Contents

Chapter 1 Product Introduction …………………………………………………..…………………………………………………..…...

1.1 Product Model …………………………..…………………………………………………..………..……….……….………

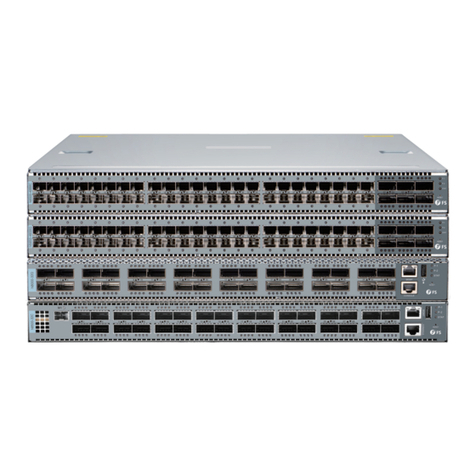

1.2 Front Panel (S8050-20Q4C)………………………………………………..………………………………………………

1.3 Rear Panel (S8050-20Q4C)…………………………………………………..………………………………………….....

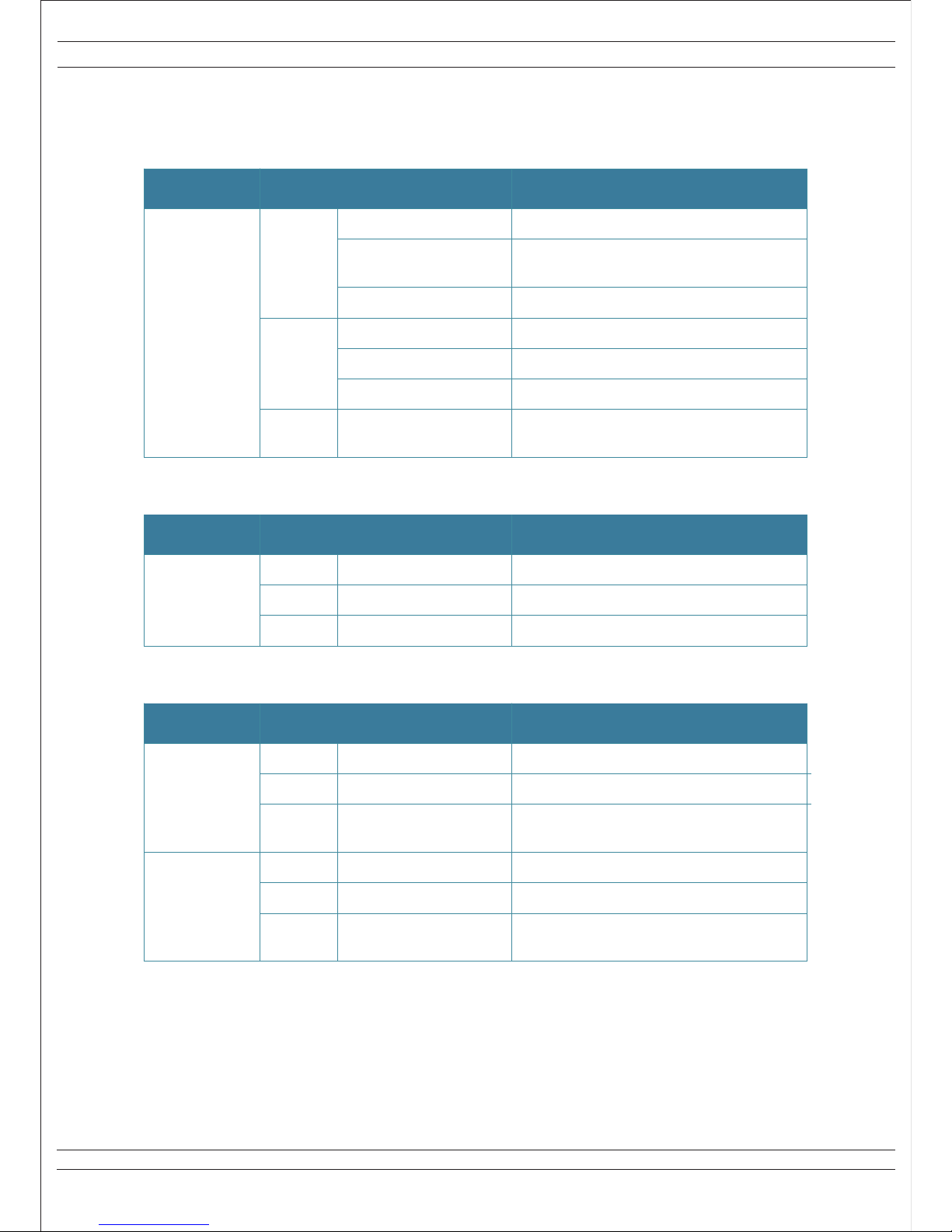

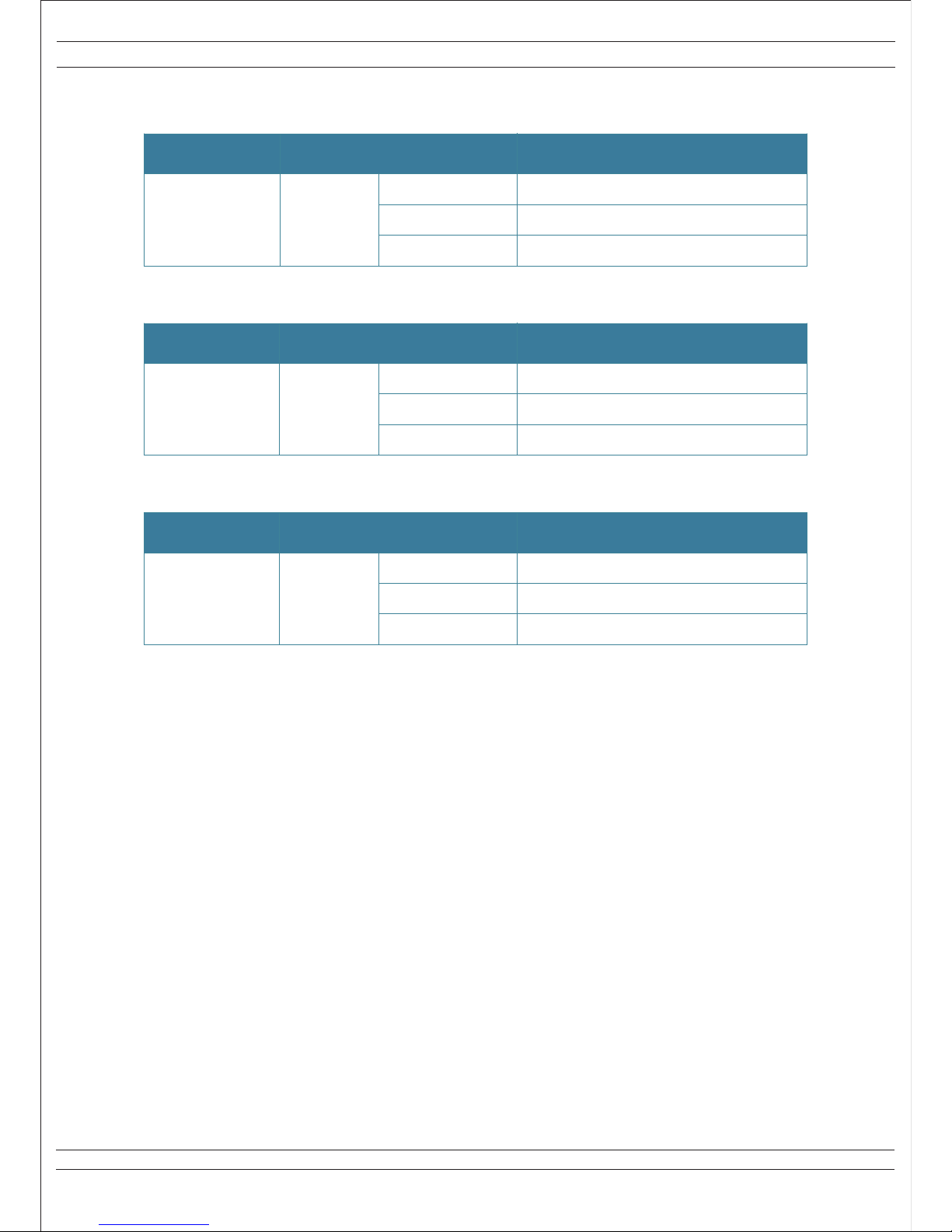

1.4 FS S8050 Series Switch LED Introduction ………………………………………..………………………………...

1.4.1 System LED Indicator ……………………………………………………..……………………………………....……..

1.4.2 FAN LED Indicator ……………………………………………………..…………………………………………………..

1.4.3 Power Supply LED Indicator ……………………………………………………..……………………………………

1.4.4 Ethernet Management Interface LED Indicator ……………………………..…………………………………

1.4.5 40G QSFP+ Indicator ……………………………………………………..………………………………………………

1.4.6 100G QSFP28 Indicator ……………………………………………………..…………………………………………...

Chapter 2 Switch Installation ……………………………………………..………………………………………………………………....

2.1 Preparation for Installation ……………………………………………………..………………………………………....

2.1.1 Safety Precaution ……………………………………………………..……………………………………………………

2.1.2 Installation Site ………………………………………………..…………………………………………………………….

2.1.3 Installation Tools ……………………………………………………..……………………………………………………..

2.2 Installation ……………………………………………………..…………………………………………………………………

2.2.1 Introduction of Mounting Brackets ………………………………………………..………………………………...

2.2.2 Install the Switch into a Rack with Front Mounting Brackets ………..…………………………………...

2.2.3 Install the Switch on a Workbench ……………………………………………..……………………………………

2.2.4 Installation and Removal of Power Module ……………………………………..……………………………….

2.3 Grounding Connection ……………………………………………………..……………………………………………….

Chapter 3 Interface Module and Cable Connection Description ……………………………..……………………………...

3.1 Interface Module Description ……………………………………………………..……………………………………..

3.1.1 Ethernet Port ……………………………………………………..…………………………………………………………..

3.1.2 Console Port ……………………………………………………..……………………………………………………………

Chapter 4 Initial Power-on and Start-up of Switch ……………………………………………..…………………………………..

4.1 Building Configuration Platform and Connecting Cable …………..………………………………………….

4.2 Setting Terminal Parameter (Windows Super Terminal) ………………..……………………………………...

4.3 Setting Terminal Parameter (SecureCRT from VanDyke Software)………..……………………………….

4.4 Switch Power-on………………………………………………..………………………………………………………...……

Chapter 5 Switch Software Loading………………………………………………………..……………………………………………..

Chapter 6 Upgrade of Operating System ………………………………………………………..……………………………………..

Chapter 7 Maintenance and Troubleshooting ………………………………………………………..……………………………….

7.1 Loading Failure Processing …………………………………………………..………………………………………...…

7.2 User Password Lost …………………………………………………..……………………………………………………..

7.3 Power System Troubleshooting …………………………………………………..……………………………………..

7.4 Configuration SystemTroubleshooting …………………………………………..…………………………………..

INSTALLATION INSTRUCTIONS

© FS.COM 2016 FS016

I

For Technical Support: www.fs.com/service.html

1

1

2

2

3

3

3

3

4

4

4

5

5

5

5

7

7

7

8

9

9

10

11

11

11

11

12

12

12

14

15

16

17

18

18

18

18

18