4.8.2 Feed system - Screw 2 on LB 62

4.8.3 Feed system - Rotary agitator 63

4.8.4 Discharge - Cyclone 1 (feed system-

configuration 8)

64

4.8.5 Feed system - Cyclone 1 / 2 (suction

screw)

65

4.8.6 Feed system - Cyclone 1 / 2 (4/8 probe

switch)

66

4.9 Network pump 68

4.9.1 Network pump - Status 68

4.9.2 Network pump - Temperatures 69

4.9.3 Network pump - Service 70

4.10 Cascade 72

4.10.1 Cascade - Status 72

4.10.2 Cascade - Backup boiler 72

4.10.3 Cascade - Temperatures 73

4.10.4 Cascade - Service 74

4.11 Difference regulator 75

4.11.1 Difference regulator - Status 75

4.11.2 Difference regulator - Temperatures 75

4.11.3 Difference regulator - Times 76

4.11.4 Difference regulator - Service 76

4.12 Circulation pump 77

4.12.1 Circulation pump - Status 77

4.12.2 Circulation pump - Temperatures 77

4.12.3 Circulation pump - Times 78

4.12.4 Circulation pump - Service 78

4.13 Manual 79

4.13.1 Manual - Manual operation 79

4.13.2 Manual - Digital outputs 80

4.13.3 Manual - Analogue outputs 80

4.13.4 Manual - Digital inputs 81

4.14 System 82

4.14.1 System - Settings 82

Setting - Boiler temperature

82

Setting - Slide-on duct

83

Setting - Flue gas

84

Setting - Ignition

92

Setting - Air settings

93

Setting - Fuel slide-in

95

Setting - Vibration / WOS / Cleaning

98

Setting - WOS / Cleaning

99

Set - Cleaning

100

Setting - Combustion chamber

101

Setting - Lambda values

103

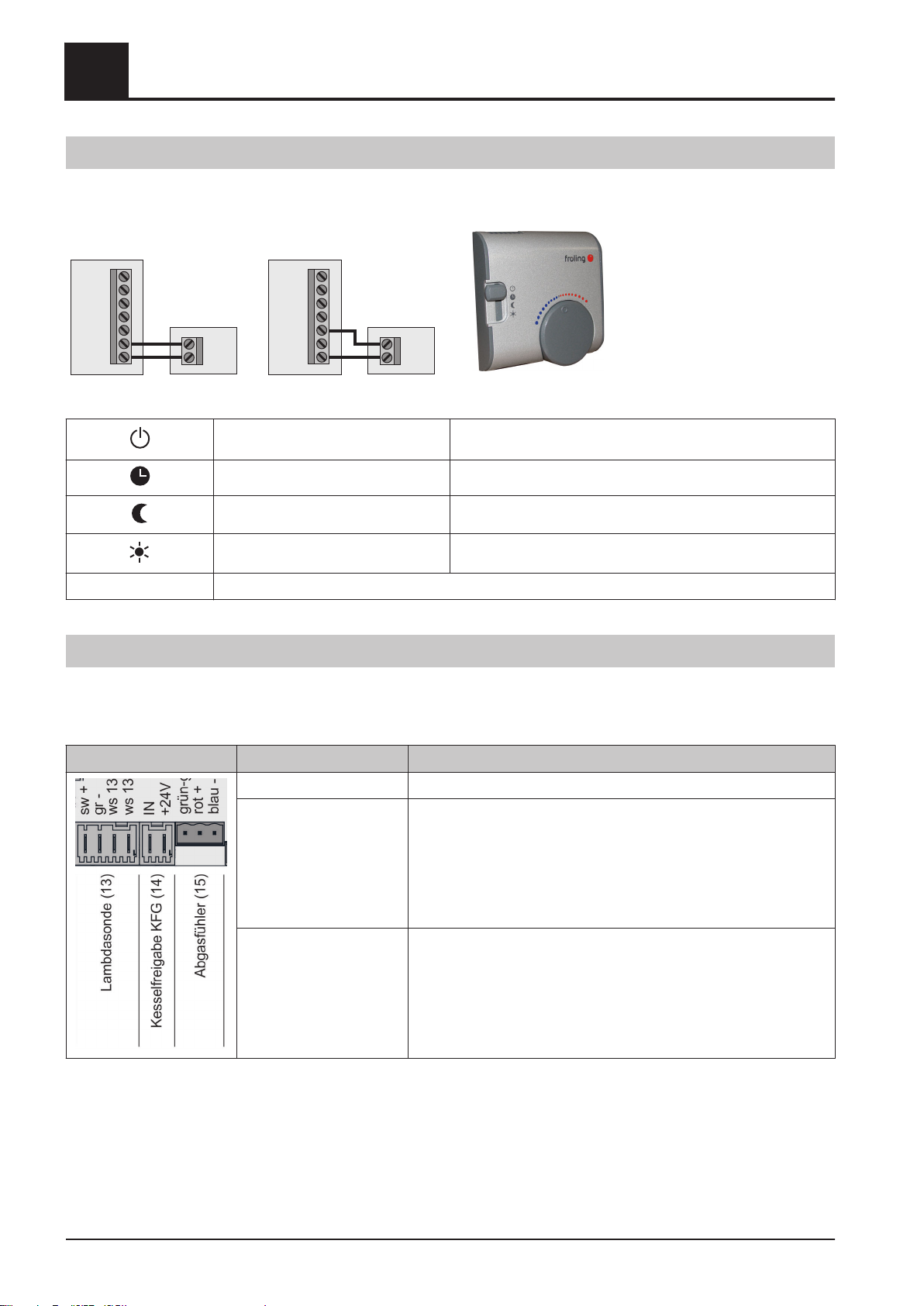

Set - Lambda probe

104

Setting - General settings

106

4.14.2 System - Current values 108

Operation hours

108

4.14.3 System - Sensors and pumps 109

4.14.4 System - System selection 109

4.15 Diagnostics 110

4.15.1 Diagnosis – Current fault list 110

4.15.2 Diagnosis – Clear pending error 110

4.15.3 Diagnostics - Error history 110

4.15.4 Diagnostics - Clear error history 110

4.16 Touchscreen 111

4.16.1 Touchscreen - Display settings 111

Display settings - General

111

Display settings - Basic display

112

Display settings - Date / Time

112

Display settings - Software update / Service

112

4.16.2 Touchscreen - Display operating rights 113

Froling Connect

114

4.16.3 Touchscreen - Display allocation 114

5 FAQ 115

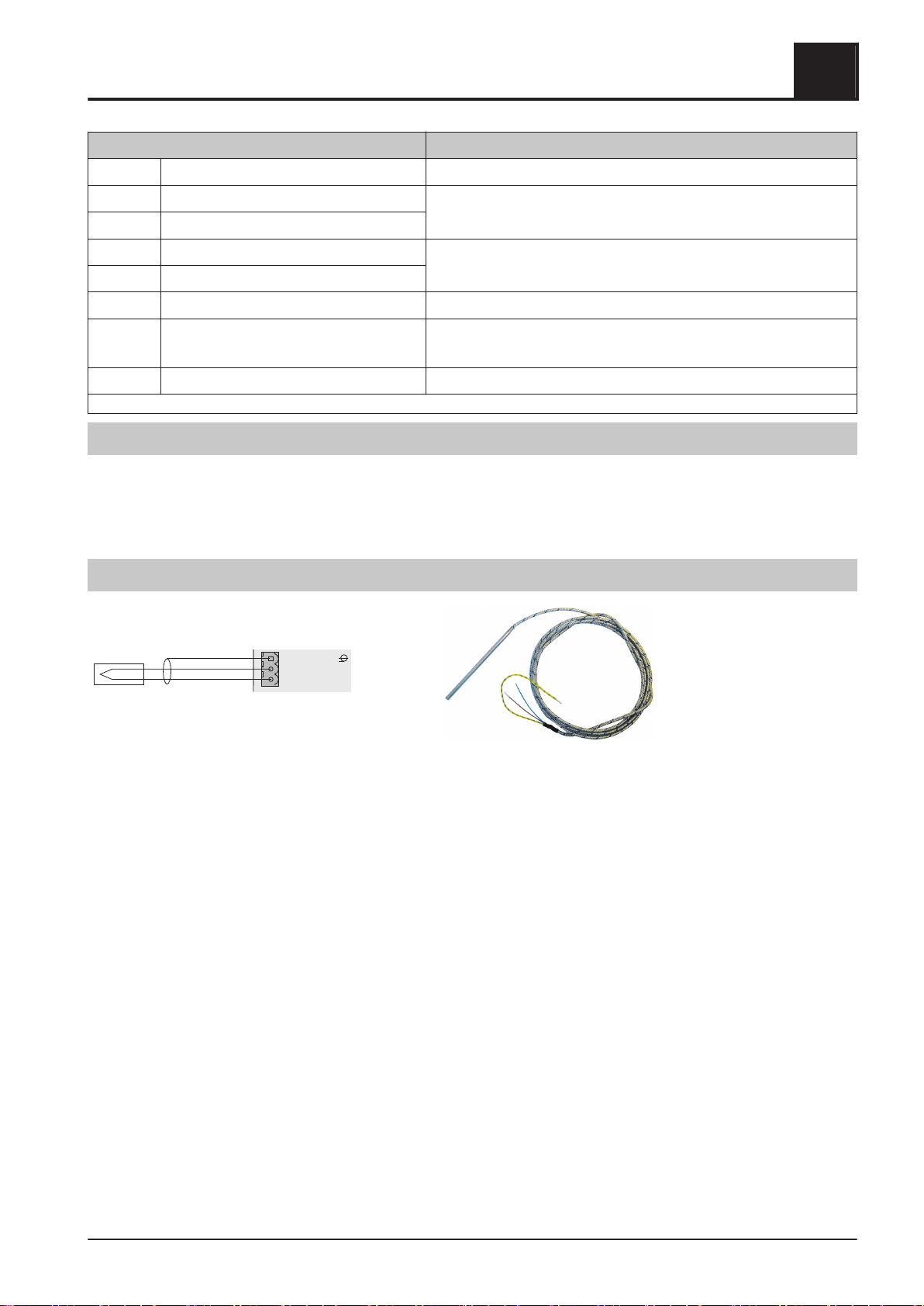

5.1 Calibrate the broadband probe 115

5.2 PDM / 0 - 10V settings 116

5.3 Boiler operating statuses 117

5.4 Boiler modes 118

5.4.1 "Automatic” mode without storage tank 118

5.4.2 “Automatic” mode with storage tank 119

5.4.3 “Continuous load” mode without storage

tank

120

5.4.4 “Continuous load” mode with storage

tank

120

5.4.5 “Domestic hot water” mode without

storage tank

120

5.4.6 “Domestic hot water” mode with storage

tank

122

5.5 Setting times 123

5.6 Calibrating the touchscreen 125

5.7 Software update Lambdatronic 3200 127

5.7.1 Carrying out a software update on the

boiler controller

128

5.7.2 Carrying out a software update on the

touch control

130

5.7.3 Finishing a software update 131

6 Notes 132

7 Appendix 134

7.1 Addresses 134

7.1.1 Address of manufacturer 134

Customer service

134

7.1.2 Address of the installer 134

Table of contents

Service manual Lambdatronic H 3200 for wood chip boiler | B1480519_en 3