Forma Scientific 3920 User manual

Other manuals for 3920

2

Table of contents

Other Forma Scientific Laboratory Equipment manuals

Forma Scientific

Forma Scientific 1122 User manual

Forma Scientific

Forma Scientific 1284 User manual

Forma Scientific

Forma Scientific 3911 User manual

Forma Scientific

Forma Scientific 1284 User manual

Forma Scientific

Forma Scientific 8172 User manual

Forma Scientific

Forma Scientific 3911 User manual

Forma Scientific

Forma Scientific 3911 User manual

Forma Scientific

Forma Scientific ThermoQuest 3110 Series Operating instructions

Forma Scientific

Forma Scientific 3911 User manual

Forma Scientific

Forma Scientific 3940 Operating instructions

Popular Laboratory Equipment manuals by other brands

Thermo Scientific

Thermo Scientific Pierce G2 user manual

Heathrow Scientific

Heathrow Scientific Vortexer instruction manual

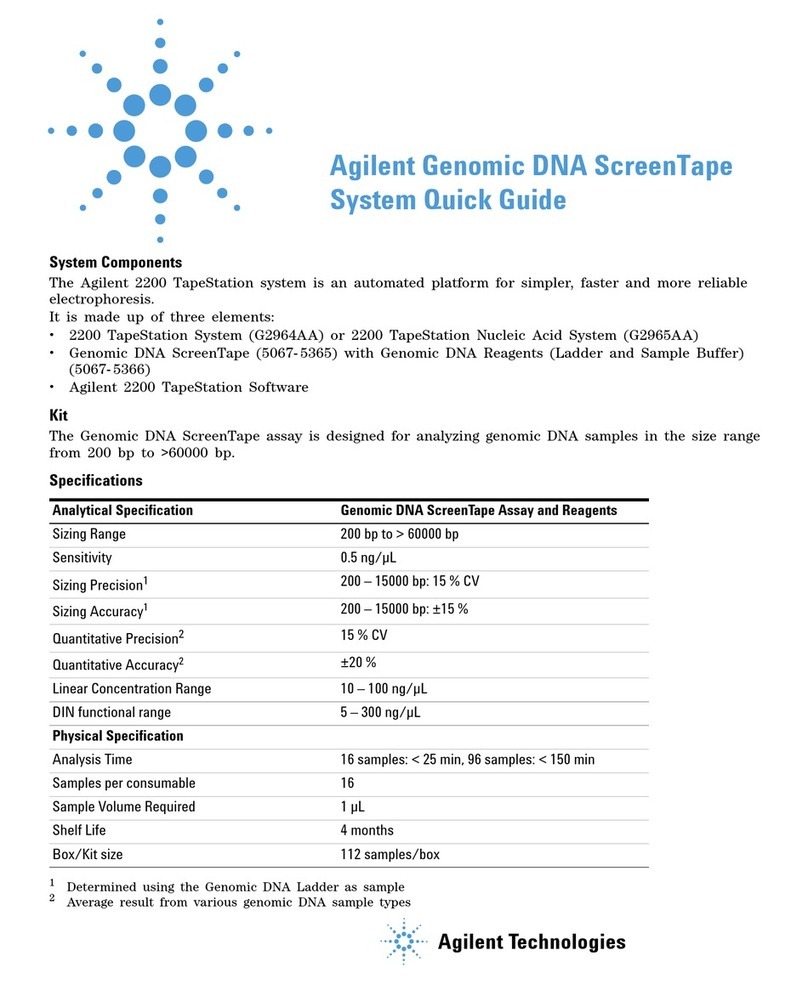

Agilent Technologies

Agilent Technologies Genomic DNA ScreenTape System quick guide

FujiFilm

FujiFilm FUJI DRI-CHEM IC CUPS Instructions for use

Heidolph

Heidolph Hei-TORQUE Expert operating instructions

GE

GE akta start manual

Hettich

Hettich ROTANTA 460 S operating instructions

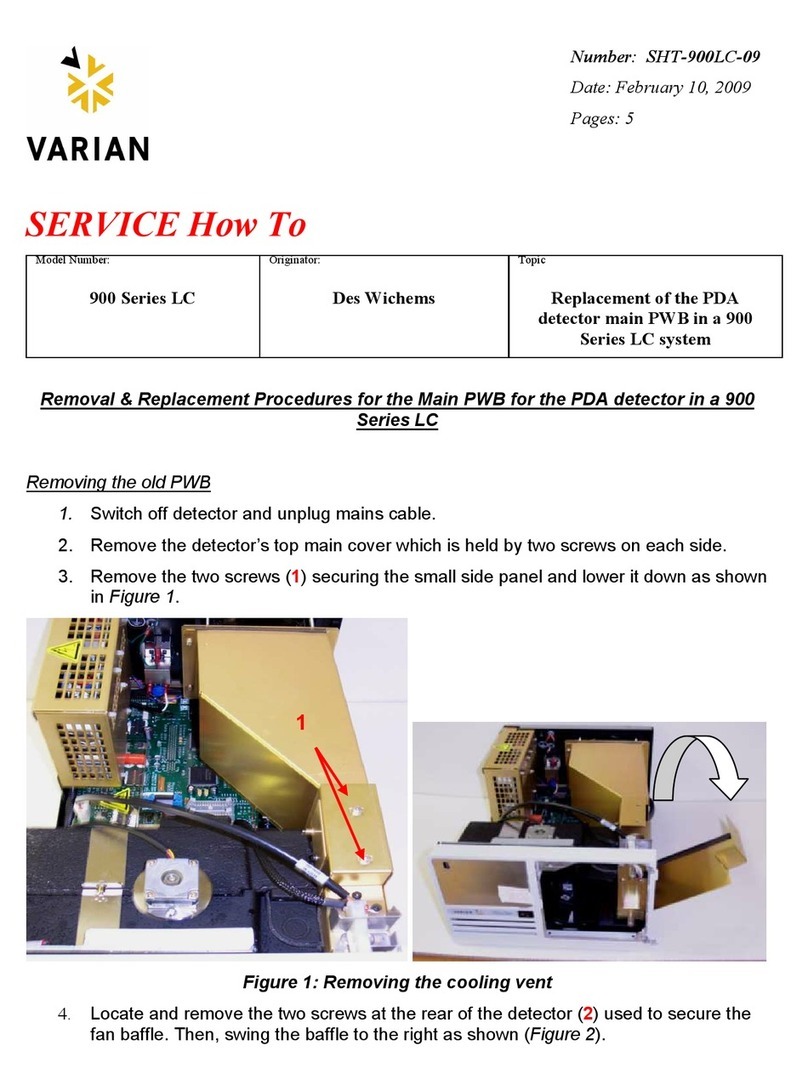

Varian

Varian 900-LC Series Removal & Replacement Procedures

Reverberi

Reverberi Full Clave B 20 Operation and maintenance manual

Fisher Scientific

Fisher Scientific Isotemp 148 instruction manual

Tecnomed Italia

Tecnomed Italia STERIL FAN SFA2030F manual

Altana

Altana BYK byko-drive S Short instructions