FormaModel 1280/1290 Series _______________________________________Operation

4-4

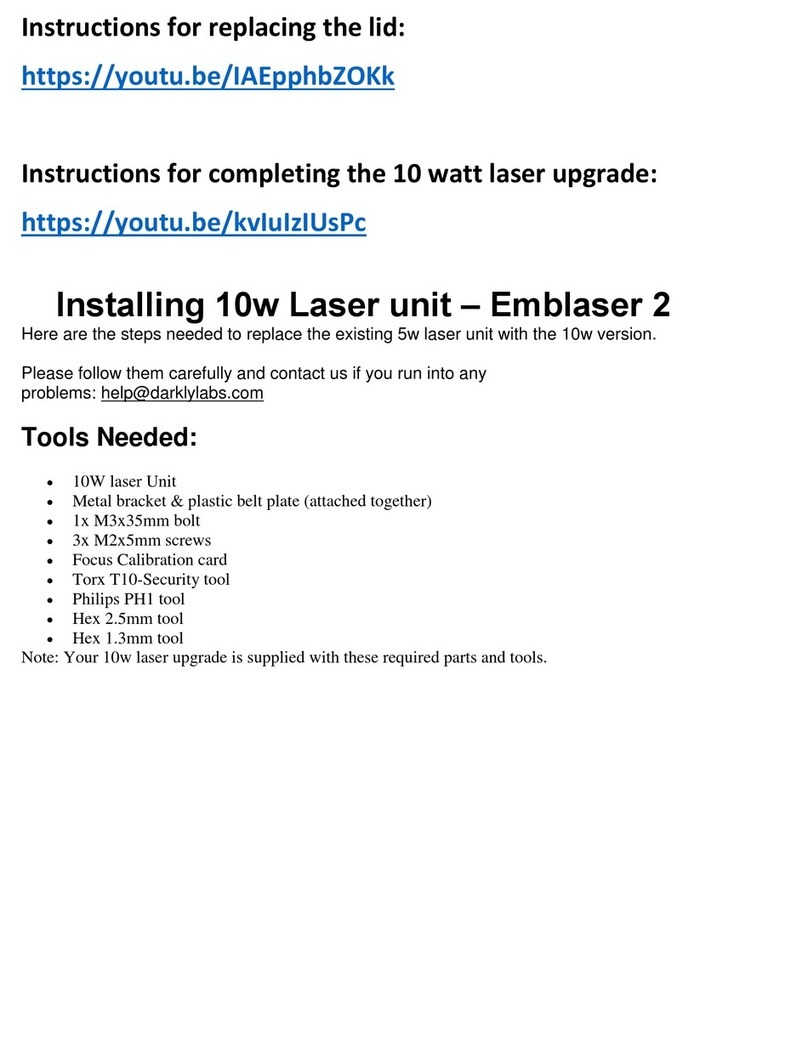

Receptacle Fuses (7 Amp, Models 1284, 1285 and 1288)

(3 Amp, Models 1286, 1287, 1290 and 1291) - The receptacle fuses (2),

located directly below the Blower Motor/Lights Reset Button, are for the receptacles only. If

an overload occurs, the fuses will open and require replacement.

Note: !Turn the power off.

!Unplug the unit.

!Replace the fuses - Forma P/N 230182, 7 Amp, ¼” x 1¼”

Forma P/N 230166, 3 Amp, ¼” x 1¼”

(Two spare fuses are located in a bracket on the inside of the control

panel.)

Receptacles - Receptacles (115 Volts) are located on the left and right sidewall of the

workstation. Power is controlled by the receptacle switch located on the control panel. The

maximum load is 5 amps total for Models 1284, 1285 and 1288. Models 1286, 1287, 1290 and

1291 have a maximum load of 2 amps total. Models 1285 and 1287 are equipped with 2 single

European 230V receptacles.

Drain Valve - The drain valve, located on the right front side of the cabinet, is provided for

the safe drainage of the drain pan. This valve must remain closed while work is being

performed in the cabinet and be used only in the event of a major spill.

If a spill occurs, immediately consult a biological safety officer or

other qualified individual for proper procedures. To contain a spill,

connect a sealed hose from the drain valve to a sealed container.

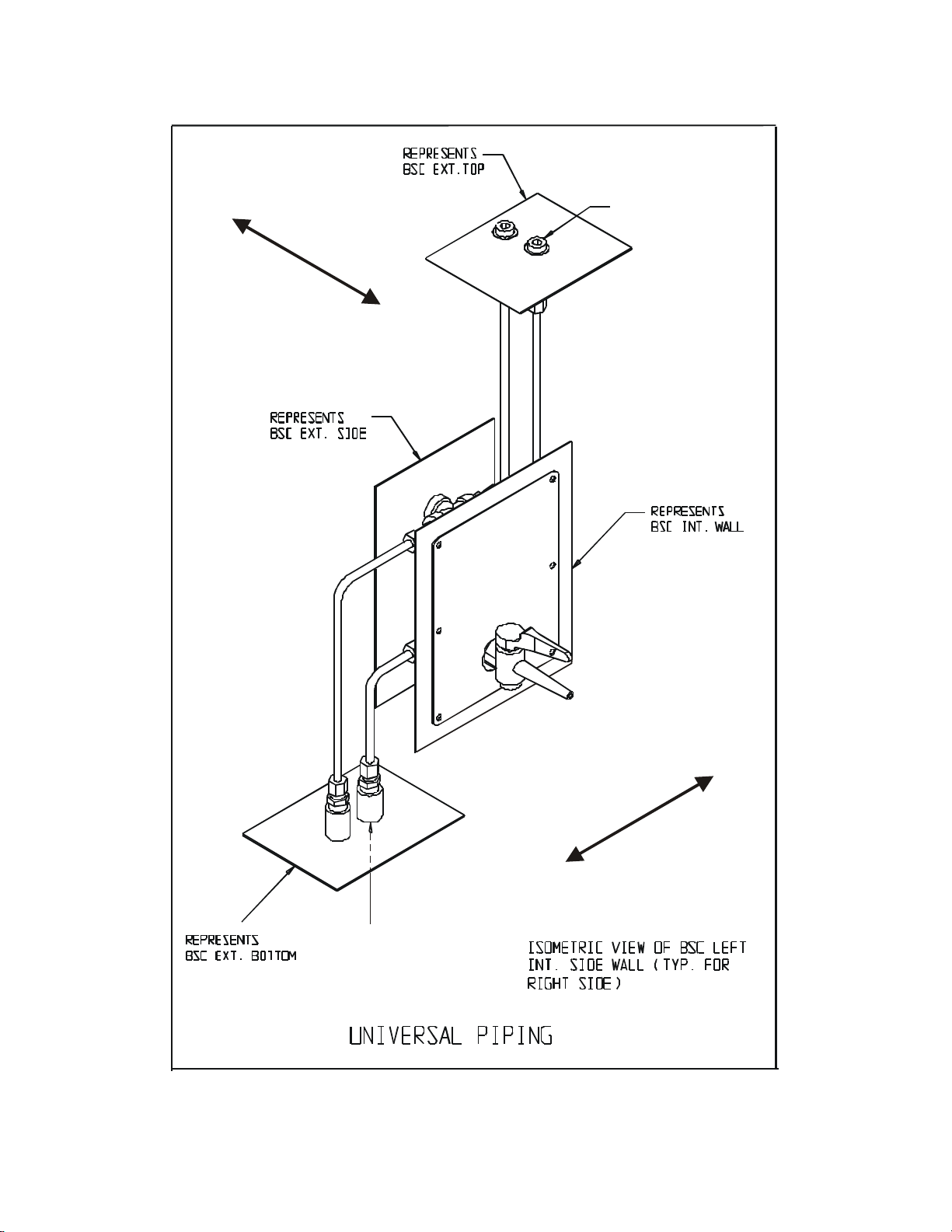

Service Valves - Two service valves are standard with each cabinet. These valves are located

on the right and left side of the workstation and can be coded with the type of service that

they supply. Identification index buttons are supplied.

The cabinet supports four service valves. Additional valves may be purchased from Forma

Scientific.

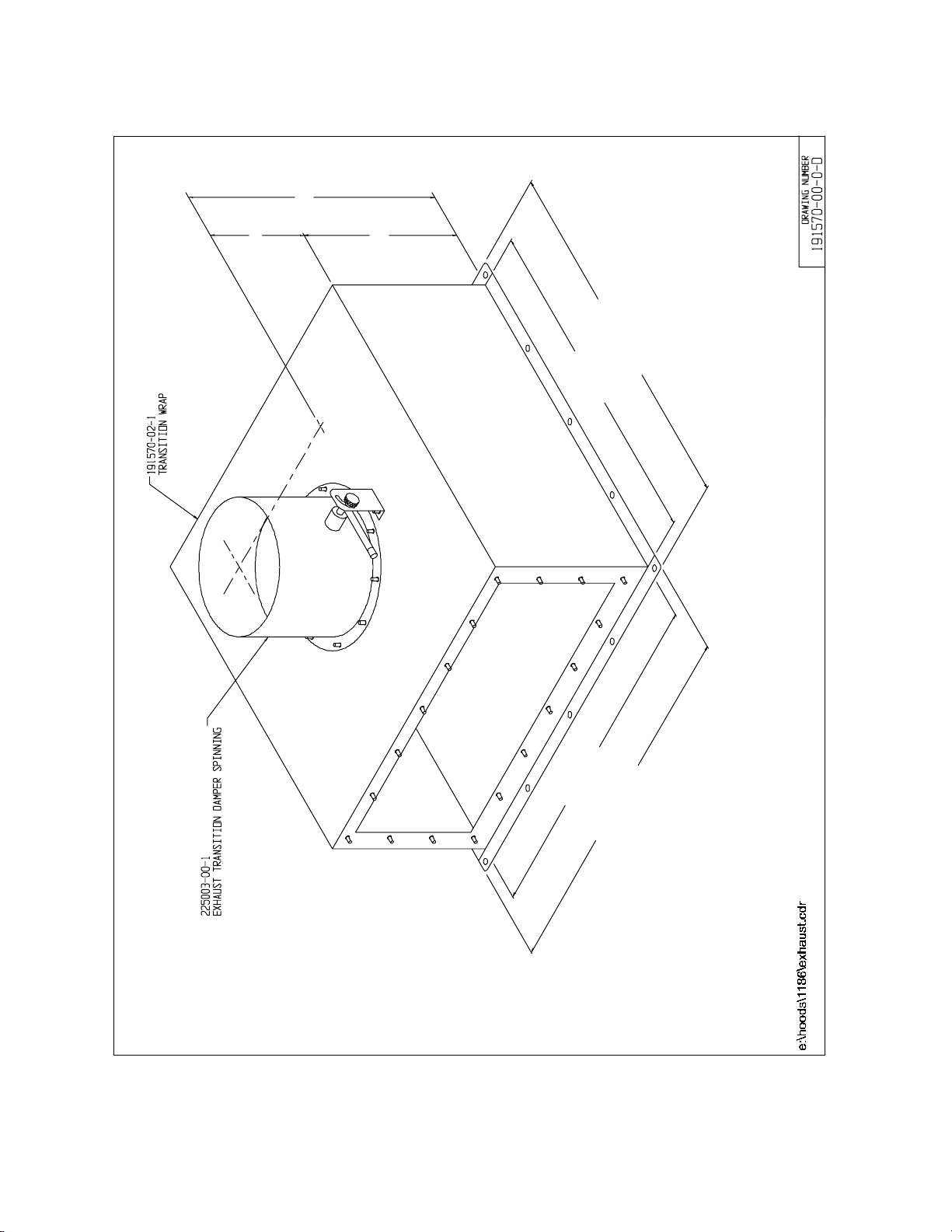

Exhaust Filter Guard - The exhaust filter guard, located on top of the exhaust filter,

protects the exhaust airflow and prevents the storage of objects on top of the housing.

Sliding Window Assembly - The sliding window assembly allows the operator to raise the

glass window to place items within the work area. If the sliding window is above the 10-inch

level, a red light and audible alarm warns that an unsafe condition exists.

When work is being performed in the cabinet, the sliding window must be at

the 10-inch position to avoid contamination to product and personnel.