Section

1

Introduction

&

Specifications

1

-

1. INTRODUCTION

1

-

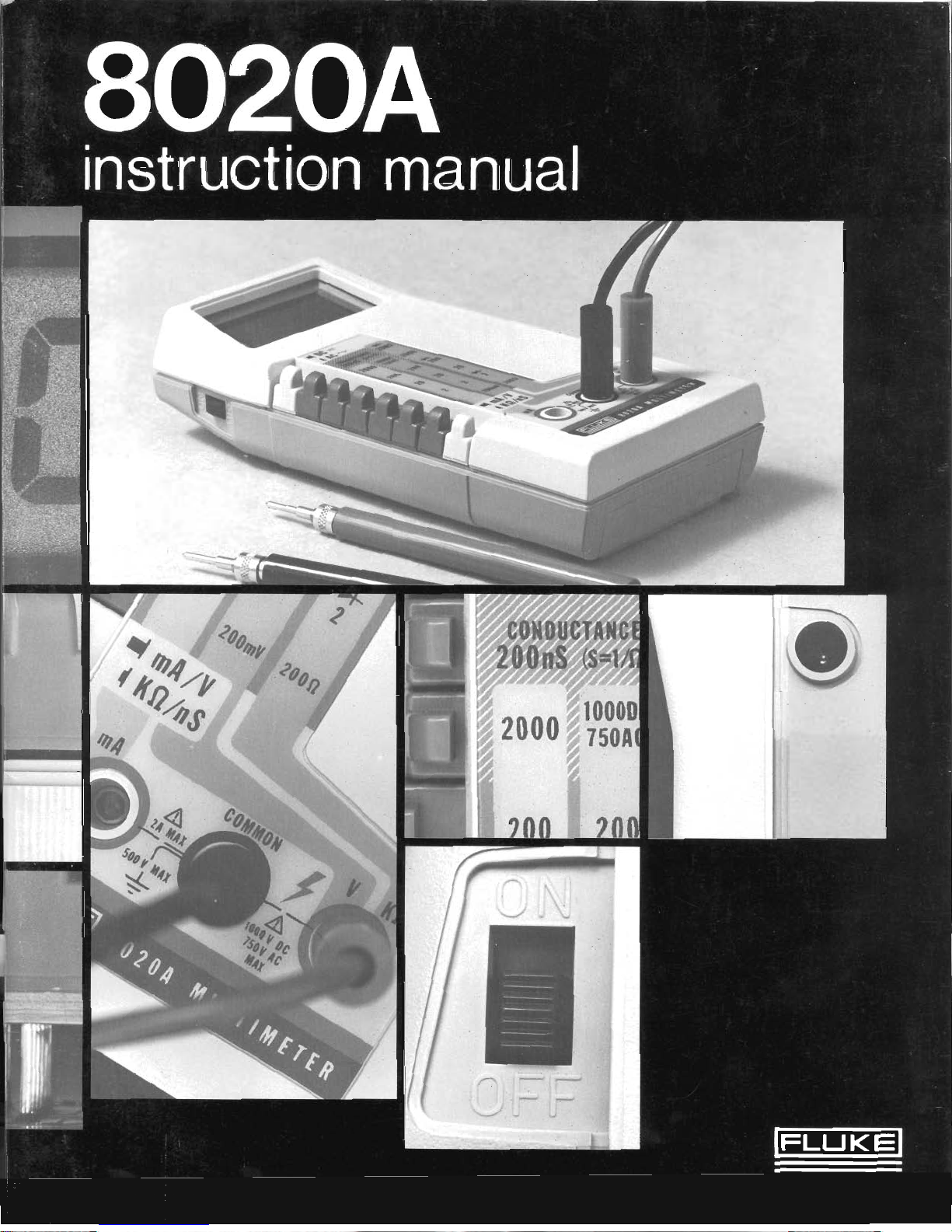

2. The Fluke Model 8020A is a portable 3%

-

digit,

pocket

-

sized multimeter that is ideally suited for field,

lab, shop, bench, or homeapplications. It weighsinatan

impressive369 grams (13 ounces) with battery,and packs

more measurement power than the heavy

-

weights.

Here's a review of some of the features that qualify the

8020A as a real pro:

All VOM functions plus the versatile conductance

function (six in all) are included as standard.

DC Voltage

-

100 pV to lOOOV

AC Voltage

-

100 pV to 750V

DC Current

-

1 pA to 2000 mA

AC Current

-

1 pA to 2000 mA

Resistance

-

0.1R to 20 MR

Conductance

-

0.1 nS to 200 nSand .001 mS to 2 mS

(S

=

siemens

=

1

/

R).

CONDUCTANCE!! A new multimeter function that

allows fast, accurate, noise free resistance measure

-

ments up to 10,000 MR.

Line operation is possible using a Model A81 Battery

Eliminator (See Section 6, accessories).

Effective overload and transient protection on all

ranges.

overrange indication on each range.

Long term calibration (1 year) is achieved by using

high stability components, and minimizing adjustments

(three total).

Full auto

-

polarity operation.

Dual slope integration toensure fast, accurate, noise

free measurements.

A complete line of range extending accessories is

available.

1-3. PREPARING FOR OPERATION

1

-

4. Unpacking

1

-

5. When received, the 8020A shipping carton

The

latest IC

and

is

used

to

should contain the items listed below. Account for, and

achieve the lowest possible component count. This, in

inspect

each

item

before the

is

discarded.

In

the

turn, ensures reliability, accuracy, stability and a really event of a damaged instrument, contact your nearest

rugged, easy

-

to

-

handle instrument. John Fluke Service Center as listed at the rear of this

Up to 200 hours of continuous operation can be

expected from a single, inexpensive, 9V, alkaline battery

(transitor radio/calculator type).

Low battery voltage automatically detected and

displayed.

No needles to bend. No parallax and no zero adjust.

Just a high contrast, easy

-

to

-

read, 3-112 digit, liquid

crystal display.

manual. Please retain. and use the shipping container if

reshipment is required.

Contents:

1

-

Model 8020A Multimeter

1

-

Model 8020A Instruction Manual

1

-

9V Battery

1

-

Set of Test Leads (red and black)

1

-

8020A Operator's Guide (plastic card)

X

-

Accessories as ordered