4WWW.FUHR.DE

These instructions are aimed at door fabricators and contain important information regarding installation, commissioning and

operation pertaining to the FUHR multipoint locking system multitronic 881. Please read carefully prior to installation and com-

missioning. The points raised here provide supplementary information to the FUHR product information M3/3. The importance of

their compliance must be pointed out to builders and end-users. In the event of non-compliance with these imperative instructions,

faultless system operation cannot be warranted.

We assume that the installation as well as commissioning is carried out exclusively by professional staff.

Text passage denoting this symbol is relevant to safety and must be strictly adhered to.

The FUHR multipoint locking system multitronic 881 has been designed and manufactured taking safety-related regulations and

harmonised standards into account.

The safety of the FUHR multitronic product largely depends on its correct installation and regular

maintenance! The installation of the electronic components requires particular care, since abrasion points,

defective cables, damaged contacts, etc. affect security and can lead to the malfunction of the system. Please

ensure that all components are in perfect functioning condition prior to installation. Damaged or defective

components may not be used under any circumstances. Use the locking system only in technically

perfect condition! Malfunctions that impair security are to be eliminated immediately. Until the

malfunction has been eliminated, the drive unit is to be switched off and operated mechanically! The power

supply unit’s power feed is to be disconnected when working on the locking system and live components.

The FUHR multipoint locking system multitronic 881 has been engineered to be used in conjunction with the provided FUHR

multitronic components. We accept no liability for improperly installed systems and/or the use of non-original or non factory

approved system accessory parts. The modification of components or the use of non approved accessory components can cause

malfunctions. Material damage or personal injury resulting from non-compliance with the installation, operation and maintenance

instructions or inappropriate operation invalidates the warranty. We assume no liability for any consequential damage.

The FUHR multipoint locking system multitronic 881 must be protected from humidity. It is not suitable for areas with high humidity

and chemical substances.

The FUHR multipoint locking system multitronic 881 has been primarily designed for installation in main entrance doors,

apartment doors and back doors. The system with 2 hook bolts (type 3) has been tested and certified in accordance with

DIN EN 179. The variants with 2 round bolts (type 8) and with 2 hook and dual round bolts (type 11) have been tested and

certified in accordance with DIN EN 1125. For this purpose durability testing in the highest grade (grade 7) with 200,000

operations was carried out successfully.

When using in heavily frequented doors (more than 50 operations per day) e.g. in public or office building pro-

jects, it is necessary to use either of the two day-latch functions during busy periods (refer chapter 6.1).

All images, dimensions, product and design related information contained in these instructions represent the latest

developments regarding the FUHR multipoint locking system multitronic 881 at the time of printing. This product is subject to a CIP

(continuous improvement process) and is constantly enhanced to reflect the latest technology. For the purpose of your satisfaction,

we reserve the right to implement changes to this product. Model and product claims cannot be lodged.

The latest version of these instructions is published on our website www.fuhr.de.

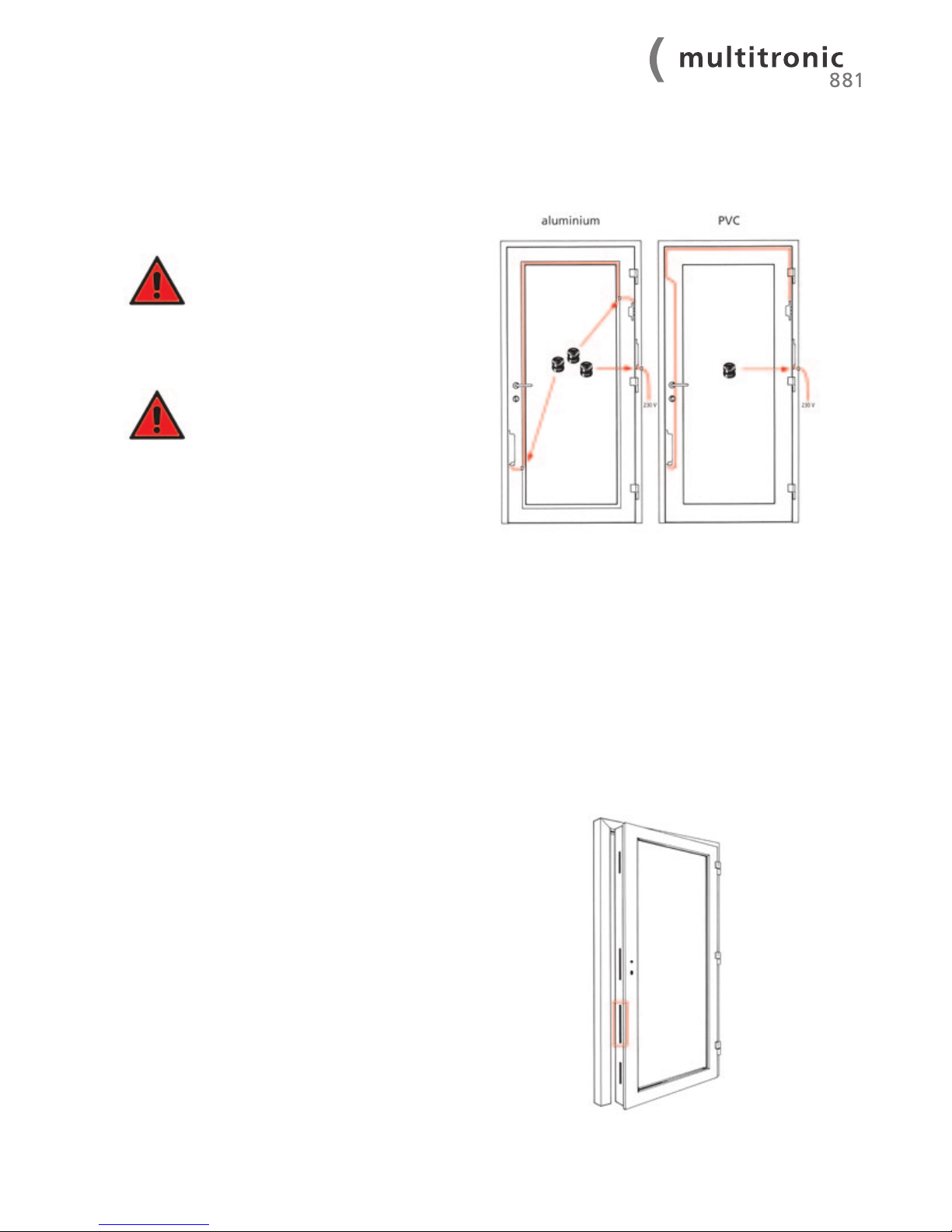

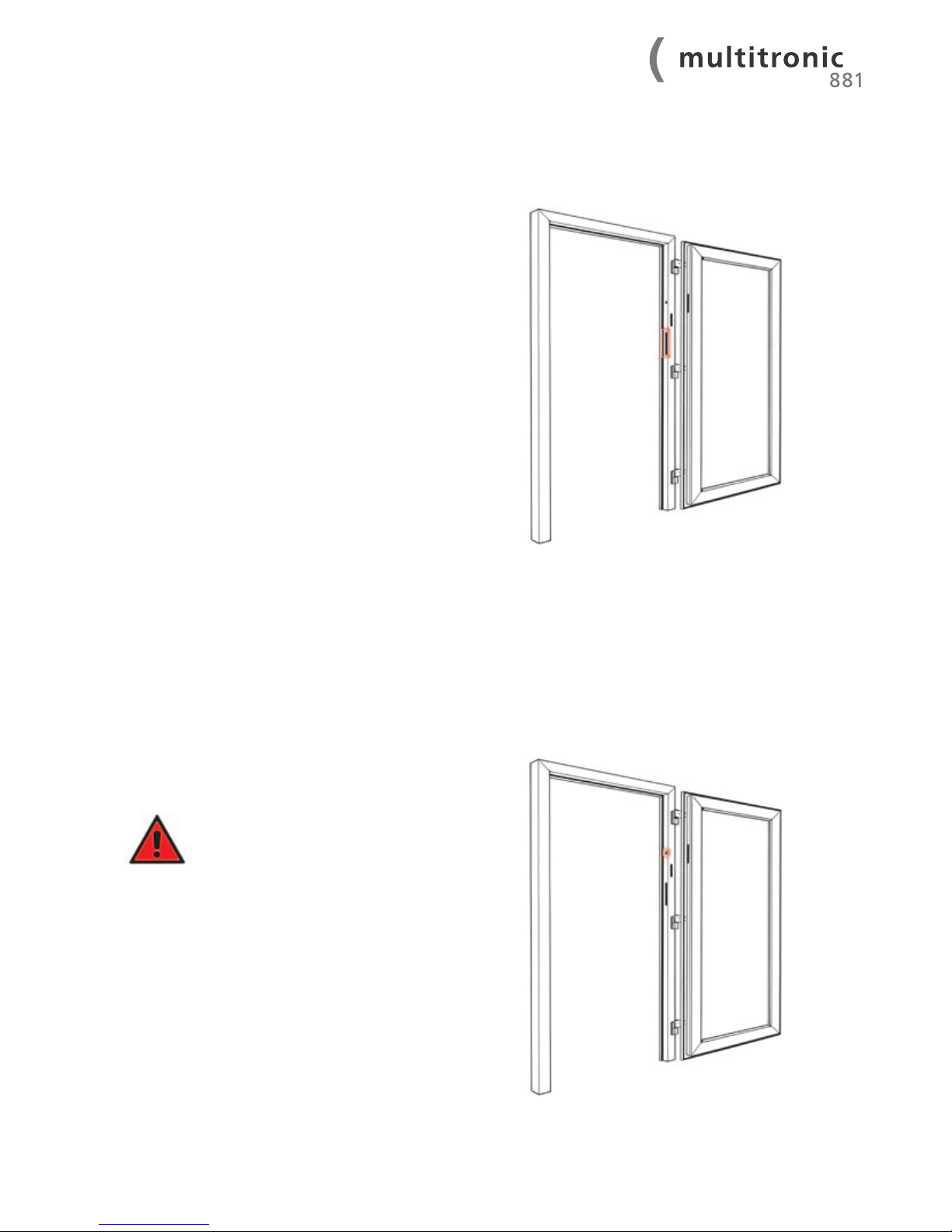

The installation steps depicted on the following pages serve as a schematic diagram. Due to the numerous profiles available on the

market, there may be slight deviations in specific points. It is therefore imperative that the profile-related routing drawing provided

with the FUHR multitronic set is adhered to. Please contact your sales partner or the manufacturer in the event of discrepancies or

queries.

The indicated sequence in these installation instructions is exemplary. The sequence may be varied if required.

IMPORTANT!

All components contained in the set (particularly the control unit and the radio key) are coordinated and should not be

used in conjunction with other sets.

2 Important information/safety instructions