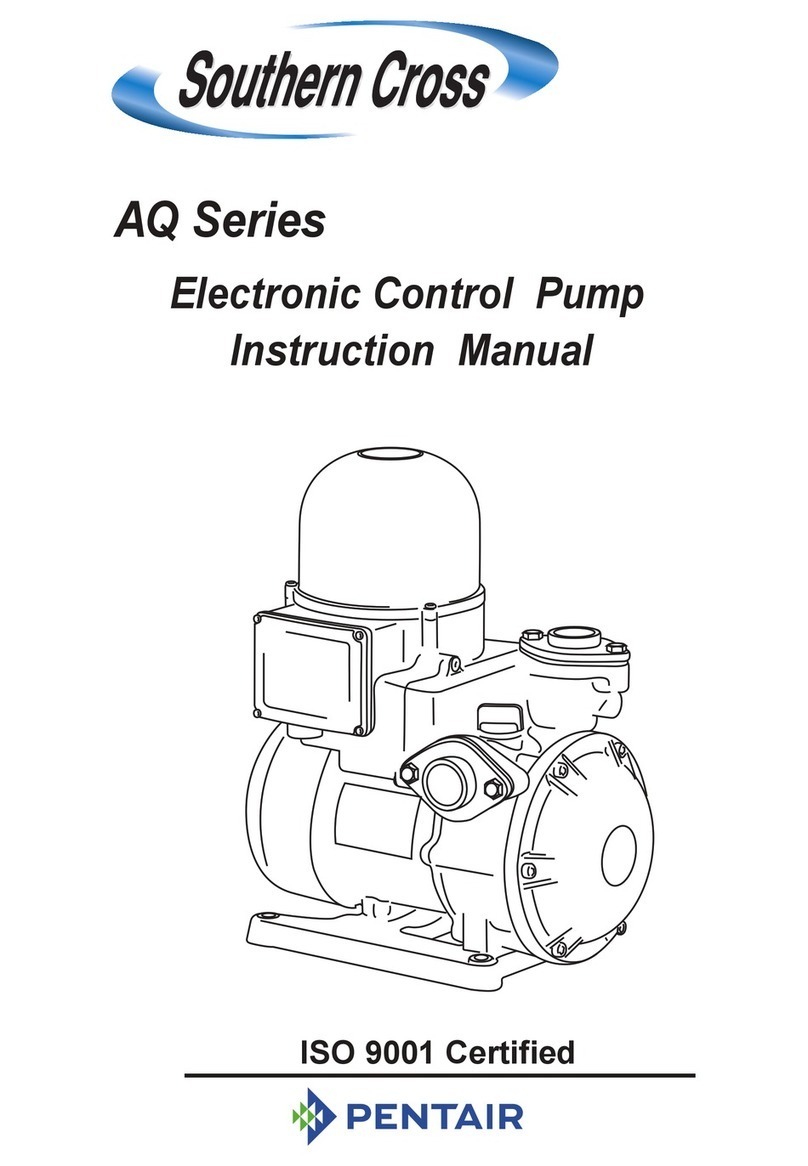

WARNING: DISCONNECT POWER TO PUMP AND OPEN VALVE TO

RELIEVE WATER PRESSURE PRIOR TO SERVICING PUMP

2

1

4

6

9

3

A

5

B

A

BC

D

C

7Includes items 1 thru 4

8

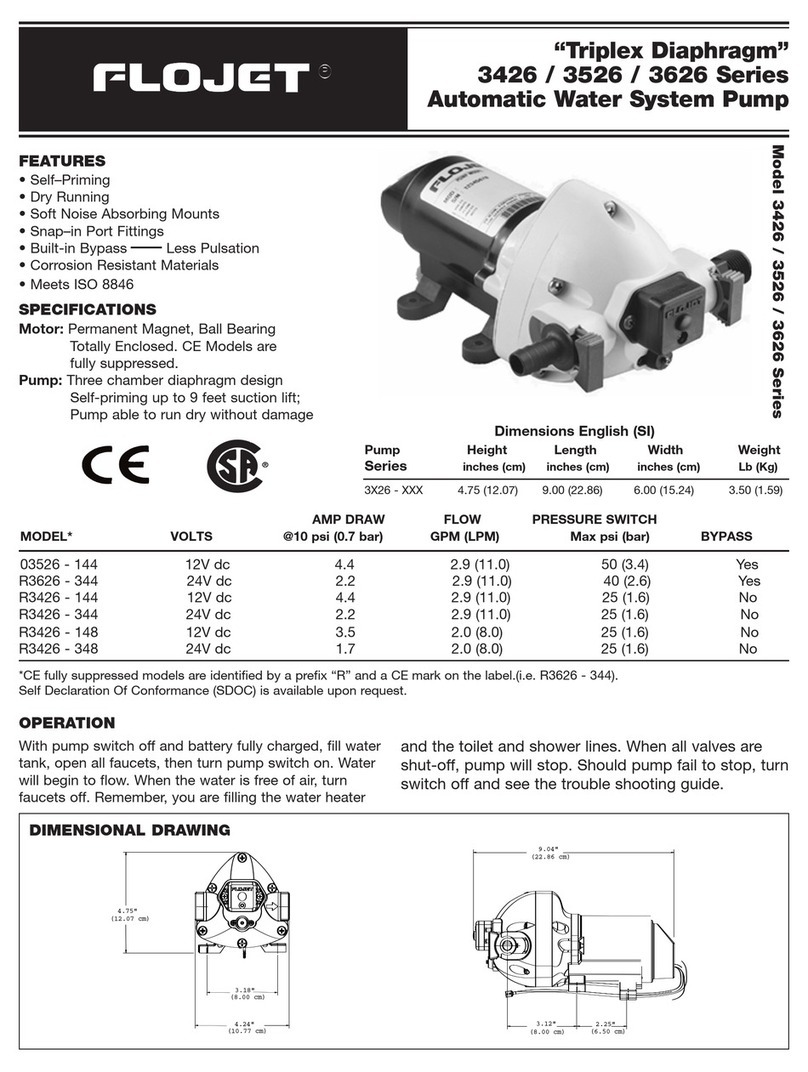

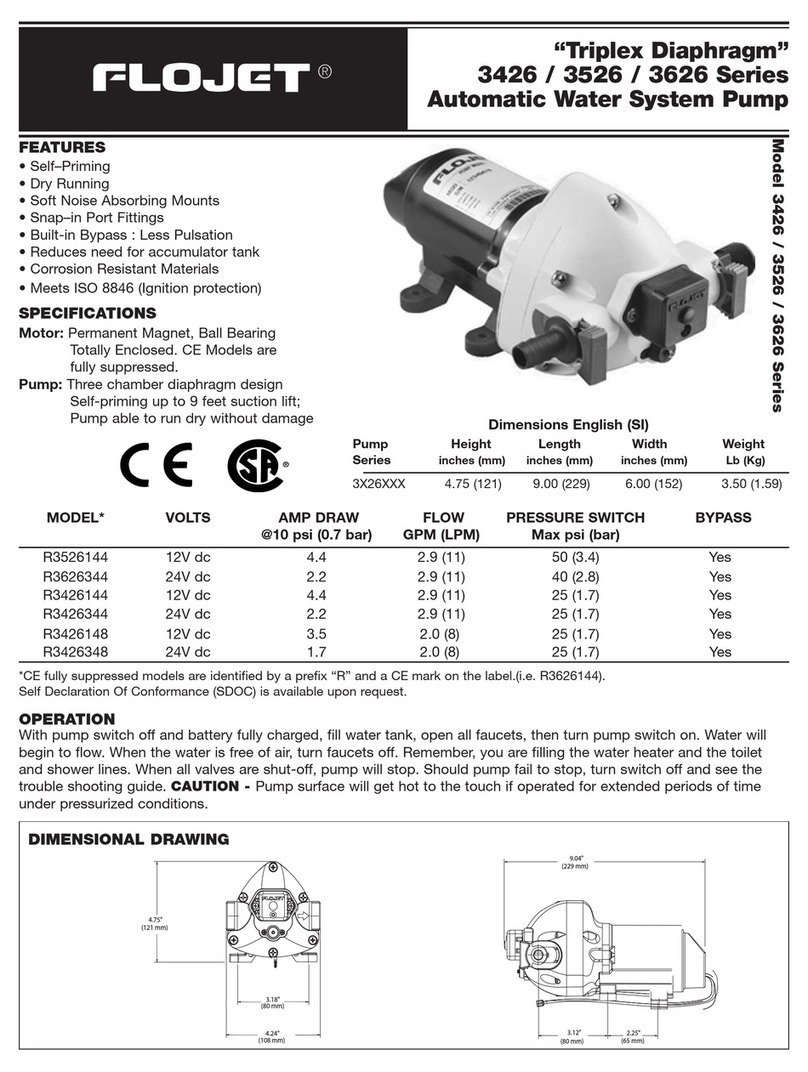

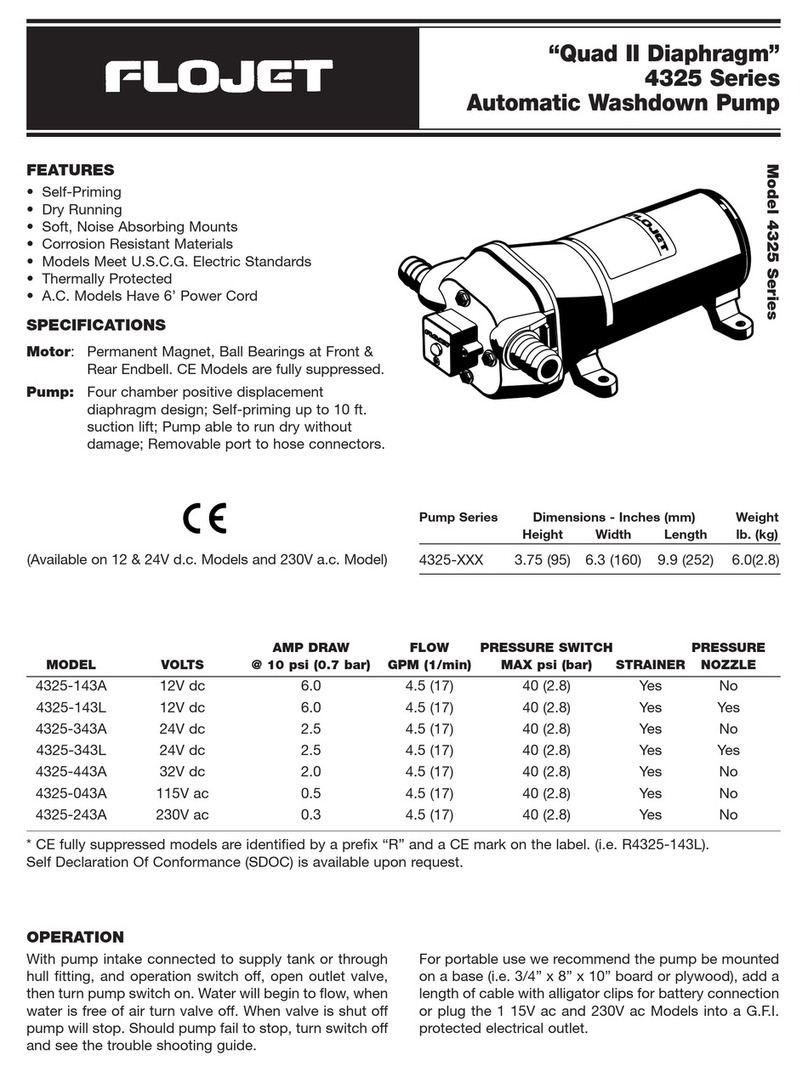

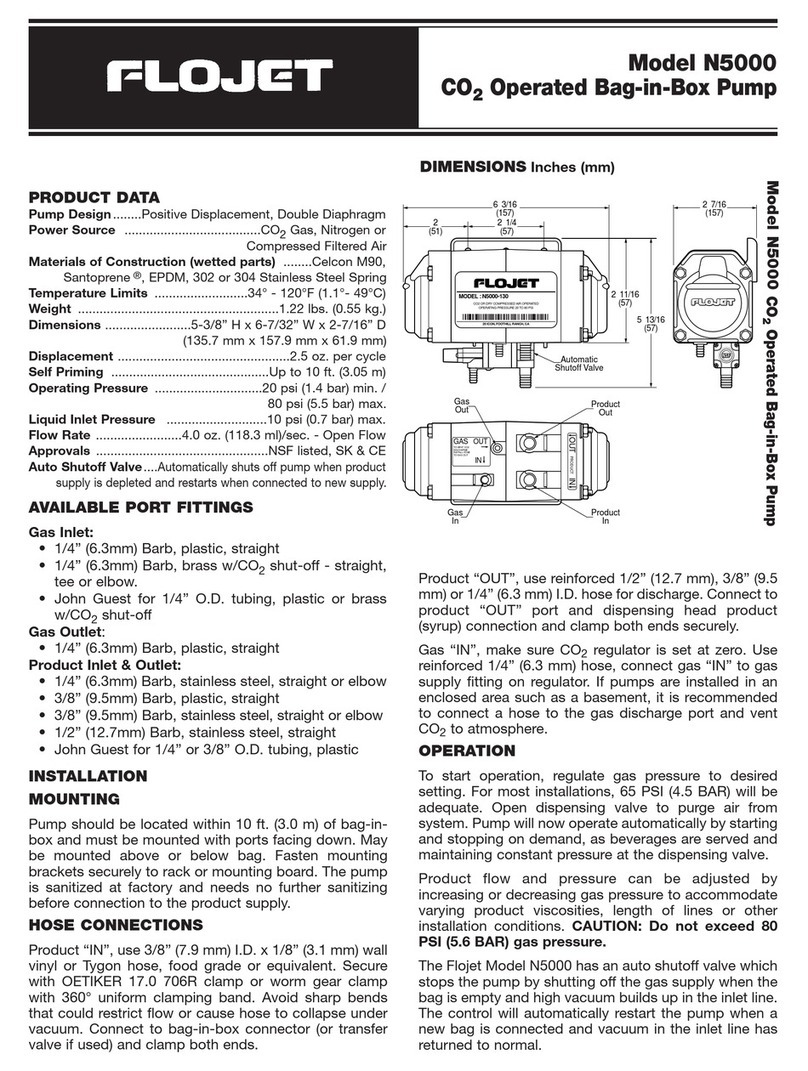

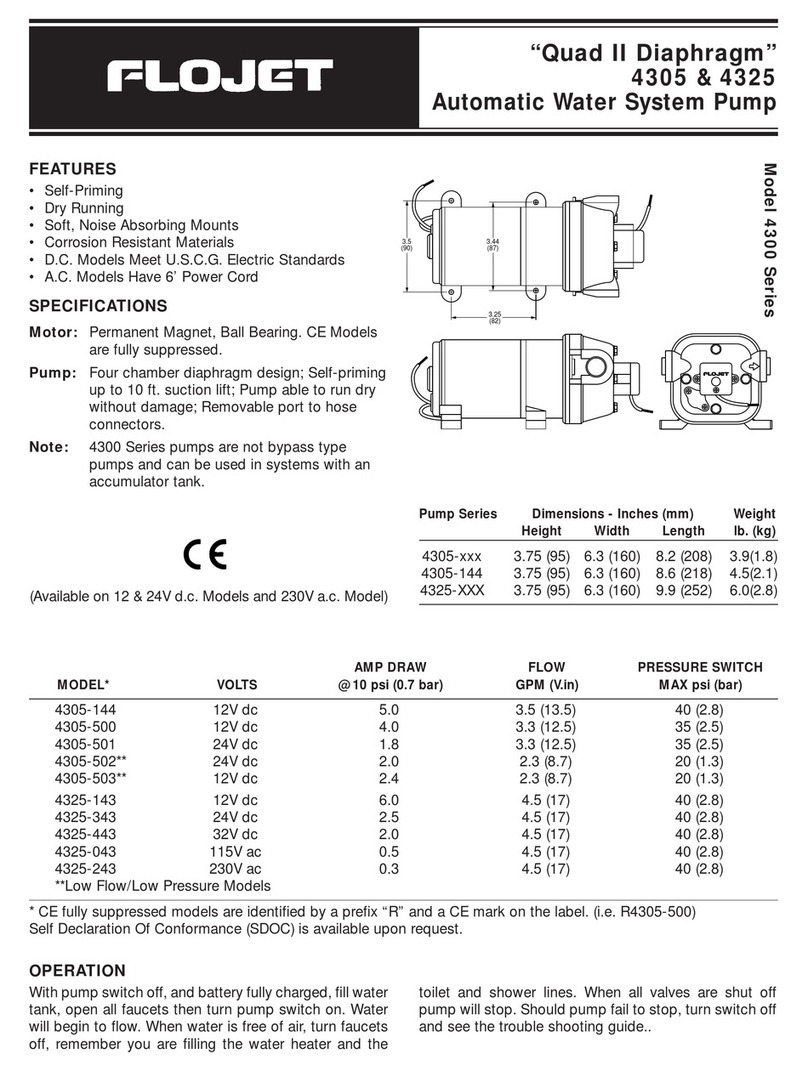

Key Part No. Description Qty

“ 120796-000A Base 1

6 20381-022 Port Kit - (set of 2)

Hose Barb, 90° 3/4” 1

Hose Barb, Straight 3/4” 1

7 20406-002A Pump Head Assy. 1

8 20408-000 Port Clips (Set of 2) 1

9 02090-118 Pressure Switch - 40 PSI Off, Sealed 1

“04325-143A

Complete MPU w/Strainer - 12V 4.5 GPM

1

“ 04305-144A

Complete MPU w/Strainer - 12V 3.5 GPM

1

“ 04305-500A

Complete MPU w/Strainer - 12V 3.3 GPM

1

“04325-343A

Complete MPU w/Strainer - 24V 4.5 GPM

1

“ 04325-443A

Complete MPU w/Strainer - 32V 4.5 GPM

1

“04325-043A

Complete MPU w/Strainer - 115V 4.5 GPM

1

“ 01740-000 Strainer, Inline 3/4” Hose Barb 1

Key Part No. Description Qty

0 20409-043 Service Kit*

1 20404-003 Upper Housing Assy Kit 1

220407-030 Check Valve Kit - EPDM 1

w/O-Ring & Ferrules

3 20403-040 Diaphragm Kit, Santo 1

w/Pistons & Screws

4 20419-002 Lower Housing 1

502009-080A Motor 12 Volt DC 2840-100 1

02009-087A Motor 12 Volt DC 2840-110 1

02009-073A Motor 12 Volt DC 2840-120 1

02019-027A Motor 24 Volt DC 2840-300 1

02049-026A Motor 32 Volt DC 2840-400 1

02029-091A Motor 115 Volt AC 2840-000 1

“ 20799-000A Accumulator Tank 1

*Service Kit includes #2, #3, #8 and drive cam assembly.

!!