FRONIUS TPS 270i C User manual

Other FRONIUS Welding System manuals

FRONIUS

FRONIUS Pull User manual

FRONIUS

FRONIUS RC Panel Pro User manual

FRONIUS

FRONIUS TransSteel 3500 User manual

FRONIUS

FRONIUS TransSteel 2200c User manual

FRONIUS

FRONIUS CWF 25i User manual

FRONIUS

FRONIUS MTG 250i User manual

FRONIUS

FRONIUS Ignis 180 User manual

FRONIUS

FRONIUS VR 4000 Case D200 User manual

FRONIUS

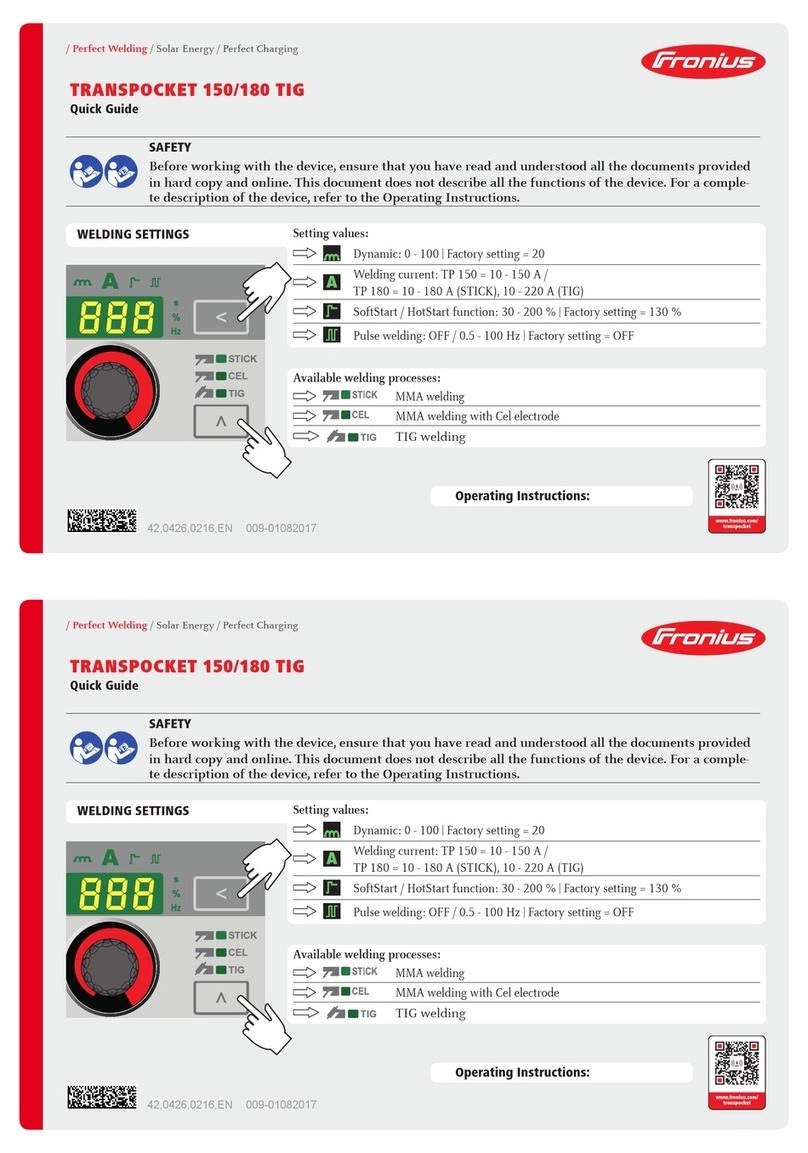

FRONIUS TransPocket 150 User manual

FRONIUS

FRONIUS PullMig User manual

FRONIUS

FRONIUS TransSteel 5000 User manual

FRONIUS

FRONIUS Ignis 150 User manual

FRONIUS

FRONIUS MAGIC WAVE 2000 FUZZY User manual

FRONIUS

FRONIUS Robacta TC 2000 User manual

FRONIUS

FRONIUS TransSteel 4000 Pulse User manual

FRONIUS

FRONIUS OPT/i TWIN SyncBox User manual

FRONIUS

FRONIUS TransTig 1600 Guide

FRONIUS

FRONIUS TransPocket 180 User manual

FRONIUS

FRONIUS TransTig 170 User manual

FRONIUS

FRONIUS MTG 250d User manual

Popular Welding System manuals by other brands

Hobart Welding Products

Hobart Welding Products AirForce 375 owner's manual

GF

GF MSA 330 instruction manual

Hakko Electronics

Hakko Electronics FX-888D instruction manual

Abicor Binzel

Abicor Binzel ABIPLAS WELD 100 W operating instructions

EWM

EWM Taurus 355 Basic TDM operating instructions

Thermal Dynamics

Thermal Dynamics PakMaster 100 XL plus operating manual