8 9

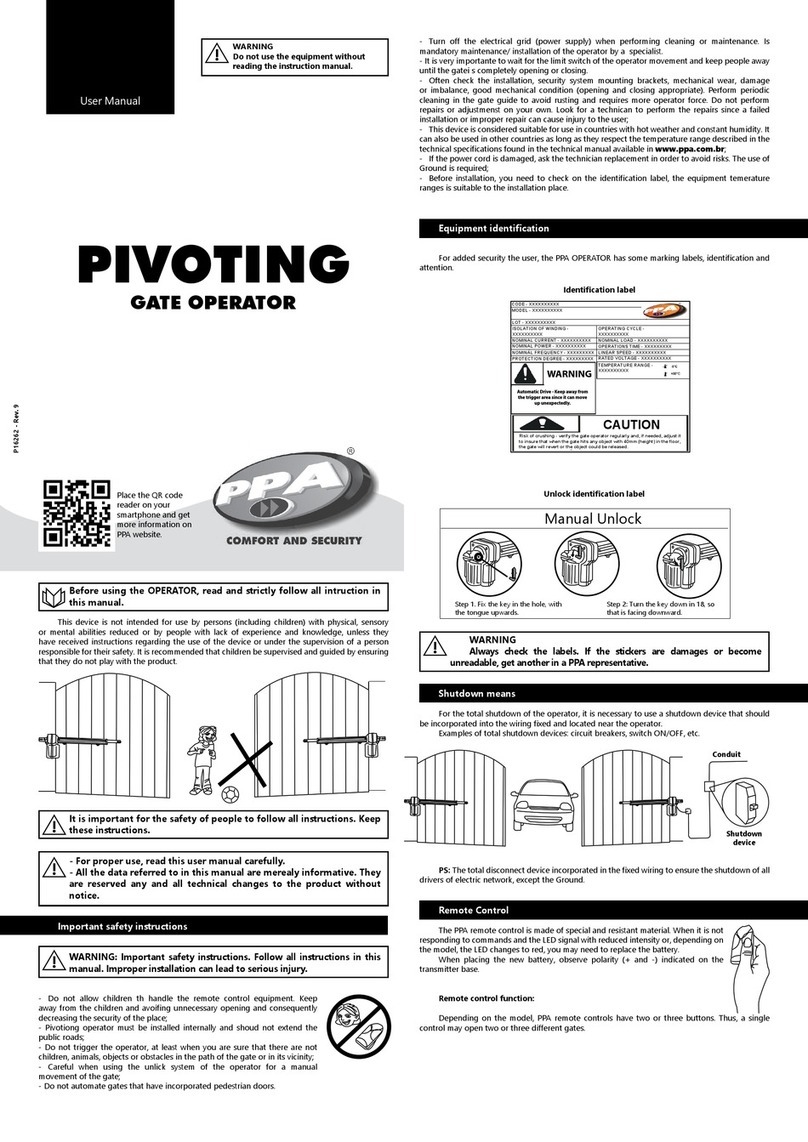

GATE CARE BEFORE OPERATION

Before applying the operator to the gate, some procedures must be taken:

-Check the performance of the gate before starting the machine installation;

-Check the eort required to move the gate. It should be moved smoothly along

the entire route. To check this eort, move the gate at a distance of 80 cm from the

turning point (where the operator exerts force to move);

-The gate must have a resistant structure and, as much as possible, non-deformable.

INSTALLATION AND FIXING THE

OPERATOR

Before installing the operator, remove all unnecessary cables

and disable any equipment or system connected to the electrical

network.

To install the equipment, follow the steps mentioned below:

The gearmotor is universal, so it can be installed on both sides, left-hand leaves and

right-hand leaves.

LEFT / RIGHT

To x the equipment, carefully follow the instructions below:

1st Step: The gate must open to the interior of the property. Provide a 150mm x

150mm x 1/4”at iron base. This will be the base of the xture.

2nd Step: Fix, on the wall or on the gate column, the base of the xing bracket at

a distance of 25 to 60 mm from the turning point of the gate and at the desired

height for xing the operator to the gate, as shown in the gure below.

3rd Step:Weld the xing bracket to the base, according to instructions / illustrations

below.

MEASURES FOR INSTALLATION OF FIXING BRACKETS

OPERATOR X Y Z LENGTH MAXIMUM

LEAF

SK (STANDARD) 130 130 50 2000

SK (SUPER) 215 215 50 3000

SK PREDIAL

(STANDARD) 175 175 50 2000

SK PREDIAL (SUPER) 350 350 50 3500

SK PREDIAL (MEGA) 400 400 50 4500

Maximum allowable measurements for standard installation (in millimeters)

BASE

OF THE

FIXTURE

COLUMN

TURN POINT

25 mm to

60 mm

GATE LEAF