NANO PRO

2

1. Index

2. Presentation...................................................................................................................................................................................3

3. Warnings and Warranty Terms ..........................................................................................................................................................4

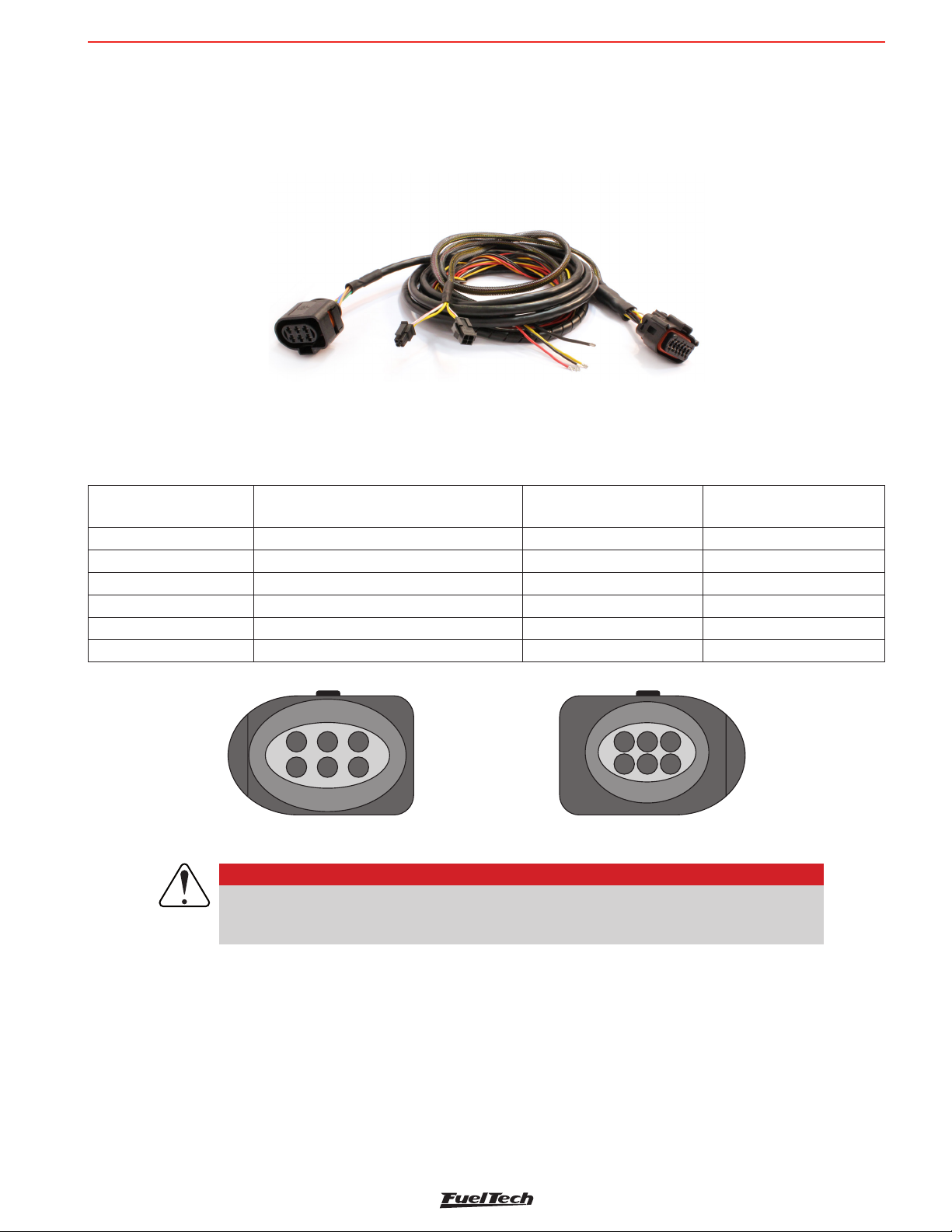

4. Characteristics................................................................................................................................................................................5

4.1 Package contents.....................................................................................................................................................................5

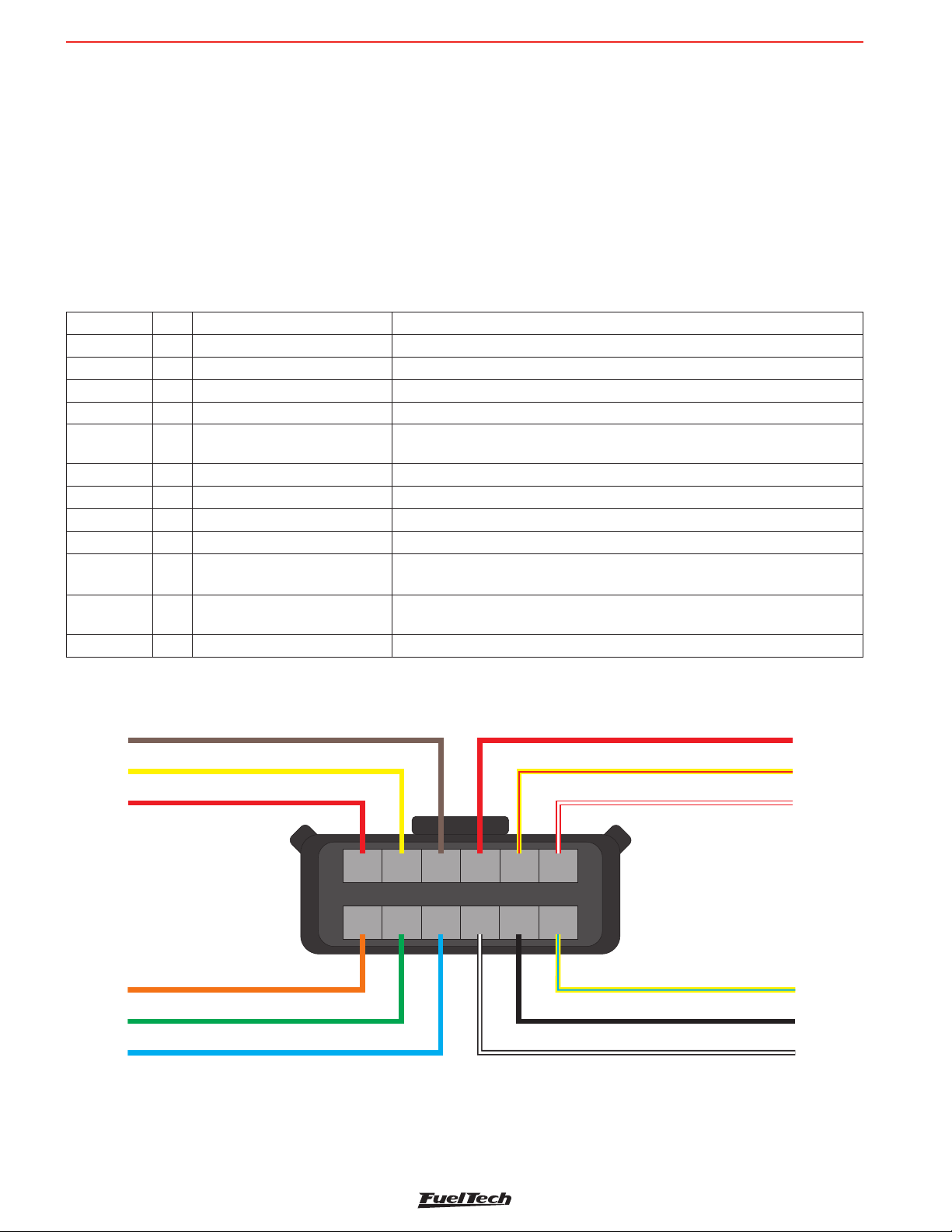

5. Nano PRO Electrical Installation.........................................................................................................................................................6

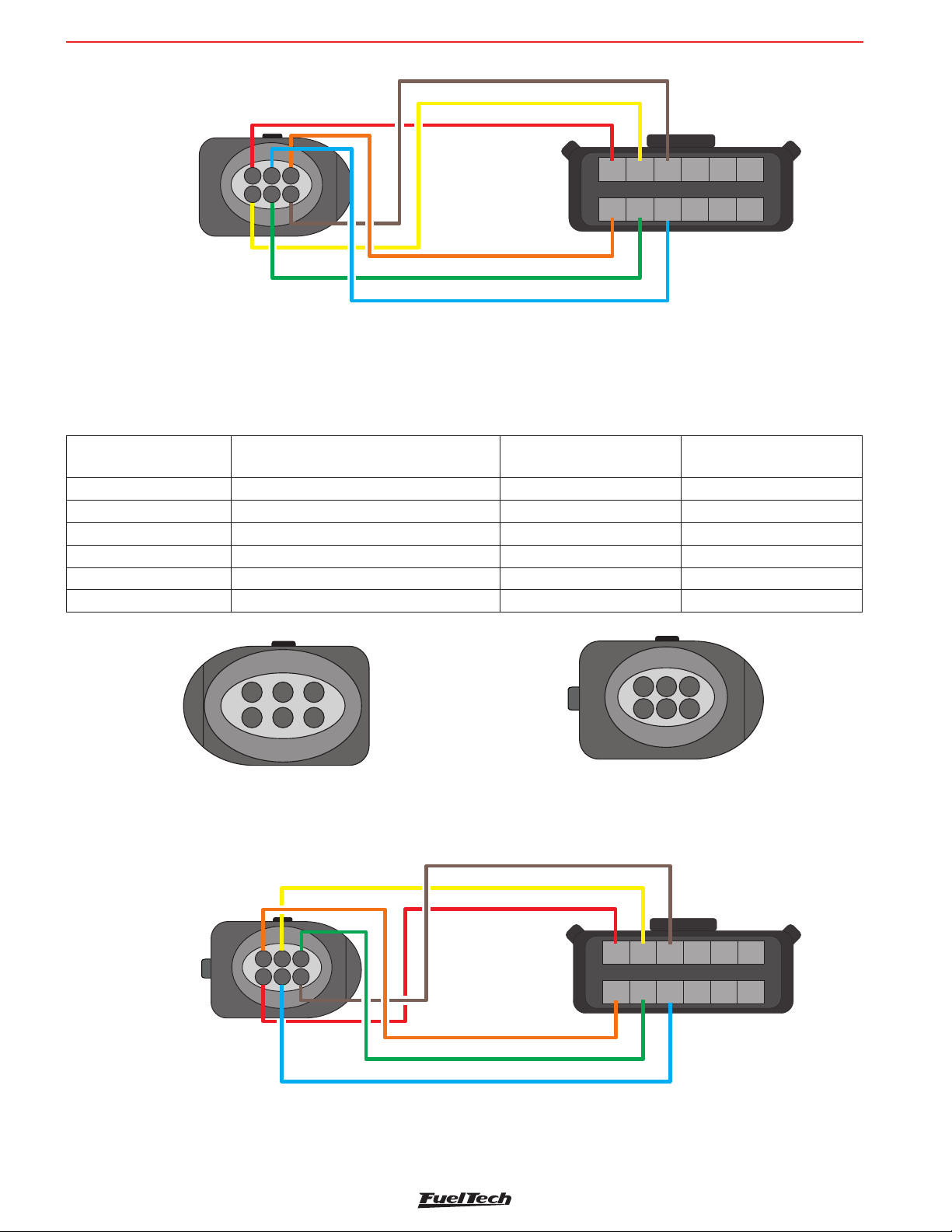

5.1 Adapter harnesses ....................................................................................................................................................................7

5.2 Replacement of Bosch LSU sensor connector 4.2 for 4.9..............................................................................................................7

5.2 Replacement of Bosch LSU sensor connector 4.2 for 5.2..............................................................................................................8

5.3 Replacement of Bosch LSU sensor connector 4.2 for NTK.............................................................................................................9

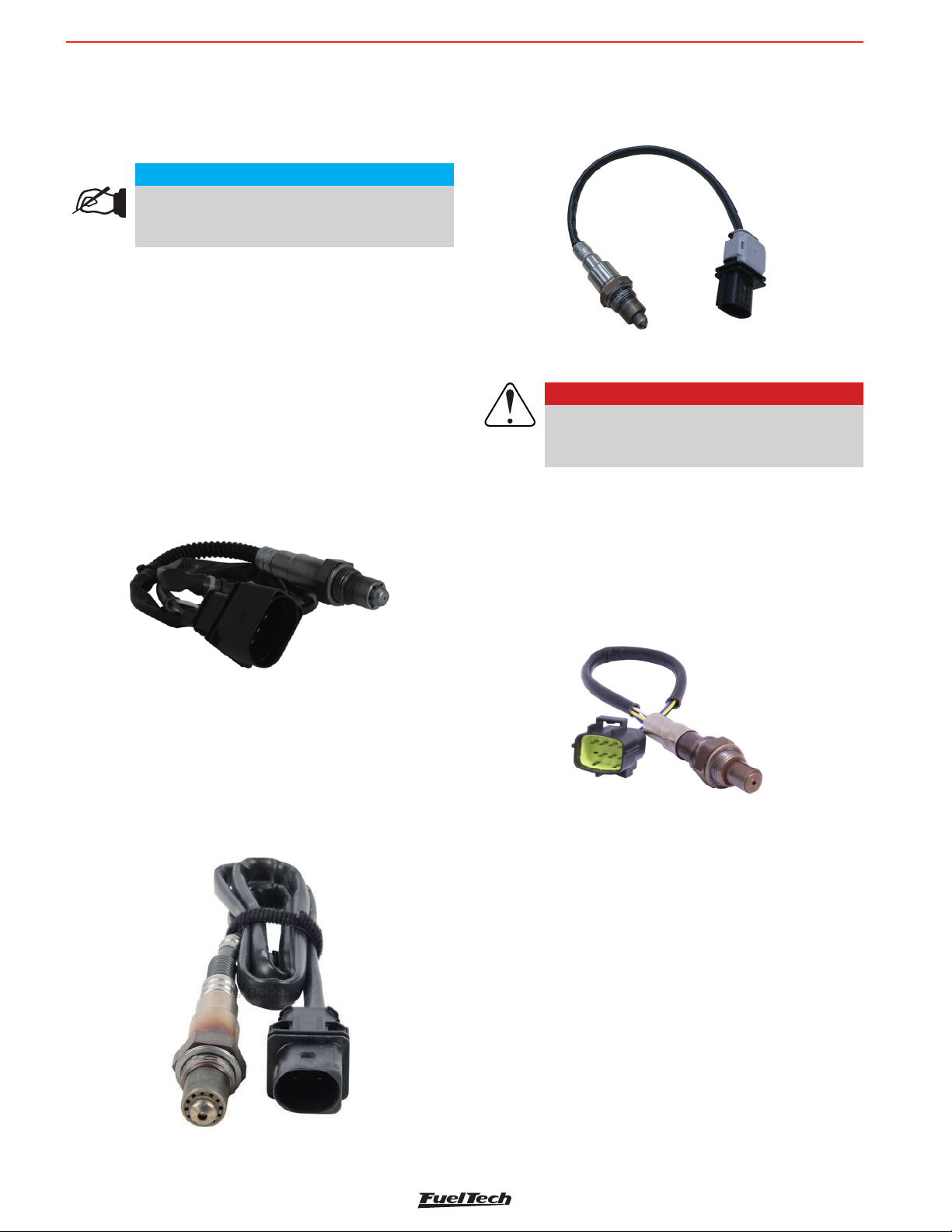

6. Wide Band O2 Sensor ..................................................................................................................................................................10

6.1 BOSCH LSU 4.2 O2 Sensor ....................................................................................................................................................10

6.2 BOSCH LSU 4.9 O2 Sensor ....................................................................................................................................................10

6.3 BOSCH LSU 5.2 O2 Sensor ....................................................................................................................................................10

6.4 NTK O2 Sensor......................................................................................................................................................................10

6.5 O2 Sensor Installation .............................................................................................................................................................11

7. CAN Communication.....................................................................................................................................................................11

8. Conguration through the Nano PRO Interface ..................................................................................................................................12

8.1 Dashboard conguration..........................................................................................................................................................12

8.2 Display conguration ...............................................................................................................................................................13

8.3 Heating setup.........................................................................................................................................................................13

8.4 O2 sensor conguration ..........................................................................................................................................................14

8.5 Manual .................................................................................................................................................................................14

8.6 Language..............................................................................................................................................................................14

8.7 About ...................................................................................................................................................................................15

9. Conguration via the FTManager Interface ........................................................................................................................................16

9.1 Datalogger Channels...............................................................................................................................................................17

9.2 Nano PRO Software Update .....................................................................................................................................................18

10. Lambda Readings analog outputs ...................................................................................................................................................19

10.1 Lambda Analog Output in Volts – 5.14 to 17.6AFR...................................................................................................................19

10.2 Lambda Analog Output in Volts – 8.7 to 16.2 AFR (default)........................................................................................................19

10.3 Lambda Analog Output in Volts – 9.6 to 19.1 AFR....................................................................................................................19

10.4 Lambda Analog Output in Volts – 9.6 to 58.8 AFR....................................................................................................................19

10.5 Lambda Analog Output in Volts – 9.6 to 146.9 AFR..................................................................................................................19

11. Analog output Lambda/AFR ...........................................................................................................................................................19

12. Nano PRO Codes .........................................................................................................................................................................20

12.1 Informative Codes.................................................................................................................................................................20

12.2 Error Codes .........................................................................................................................................................................20

13. Fixing template (in)........................................................................................................................................................................21