4.7 Fuel 71

4.7.1 Fuel - Service 71

4.8 Feed system 71

4.8.1 Feed system - Screw 1 on LB 71

4.8.2 Feed system - Screw 2 on LB 72

4.8.3 Feed system - Rotary agitator 73

4.8.4 Discharge - Cyclone 1 (feed system-

configuration 8)

74

4.8.5 Feed system - Cyclone 1 (suction screw) 76

4.8.6 Feed system - Cyclone 1 (4/8x toggle) 77

4.8.7 Feed system - Cyclone 1 (1-2-3 suction

module)

78

4.9 Network pump 80

4.9.1 Network pump - Status 80

4.9.2 Network pump - Temperatures 80

4.9.3 Network pump - Service 81

4.10 Cascade 82

4.10.1 Cascade - Status 82

4.10.2 Cascade - Backup boiler 82

4.10.3 Cascade - Temperatures 83

4.10.4 Cascade - Service 84

4.11 Difference regulator 85

4.11.1 Difference regulator - Status 85

4.11.2 Difference regulator - Temperatures 85

4.11.3 Difference regulator - Times 86

4.11.4 Difference regulator - Service 86

4.12 Circulation pump 87

4.12.1 Circulation pump - Status 87

4.12.2 Circulation pump - Temperatures 87

4.12.3 Circulation pump - Times 88

4.12.4 Circulation pump - Service 88

4.13 Manual 89

4.13.1 Manual - Manual operation 89

4.13.2 Manual - Digital outputs 90

4.13.3 Manual - Analogue outputs 90

4.13.4 Manual - Digital inputs 91

4.14 System 92

4.14.1 System - Settings 92

Setting - Boiler temperature

92

Setting - Slide-on duct

92

Setting - Flue gas

93

Setting - Ignition

101

Setting - Air settings

102

Setting - Fuel slide-in

104

Setting - Vibration / WOS / Cleaning

107

Setting - WOS / Cleaning

108

Set - Cleaning

109

Setting - Combustion chamber

110

Setting - Lambda values

112

Set - Lambda probe

113

Set - Quantity of heat calculation

115

Setting - General settings

115

4.14.2 System - Current values 116

Operation hours

116

4.14.3 System - Sensors and pumps 117

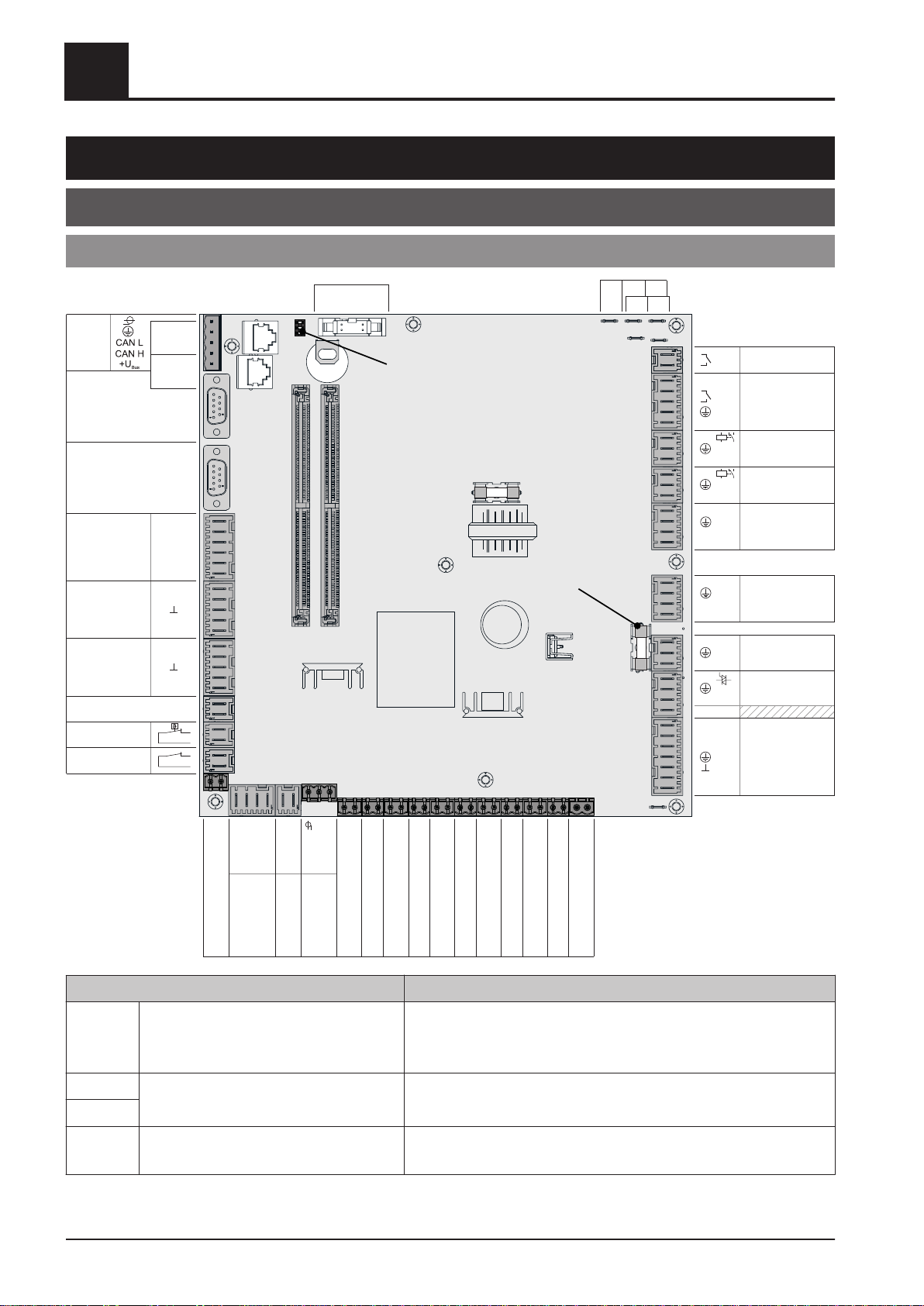

4.14.4 System - System selection 117

4.15 Diagnostics 118

4.15.1 Diagnosis – Current fault list 118

4.15.2 Diagnosis – Clear pending error 118

4.15.3 Diagnostics - Error history 118

4.15.4 Diagnostics - Clear error history 119

4.16 Touchscreen 120

4.16.1 Touchscreen - Display settings 120

Display settings - General

120

Display settings - Basic display

121

Display settings - Date / Time

121

Display settings - Software update / Service

121

4.16.2 Touchscreen - Display operating rights 122

Froling Connect

122

4.16.3 Touchscreen - Display allocation 123

5 FAQ 124

5.1 Activation options of pump outlets 124

5.2 Boiler operating statuses 125

5.3 Determination of the quantity of heat 126

5.3.1 Assembly Information 126

5.3.2 Functioning and configuration 126

Calculating the feed output of the circulating pump

126

Setting the type of heat quantity calculation

127

Configuring the heat quantity calculation

127

5.4 Boiler modes 128

5.4.1 "Automatic” mode without storage tank 128

5.4.2 “Automatic” mode with storage tank 129

5.4.3 “Continuous load” mode without storage

tank

130

5.4.4 “Continuous load” mode with storage

tank

131

5.4.5 “Domestic hot water” mode without

storage tank

131

5.4.6 “Domestic hot water” mode with storage

tank

132

5.5 Setting times 133

5.6 Calibrating the touchscreen 135

5.7 Software update Lambdatronic 3200 137

5.7.1 Carrying out a software update on the

boiler controller

138

5.7.2 Carrying out a software update on the

touch control

140

5.7.3 Finishing a software update 141

Table of contents

Service manual Lambdatronic H 3200 for wood chip boiler | B1480721_en 3