Table of Contents

1. Notes on This Manual ................................................................................................................. 1

1.1 Scope of Validity ....................................................................................................................1

1.2 Target Group ......................................................................................................................... 1

1.3 Symbols Used ........................................................................................................................1

2. Safety .............................................................................................................................................2

2.1 Appropriate Usage ................................................................................................................ 2

2.2 PE Connection and Leakage Current .................................................................................... 3

3. Introduction ................................................................................................................................... 4

3.1 Basic Features ....................................................................................................................... 4

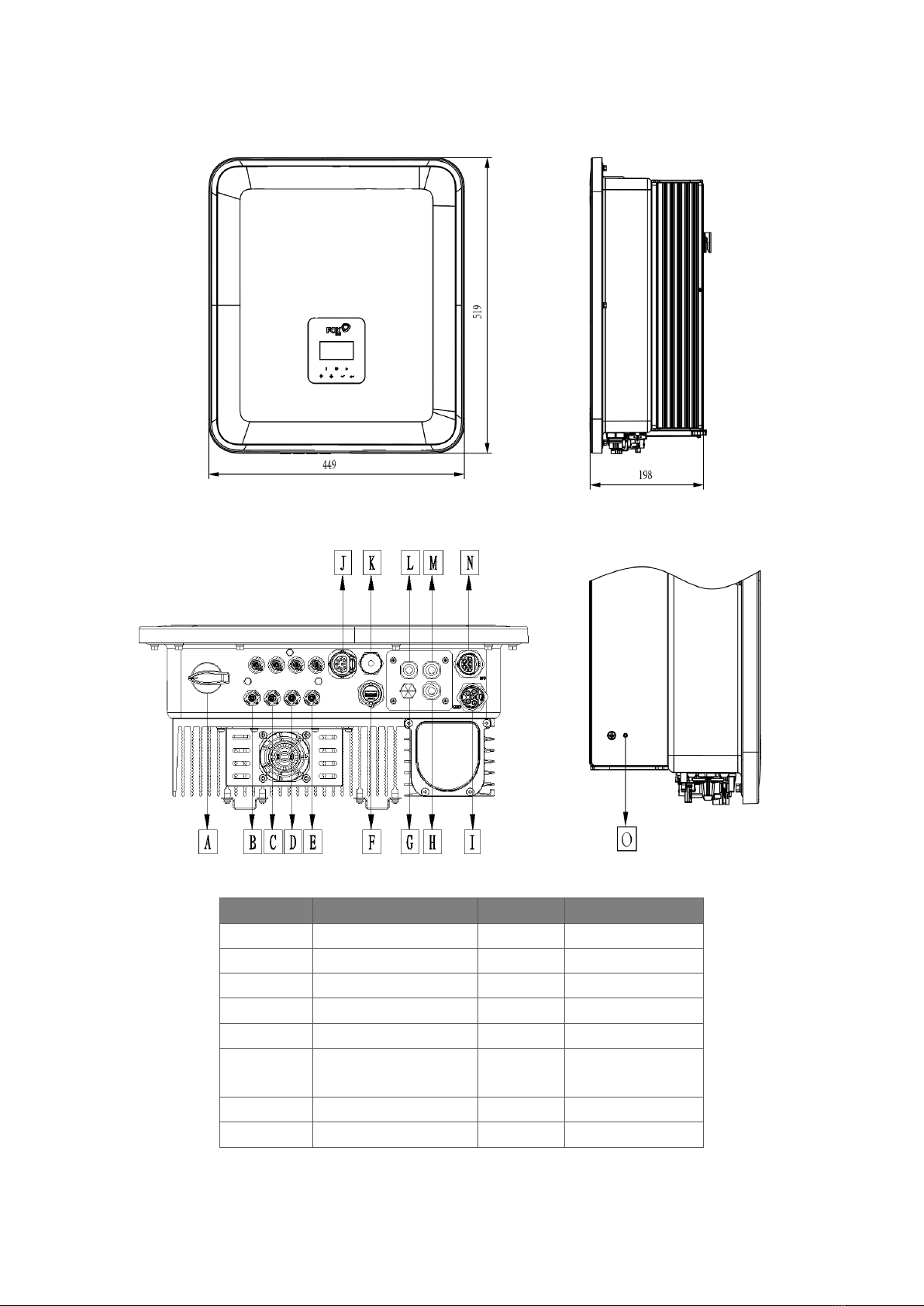

3.2 Dimensions ........................................................................................................................... 6

3.3 Terminals of inverter .............................................................................................................6

4. Technical Data ..............................................................................................................................7

4.1 PV Input (For H3 Only) ..........................................................................................................7

4.2 Battery ...................................................................................................................................7

4.3 AC Output/Input ................................................................................................................... 7

4.4 EPS Output ............................................................................................................................ 8

4.5 Efficiency and Protection ...................................................................................................... 8

4.6 General Data ......................................................................................................................... 9

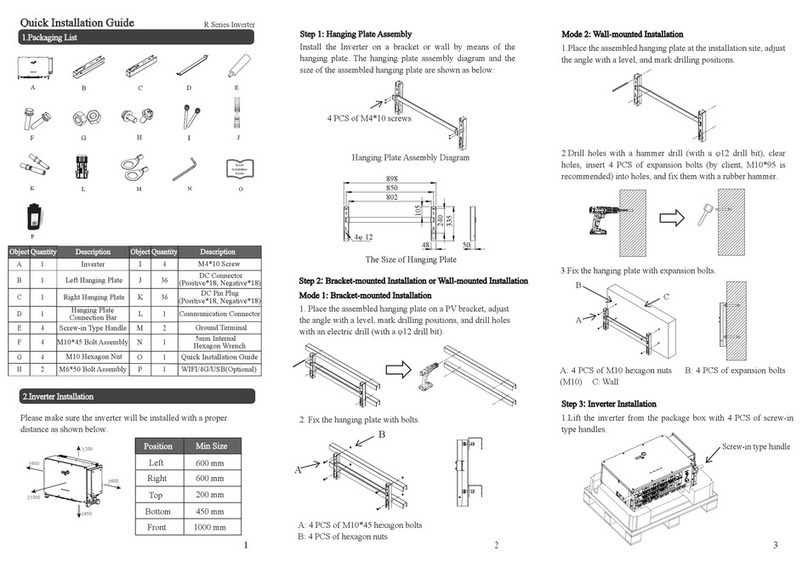

5. Installation ...................................................................................................................................10

5.1 Check for Physical Damage .................................................................................................10

5.2 Packing List ..........................................................................................................................10

5.3 Mounting ............................................................................................................................ 11

6. Electrical Connection ................................................................................................................ 14

6.1 PV Connection (For H3 Only) ..............................................................................................14

6.2 Battery Connection .............................................................................................................16

6.3 Grid Connection ..................................................................................................................17

6.4 Earth Connection ................................................................................................................ 20

6.5 Electrical Connection .......................................................................................................... 21

6.6 EPS Connection (Non-parallel State) .................................................................................. 29

6.7 System Connection Diagrams .............................................................................................29

6.8 Inverter Start-Up .................................................................................................................30

6.9 Inverter Switch Off ..............................................................................................................30

7. Firmware Upgrading ..................................................................................................................31

8. Operation .................................................................................................................................... 32

8.1 Control Panel .......................................................................................................................32

8.2 Function Tree ...................................................................................................................... 33

9. Maintenance............................................................................................................................... 35

9.1 Alarm List ............................................................................................................................ 35

9.2 Troubleshooting and Routine Maintenance .......................................................................40

10. Decommissioning .................................................................................................................... 41

10.1 Dismantling the Inverter ...................................................................................................41

10.2 Packaging .......................................................................................................................... 41

10.3 Storage and Transportation .............................................................................................. 41