i

Table of Contents

Title Page

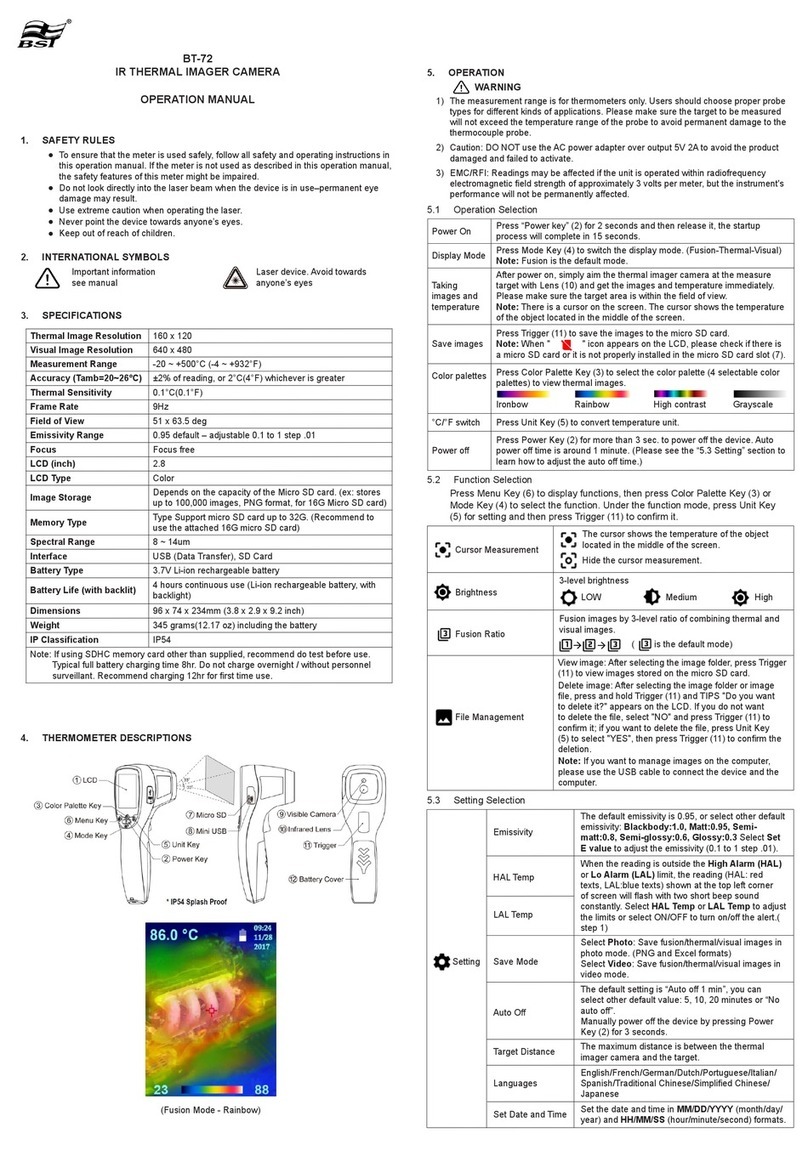

1. Safety Instructions .................................................................................. 1

2. Product Description ................................................................................ 3

2.1. System Architecture .................................................................................... 4

3. Technical Data ......................................................................................... 5

3.1. General Specifications ................................................................................ 5

3.2. Electrical Specifications .............................................................................. 5

3.3. Measurement and Optical Specifications .................................................... 6

3.4. Dimensions ................................................................................................. 6

3.5. Scope of Delivery ........................................................................................ 7

4. Basics to keep in mind ............................................................................ 7

4.1. ThermoView® TV40 Imager Location .......................................................... 7

4.2. Measurement of Infrared Temperatures ...................................................... 8

4.3. Emissivity of Target Object ......................................................................... 8

5. Installation................................................................................................ 8

5.1. Ambient Temperatures ............................................................................... 8

5.2. Environment ............................................................................................... 8

5.3. Electrical Interference ................................................................................. 8

5.4. Geometry .................................................................................................... 9

5.4.1. Spot size (IFOV) calculation of aperture angle for different lens types .... 9

5.5. Focusing ..................................................................................................... 10

5.6. Mounting ..................................................................................................... 10

5.7. Cable Connections ..................................................................................... 10

5.7.1. Connecting the GigE Vision Ethernet Communication Cable .................. 10

5.7.2. Connecting the Power Supply Cable ...................................................... 11

5.8. GigE Vision Communication ....................................................................... 12

5.9. ThermoView® LED Status Indicator............................................................. 12

6. Internal ThermoView® Web-Server Application ..................................... 13

7. Accessories ............................................................................................. 14

7.1. Available electrical accessories for ThermoView® cameras ........................ 14

7.1.1. Power supply cable, 80°C max., 7.5m (25ft.), (A-CB-LT-PS-07) ............. 14

7.1.2. Power supply cable, 80°C max., 25m (80ft.), (A-CB-LT-PS-25) .............. 15

7.1.3. Power supply cable, 80°C max., 50m (160ft.), (A-CB-LT-PS-50) ............ 15

7.1.4. Ethernet cable, 80°C max., 7.5m (25ft.), (A-CB-LT-M12-W08-07) .......... 15

7.1.5. Ethernet cable, 80°C max., 25m (80ft.), (A-CB-LT-M12-W08-25) ........... 16

7.1.6. Ethernet cable, 80°C max., 50m (160ft.), (A-CB-LT-M12-W08-50) ......... 16

7.1.7. PoE Injector (Standard), 115/230VAC, (A-TV-POE1) ............................. 16

7.1.8. PoE Injector (Industrial), 115/230VAC, (A-TV-POE2) ............................. 17

7.1.9. 24 VDC 1.3 A industrial power supply, DIN rail mount (A-PS-DIN-24V).. 19

7.1.10. Ethernet Cable 25 m (82 ft), two RJ45 connectors (A-CB-LT-RJ45-25) .. 19

7.1.11. Fiber Optic to Ethernet Converter (A-CON-FO-RJ45) ............................. 20

7.1.12. Fiber Optic Cable 150 m (492 ft) (A-CB-FO-150) ................................... 22

7.1.13. Fiber Optic Cable 300m (984ft) (A-CB-FO-300) ..................................... 22

7.1.14. 4-Port Gigabit Ethernet Switch (A-CON-SW) .......................................... 22

7.1.15. Ethernet cable (short) for Junction Box (A-CB-LT-RJ45-03) ................... 24

7.1.16. Digital In, 16 each (A-CON-16DI) ........................................................... 25