2

Index

1. Presentation ................................................................................... 3

2. Warnings and warranty terms ............................................................ 4

3. Characteristics ................................................................................ 5

3.1 Package contents...................................................................... 5

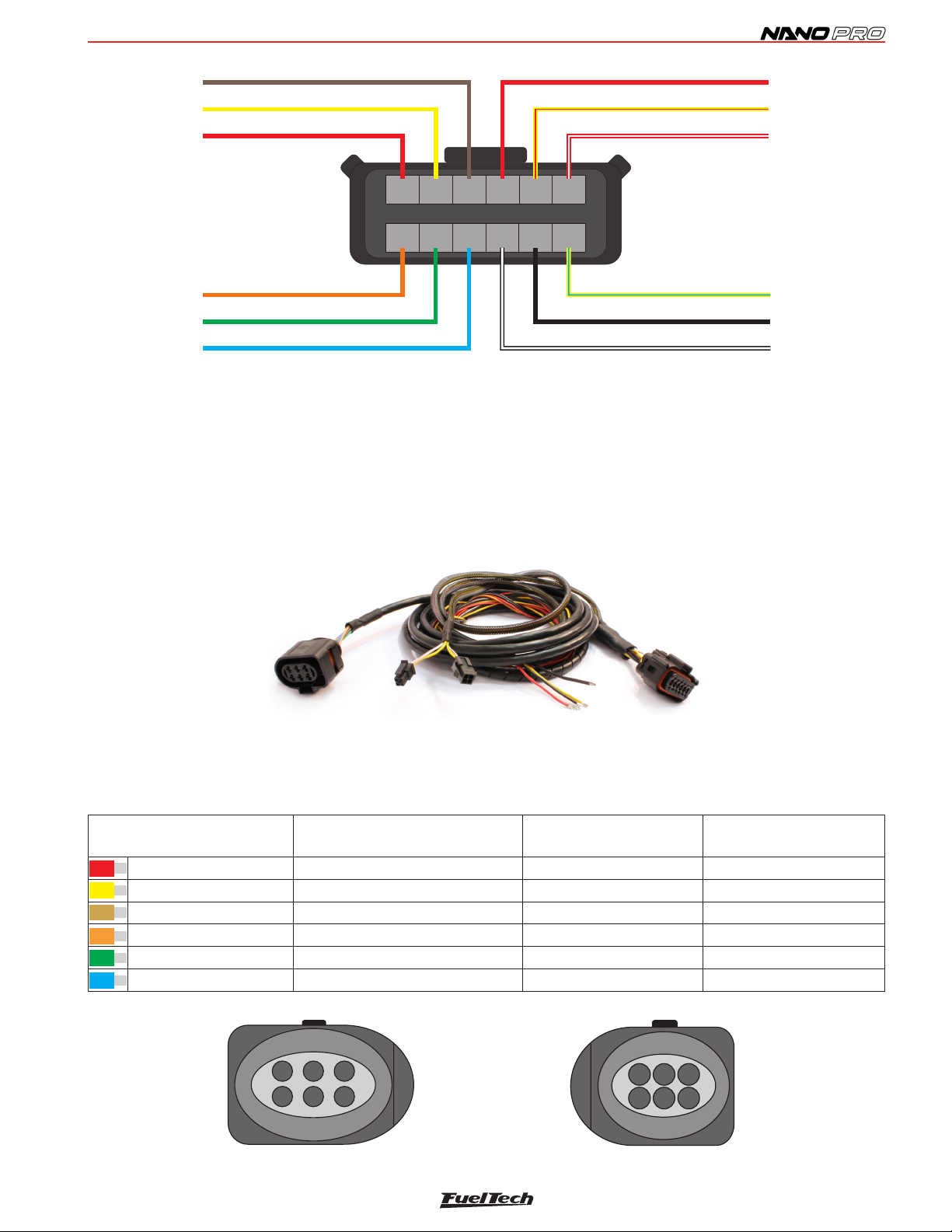

4. NanoPRO electrical installation........................................................... 6

4.1 Adapter harnesses..................................................................... 7

4.2 Replacement of Bosch LSU sensor connector 4.2 for 4.9............... 7

4.3 Replacement of Bosch LSU sensor connector 4.2 for 5.2............... 8

4.4 Replacement of Bosch LSU sensor connector 4.2 for NTK.............. 9

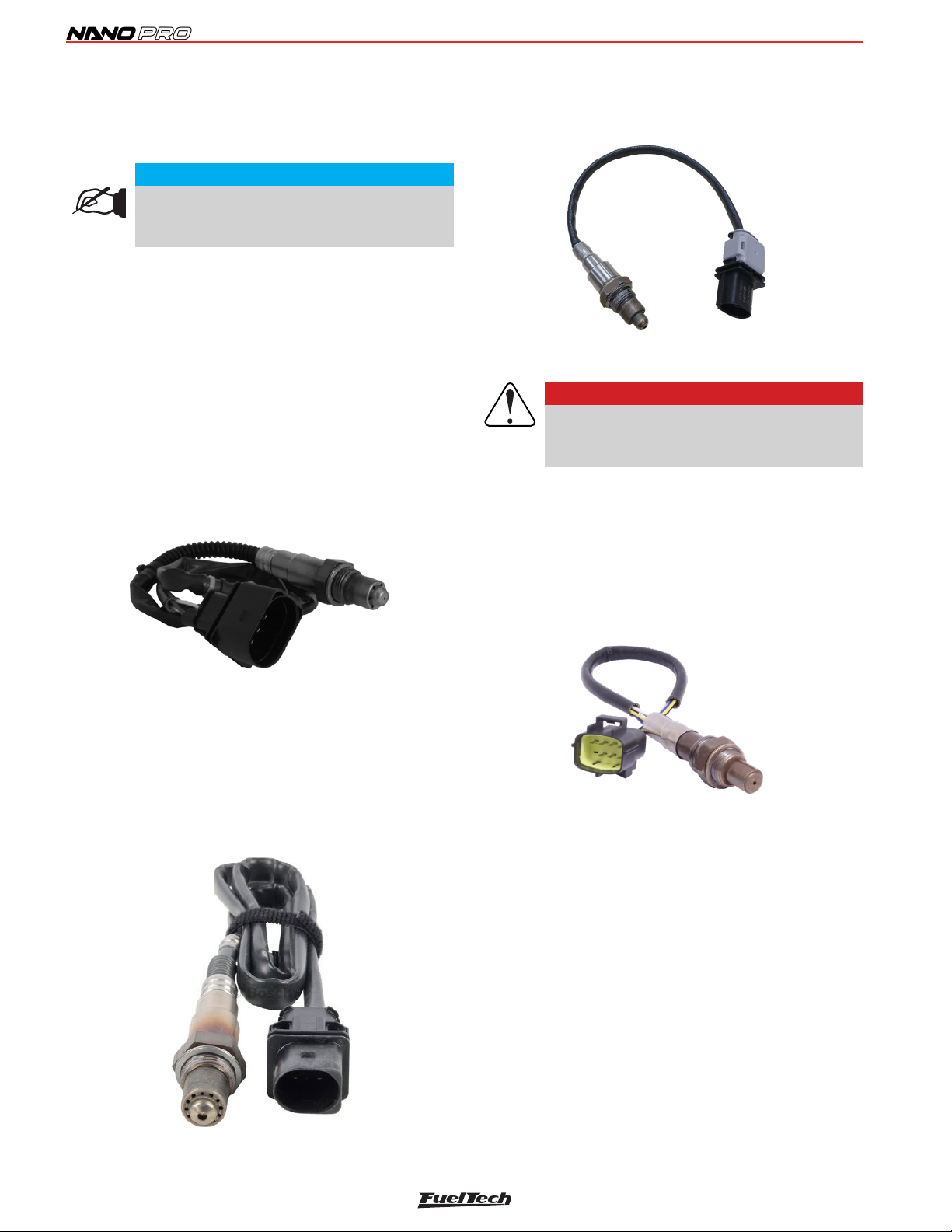

5. Wide band O2 sensor .................................................................... 10

5.1 Bosch LSU 4.2 O2 sensor ....................................................... 10

5.2 Bosch LSU 4.9 O2 sensor ....................................................... 10

5.3 Bosch LSU 5.2 O2 sensor ....................................................... 10

5.4 NTK O2 sensor ....................................................................... 10

5.5 O2 sensor installation............................................................... 11

5.6 O2 sensor for use in Diesel powered vehicles .............................. 11

6. OBD-II harness installation .............................................................. 12

6.1 Harness identication ............................................................... 12

6.2 OBD-II connector identication .................................................. 12

7. CAN communication ...................................................................... 13

7.1 FTCAN 2.0............................................................................. 13

7.2 FTCAN 1.0............................................................................. 13

8. Conguration through the NanoPRO interface .................................... 14

8.1 Dashboard conguration........................................................... 14

8.2 Display conguration................................................................ 15

8.3 Heating setup ......................................................................... 16

8.4 O2 sensor conguration ........................................................... 16

8.5 Manual .................................................................................. 17

8.6 Language............................................................................... 17

8.7 About .................................................................................... 17

87.8 Settings ............................................................................... 17

9. Conguration via the FTManager interface......................................... 19

9.1 Datalogger channels ................................................................ 20

9.2 NanoPRO software update........................................................ 21

10. Lambda readings analog outputs ..................................................... 22

10.1 Lambda analog output in Volts – 5.14 to 17.6 AFR ................... 22

10.2 Lambda analog output in Volts – 8.7 to 16.2 AFR (default) ......... 22

10.3 Lambda analog output in Volts – 9.6 to 19.1 AFR ..................... 22

10.4 Lambda analog output in Volts – 9.6 to 58.8 AFR ..................... 22

10.5 Lambda analog output in Volts – 9.6 to 146.9 AFR ................... 22

11. Analog output lambda/AFR ............................................................. 22

12. NanoPRO codes ........................................................................... 23

12.1 Informative codes.................................................................. 23

12.2 Error codes .......................................................................... 23

13. Fixing template (in) ........................................................................ 24